LIST

INTRODUCTION OF PRODUCTS .....................................................................................1

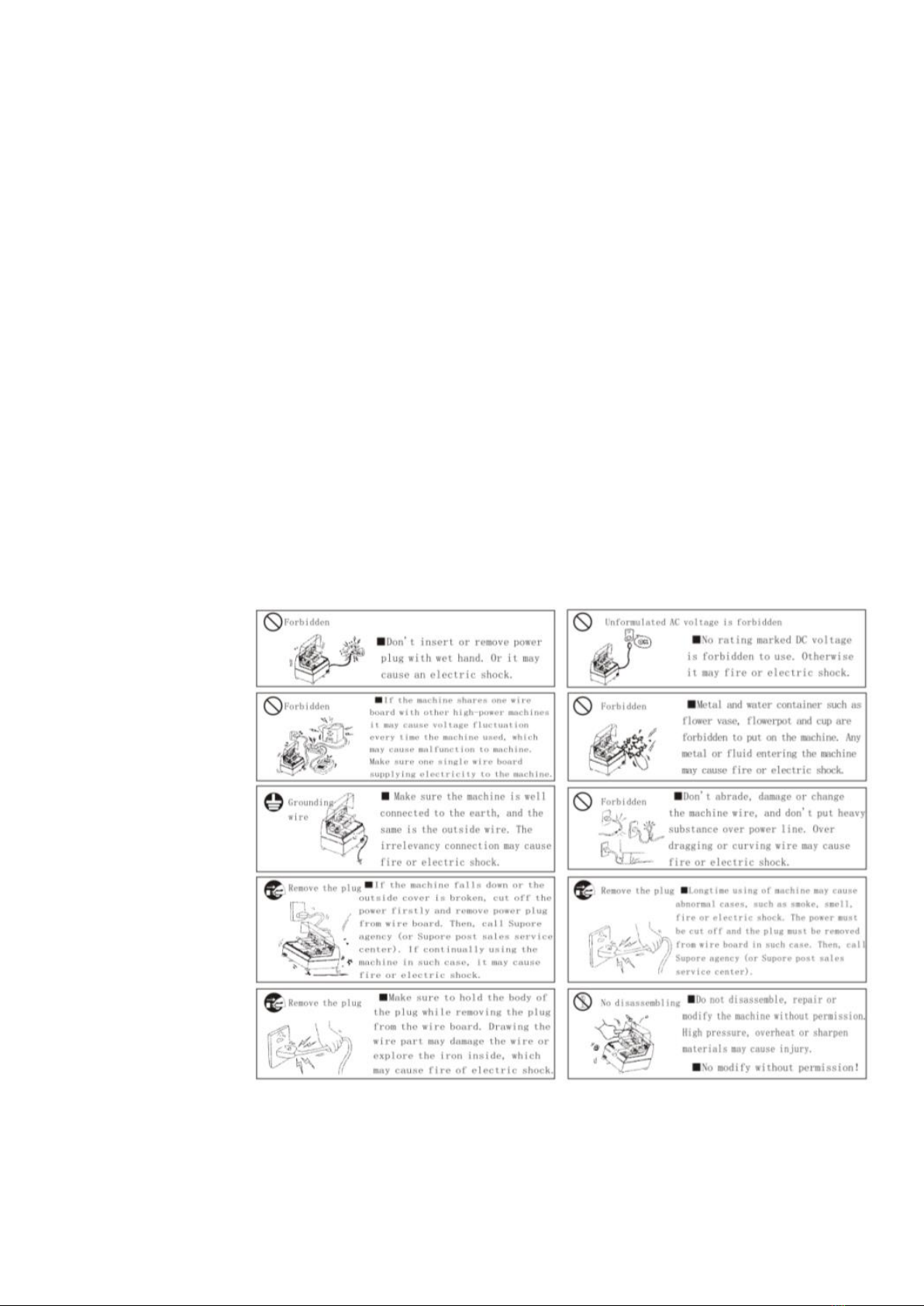

Security information:..............................................................................................................1

1、INTRODUCTION OF SECURITY SYMBOL.......................................................1

2、ENVIRONMENT OF USE.......................................................................................1

3、ATTENTION.............................................................................................................2

Introduction.......................................................................................................................................4

1、LE-300/310/310P nomenclature..........................................................................................4

2、LE-320/400/420 nomenclature .........................................................................................5

3、LE-300/310/310PControl panel.......................................................................................6

4、LE-320/400/420 control panel ....................................................................................7

USE...................................................................................................................................................8

1、INSTALLATION...............................................................................................................8

A.installation of main machine ......................................................................................8

B. INSTALLION OF WATER TANK AND PIPE........................................................8

2、DEBUGGING..................................................................................................................10

3、OPERATION PROCEDURES ......................................................................................11

4.Wheel position emendation..................................................................................................18

Maintenance....................................................................................................................................24

Before requesting service................................................................................................................25

Specifications..................................................................................................................................26

Accessories and Tools.....................................................................................................................26