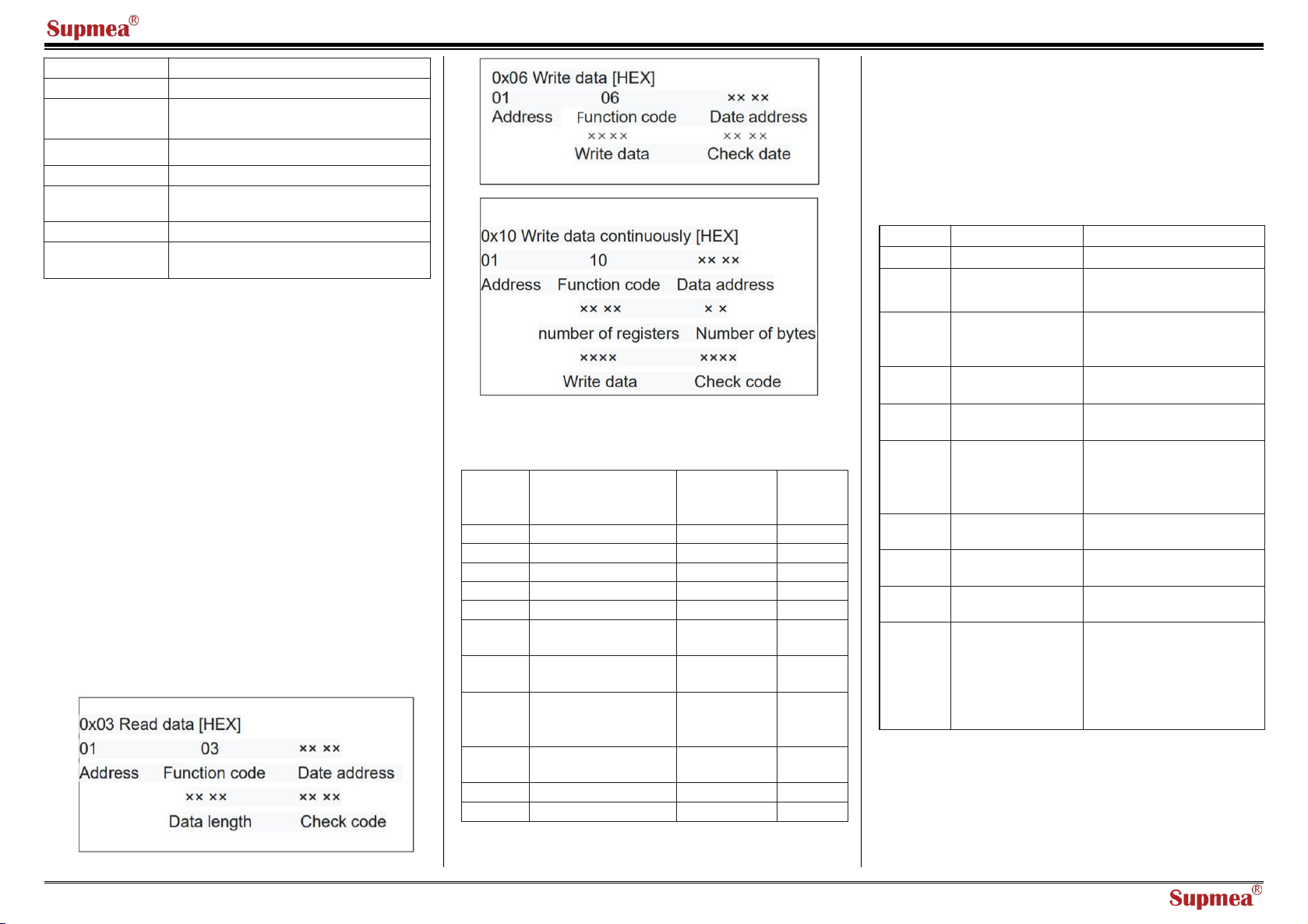

10. Common instruction set [HEX]

Read temperature, pH, pH.mV

[Send Tx]: 01 03 00 00 00 03 05 CB

[Receive Rx]: 01 03 06 00 FA 02 BC 00 06 B9 3F

Temperature = 00FA = 250 * 0.1℃= 25.0℃

pH = 02BC = 700 * 0.01pH = 7.00 pH

pH.mV = 0006 = 6 * 0.1mV= 0.6 mV

Set RS485 address

The original address is: 0x01

needs to be modified to: 0x02

[Send Tx]: 01 06 00 0B 00 02 79 C9

[Receive Rx]: 01 06 00 0B 00 02 79 C9 (Set

successfully)

Query the RS485 address (stand-alone mode)

The device address is unknown, you can use the

address 0x00 to send the 03 command

[Send Tx]: 00 03 00 00 00 03 04 1A

[Receive Rx]: 01 03 06 00 FA 02 BC 00 06 B9 3F

Current device address = 0x01

Electrode calibration

Please use the user command set to write a

command to address 0x07 to complete the

operation

pH7.00 | [Send Tx]: 01 06 00 07 00 0D F9 CE

pH4.00 | [Send Tx]: 01 06 00 07 00 0B 79 CC

pH10.00 | [Send Tx]: 01 06 00 07 00 0F 78 0F

[Receive Rx] returns the same command as

[Send Tx], which means the calibration is

successful.

