Page 3

Table of Contents

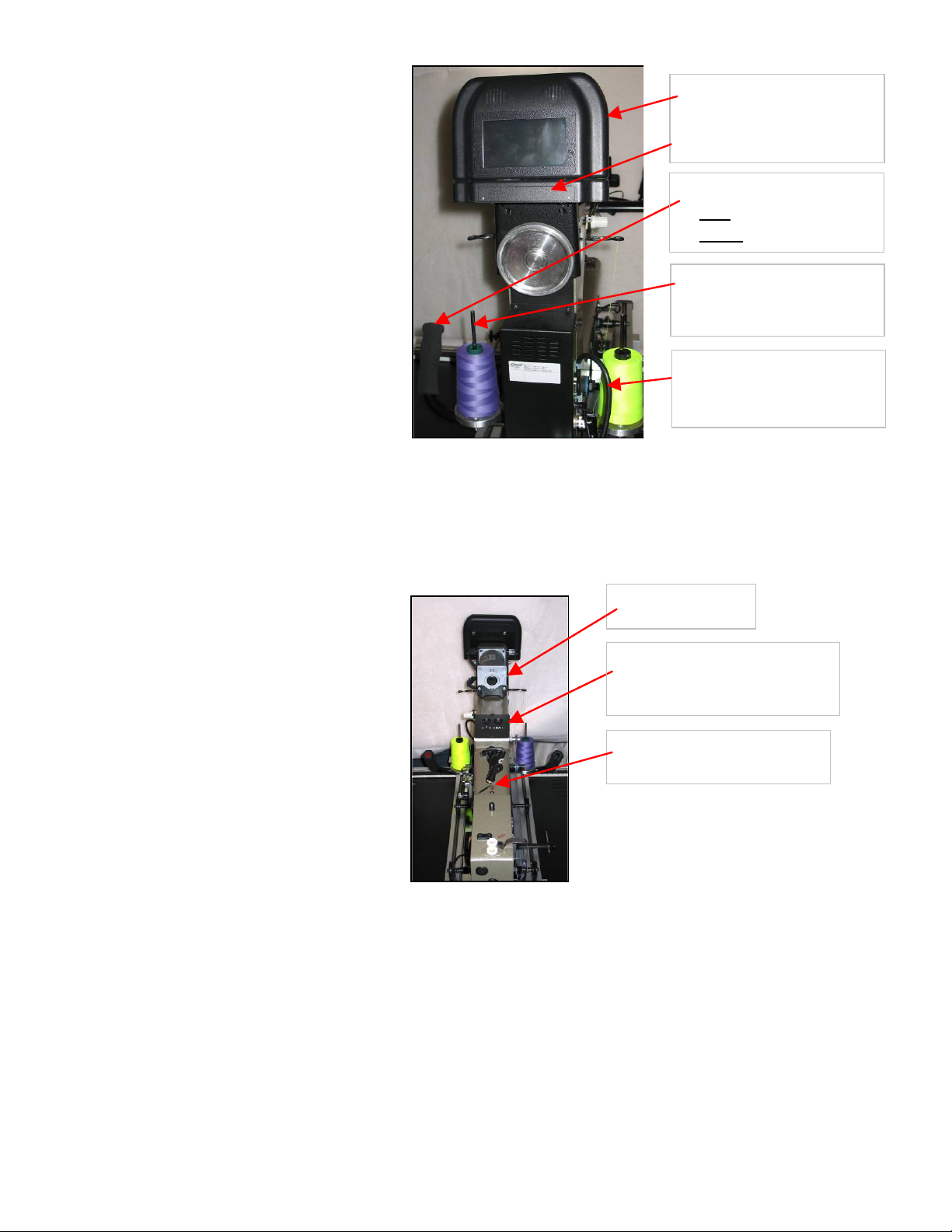

Section 1 - Tour your Gammill Vision™......................................................................................................... 6

