SureShot AC2-GP User manual

AC2-GP

Multi-Sweetener Dispenser

D-19-123 RevA

Service Manual

AC2-GP

Multi-Sweetener Dispenser

FEATURES:

Easy to install –plug in, load, dispense

Easy refill and service

Accurate, preprogrammed, consistent

portions

Drink Count Data available

Clean dispense –quick cutoff avoids messy

spills

Dispenses two products

Feet are moveable to slide under

neighboring appliances

SureShot Technical Assistance Center

1-888-777-9990 or 902-865-9602

service@sureshotdispensing.com

parts@sureshotdispensing.com

www.sureshotdispensing.com

A.C. Dispensing Equipment Inc.

100 Dispensing Way

Lower Sackville, Nova Scotia

Canada B4C 4H2

TABLE OF CONTENTS

The Dispenser....................................................1

Main Components..............................................1

Specifications.....................................................1

Safety Precautions.............................................2

Operating Instructions........................................2

Service and Warranty.........................................2

Reshipment........................................................2

Troubleshooting .................................................3

Replacement Parts.........................................3

Remove and Install Components.......................8

Tools Required ...............................................8

Auger Motor....................................................8

Power Supply ...............................................11

Transition Pieces..........................................12

Repositioning or Replacing the Door............13

Door Cable Assembly...................................14

External Power Supply Connector PCB.......15

Power Entry Module and Harnesses............16

Replace Motor Cable Assemblies ................17

Reprogramming Using a FOB......................18

Accessing the Program....................................19

Appendix 1 .......................................................21

Assembly Diagram and Service Parts Lists .21

Appendix 2 .......................................................26

Wiring Diagram.............................................26

AC2-GP Multi-Sweetener •SureShot Technical Assistance Center: 1-888-777-9990 or 902-865-9602

1

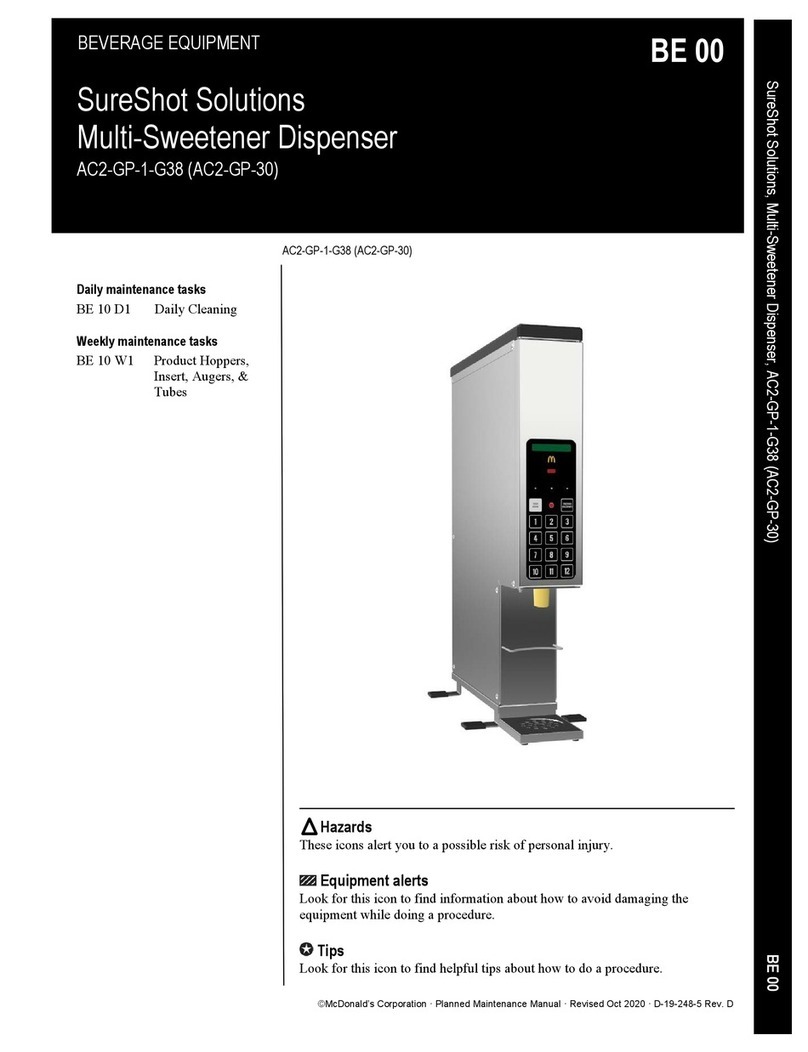

AC2-GP

Dispenser may not be exactly as shown

MULTI-SWEETENER DISPENSER

SERVICE MANUAL

Important: Read this Manual now and retain it for future reference

THE DISPENSER

The SureShot Dispensing Systems® AC2-GP Multi-Sweetener Dispenser automatically

dispenses controlled portions of two dry products such as sugar and other alternative

products for use in coffee, milkshakes, hot chocolate, health drinks and other beverages.

