6

5. Safety measures

5.1. For safe operation to work with the installation, persons who have studied the

operating manual, certified and approved by the administration of the enterprise to work, are

responsible for the operation are allowed.

5.2. When cleaning fire extinguishing powder in case of unauthorized (accidental) or regular

operation of the installation (s), it is necessary to observe precautions, prevent the ingress of

powder into the respiratory organs and eyesight. As personal protective equipment you should

use dust respirators (GOST 12.4.028-76), safety glasses of type G (GOST 12.4.013-97), rubber

gloves (GOST 20010-93) and overalls. It is allowed to use other protective equipment with

protective properties not lower than indicated.

Collection of fire extinguishing powder should be in plastic bags or other waterproof containers.

Further disposal of the collected fire extinguishing powder should be carried out according to

the instructions “Disposal and regeneration of fire extinguishing powders” M; VNIIPO, 1988, 25

pages, or a specialized organization.

5.3. The fire extinguishing powder ejected when the unit is triggered does not adversely affect

the clothing of a person, does not cause damage to property, and is easily cleaned with a

vacuum cleaner.

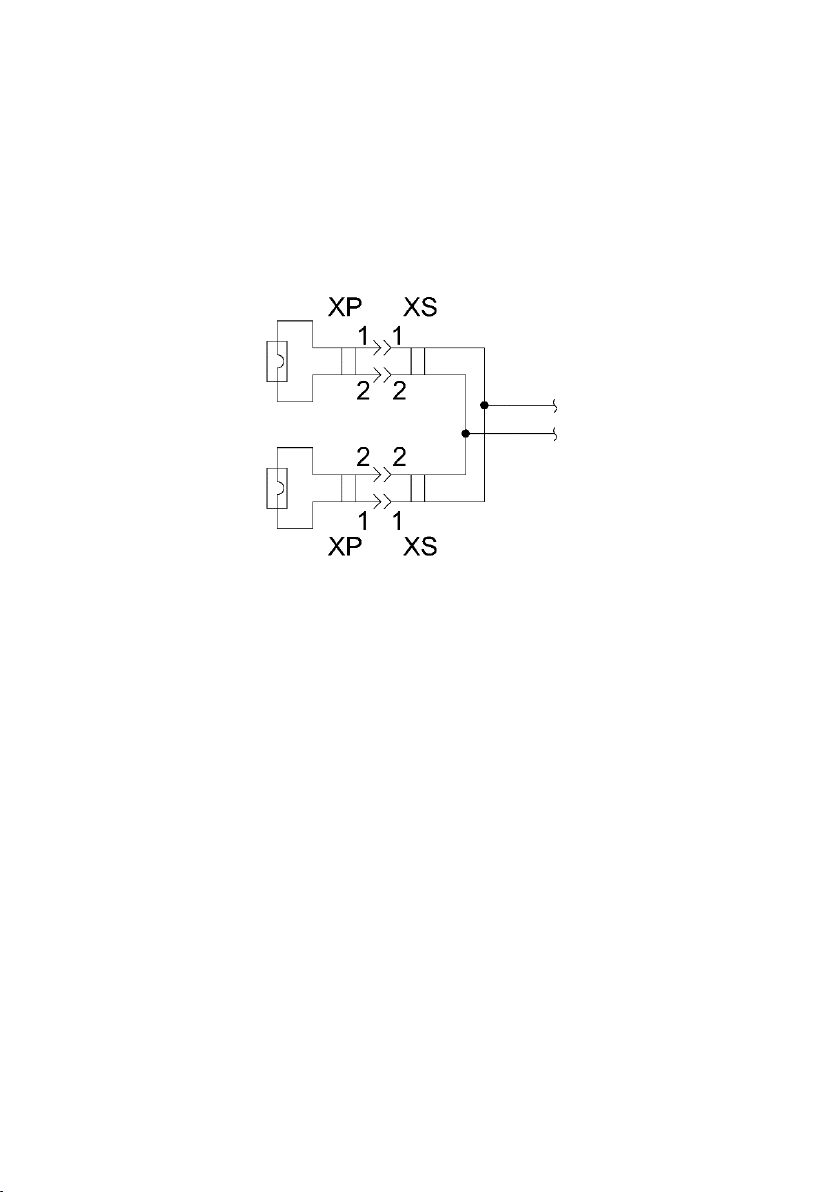

5.4. When designing electrical lines for installation start-up (installations), measures should be

taken to exclude the occurrence of pickup currents that could lead to unauthorized start-up of

the installation.

5.5. Cases of modules of powder fire extinguishing "Buran-50ST" (U1) shall be reliably

grounded.

