2

Subject to technical modification

02.2008

ASSEMBLY INSTRUCTIONS

ELECTRO CURTAIN TRACK SYSTEM 5060

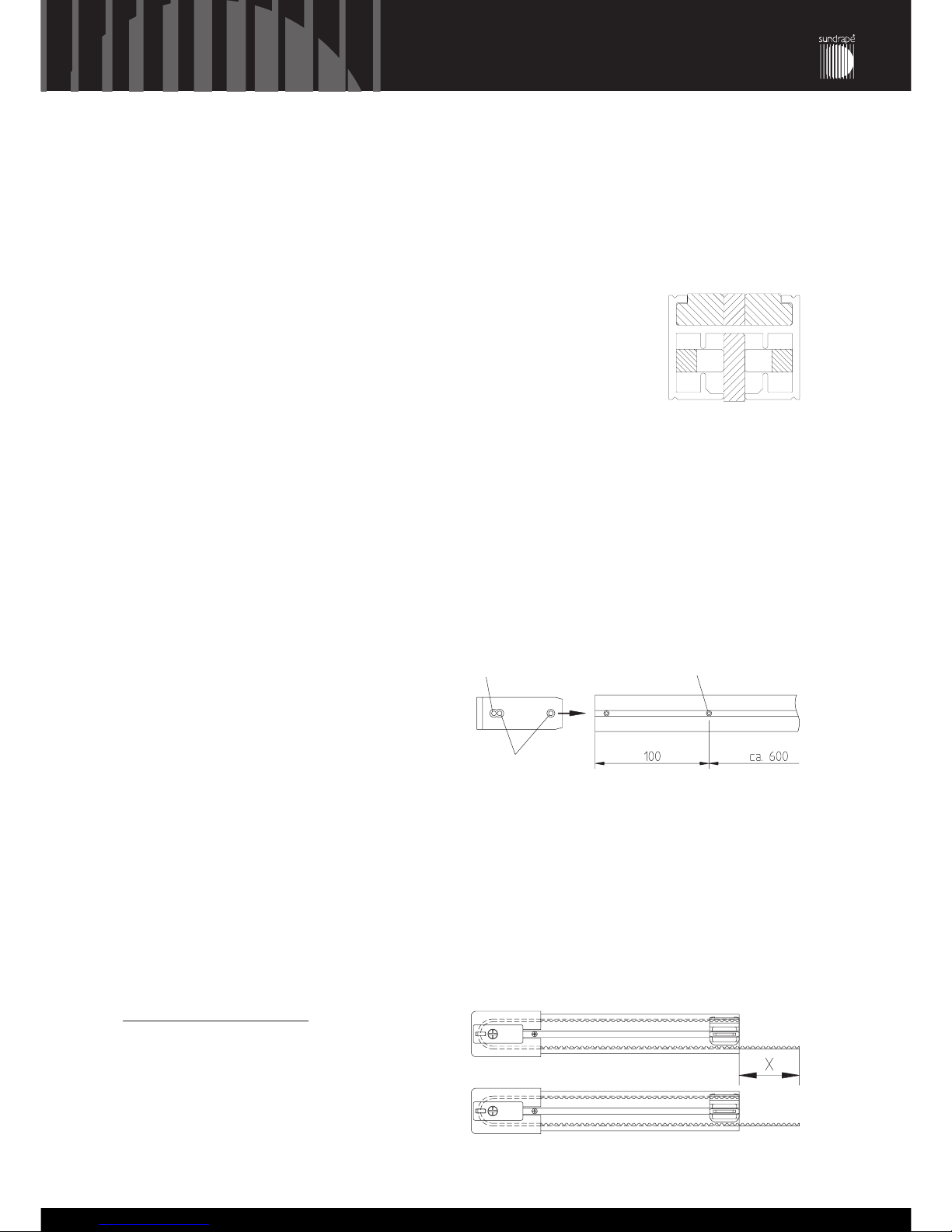

Tear drive runner unit through rail by means of a mounting hook 301 463 until a flush top rail position (3). Measure the correct

length of toothed belt and cut it correspondingly by means of a side cutter:

length of blind up to 7000 mm overlapping at the rail end (ds) 97 mm

length of blind exceeding 7000 mm overlapping at the rail end (ds) 93 mm

Once cut to the right measure, you may now put on the rail gear in its position: tear out the outstanding end of the tape a bit

more, lead it through the rail gear and plug a second drive runner flush on at the end. Insert the drive runner into the rail and plug

on the gear.

The toothed belt length is measured in a right way when the drive runners are standing at 6 to 8 mm to each other.

