- 6 - - 23 -

Symptom Cause Remedial Action Prevention

Heating

System Not

Working

(Electric

and AC/DC)

Liquid in

Finishing

Drawer

Drum Will

Not Stay

Vertical

Test to determine

whether failure has

occurred

Thermostat Failure

Heating Element

Failure

Drum Screen

Clogged

Unit tilted to wrong

side

Condensation run-

ning down vent

stack

Drum Locker

Broken

Pull drawer out and put your hand in the evapo-

ration chamber (Not in the liquid). If there is no

warmth rising from the floor of the unit, your

heating system is not working. It is most com-

monly the thermostat that has failed. If you

notice a lack of evaporation, but there is still

warmth in the heating chamber, see “Liquid

Buildup” for solutions.

Have your serial number ready and call Sun-Mar

for a replacement. (Detailed instructions are

included with the replacement part)

If the insulation behind the thermostat access

cover is moist or discolored, or heating does not

work after the new thermostat has been connect-

ed, then the heating element has failed.

Have your serial number ready and call Sun-Mar

for a replacement. (Detailed instructions are

included with the replacement part)

Please note: Because this part is not easy to

replace, and because there is far less chance

that you will need this part than a thermostat; we

recommend trying to replace the thermostat first.

Remove the finishing drawer. By reaching

through the opening, you should be able to

access the drum screen. Scrub vigorously with a

wire brush.

Use a 1/4” to 1/2” (6-12mm) wedge piece under

the right side of the unit to drain liquid more eas-

ily towards the overflow drain of the unit.

Liquid will be clear or yellowish in appearance.

Make sure all vent pipe exposed to the outdoor is

well insulated and there are no horizontal runs.

Have serial number ready and call Sun-Mar for a

replacement part.

