TABLE OF CONTENTS

1. ABOUT THIS MANUAL .........................................................................1

2. INTRODUCTION ....................................................................................1

2.1. TILLER IDENTIFICATION .........................................................................................................................................1

2.2. INTENDED USE .............................................................................................................................................................2

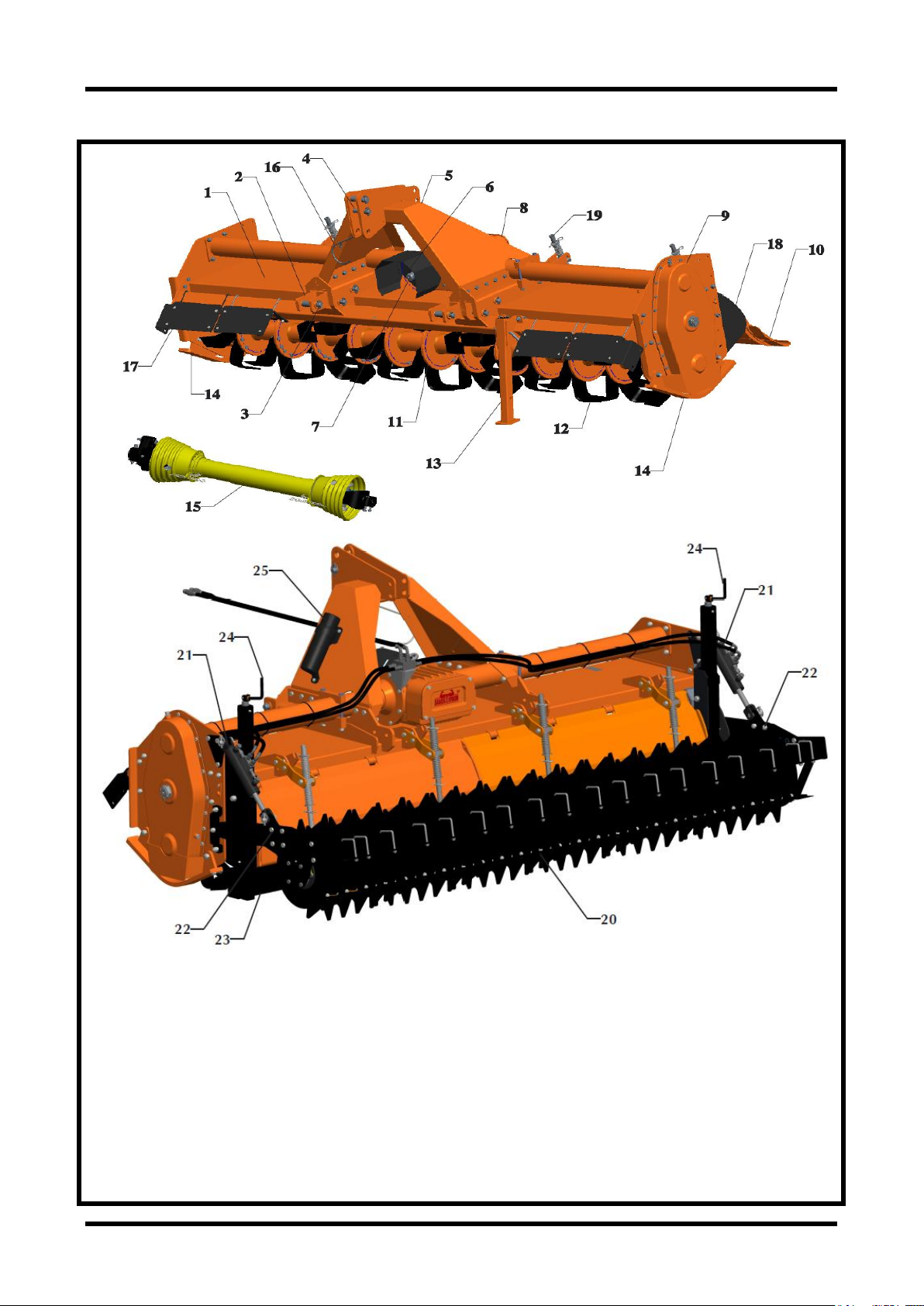

2.3. MAIN PARTS DESCRIPTION .................................................................................................................................... 3

