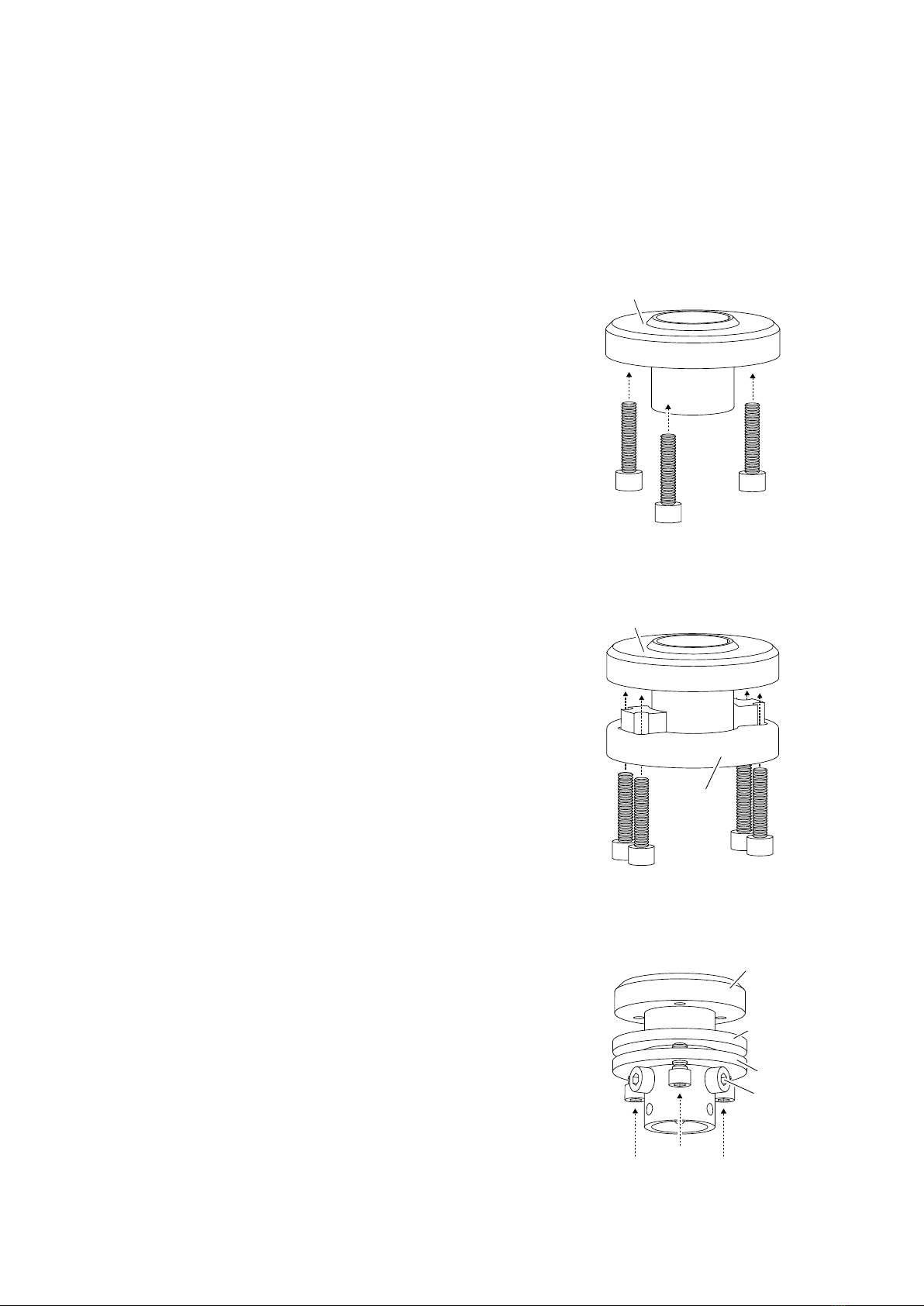

The positions of the pins are shown below:

If you have rotated the Black Knight pin holder

inside the pillar then these pin positions will

also have rotated correspondingly.

Mount Arm

With the arm held in your left hand about

15mm above the play position to provide slack

in the hoists, insert the hoist toggles into the

small holes on the thrust surface. Take care not

to strain the signal wires. Ensure the hoist

toggles are fully through and snagged. Note that

the left hoist toggle is also attached to the bias

pulley. The right hoist toggle is fixed only to the

right hoist.

If necessary, adjust the hoist spools so that the

arm is suspended by both hoists and level.

Normally there is a clearance of about two

millimetres between the underside of the arm

and the top of the post. This will be accurately

adjusted later during the Calibration process.

