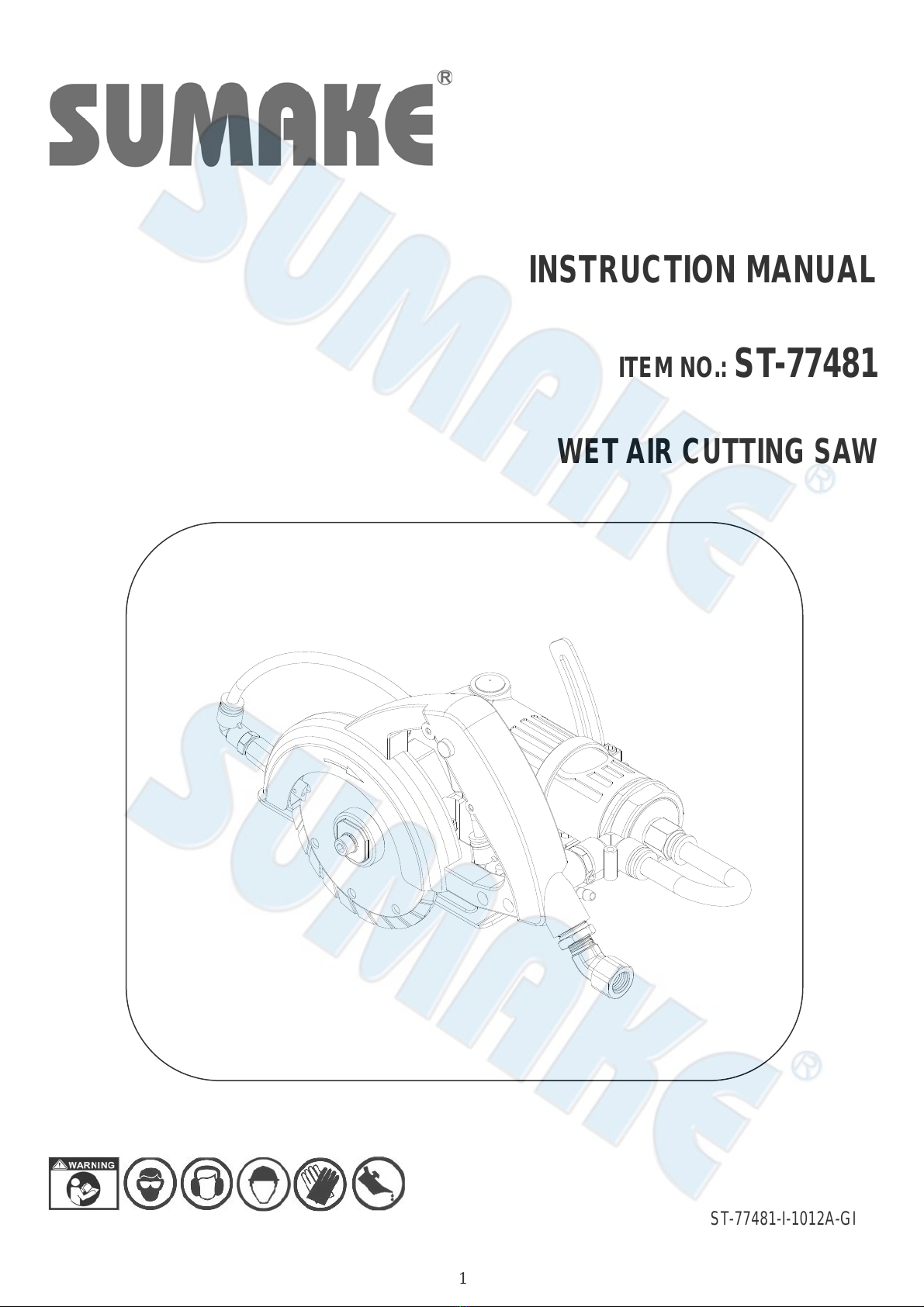

ST-77481

4" WET AIR CUTTING SAW (WITHOUT SAW BLADE)

