【M Series】Multi-turn Electric Valve Actuator

1

1 General Information...............................................................................................................................2

1.1 Safety Instructions .....................................................................................................................2

1.2 Installation, Storage, Transport..................................................................................................2

2 Product Overview..................................................................................................................................3

2.1 Features......................................................................................................................................3

3 Product Mechanical Data.......................................................................................................................4

3.1 Parts Identification.....................................................................................................................4

3.2 Nameplate Instruction................................................................................................................5

3.3 Technical Data ...........................................................................................................................6

3.4 External Gear Box .....................................................................................................................6

4 Storage, Transport and Packaging .........................................................................................................7

4.1 Receiving / Inspection ...............................................................................................................7

4.2 Storage.......................................................................................................................................7

4.3 Transport....................................................................................................................................7

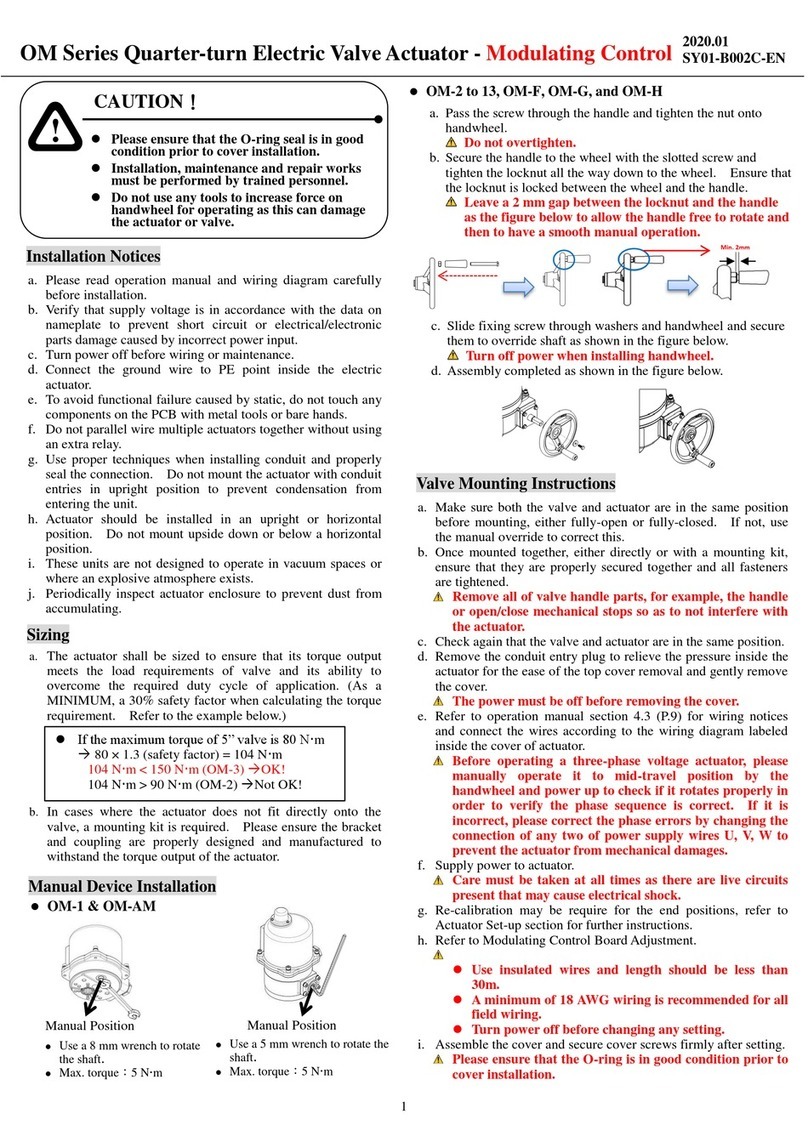

5 Mounting................................................................................................................................................9

5.1 Preparing Actuator Drive Bush..................................................................................................9

5.2 Mounting Actuator with Valve.................................................................................................10

5.3 Mount Gear Box with Valve....................................................................................................12

5.4 Mounting Actuator with Gear box...........................................................................................14

5.5 Mounting Dust-proof Stem Protection Sleeve.........................................................................15

6 Electrical Connection...........................................................................................................................16

6.1 Terminal Block Layout............................................................................................................16

6.2 Removing Terminal Cover.......................................................................................................17

6.3 Electrical Connection - Cable Connection ..............................................................................18

7 Manual Operation................................................................................................................................19

7.1 Manual Operation Steps ..........................................................................................................19

8 Electrical Operation.............................................................................................................................21

8.1 Introduction..............................................................................................................................21

8.2 User Management....................................................................................................................27

8.3 Operation .................................................................................................................................29

8.4 Status........................................................................................................................................32

8.5 Control System Settings ..........................................................................................................37

8.6 Set Maintenance Due...............................................................................................................40

8.7 Parameter Setting.....................................................................................................................42

8.8 System Control Setting............................................................................................................56

8.9 Fieldbus Setting.......................................................................................................................62

9 Servicing and Maintenance..................................................................................................................64

9.1 Battery Maintenance................................................................................................................64

9.2 Oil Replacement ......................................................................................................................65

9.3 Maintenance.............................................................................................................................66

9.4 Operation Protection................................................................................................................66

10 Troubleshooting...................................................................................................................................67

11 Warranty...............................................................................................................................................71

12 Disposal ...............................................................................................................................................71