CR 1400

4

2.1 General safety instructions

Familiarize yourself carefully with this manual and make sure that you have understood the in-

structions regarding the mulcher and related information.

Everyone using the Mulcher must follow the given instructions. If the mulcher is given temporari-

ly to other user than the owner of the machine, or if it is rented, make sure that the user has

read this manual and understood safe and proper use of the machine.

2.2 Instructions for safe use

WARNING! Minimum safety distance is 10 metres.

WARNING! The mulcher must be lowered onto the ground, the parking brake

must be applied, and the power take-off must be disengaged when leaving

the base machine!

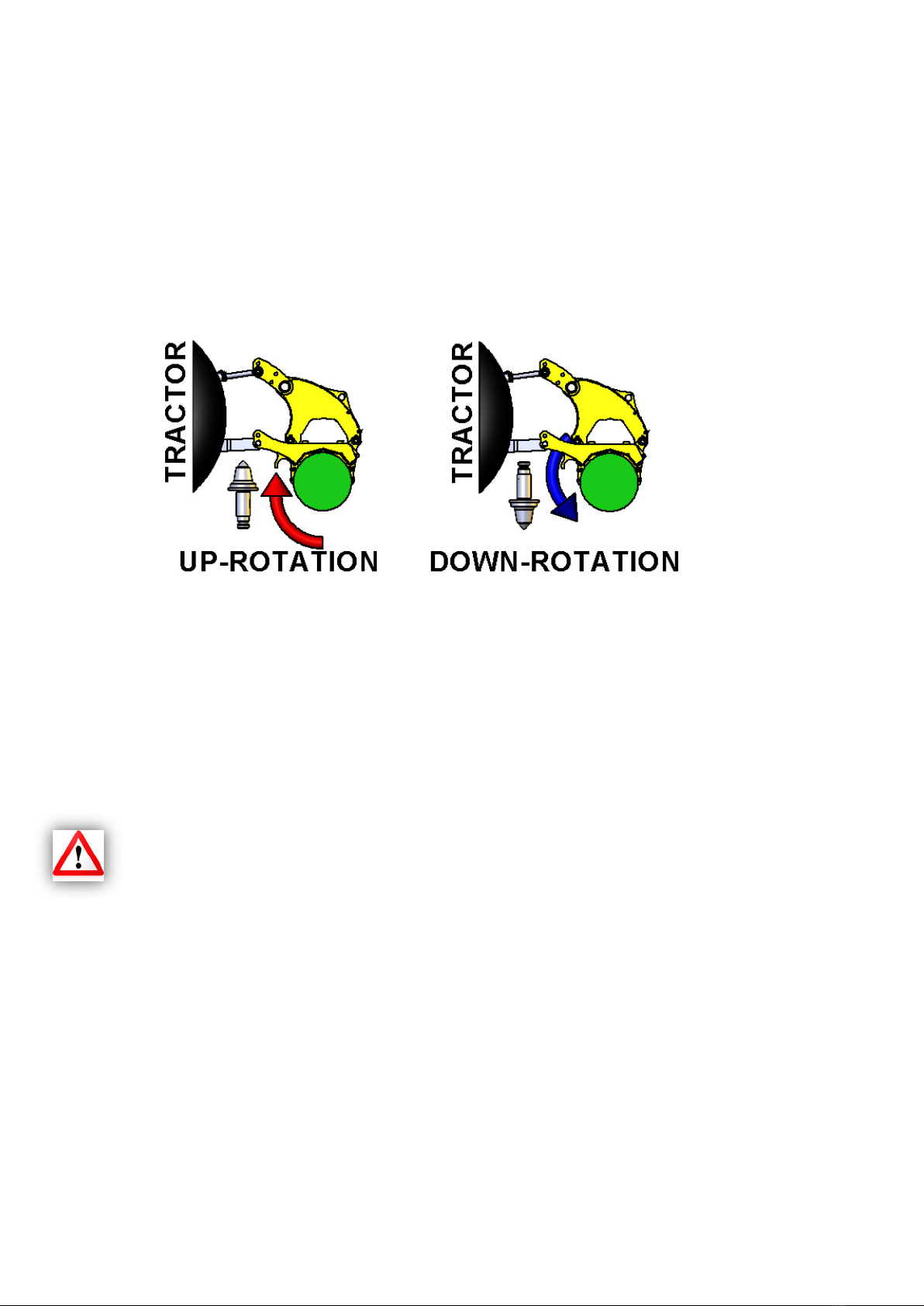

WARNING! Rotating machine parts - Never get close to rotating parts, shafts,

drums, or blades, and never attempt to service them while the machine is

running.

•When coupling or uncoupling the mulcher, make sure that the parking brake is en-

gaged. Eliminate the risk of getting crushed between the mulcher and the base

machine.

•Before operating the machine make sure that the mulcher and its hydraulic fittings

are coupled properly.

•Before moving the mulcher the operator of the mulcher / base machine must

check the operation of the control systems and movements.

•During use ensure that there are no others closer than the minimum safe distance,

and that the visibility is adequate.

•Operate the machine calmly and adjust the drive speed according to operating con-

ditions.

•Make sure that all guards are in place and fitted securely.