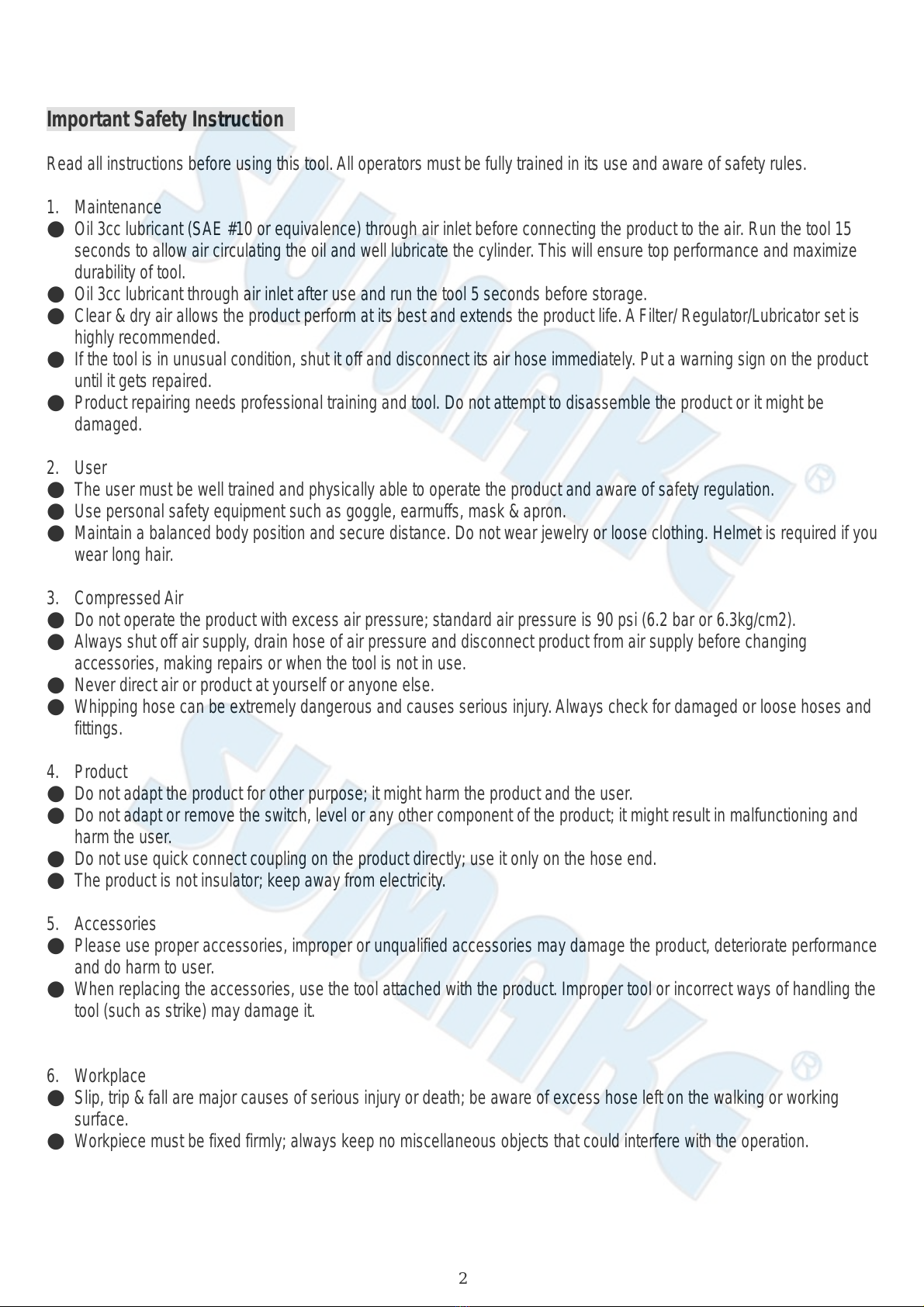

PARTS LIST

No. Parts No. Descri

tion Q't

No. Parts No. Descri

tion Q't

1 77481-01 Bod

1 55 77481-55 Tri

er 1

2 77481-02 Front Plate 1 57 77481-57 Pin 1

3 77481-03 Ball Bearin

2 58 77481-58 Pin 1

4 77481-04 Ball Bearin

1 59 77481-59 O-Rin

1

5 77481-05 Rotor 1 60 77481-60 S

rin

1

6 77481-06 C

linder 1 61 77481-61

ir Inlet Screw 1

7 77481-07 S

rin

Pin 1 62 77481-62 Water Valve Seat 1

8 77481-08 Blade 4 63 77481-63 Bushin

2

9 77481-09 Rear Plate 1 64 77481-64 Ball Valve 1

10 77481-10 Pinion Gear 1 65 77481-65 Co

er Bushin

1

11 77481-11 Rubber Ca

1 66 77481-66 S

rin

1

12 77481-12 O-Rin

1 67 77481-67 Water Valve Joint 1

13 77481-13 Lock Rin

1 68 77481-68 Shaft 1

14 77481-14 S

acer 1 69 77481-69 Screw 1

15 77481-15 Main Shaft 1 70 77481-70 S

rin

Pin 1

16 77481-16 Bearin

1 71 77481-71 Water Valve 1

17 77481-17 Ke

1 72 77481-72 Screw 1

18 77481-18 Bevel Gear 1 73 77481-73

llen Screw 3

19 77481-19 Wave Washer 1 74 77481-74 Joint Washer 2~3

20 77481-20 Retainin

Rin

1 75 77481-75 Quick Joint

L-t

e1

21 77481-21 Ball Bearin

1 76 77481-76 Screw 4

22 77481-22 Ke

1 77 77481-77

n

le Settin

Rin

1

23 77481-23 S

iral Gear 1 78 77481-78 Fix Plate 1

24 77481-24 Retainin

Rin

1 79 77481-79 Cou

lin

Nut 1

25 77481-25 Gear Box 1 80 77481-80

llen Screw 3

26 77481-26

llen Screw 6 81 77481-81 Quick Joint 1

27 77481-27 S

rin

1 82 77481-82 Exhaust Cover 1