The product is dispensed by touching selection buttons on the front of the dispenser.

The dispenser has been preconfigured to industry-standard defaults. Each button press

is preset independently to accurately dispense a specified amount of product using our

unique, state-of-the-art microprocessor technology. The products to dispense are

contained in product hoppers inside the dispenser. The auger style dispense system is

designed to work with dry products with similar consistency to sugar granules.

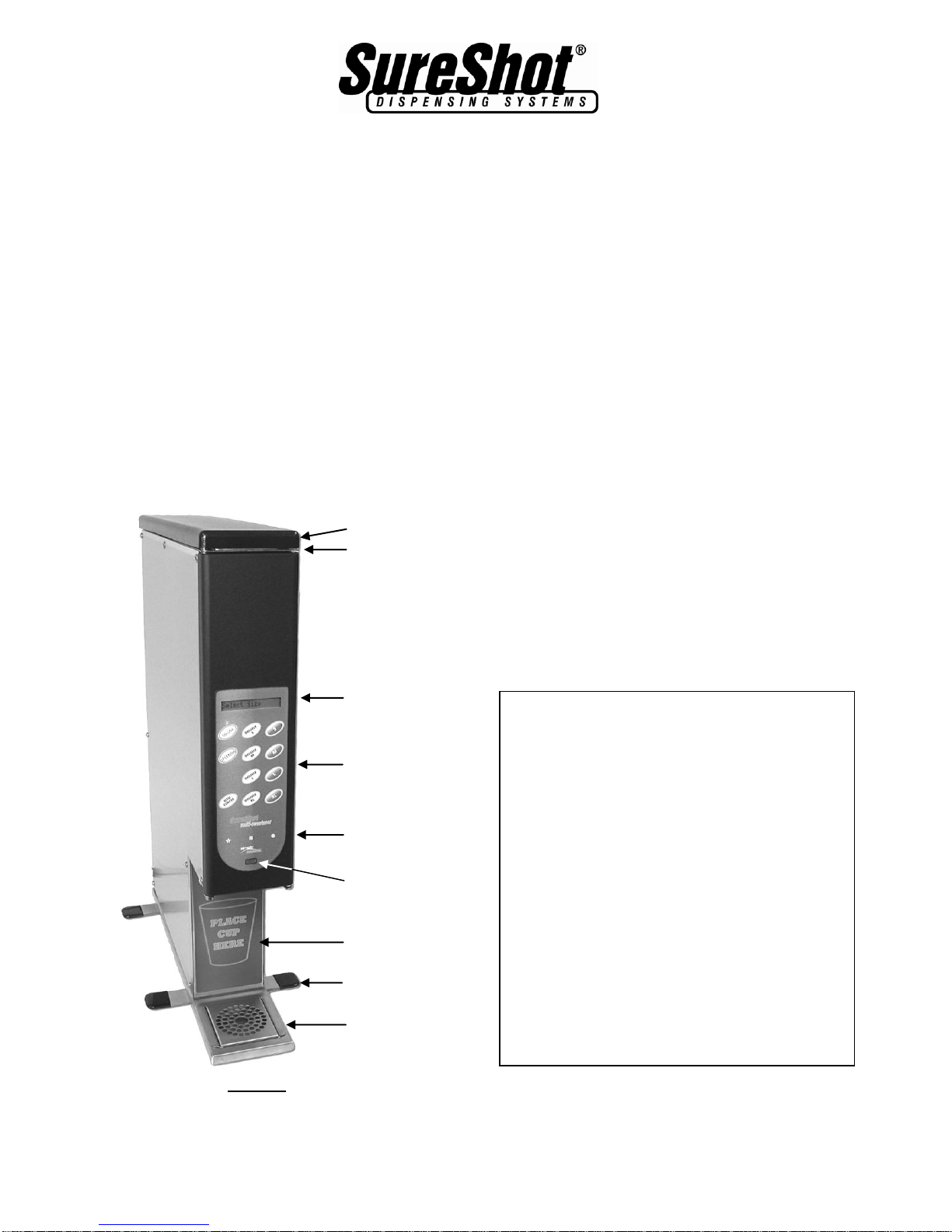

MAIN COMPONENTS

Program Mode Buttons

Program Mode

Adjustment Up

Adjustment Down

Panel Disable

LCD Display

Window

Button Panel

Infrared

Programming

Window

Program /

Maintenance

Mode Buttons

Catch Tray and

Screen

Cup Guide

(optional)

Dispenser Top

Transition Piece

(under top)

SPECIFICATIONS

Weight: 29.0 lbs/13.2 kg

(empty dispenser)

Dimensions (DxWxH): 17.75" x 4.0" x 24"

(without feet)

Dispenser height

varies with feet

selection

Hopper Capacity: Top Hopper

6.0 lbs/2.7 kg

(granular sugar)

Bottom Hopper

2.5 lbs/1.1 kg

(granular sugar)

Electrical Requirement: 100-240 VAC,

0.5 amps Max.