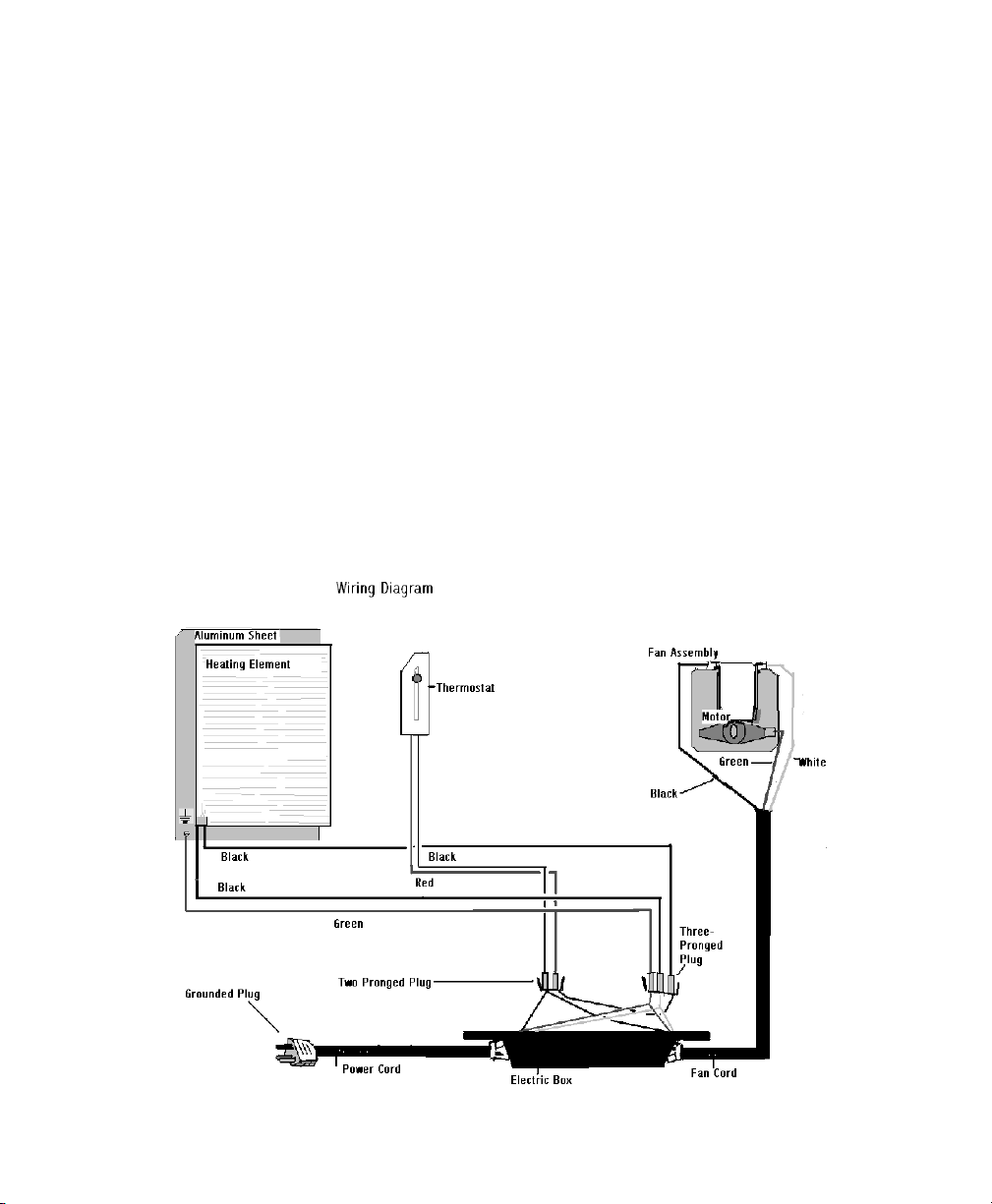

A ground fault interrupt circuit is

recommended to protect your

Centrex 2000 from power surges if

your heating system malfunctions.

Your thermostat and fan are the

two constantly moving parts on the

unit, and so are the most likely to

fail. Both are fairly easy to replace.

DO NOT wash the outside of the

unit with a hose or pressure wash-

er. Install the unit so that ground

water or weather cannot get at the

base of the unit.

When returning the drum to top

dead center position, do not bang

against drum locker with excessive

force. Remember to pull out the

drum locker button before rotating

the drum backwards.

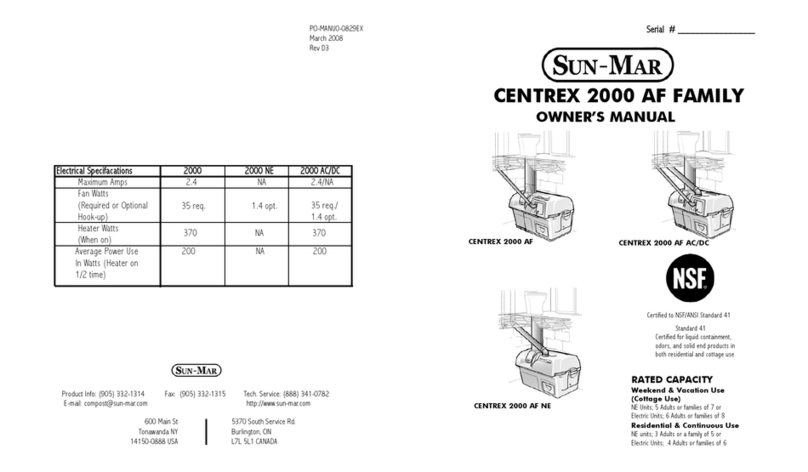

This chapter describes how to inspect your new Centrex 2000 prior to installation for damage and make

sure you have received all of the parts.

Inspecting

the unit for

damage

Check Carton

Contents

and

Familiarize

Yourself with

the

Centrex 2000

Placement of

Unit

Chapter 1

Inspection

i) If there is any visible damage to the carton-

the contents of carton MUST be inspected before signing bill of lading. Damaged units

should be refused. Call Sun-Mar immediately.

ii) Before signing the shipping papers and dismissing the driver.-

ensure that the carton contents have been inspected.

iii) If the shipper has left-

Report the damage immediately to the transport company and call Sun-Mar.

iv) Soon after delivery, remove the Centrex 2000 carefully

from the carton-

If there is hidden damage, or for any service Questions, contact Sun-Mar to determine

the best course of action.

Check that the carton contains the vent stack (pipe, fittings, roof flashing and diffusor);

“Compost Sure”, rake, drain hose and fittings, etc. Notify Sun-Mar if you are missing anything.

i) Turn the drum handle clockwise to rotate the Bio-Drum for mixing and aeration. (The drum

rotates counter-clockwise and the drum door closes). TThhiiss

iiss

hhooww

yyoouu

wwiillll

rroottaattee

tthhee

ddrruumm..

ii) Lift and remove the access door and rotate the drum until the drum opening is visible

through the the access door opening for adding “Compost Sure Blue”. TThhiiss

iiss

hhooww

yyoouu

wwiillll

aadddd

““CCoommp

poosstt

SSuurree

BBlluuee””ppeeaatt

mmoossss

mmiixxttuurree

ttoo

tthhee

ddrruumm

iii) Plug the unit’s electrical cord (Electric and AC/DC units) into a standard three-prong elec-

trical outlet, and feel the air movement from the vent outlet at the front of the unit to

ensure the vent system is working properly.

v) Pull out the compost finishing drawers at the bottom right of the unit.

vi) After the unit has been plugged in for ten minutes, place a hand on the floor of the

evaporating chamber (the area under the finishing drawer) to check it is warm to the

touch, and that the heater is working properly.

vii) Affix the “WARNING/CLEANING” sticker to the underside of the toilet seat cover, and check

that another is on the access port of the composting unit.

The unit should be installed so that the base is protected from weather. The rubber “u” chan-

nel at the bottom of the unit is well-sealed with silicone, but if the unit is sitting in water, has

snow melting against it, or rain pouring on it, this may eventually wear through and short out

the heating element. Install your unit with a protective cover of some kind around this area,

and do not install the unit in a pit where water can accumulate around it.