28 77481-28 Flat Washer 1 83 77481-83 Self Ta

in

Screw 2

29 77481-29

llen Screw 1 84 77481-84 Screw 1

30 77481-30 Gear Shaft 1 85 77481-85 Ca

1

31 77481-31 Ball Bearin

1 86 77481-86 Joint Piece 1

32 77481-32 Oil Seal 1 87 77481-87 Base 1

33 77481-33 Gear Seat 1 87a 77481-87a Base 1

34 77481-34 Wave Washer 1 87-1 77481-87-1 Su

ort Frame 1

35 77481-35 Retainin

Rin

1 87-2 77481-87-2

n

le Index 1

36 77481-36 Ke

1 87-3 77481-87-3 Screw 5

37 77481-37 S

acer 1 87-4 77481-87-4 Nut 5

38 77481-38 S

iral Gear 1 88 77481-88

llen Screw 1

39 77481-39 Retainin

Rin

1 89 77481-89 Nut 1

40 77481-40 Ball Bearin

1 90 77481-90 Flat Washer 1

41 77481-41 Gasket 1 91 77481-91 Butterfl

Nut 1

42-1 77481-42-1 Disc Guard 1 92 77481-92 Water Pi

e1

42-2 77481-42-2 Shroud 1 93 77481-93

ir Inlet Pi

e1

43 77481-43 Water Exit 1 77481-94A Disc Receiver

20mm

1

44 77481-44 Water Exit Nut 1 77481-94B Disc Receiver

22mm

1

45 77481-45 Quick Joint

L-t

e 2 95 77481-95 Disc Nut 1

46 77481-46

llen Screw 3 96 77481-96 S

rin

Washer 1

47 77481-47

llen Screw 2 97 77481-97

llen Screw 1

48 77481-48 Handle 1 98 77481-98

ir Joint 1

49 77481-49 S

rin

Pin 1 99 77481-99 Bushin

1

50 77481-50 S

rin

1 100 77481-100 Sto

er 1

51 77481-51 Push Button 1 101 77481-101 Grease Hole 1

52 77481-52 Fix Nut 1 102 77481-102 Sto

S

anner 1

53 77481-53 Tri

er Lock 1 103 77481-103

llen Wrench 1

54 77481-54 S

rin

Pin 2 ST-77481-P-1012A-GI

94