50-60Hz, 1 ph

Positionable

Feet

AC2-GP Multi-Sweetener •SureShot Technical Assistance Center: 1-888-777-9990 or 902-865-9602

2

SAFETY PRECAUTIONS

Always plug the dispenser into an approved electrical outlet.

The dispenser includes a microcontroller and must be operated on grounded

electrical wiring at all times.

Unless otherwise specified in the procedure, the dispenser should be unplugged from

its electrical source before servicing.

Do not immerse the dispenser in water.

Observe all safety precautions with this dispenser that you would with any electrical

appliance.

The dispense auger is powered by a motor with a turning shaft. To avoid possible

injury or equipment damage, keep hands and objects clear of the auger and shaft

when equipment is plugged in.

OPERATING INSTRUCTIONS

For all operating procedures and instructions refer to the operations manual specific to

the dispenser being serviced. For general operating instructions refer to manual D-19-

090.

SERVICE AND WARRANTY

Standard warranty is one year, on-site parts and labour (unless otherwise negotiated).

Access to USA and Canada-wide Technical Service Network.

The Warranty will be null and void if the dispenser is serviced by unqualified personnel.

Under warranty, service technicians must be approved and dispatched by the SureShot

Technical Assistance Center.

During the warrantee period, the SureShot Technical Assistance Center must be

contacted at 1-888-777-9990 or 902-865-9602 for approval of any proposed service

before commencing.

The customer is responsible for all costs not approved by SureShot Dispensing

Systems®.

Note: the Serial Number and Option Code of your dispenser are located on the Product

Identification Label on the back of the unit. Please refer to these numbers when

contacting the SureShot Technical Assistance Center. These numbers are crucial in

helping us provide prompt and effective service. This will save you time.

RESHIPMENT

No returns will be accepted without prior approval. Obtain a Return Materials

Authorization (RMA) number by contacting the SureShot Technical Assistance Center at

1-888-777-9990 or 902-865-9602.

Ensure pieces which may shift in transit are secured using masking tape.

If packaging is not available, it may be purchased from the SureShot Parts Department

by calling 1-888-777-9990 or 902-865-9602.

AC2-GP Multi-Sweetener •SureShot Technical Assistance Center: 1-888-777-9990 or 902-865-9602

3

TROUBLESHOOTING

The following trouble-shooting guide is intended to assist in tracking down some of the simpler

and/or more commonly occurring issues. Any actions or suggested replacement parts represent

possible causes and solutions only and are not guaranteed to correct the observed issue. If there

are any questions regarding either the procedures or the replacement parts required, please

contact the SureShot Technical Assistance Center at 1-888-777-9990 or 902-865-9602.

Replacement Parts

To determine replacement parts, refer to Appendix 1 on page 21.

Note: The Serial Number and Option Code of the unit must be included with the order

information for many of the replacement parts. Both are located on the Product

Identification Label on the back of the unit.

Problem

Action

Dispenser does not

turn on (LCD remains

blank after plugging in

the unit and none of

the buttons function).

The inability to turn on is an indication that either power is not reaching

the control circuit board in the door or the door itself is defective. Follow

through the steps described below to isolate the issue. Check unit

functionality after each step and repair defect or replace parts as

required.

1. Check to ensure that the wall outlet is functioning.

2. Check that all external power cord(s) are completely and securely

connected at all points.

3. On Units with an external power supply1:

a. Verify that the retaining nut on the power feed-through on the

back of the unit is fully installed. (If the nut has backed-off it may

prevent full connector engagement.)

b. Verify that the connection from the power cord to the jack on the

back of the unit is secure by trying to move the connector. If the

power comes on for any length of time then the connection is

poor. If the connector cannot be tightened further then the power

entry PCB may have to be replaced (see page 15).

c. Verify supply functionality –remove the power cord jack from the

back of the unit and using a volt-meter verify that there is 12 VDC

at the power supply by probing the connector jack. If 12 VDC is

present, re-connect to machine.

4. Check that the door cable is completely and securely connected to

the circuit board in the door. To do this:

a. Open the front door and remove door wire grommet

b. Gently tug on door cable to ensure secure connection.

5. With the unit powered on, verify power at door connector –open

door, remove door connector and confirm that voltage across pins 1

(or 2) and 4 (or 5) is 12 VDC. If there is power on the cable

connector but the door does not function when properly connected,

then the door may require replacement.

1

On units with Serial Number XXXX-003874 and lower the power supply is an external type as

shown on page 11. After that serial number the power supplies were installed inside the unit.

AC2-GP Multi-Sweetener •SureShot Technical Assistance Center: 1-888-777-9990 or 902-865-9602

4

Note: attachments to multi-meter probes may be required to access

connector contacts.

6. If there is no power at the door connector then trace back to where

the power is lost. To do this remove the right side panel (preferred) or

left side panel as viewed from the front of the unit.

