2

WARRANTY:

• All Standard Line Tables carry a one-year warranty on materials and workmanship (upholstery is warranted for workmanship

only).

• Presge Line and Contemporary Tables carry a two-year warranty on materials and workmanship (upholstery is warranted for

workmanship only).

• Elevaon columns installed on Contemporary tables are warranted for one year by the manufacturer of the provided columns.

• As a courtesy service we will ship replacement parts to you at no expense, however you will be responsible for the installaon

of the provided parts. The excepon to this service is tables which have been shipped outside the Connental US. In such

situaons the customer will be responsible to cover applicable shipping costs less an equivalent Domesc shipping allowance.

At Sun Chiropracc Tables, LLC sole discreon “hard parts” (dened as those mechanical table parts subject to wear and breakage)

may be provided to the original customer at no charge except for the cost of shipping, at any me both before and aer the

terminaon of the warranty periods stated above.

10 DAY RETURN POLICY:

We oer a 10 day, no-quesons asked return policy for all the standard tables we oer. Please note that this policy does NOT

include tables with custom colors or other customized opons. Tables with a custom color or other custom opons may not be

returned for any reason.

If not sased with your table for any reason you may return it at your expense for a complete refund excluding original shipping

paid. You must contact us within 10 days of arrival to let us know that you will be returning the table. This allows you 10 full days to

decide if you are happy with your purchase.

Returns will not be accepted if you fail to contact us within 10 days of the table's delivery. Tables must be returned in "new"

condion. Tables not returned in "new" condion will have their refund decreased by the stated cost of noted damage.

For the most updated warranty and return policy informaon, please see our website at sunchirotable.com.

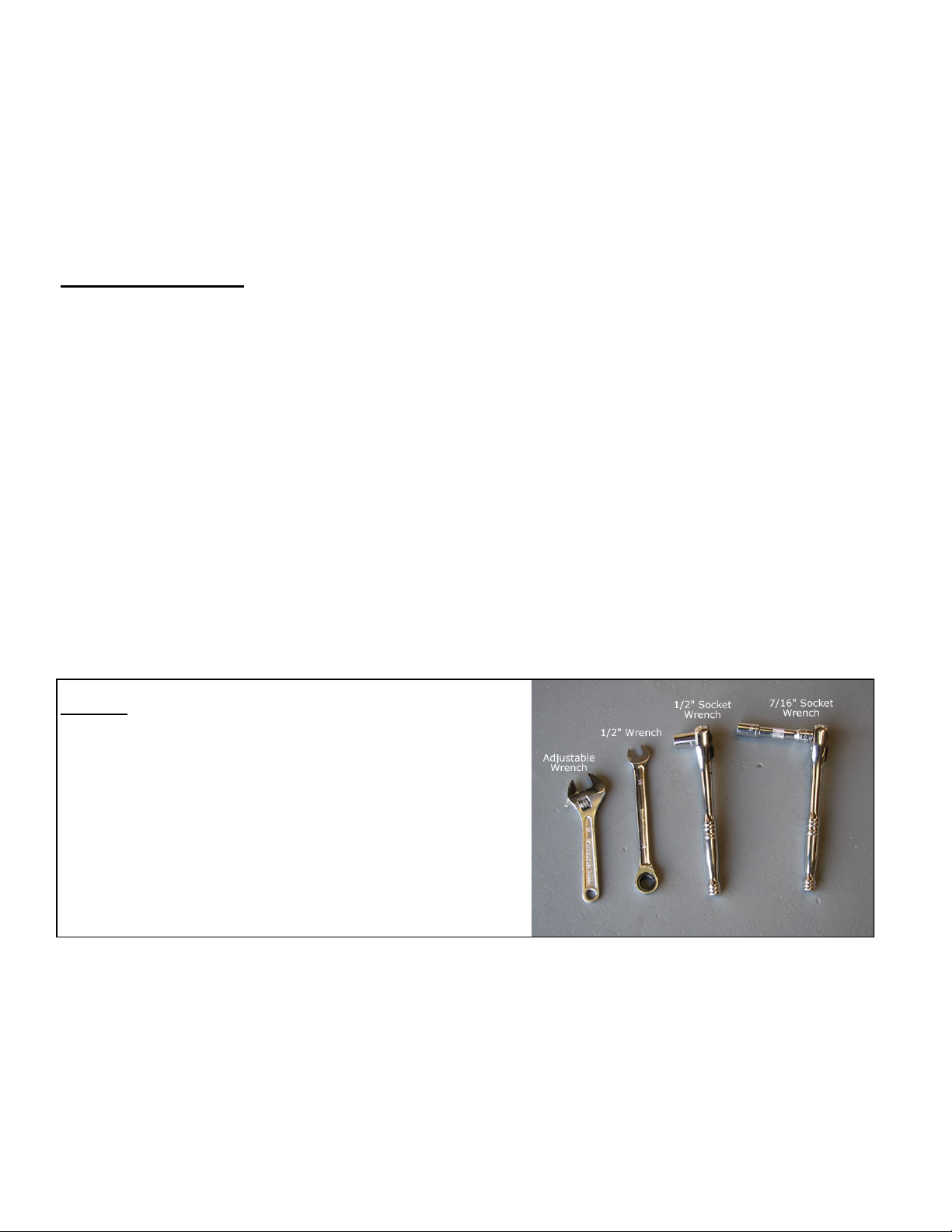

TABLE LEVELING AND MAINTAINANCE:

Table Leveling:

To level your table, place it in the approximate posion where it will be used. The bolt holes on the legs are oversized to

accommodate approximately 1/8” of leveling and ease assembly.

When the table is in posion, loosen the 12 leg bolts to just snug. DO NOT loosen them to the point where the washers will spin.

Place your hands on the table and “wiggle” it a bit so it can sele to the shape of your ooring. When sased, and without

moving the table, from the underside ghten the bolts to snug. DO NOT over ghten. The bolt is fully ghtened when the cut lock

washer is fully compressed and at.

Leg Maintenance:

As paents are treated the table will sele over me. This can cause the leg bolts to require ghtening. We suggest that you

ghten the leg bolts once aer about 2 weeks of use and again at about 3 months. You can then check the bolts about once every

6 months for maximum safety.

If at any me the table legs seem or appear loose, please ghten them. DO NOT wait for a scheduled maintenance period. It is a

good idea for liability purposes to keep a log of when you maintain all of your equipment.

General Maintenance:

To keep your tables in opmal condion, don’t forget to do roune table maintenance and keep a record of your inspecons. You

will nd a printable maintenance log on our website under the Customer Support > Table Documentaon tab. In the boom le

hand corner of the log there is a quick list of what should be done during the periodic inspecons. We suggest that your tables be

inspected and lubricated every 90 to 120 days for opmal performance.