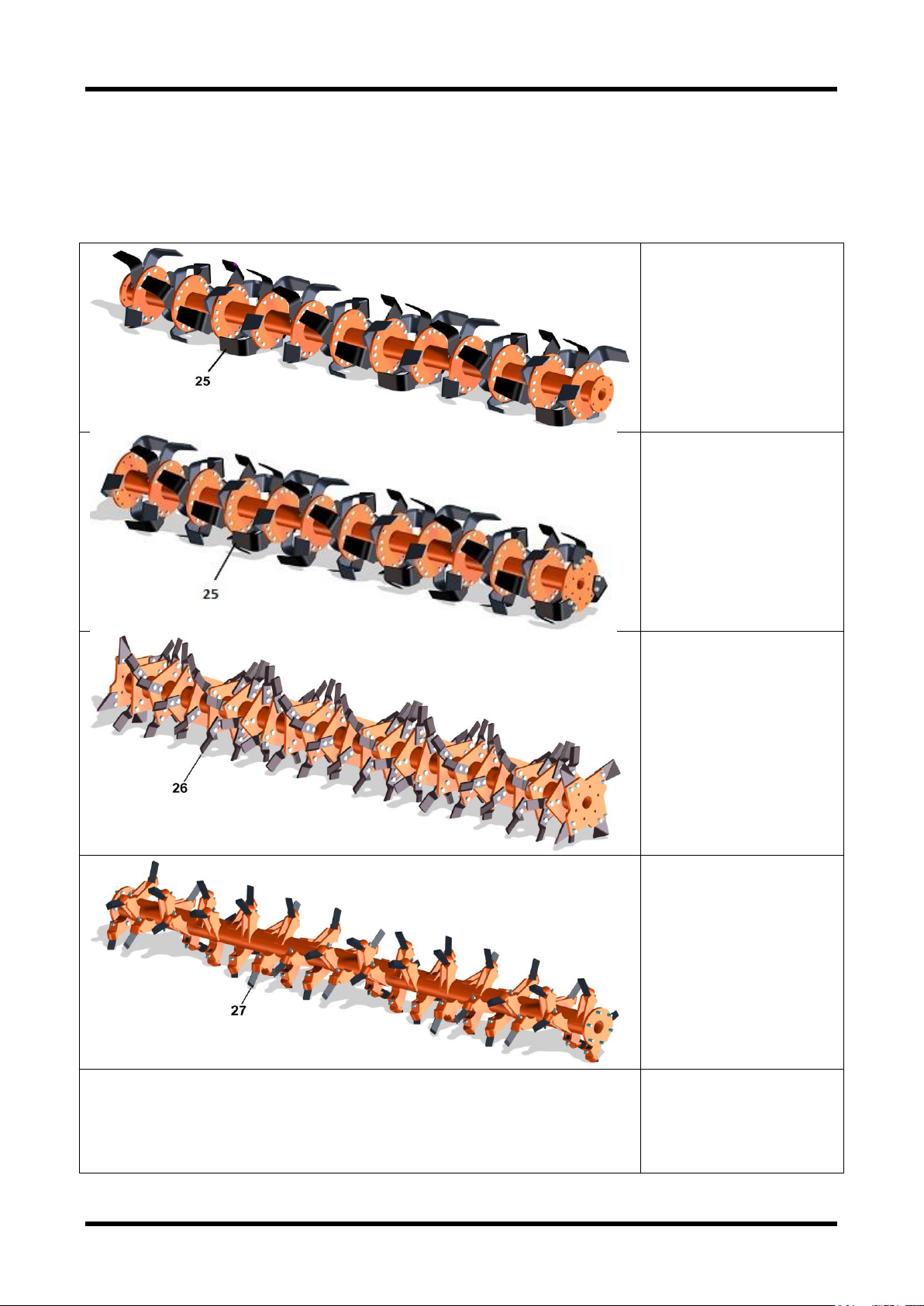

ROTORS ..................................................................................................................................................................4

ROLLERS ...............................................................................................................................................................5

2.4. TILLER SPECIFICATION ............................................................................................................................................6

3. SAFETY .....................................................................................................7

3.1. GENERAL SAFETY INSTRUCTIONS .......................................................................................................................7

3.2. EQUIPMENT SAFETY INSTRUCTIONS .................................................................................................................8

3.3. OPERATING SAFETY INSTRUCTIONS ..................................................................................................................9

3.4. TRANSPORTING SAFETY INSTRUCTIONS ...................................................................................................... 10

3.5. MAINTENANCE SAFETY INSTRUCTIONS ....................................................................................................... 11

3.6. STORAGE SAFETY INSTRUCTIONS .................................................................................................................... 12

3.7. SAFETY LABELS ......................................................................................................................................................... 12

SAFETY LABELS POSITION AND DESCRIPTION ................................................................................ 13

4. SET-UP .................................................................................................. 18

4.1. LOWER HITCHES POSITIONING ......................................................................................................................... 18

4.2. CONNECTING TO THE TRACTOR ....................................................................................................................... 21

4.3. DRIVELINE INSTALLATION ................................................................................................................................. 22

DRIVELINE LENGTH CHECK ...................................................................................................................... 22

4.4. HYDRAULIC CONNECTION ................................................................................................................................... 24

4.5. CONNECTION OF ADDITIONAL IMPLEMENTS ............................................................................................ 24

4.6. TRACTOR-TILLER STABILITY ............................................................................................................................. 25

5. OPERATING ......................................................................................... 26

5.1. START UP ..................................................................................................................................................................... 26

5.2. OPERATING INSTRUCTIONS ................................................................................................................................ 27

5.3. ADJUSTMENTS ........................................................................................................................................................... 28

LOWER HITCHES ADJUSTMENT .............................................................................................................. 28

FRICTION CLUTCH ADJUSTMENT ........................................................................................................... 28