7. On Units with an internal power supply:

Caution: the power supply and input connections are 110 VAC.

a. Ensure that all connections to the power supply and power entry

module are in place and secure.

b. Remove the input connector (with black and white wires) and

verify the voltage at the output of the wiring harness is 110 VAC.

If there is no voltage then either the power cord, the power entry

module or the power wire harness is defective and may need to

be replaced. Examine each further as required to find the

defective part.

c. Replace the power supply input connector and remove the output

connector on the top of the power supply. Check that the voltage

on the power supply output pins is 12 VDC. If the power is

present at the input but not at the output then the power supply

may need to be replaced.

- +

8. On Units with an external power supply:

a. Check the integrity of each connector and examine the wires for

breaks or other damage. If the integrity is unclear, replace with

new wire to see if problem is corrected. Replace as required.

b. Check the power availability of each connector in turn using the

diagram shown in step 5 as a guide. As can be seen with the

side panel removed, the wiring is a sequential series of wires

with RJ45 connectors at each end. A break in connection at any

point eliminates power (or communication) from propagating to

any points “downstream” of the break. Replace any damaged

wires or components as required.

Dispenser resets

intermittently (goes

through power-up

sequence)

The intermittent resetting of a unit is usually an indication of a faulty

connection somewhere between the power supply and the control PCB in

the door. To find the fault:

AC2-GP Multi-Sweetener •SureShot Technical Assistance Center: 1-888-777-9990 or 902-865-9602

5

1. Check all connections in line with door power (see “Dispenser does

not turn on” troubleshooting section above) and verify that they are

completely and securely connected. Repair or replace any defective

parts as required.

2. If all connections are secure and symptoms recur without any

connections being compromised then the issue is likely to be either a

faulty power supply or an intermittent connection on the PCB in the

door.

3. If possible, replace the power supply with one that is known to

function properly and verify that intermittency disappears. If it is still

present then the intermittency is likely in the door and the door may

need replacement (see Page 13).

Button panel “locks-up”

or functions

unpredictably

As the unit is controlled by a micro-controller it is possible that under

some conditions (such as power surges or brown-outs) that a part of the

program becomes corrupted. To correct this condition:

1. Reset the unit by unplugging and re-connecting power. If problem

persists then continue to next step.

2. If this is not the issue and the problem persists the unit should be re-

programmed using a FOB (see page 18).

3. If the problem is still not corrected then the issue is a likely to be a

defective PCB and the door may have to be replaced (see page 13).

LCD display is blank

(or all black squares)

but unit continues to

function normally

otherwise.

An LCD that does not display properly may be caused by either a

defective LCD module or a faulty program. To determine the likely cause:

1. Reset the unit by unplugging and re-connecting power. If the LCD

continues to show a blank including during the power-up sequence

(during Reset) then the LCD is defective and the door may need to

be replaced. If the LCD does display characters during the power-up

sequence but not once the reset is complete then continue to next

step.

2. Re-program the unit using a FOB to over-write the corrupted program

with a new one.

Unit dispenses

incorrect amount of

product.

There can be several causes for the unit to dispense incorrect amounts

of product. The following steps should be followed to diagnose and

correct this issue:

1. Ensure that unit is set up and being operated correctly:

a. Ensure that hopper contains adequate amount of product - the

hopper should be filled at least to the low level mark.

b. Ensure that the hopper is securely positioned in the unit and

properly engaged with the motor coupler (See Loading Hoppers

in Operational Manual)

c. Ensure all required selections have been made: Beverage Type,

Product Selection, Size etc.

d. Ensure that the dispense Target is set correctly (refer to

Operations Manual if required).

e. Ensure that the correct Product type has been selected in the

program (refer to Operations Manual if required).

f. Ensure that the Volume Adjust is correct. (The factory default is

zero but it may be altered to compensate for local variations of

the product - refer to Operations Manual if required).

g. Ensure that the product delivery tubes are not twisted, kinked,

pinched-off or blocked.

AC2-GP Multi-Sweetener •SureShot Technical Assistance Center: 1-888-777-9990 or 902-865-9602

6

2. Reset the unit by unplugging and re-connecting power.

3. Verify that the auger is clean and is able to move freely by removing

the hopper and manually rotating the auger.

4. Ensure that the motor coupler is securely attached to the motor shaft

by removing the hopper and twisting it. If the coupler is firmly

attached, the motor/gearbox can be heard and felt to rotate. If it is

loose it may rotate freely or pull off easily and should be corrected by

tightening the coupler attachment screw.

Note:. When installing or tightening a coupler, make sure that the

coupler is pushed back to the plastic spacer but not tight enough to

restrict the coupler from rotating freely.

Note: In newer models the coupler can only be installed with the

clamping screw parallel to the flat side of the shaft.

5. If the coupler does not rotate smoothly and freely then it is possible

that the motor/gearbox assembly is damaged and may need to be

replaced. To verify this, re-position the coupler by loosening and re-

tightening it as described in the note above. If the coupler is still

unable to turn then the motor assembly may have to be replaced.