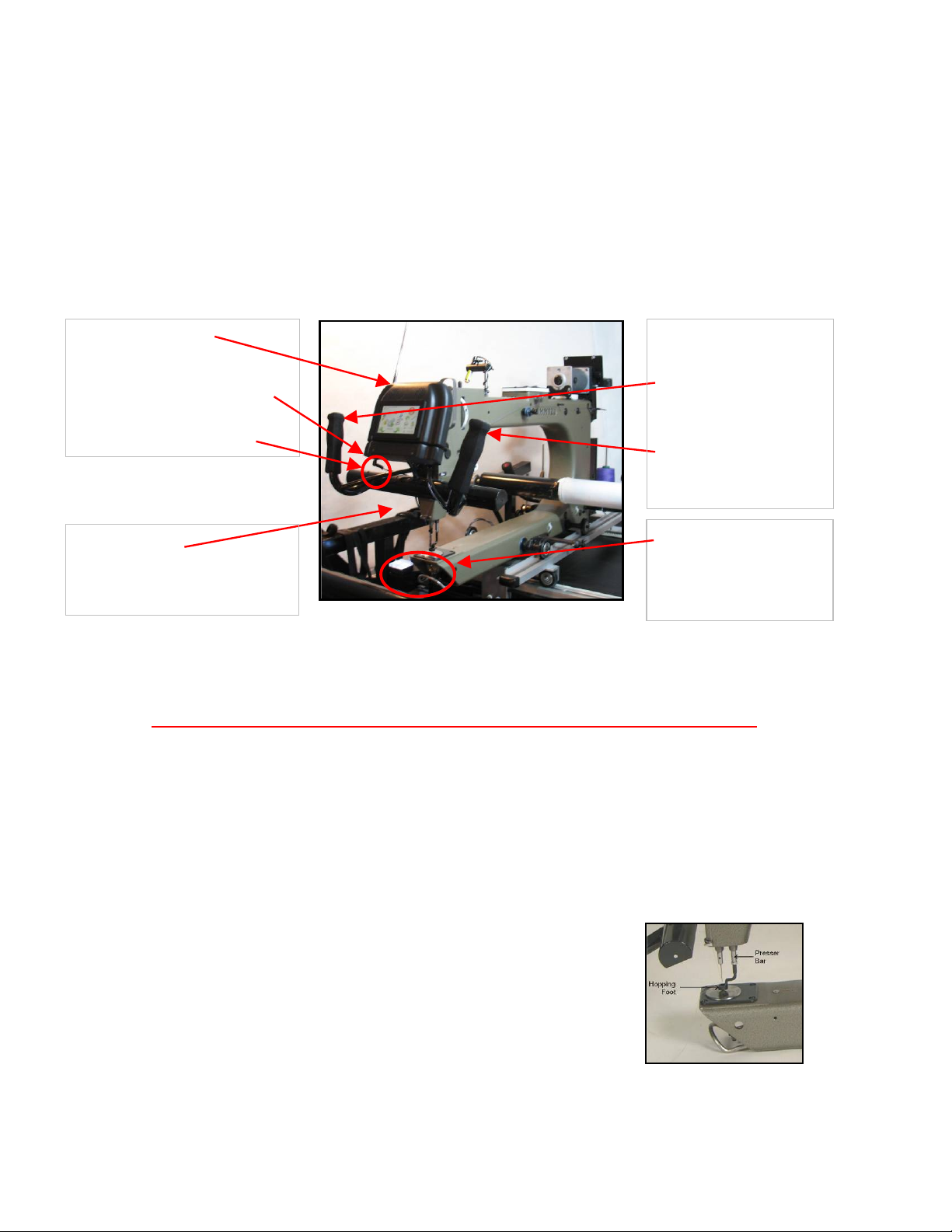

Gammill Vision™ - Front View ....................................................................................................................... 6

