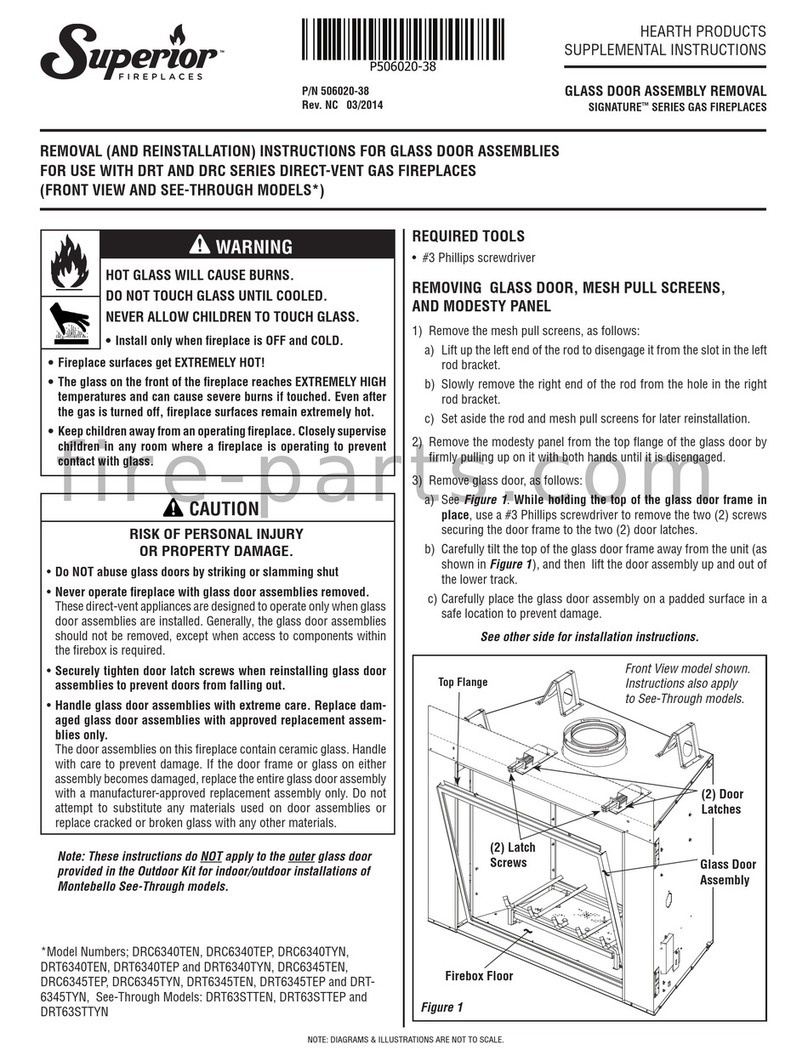

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

4

If the horizontal distance from the peak of the

roof is less then 10', thetop of the chimney must

be at least 2' above the peak of the roof.

If the horizontal distance from the chimney

edge to the peak of the roof is more than 10' a

chimney height reference point is established

on the roof surface 10' horizontally from the

chimney edge. The top of the chimney must

be at least 2' above this reference point. In all

cases, the chimney cannot be less then 3' above

the roof at the edge of the chimney.

The 2' in 10' rule is necessary in the interest

of safety but does not ensure smoke-free op-

eration. Trees, buildings, adjoining roof lines,

adverse wind conditions, etc., may require a

taller chimney should the fireplace not draft

properly (Figure 15).

FTF8 CHIMNEY COMPONENT

CALCULATIONS

The minimum installed height of the completed

fireplace system is 10' 6". The maximum height

is 40' 0" when the chimney is exposed.

To determine the number of chimney sections

and chimney components required, follow

these steps:

1. Determine total vertical height of thefireplace

installation. This dimension is the distance from

the surface the fireplace sets on to the point

where smoke exits from the termination.

2. Determine the number of chimney com-

ponents required, except chimney sections.

This would include thimbles, extensions, roof

flashing, etc.

3. The effective heights of the components

are:

The Fireplace = 37”

FTF8-12 = 10-1/4”

FTF8-18 = 16-1/4”

FTF8-24 = 22-1/4”

FTF8-36 = 34-1/4”

FTF8-48 = 46-1/4”

FTF8-CTD Termination = 6”

4. Determine amounof chimneyheight required

by subtracting total combined height of all pre-

selected components (fireplace and chimney

components from total desired height).

Reference Vertical Elevation Chart and deter-

mine the number of chimney sections (quantity

and length) required.