6. Ensure that the motor is securely attached to the chassis by trying to

move the coupler side-to-side with the hopper removed. If it is loose,

tighten it and retest.

If the “Dispensing…” message persists for several seconds after the

dispense cycle has completed it is an indication that the rotary encoder

on the back of the motor assembly has become loose. To verify that this

is the problem:

7. Try dispensing several sizes of the same product. If the rotary

encoder is loose then all sizes will dispense approximately the same

amount of product. Also, the dispense cycle sounds different. Rather

then a sharp starting and stopping of the motor, the motor stops

slowly over a second or two at the end of dispense. In addition, in

units where the motors have a reverse rotation at the end of

dispense, the reverse portion of the dispense cycle is missing which

can be heard by the lack of the extra motor activation at the end of

each dispense.

8. Remove the left or right side cover and remove the hopper.

9. Holding the motor coupler with one hand, try moving the disk on the

rear of the motor shaft. It should only allow a small amount of rotation

before the coupler turns (the gearbox has a 10:1 ratio) and it should

not permit any axial movement on the shaft. See Figure 6 on page 9

for view of rotary encoder.

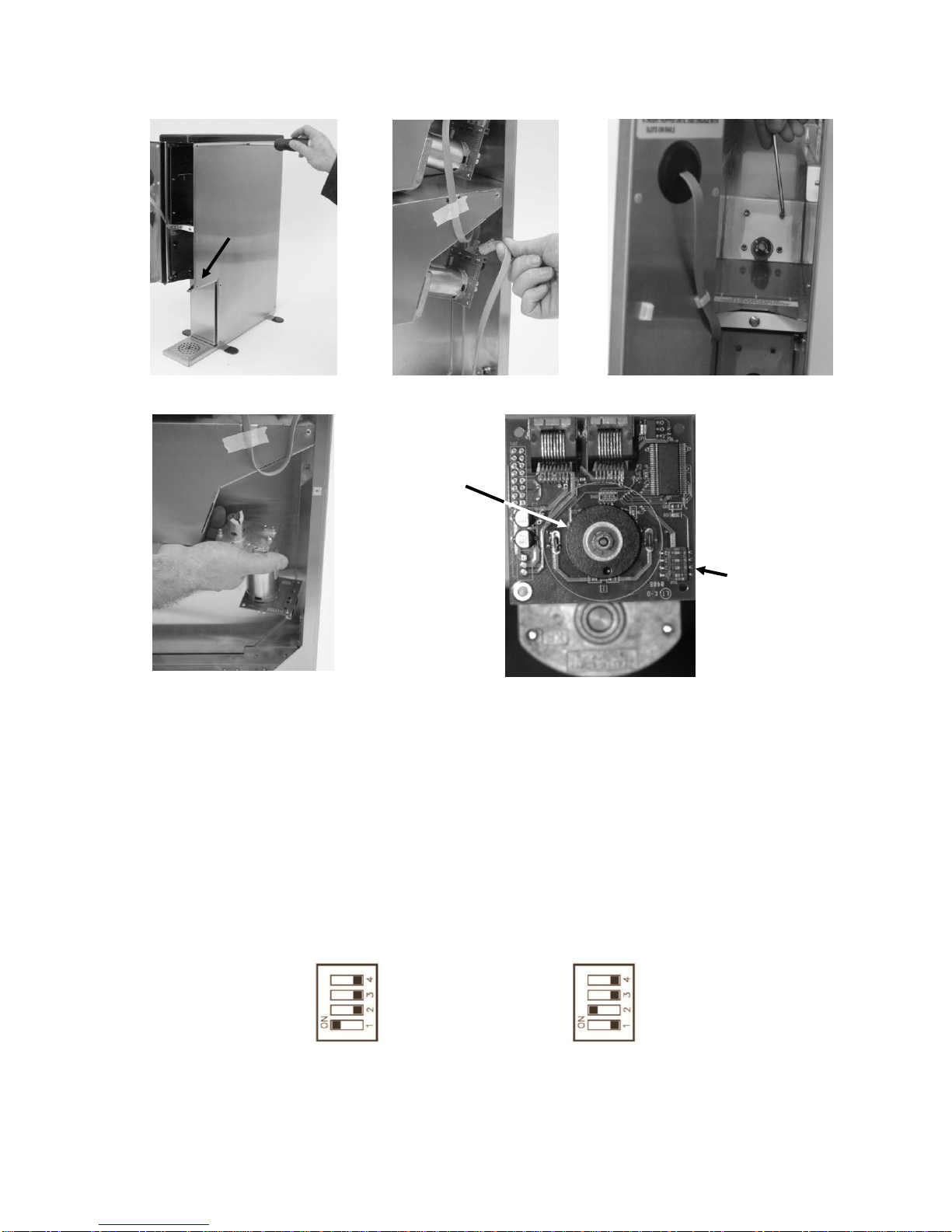

Note: Care should be taken not to disrupt the dipswitch on the motor

circuit card as any change in the dipswitch settings will cause the unit

to malfunction. The dipswitch is on the left hand side of the card (as

viewed from the front of the unit looking back) near the bottom of the

card. See page 9 for illustration of dipswitch.