When calibrating, please put the electrode into

the standard liquid, wait for the signal to stabilize

before performing the calibration operation

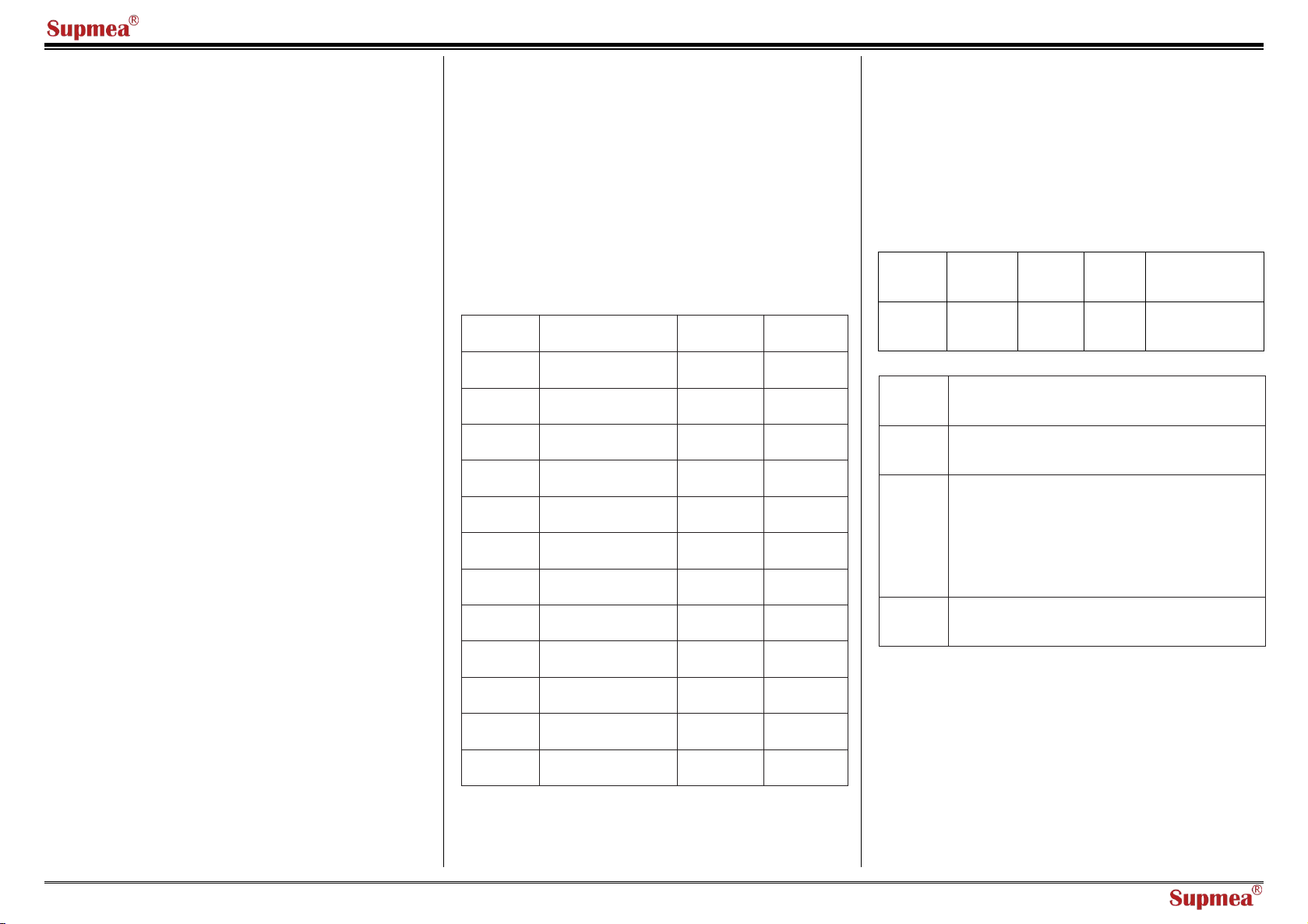

11. Restore factory default settings

Please use the user command set to write the

command to address 0x07 to complete the operation

restore the factory default | TX: 01 06 00 07 00 D2 B8

56

[Receive Rx] returns the same command as [Send

Tx], which means the recovery is successful.

Execute user commands

Users can write commands to address 0x07 to

perform corresponding device operations.

The content of this address cannot be

written into data, such as executing

commands,

It means that the current sensor status

cannot perform this operation.