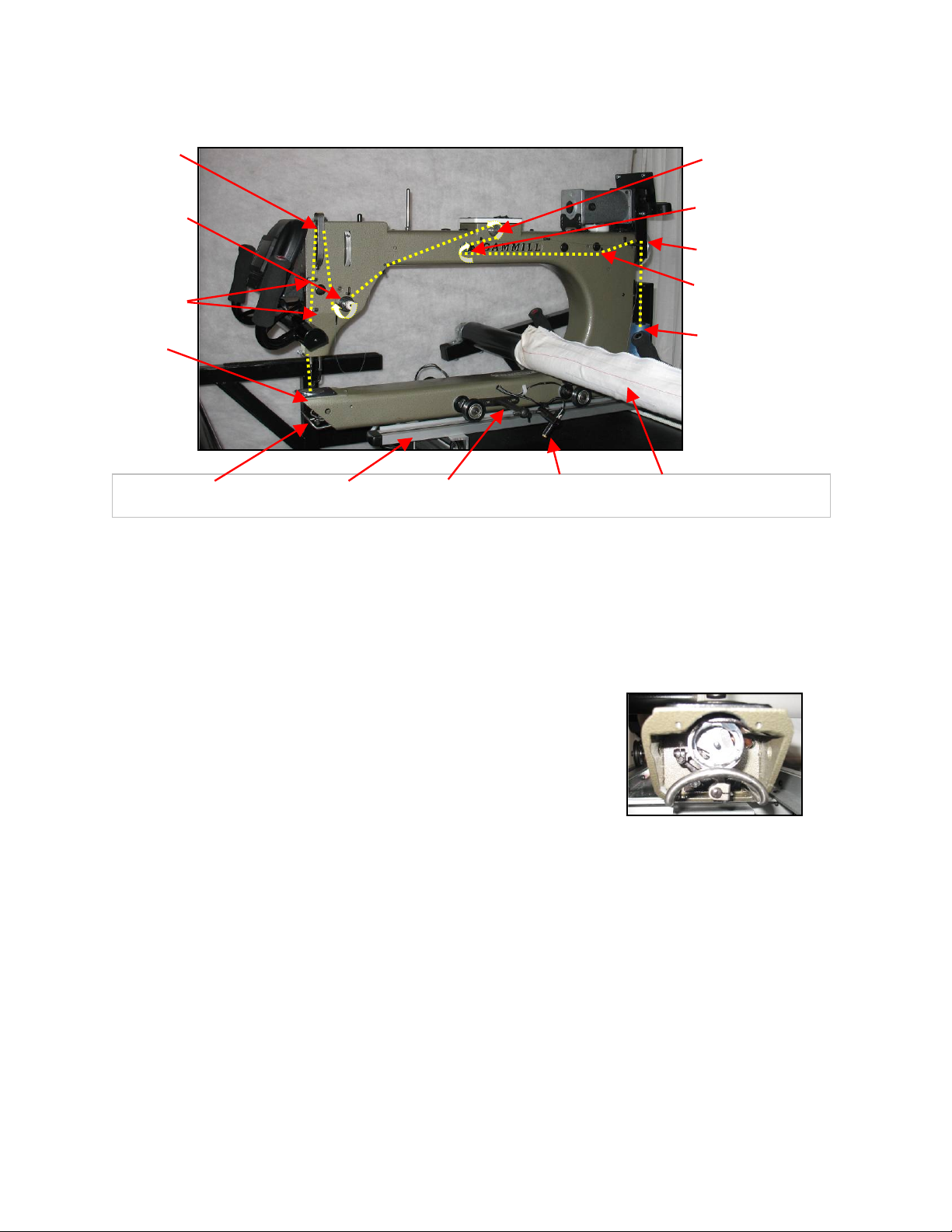

Gammill Vision™ - Right SideView ................................................................................................................ 7

Gammill Vision™ - Left Side View ................................................................................................................. 8

Gammill Vision™ - Back View ....................................................................................................................... 9

Gammill Vision™ - Top View ....................................................................................................................... 10