If this examination is inconclusive the motor may need to be removed

for closer examination. If the rotary encoder is loose the motor

assembly will have to be replaced.

AC2-GP Multi-Sweetener •SureShot Technical Assistance Center: 1-888-777-9990 or 902-865-9602

7

Dispenser behaves

erratically… either:

1. opposite product

dispenses from the

one selected,

2. both products

dispense at same

time,

3. neither product

dispenses,

4. the same product

dispenses

regardless of

product selection,

or

5. unit continually

resets when

dispense button is

pressed.

If any or several of these symptoms appear after a motor replacement or

other service work has been performed it may be due to an incorrect

dipswitch setting on a motor driver circuit card (See Figure 6 on page 9).

The dipswitches are used by the controlling software to identify each

motor separately on the communication bus. To determine whether this

is the issue and to correct it:

1. Remove the left side panel (as viewed looking at the front of the unit).

2. Examine dipswitch settings (See Page 9 for setting details) and

confirm that they are correct according to the diagram.

3. If one or both are not set as shown in the diagram, correct using a

fine-tipped object such as a ball point pen. Once reset the unit must

be re-booted by powering down / up again.

4. If the problem persists, the motor driver program may have been

corrupted. Re-program the driver using ‘Driver DL Force’ as

described on page 19.

5. If the problem persists it is possible that the dipswitch itself is

defective. To help identify this situation, change the dipswitch setting

on one of the motor assemblies to an unrecognized address by

toggling switch 3 or 4 to the “on” position. This makes sure that the

motor will not respond to any dispense signals and leave the other

motor free to respond normally without interference from the first

motor. If this corrects the issue then the first motor assembly may be

defective and may need to be replaced.

Dispenser accumulates

product inside the unit.

An accumulation of product inside the unit around the bottom of either

hopper can be caused by several things. To identify the cause and to

correct:

1. If the unit is a “Fill-in-Place” unit (with removable top cover), verify

that the transition piece (see Appendix 1) on the top of the unit is

present and seated properly. This part forms a funnel to direct the

product into the top hopper. If not present, product can leak past the

hopper to the inside of the unit. Replace or reposition if required.

2. Check the product delivery tubes for any breaks and for proper

attachment to the hoppers. Re-attach or replace if required.

If the product accumulation is around the back of the hopper (around the

motor coupler) it may be an indication that the auger shaft or auger

bushing is worn, enabling product to leak out the rear of the hopper. To

confirm this diagnosis and to correct the issue:

3. Remove the hopper assembly and examine the fit of the auger in the

rear of the hopper assembly. It should be snug with no sideways play

in the bushing. If sideways play is present then the auger assembly

may have to be replaced.

Button panel “locks-up”

(LCD is ON but none of

the buttons function)

The dispenser is controlled by a micro-controller and may be subject to

temporary disruption by some types of power anomalies. If the button

panel “locks-up” it is an indication that the micro-controller operation has

been corrupted. If this happens all functions stop working. To correct this

issue:

1. Unplug the dispenser, wait 10 seconds, then plug the dispenser back

in. This resets the microcontroller.

2. If this does not correct the issue then the program itself may have

become corrupted and the unit may have to be re-programmed using

a FOB (See page 18).

AC2-GP Multi-Sweetener •SureShot Technical Assistance Center: 1-888-777-9990 or 902-865-9602

8

The auger motor does

not respond to

dispense commands

(no sound or sign of

movement)

The motor is controlled by a software program running on a micro-

controller in the motor assembly which in turn is controlled by a micro-

controller and software in the door. A non-responsive auger motor can be

an indication of several things. To determine the likely cause of the issue

and to correct it:

1. Remove the hopper assembly and try rotating the coupler by hand. If

the coupler either does not rotate at all or requires excessive force

then it is likely that the motor assembly has seized and may need

replacement (see page 9).

2. If the auger coupler rotates freely then it is possible (although

unlikely) that the motor driver software has become corrupted. A

copy of the driver software, however, is kept in the door software and

can be downloaded to the motor driver chip to correct this issue. To

do this follow the Program Mode > Service Page > Driver DL Force

instructions on page 19.

3. If the issue persists after successfully re-loading the driver software

then the connections and wires between the door and the motor

assembly should be checked for signs of damage. Any suspect wires

should be checked by installing new wires and replaced as required.

4. If the problem persists then the dipswitch setting should be checked

(see page 9 for description of correct settings)

5. If the problem still persists then it is likely that the motor assembly

itself is damaged and may have to be replaced.

Door does not stay

closed

The door latches when the door latch screw on the top of the door

opposite the hinge snaps into the latching hole in the top plate. If the

screw is missing or the top plate becomes bent then the latch will not

work properly.

1. Check to see if the latching screw on the top right hand side of the

door is present and secure. Correct as required.