5.6. Connection of the unit to the control devices of the start-up system should be carried out

after firmly fixing the unit on the object and completing the complex of commissioning works

throughout the fire-fighting automation system with the power supply of the system turned off.

5.7. Check the installation start circuit with current not more than 0.1 A.

5.8. It is prohibited:

• Connect the installation to any power supply before regular installation at the facility.

• Perform any repairs when the installation is connected to the start-up circuit.

• Carry out welding or other hot work near the installation at a distance of less than 2 meters.

• Store and place the unit near heaters where the temperature may exceed 95 ° C.

• Expose powder fire extinguishing modules to shocks that cause deformation of the housing

depressurization.

• Operate powder extinguishing modules in case of damage to the casing, membrane, cable

entry and triggering unit.

• Conduct any testing of the installation without the agreement of the manufacturer.

6. Preparation of installation to work and placement on the object

6.1. Remove the installation from the packaging and make a visual inspection for defects in

the enclosures. Check completeness.

6.2. The installation should be located on the horizontal surfaces of the protected object.

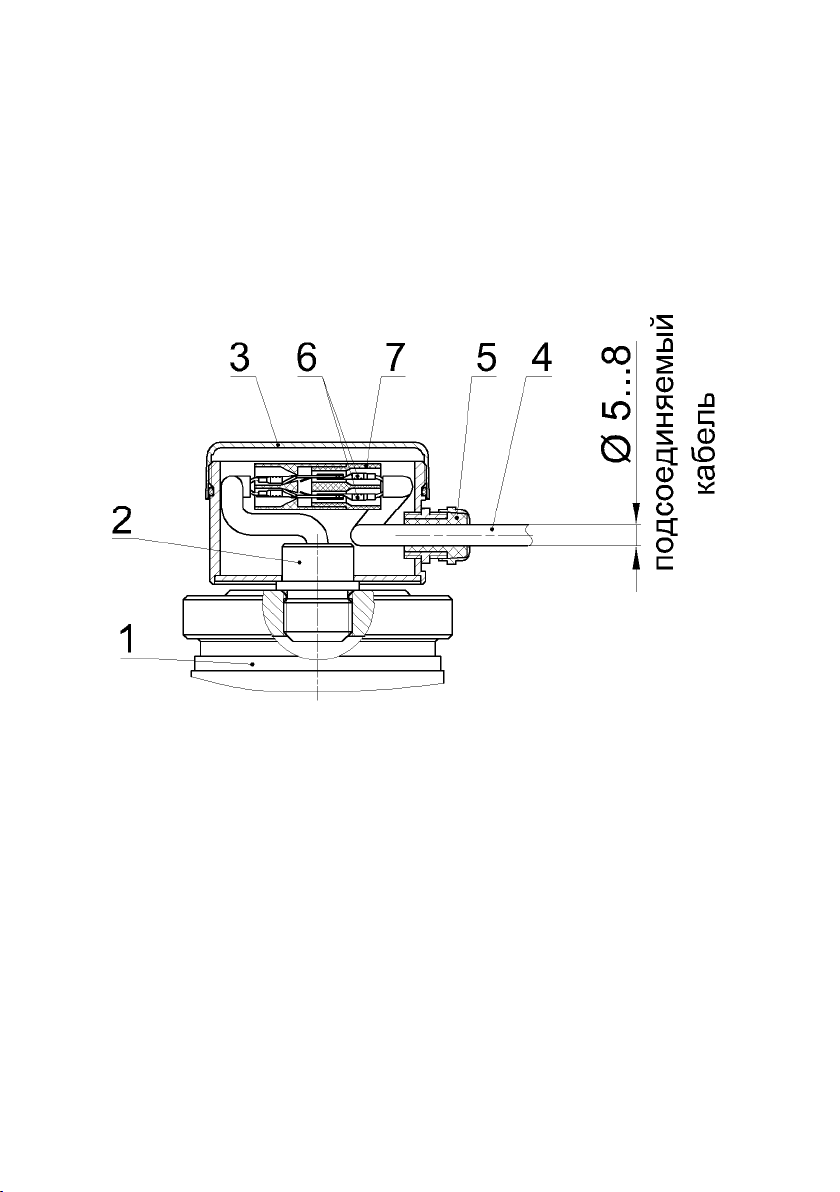

Fix the installation with four anchor bolts (for example: HNM 10x60), the coordinates of the

mounting holes of the set are shown in Fig.1.

6.3. Connect guide pipes B II and SV II with sets of sprayers to the outlet openings of the

membrane assemblies of the powder-extinguishing module Buran-50ST(U1).