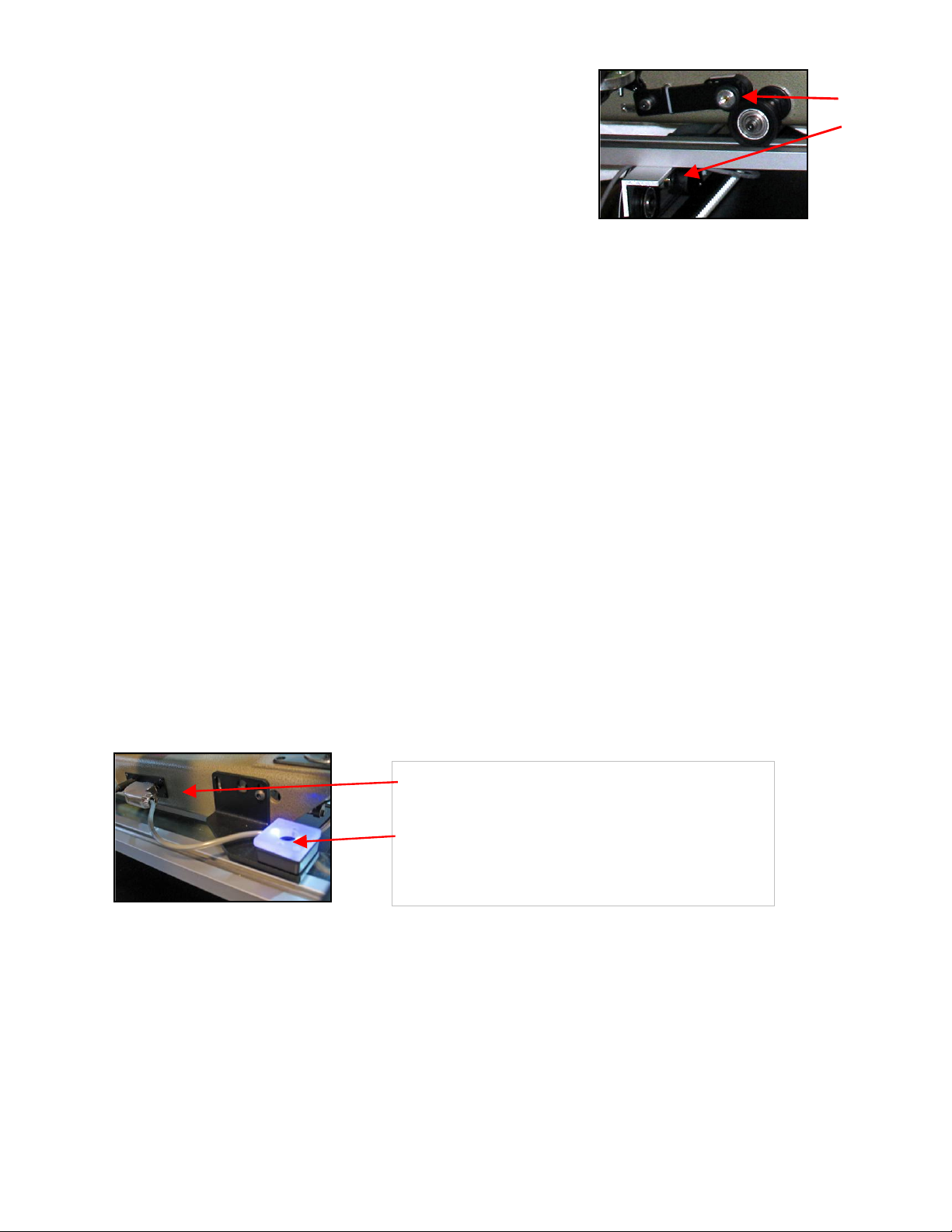

Gammill Vision™ - Bottom Crosstrack (aka Carriage)................................................................................. 11

Tour Your Table ........................................................................................................................................... 12

GS-1PA Table.......................................................................................................................................... 12

Home-Pro Table ...................................................................................................................................... 13

Section 2 – Getting Ready to Quilt ............................................................................................................... 13

About the manual ................................................................................................................................ 13

About the instructions.......................................................................................................................... 13

Threading the Machines .............................................................................................................................. 13

Back Section............................................................................................................................................ 14

Middle Section ......................................................................................................................................... 15

Front Section ........................................................................................................................................... 16

Threading the Gammill Vision™ 18-8...................................................................................................... 17

Using the On-board Bobbin Winder ............................................................................................................. 17

Winding bobbins while quilting................................................................................................................. 18

Winding bobbins before quilting............................................................................................................... 18

Using a Stand-alone Bobbin Winder ............................................................................................................ 19

About the Bobbin Case ................................................................................................................................ 19

Inserting the Bobbin Case ....................................................................................................................... 20

Setting the Tensions .................................................................................................................................... 20

Set the Intermittent Tension..................................................................................................................... 20

Set the Rotary Tension ............................................................................................................................ 21

Set the Bobbin Case Tension .................................................................................................................. 21

Checking the Top Thread Tension ...................................................................................................... 21

Changing the Top Thread Tension...................................................................................................... 22

Section 3 - Navigating The Screens ............................................................................................................. 23

Turning on (and off) the machine................................................................................................................. 23

Initialization:......................................................................................................................................... 23

Main Screen - Carousel of Patented Applications ....................................................................................... 24

Stitcher Modes......................................................................................................................................... 24

About the Stitch-regulator - ................................................................................................................. 24

Channel Locks ......................................................................................................................................... 25

Stitch Monitor ...................................................................................................................................... 26

FM Tuner ................................................................................................................................................. 28

Tools / Diagnostics .................................................................................................................................. 29

Settings / Preferences ............................................................................................................................. 30

Main Screen - Settings................................................................................................................................. 30

Main Screen - Setting Changes............................................................................................................... 30

Main Screen - Status Information ................................................................................................................ 32

Stitcher Status Button .............................................................................................................................. 32

Needle Positioner .................................................................................................................................... 33