2. If the screw is present and secure and the door still does not latch

properly, adjust the top plate position by carefully bending up or

down as required. When located correctly, the hole in the top plate

should hold the latching screw firmly when the door is closed but

allow the door to open and close with comfortable ease.

REMOVE AND INSTALL COMPONENTS

Tools Required

All service procedures can be performed with a minimum of tools as follows:

Medium sized Phillips screwdriver

Small sized Phillips screwdriver

5/16" wrench

10mm wrench

3/32" Allen wrench

7/64” Allen wrench

9/64" Allen wrench

Multi-meter

Power Drill

Rivet Gun

Figure 1

AC2-GP Multi-Sweetener •SureShot Technical Assistance Center: 1-888-777-9990 or 902-865-9602

9

Auger Motor

Figure 2

Figure 3

Figure 4

Figure 5

Figure 6

Removal:

1. Unplug power cable from power outlet or from rear of dispenser.

2. Remove the hopper connected to the motor being replaced.

3. Remove either side panel using Phillips screwdriver to remove all the screws holding the

side panel on. See Figure 2

4. Unplug the motor connector cables from the back of motor assembly being replaced. See

Figure 3.

5. From the inside of the hopper compartment, remove the four 8-32 screws holding the

motor in position, using a 9/64”Allen key. See Figure 4.

6. Remove the motor assembly. See Figure 5.

7. Before installing the new motor assembly, make sure that the dipswitches are set

correctly as indicated below:

Upper Motor Dipswitch Setting Lower Motor Dipswitch Setting

Note: The dipswitch settings are shown as viewed in Figure 6.

Rotary

Encoder

Dipswitches

Short

Screw

AC2-GP Multi-Sweetener •SureShot Technical Assistance Center: 1-888-777-9990 or 902-865-9602

10

Installation:

8. Replace the motor assembly by installing the four 8-32 screws.

Note: It is recommended that thread-locker be used on these screws when replacing them.

9. Plug connector cables back into the connectors located on motor PCB. Care should be

taken to ensure that the right cables are re-attached to prevent over-stretching the wires.

10. Install the side panel.

Note: Short screw located in lower- front location as indicated in Figure 2.

11. Install hopper

12. Plug power cable back into unit.

AC2-GP Multi-Sweetener •SureShot Technical Assistance Center: 1-888-777-9990 or 902-865-9602

11

Power Supply

Early models of the AC2-GP (Serial Numbers XXXX-003874 and earlier) were equipped with an

external power supply as shown in Figure 7 below. Later models have the power supply mounted

inside the unit on the lower part of the back panel. To replace the power supply follow the

directions for the type being serviced.

External Power Supply:

Figure 7

Removal:

1. Unplug the power supply from the wall and disconnect from the back of the unit.

Installation:

1. Ensure that all cords are completely and securely connected together.

2. Plug the cord connecting the power supply to the dispenser into the back of the dispenser

and fully tighten the screw-lock.

3. Plug the other cord from the power supply into the wall outlet.

Internal Power Supply:

Figure 8

Removal:

1. Unplug power cable from power outlet or from rear of dispenser.

2. Remove either the left or the right side panels from the unit.

3. Unplug the input and output connectors from the power supply.

4. Unscrew the four corner screws using the small sized Phillips screwdriver.

Installation:

5. Hold the new power supply into place and install the bottom two screws.

6. Install each of the upper screws ensuring to replace grounding lugs, one under the head

of each mounting screw.

7. Plug the output (12 VDC) and input (110 VAC) connectors into the top and bottom of the

power supply respectively.

8. Replace the side panel –make sure to replace the short screw in the correct location

(see Figure 2 on page 9).

9. Plug power cable into outlet.

AC2-GP Multi-Sweetener •SureShot Technical Assistance Center: 1-888-777-9990 or 902-865-9602

12

Transition Pieces

Figure 9

Figure 10

Figure 11

Figure 12

Removal:

1. Remove the plastic top lifting it up and off. See Figure 9

2. Remove the plastic transition piece by lifting it up and out of the stainless steel transition.

See Figure 10

3. Remove the screws holding on the Stainless steel transition using a Phillips screw driver.

See Figure 11

4. Lift off the Stainless steel transition by lifting it up and off. See Figure 12

Installation:

5. Install new Stainless steel transition over the side panels and install screws. Make sure to

install the short screw in the location indicated.

6. Replace plastic parts onto unit.

Short

Screw

AC2-GP Multi-Sweetener •SureShot Technical Assistance Center: 1-888-777-9990 or 902-865-9602

13

Repositioning or Replacing the Door

Figure 13

Figure 14

Figure 15

Figure 16

Figure 17

Figure 18

Removal:

1. Open the dispenser door fully (180°). See Figure 13.

2. Remove door cable from clamp and pop out the black grommet from the door. See

Figure 13

3. Unplug the door cable from behind the grommet.

4. Lift the top off the dispenser.

5. Remove the fastener from the top of the door, using a 3/32 Allen key. See Figure 14.

Hold onto door when removing fastener. See Figure 15.Retain fastener for installation.