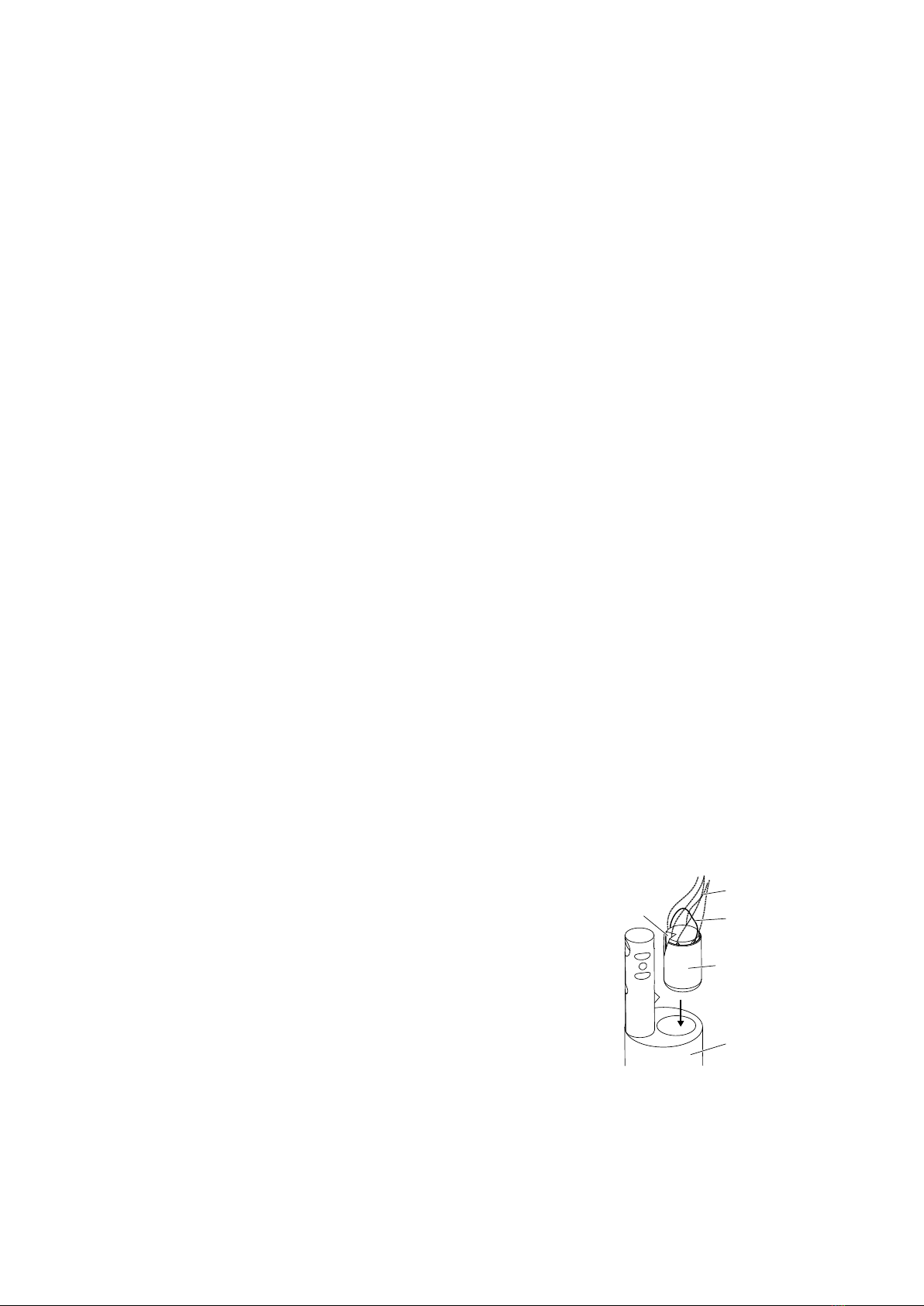

If None, Install Cartridge

If you did not install your cartridge before

mounting the arm, place a folded tissue

between the pivot and thrust box to protect

them during cartridge installation.

For a three-bolt mounting, temporarily remove

the finger-lift and use its hole to access the third

bolt with an Allen key or screwdriver.

Large head cartridge bolts or large nuts will not

fit in the headshell. It is possible to file large

bolt-heads and nuts in a drill or by hand.

Contact SUPATRAC if you are unable to

procure compatible bolts.

Attach Counterweight

When setting downforce, always obstruct

movement of the arm by holding it in your left

hand while adjusting the counterweight with

your right. Attach a magnetic counterweight

under the thrust box and squeeze it forwards

for more downforce or backwards for less. Keep

the counterweight centred on the axis of the

arm by pinching the thrust box from both sides

between thumb and fingers. You can centre the

counterweight by feel. Keeping the

counterweight centred in this way makes it less

necessary to adjust lean (azimuth) after

adjusting downforce.

Multiple counterweights are normally supplied

to cater for an extremely wide range of

cartridges weights, compliances and tracking

weights (downforces).

To measure downforce with the supplied

downforce scale, place it on the bare platter