We recommend removing the

chuck from the drill and threading

the Cam-Coupling on to the drill

mandrell. This makes the whole

assembly shorter with much better

balance.

If this is the method you

choose, please see picture #1.

Some drills have a left threaded Reversing-Screw

holding the chuck onto the drill. Open the Chuck

all the way. Then look inside the chuck to see what

style of screw head is used (Allen head, Phillips,

Straight ,etc....) This screw is removed by turning the

screw clockwise while holding the chuck from

turning with the chuck key in place as in picture #1.

Once the Reversing-Screw is removed hit the back

end of the Chuck-Key with a hammer as shown and

the Chuck will unscrew.

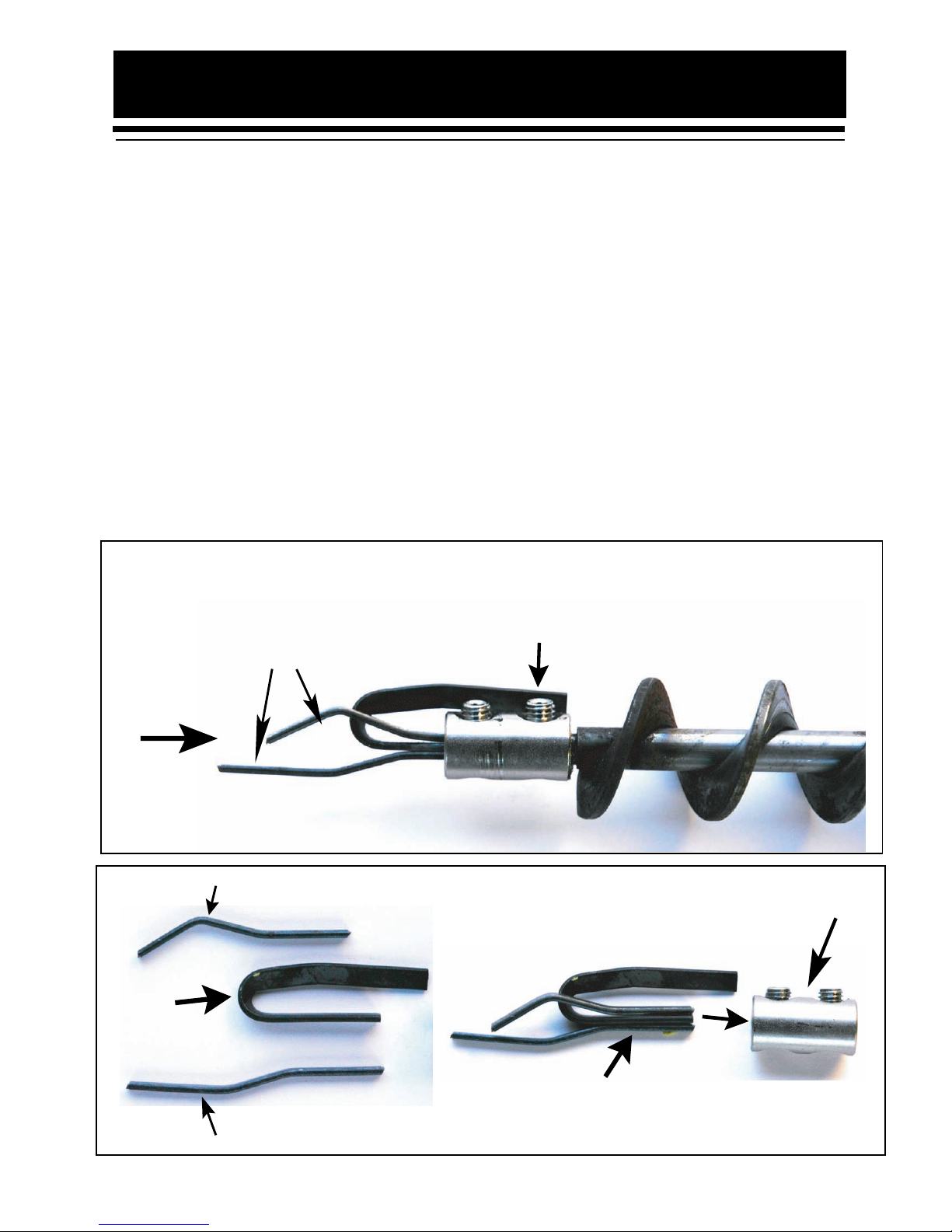

1.

If you do not remove the Chuck from your

drill simply chuck the 3/8th inch

CAM-Stud (#704) into the chuck as shown .

2.

To connect the drill to the

Quikpoint assembly simply

put the drill in forward and

screw the drill arbor or the

cam stud into the back of the

Cam-Coupling see fig#3

3.

4. 5.

Slip the Ring-Clamp

(#711)over the drill and

Drill Mount Arms.

Secure Ring-Clamp

in suitable place on

drill . Avoid covering

air vents.

6. 7.

If needed, the Drill Mount Arms (#710) can

be extended back by mounting the

arms as shown with two bolts

Mounting a Drill

Drill with chuck

removed

Drill with chuck and

male Cam-Stud

6.

(#710)

To install Cam-Guard (#909)

after drill is mounted push

up under and between Drill

Mount Arms then snap over

hopper tongue.