SureShot ATOMIZER User manual

SURE SHOT ATOMIZER SPRAYERS

INSTRUCTIONS

Refillable, Reusable. Extra Versatile.

Pressurized by Free Air.

DIRECTIONS FOR OPERATING MODEL “B” SPRAYERS

1) ALWAYS DEPRESSURIZE SPRAYER BEFORE

REMOVING ANY PARTS. The pressure maybe let

out of the sprayer one of the two following ways:

a) Tip the sprayer upside down and depress nozzle

until no pressure is left. If some liquid is left in

the sprayer when attempting this procedure

makesure you aim the nozzle at a place where

alittle bit of liquid can be expelled.

b) RemoveB13 blackcap from filler assembly and

use small probe to depress the valvecore until

all the pressure escapes. NOTE: Make sure the

sprayer is upright and the filler assembly is

pointed away from you when depressing the

valve core.

2) Remove the complete top assembly from the

canister once all the air has been let out of the

sprayer. Do this by grasping the body in one hand

and the canister in the other and unscrewing

counterclockwise completely.

3) Fill canister 2/3 full ( 7,8 or 16 ounce maximum

capacity) with light, clean liquid. Make sure the liquid

you are putting into the sprayer is CLEAN and FREE

OF FOREIGN PARTICLES. See ACCESSORIES on

page 3 for the liquid filling/measuring device.

4) Place complete top assembly on the canister and

firmly hand tighten.

5) Choose the nozzle you wish to use from the poly

bag in the carton. Once you have chosen the nozzle,

assemble it to the stem of the B15/B16 valve on top

of your sprayer. NOTE: Nozzle must be firmly

pushed into place.

6) Pressurize sprayer with compressed air by holding a

standard air chuckonto the filler assembly stem and

depress the valvecore. Hold the air chuckin place

until you hear the line pressure equalize with the

pressure in the sprayer.Hold the sprayer upright

while pressurizing. Working pressure is 80 - 145 psi.

At least 80 psi is necessary to spray the full 7, 8 or

16 ounces without repressurizing. THE MAXIMUM

PRESSURE SHOULD NOTEXCEED 200 PSI.

7) The Model “B” sprayer is now ready to use.

8) For best results, the liquid to be sprayed should be

lighter then a No. 10 motor oil. (If liquid is too

heavy a pin stream will result). Dilute with a

suitable diluent until desired spray is obtained.

CAUTION: Never point the nozzle of sprayer towards

yourself or any other person. Always point the nozzle of

the sprayer away from yourself and toward the intended

target before depressing the nozzle.

NOTE: ALWAYS CHECK WITH THE CHEMICAL

SUPPLIER FOR CHEMICAL COMPATIBILITY WITH

O’RINGS, VALVES AND CANISTERS.