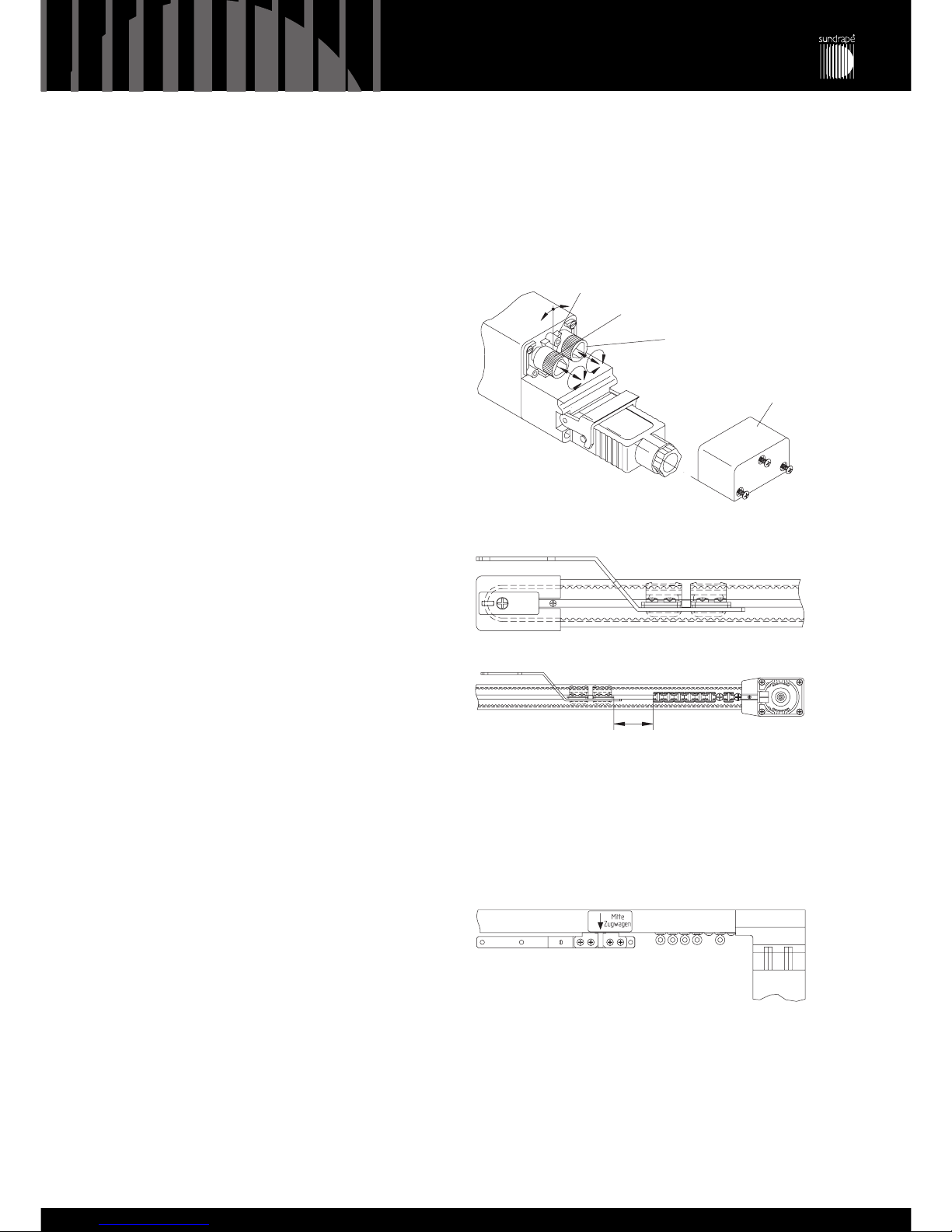

Toothed belt drive, two-part fabric:

Proceed as described for “one-part fabric”. Then

sign the middle of the rail with a pencil and tear

drive runner exactly to the middle of the rail (4).

Then sign this center position on the belt by

means of a laquer pen (remove overrun colour).

Now remove rail gear and counter bearing and

plug in nds-drive runner with traverse joint

exactly at the sign you previously made with the

laquer pen (5). Then, by means of the mounting

hooks, move the drive runners towards each

other, plug on rail gear and counter bearing

again and assemble ds-drive runner with tra-

verse joint, fix with clip. Finally, move both drive

runners with traverse joint to the middle: both

traverse joints meet exactly in the middle (6).

Advice: According to operating side, insert left or right traverse joint, in case of center closing blinds, use two left or two right

traverse joints. The edge of the traverse joint always shows to nds-side respectively in case of center closing blinds to the

middle of the rail.

6.

Fix rail gear, counter bearing (in case of tandem motor: two rail gears) and rail profile from inside with one countersunk screw

each, 2,9 x 9,5.

7.

If necessary, tear traverse joint away from ds gear by hand so that the runners can be inserted.

8.

Insert the corresponding number of drive run-

ners or gliders (type of runner depends on type

of blind) through gear aperture into the rail. In

case of center closing blinds, remove cover of

counter bearing at nds-side. Fix the very first

roller or glider at ds-side and nds-side at 95 mm

by means of a locking device (7). Insert the

locking devices in the same way as the runners

or gliders: through aperture of gear. After this

process, screw cover of counter bearing on

again.

(4)

(4)

(6)

(7)

(5)

sign middle of the rail

put drive runner on the mark

middle off the rail

port for runners or gliders

mark belt with laquer pen

mark