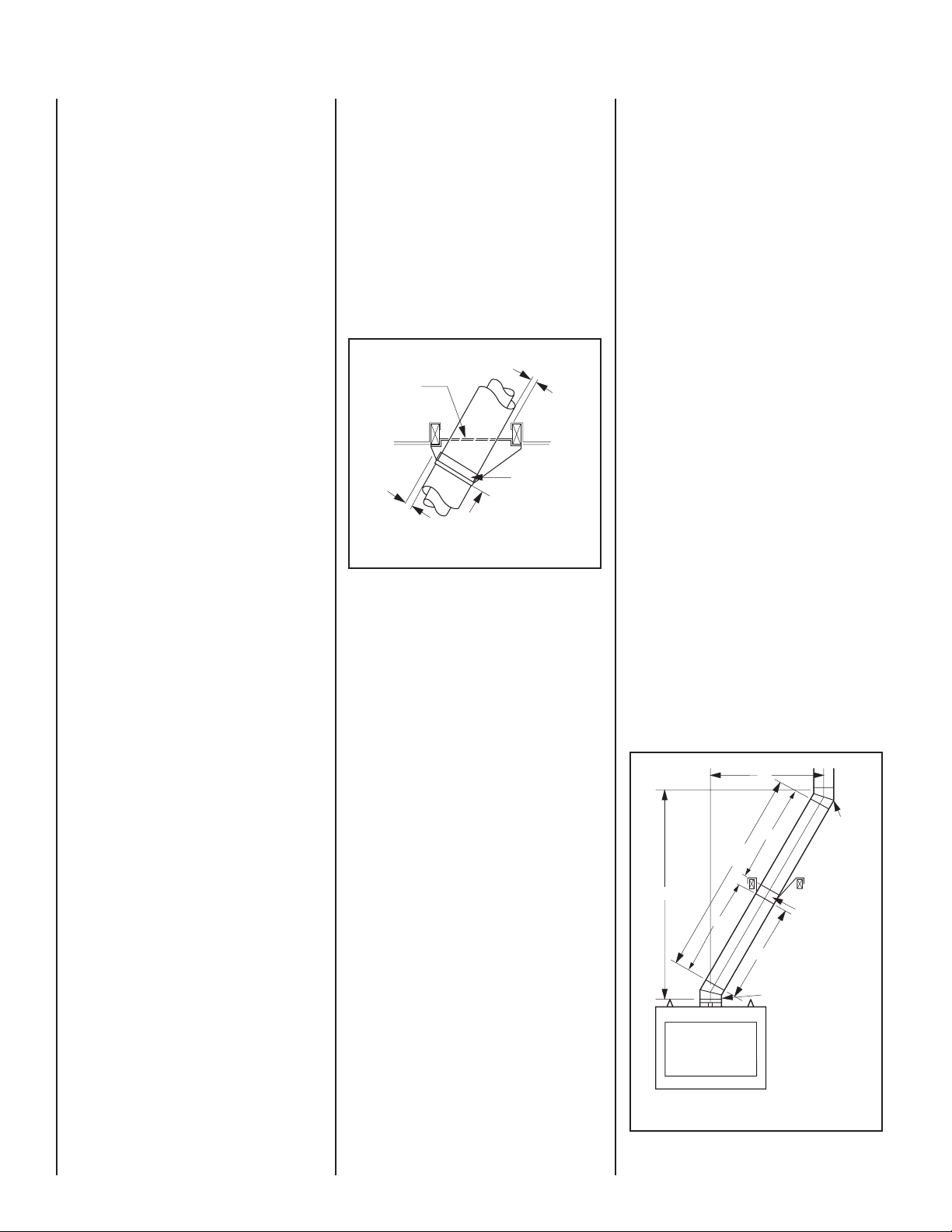

To clear any overhead obstructions, you may

offset your chimney systemusing Security's 30°

offset and return elbows. Use two elbows - an

offset elbow to initiate the offset and a return

elbow to terminateit. A 30° offset elbow, angling

in any direction,may be thefirst component used

off the top of the fireplace flue collar.

The offset and return elbows may be attached

together, or a section or sections of chimney

may be used between, but do not exceed 20' in

total length between elbows. If sections of pipe

exceed 10' between elbows,a chimney stabilizer

must be used at the midpoint (see Figure 17).

The stabilizer support straps must be attached

under tension (in shear) to structural framing

members above. When two sets of elbows

are used, the maximum combined length of

chimney used between elbows cannot exceed

20' (see Figure 18). Example: If C1= 10' then

C2cannot exceed 10'.

If an offset exceeds 6' in length, each chimney

joint beyond the first 6' of offset to the return

elbow, must be secured by a No. 8 x 1/2" sheet

metal screw located at the underside of the joint

(see Figure 20).

A 1/8" diameter hole must be drilled in the

chimney joint using a 1/8” diameter drill. Hole

should be drilled in center of joint overlap (see

Figure20). Be sureto drill only through theouter

chimney casting. Do not puncture the inner flue.

Maximum offset of chimney system is 30°.

Two offsets must not be assembled to form

a 60° offset. However, two sets of offset and

return elbows may be used on a single flue

system, provided the total height of the system

exceeds 25'.

Return elbow support straps must be securely

attached under tension (in shear) to structural

framing members above. Do not substitute a

FTF8-30 offset elbow in place of a FTF8-E30

return elbow.

OFFSET CALCULATIONS

Step 1. Use Offset Chart to determine amount of

horizontal offset (A) and height (B) for various

chimney section assemblies.

Step 2. Use “Height of Chimney Only” column

in The Vertical Elevation Chart to determine

combinations of chimney used above return

elbow to achieve desired heights. Reference

Components Effective Height Chart in vertical

elevation chart section.

Step 3. Use Elevation Chart as job estimator

only. Add necessary firestop spacers and sta-

bilizers as required. Firestop spacers must be

used as shown in Figure 16 and stabilizers as

shown in Figure 9.

Stabilizer

A

1

20'

Max.

B

1

10' Max.

Offset

Elbow

Return

Elbow

C

2

C

1

Figure 17

Figure 16

F8FS30

Firestop Spacer

FTF8-S4 Stabilizer

30°Firestop

And Room Above

10'

Max.

Room Above

1" Min.

Air Space

1" Min.

Air Space

SPECIAL OFFSET INSTRUCTIONS

Chimney 30° Offset through Floor or Ceiling

It may be necessary to assemble the chimney

at 30° when passing through the floor or ceil-

ing area. Use the F8FS30-2 firestop spacer as

shown in Figure 16. Support the chimney at

floor or ceiling penetration with a FTF8 stabilizer

if distance of chimney below ceiling is 10' or

more. Maintain 1" minimum air space to com-

bustibles from chimney sections. The chimney

must pass vertically through the attic space.