Steps 6 to 11 Optional for door swing direction

6. If repositioning door hinge to swing in opposite direction, remove the screw in the cable

locator plate. See Figure 16.

7. Remove Phillips screw from top of door using Phillips screw driver. See Figure 17.

8. Remove hinge standoff from bottom of door using 5/15" wrench. See Figure 17.

9. Remove the 2 grommets from chassis. See Figure 17.

10. Install all the removed fasteners and hardware on the opposite side from which they were

removed.

11. Flip cable and locator plate to position cable on opposite side of chassis. See Figure 18.

Installation:

12. Install the new door with fastener. See Figure 18

13. Plug in the cable removed and replace the grommet. See Figure 18

14. Close door.

AC2-GP Multi-Sweetener •SureShot Technical Assistance Center: 1-888-777-9990 or 902-865-9602

14

Door Cable Assembly

Figure 19

Figure 20

Figure 21

Figure 22

Figure 23

Figure 24

Removal:

1. Unplug power cable from power outlet or from rear of dispenser See Figure 19

2. Remove top hopper to make access to cable locator easier. See Figure 20

3. Remove left side panel by using a Phillips screwdriver to remove all the screws holding

the side panel on. See Figure 21

4. Unplug the door cable connector from the back of top motor assembly located closest to

left hand side. See Figure 22

5. Remove the cable from the cable clamp located under the upper hopper compartment.

See Figure 22

6. Remove door cable from clamp and pop out the black grommet from the door. See

Figure 23

7. Unplug the door cable from behind the grommet. See Figure 23

8. Remove the cable locator screw using Phillips screw driver. See Figure 23.Retain

screw for replacement cable assembly.

9. Remove the door cable assembly though the front of the unit. See Figure 24

Installation:

10. Reverse the sequence to install the replacement cable assembly.

Note: Make sure cable connector with grommet end is out when replacing new cable.

Note: Short screw located at front in lower hopper location. (See Figure 2 on page 9).

11. Plug power cable into outlet.

AC2-GP Multi-Sweetener •SureShot Technical Assistance Center: 1-888-777-9990 or 902-865-9602

15

External Power Supply Connector PCB

(For units with external power supplies only)

Figure 25

Figure 26

Figure 27

Figure 28

Figure 29

Figure 30

Removal:

1. Unplug power cable from power outlet or from rear of dispenser. See Figure 25

2. Remove either side panel by using a Phillips screwdriver to remove all the screws holding

the side panel on. See Figure 26

3. Disconnect the cable from the power supply PCB assembly. See Figure 27

4. Remove nut from connector at rear of dispenser using a 10mm wrench. See Figure 28

5. Remove the power supply PCB assembly by gently pulling to detach the mounting tape

from the frame. See Figure 29.

Installation:

6. Remove retaining nut and adhesive protective backing on new power supply assembly

and position into frame.

7. Replace the nut onto new connector.

8. Connect the cable to the power supply assembly.

9. Position the side panel onto the frame and replace screws.

Note: Short screw located at front in lower hopper location (See Figure 2 on page 9).

10. Reconnect power supply.

11. Plug power cable into outlet.

AC2-GP Multi-Sweetener •SureShot Technical Assistance Center: 1-888-777-9990 or 902-865-9602

16

Power Entry Module and Harnesses

(For units with internal power supplies only)

Figure 31

Figure 32

Figure 33

Figure 34

Figure 35

Removal:

1. Unplug unit from the wall.

2. Remove either side panel by using a Phillips screwdriver to remove all the screws holding

the side panel on. See Figure 31

3. Unplug the power cord from the unit. See Figure 32.

4. Disconnect the wiring harness connectors from the power entry module (and from the

power supply if the harness is being replaced). See Figure 33.

5. Remove the power entry module by drilling out the fastening rivets from the rear of the

unit. Pliers may be needed to hold the end of the rivet on the inside of the unit to prevent

it from rotating. See Figure 34.

Installation:

6. Rivet a new power entry module into place using 1/8” diameter, domed, stainless steel

pop rivets with a 0.18” grip. Ensure to install the module in orientation as shown to avoid

confusing the wire connections.

Note: Alternatively, the power entry module can be installed using 4-40 stainless

machine screws with a nut and washer on the inside.

7. Replace the power wiring harness and ground wire.

8. Position the side panel onto the frame and replace screws. Make sure to install the short

screw in the location indicated.

9. Plug power cable into back of unit and into outlet.

Short

Screw

Other manuals for AC2-GP

1

Table of contents

Other SureShot Beverage Dispenser manuals

Popular Beverage Dispenser manuals by other brands

La Sommeliere

La Sommeliere DVV22 manual

MICROMATIC

MICROMATIC INLINE MININIM User manual & installation guide

lancer

lancer Sensation 30 installation guide

Bunn

Bunn FMD-1 Specifications

Flavor Burst

Flavor Burst Dual Series Operation manual supplement

lancer

lancer BEVARIETY MCY-22 Installation and service manual