SPRAYER NOT RECOMMENDED FOR USE WITH PAINTS

DO NOT PRESSURIZE SPRAYER WITHOUT B25

VALVE HEAD IN PLACE AND FIRMLY HAND TIGHTENED

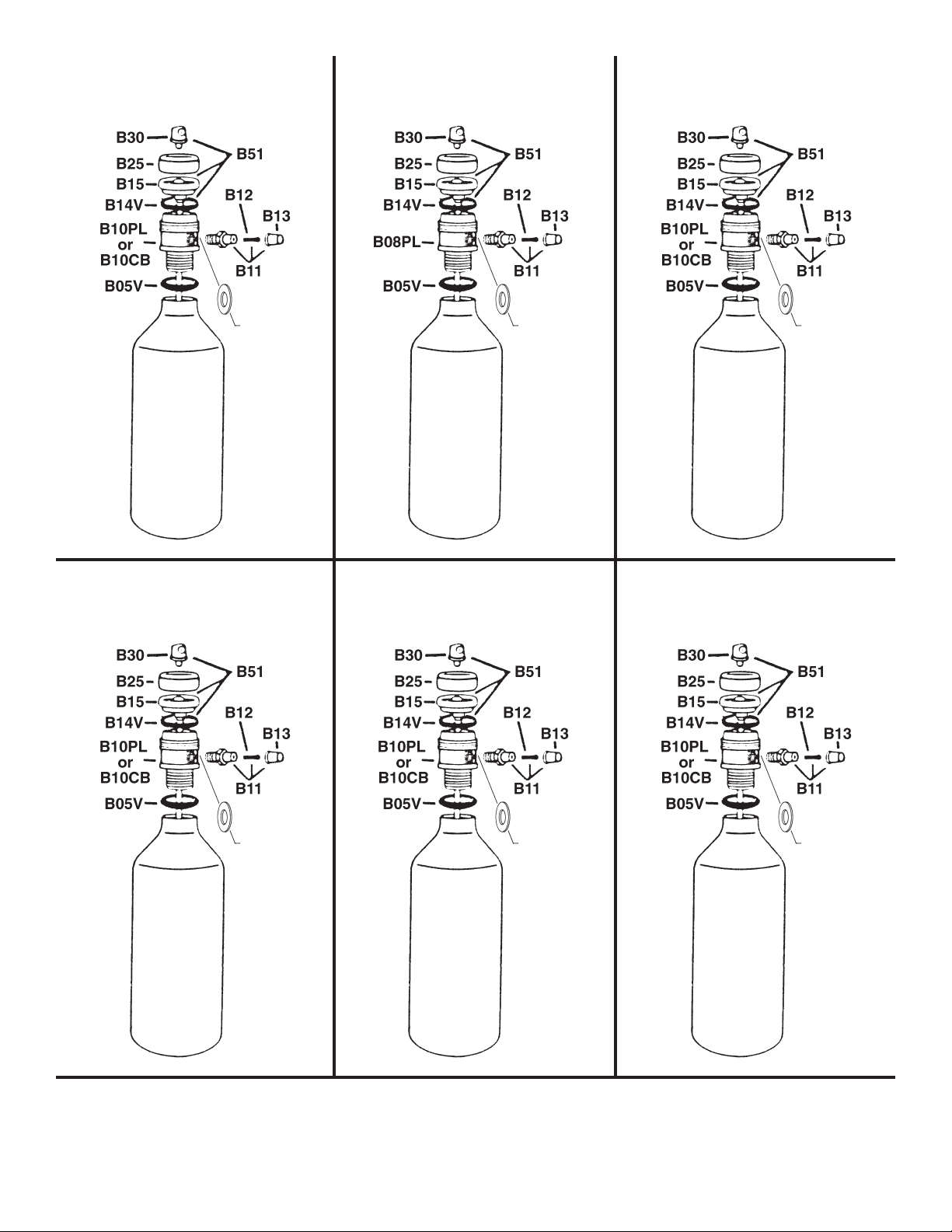

MODEL B

16 oz.

8oz.

7oz.

PL — DESIGNATES PLASTIC BODY

CB — DESIGNATES CHROME BRASS BODY

B8000PL / B8000CB

ALUMINUM

B8300PL / B8300CB

ALUMINUM

B8100PL / B8100CB

PLATED ALUMINUM

B8400PL/B8400CB

PLATED,BRUSHED

ALUMINUM

B8700PL / B8700CB

PLATED,BRUSHED

ALUMINUM

B8200PL

ALUMINUM

-B45

B11W

-B46 -B47 - B48

-B43 -B44

B11W

B11W

B11W

B11W

B11W

PART# DESCRIPTION

B05BUNA Buna O’Ring

B05N Neoprene O’Ring

B05EP Ethylene Propylene O’Ring

B05V Viton® O’Ring

B08PL Plastic Body (8200 only)

B10CB Chrome Brass Body

B10PL Plastic Body

B11 Air Filler Assembly

(includes B11W, B12 & B13)

B11W Teflon® Washer

B12 ValveCore - Viton®

B13 Black Cap

B14BUNA Buna O’Ring

B14N Neoprene O’Ring

B14EP Ethylene Propylene O’Ring

B14V Viton® O’Ring

B15 Viton® Valve

B15N Neoprene Valve

B16 Buna Valve

B17 Butyl Rubber Valve

B25 Aluminum Valve Head

B30-001 Pin Stream Nozzle

B30-035 Medium Spray Nozzle

B30-040 Fine Spray Nozzle

PART# DESCRIPTION

B30-043 Regular Spray Nozzle

B30-080 Coarse Spray Nozzle

B32 Plastic Adjustable Nozzle for all

Model “B”s

B43

7ounce Aluminum Canister (8200)

B44

8ounce Aluminum Canister (8300)

B45 16 ounce Aluminum Canister

(8000)

B46 16 ounce Plated Aluminum

Canister (8100)

B47 16 ounce Plated, Brushed

Aluminum Canister (8400)

B48 8ounce Plated, Brushed

Aluminum Canister (8700)

REPAIR KITS

B51 6Complete Valve Assemblies - contains

6each - B14V & B15 and 3 each -

B30-001 w/6” tube & B30-043

BK50 Complete Repair Kit contains B05V, B11,

B12, B13, B25, 6 each - B14V & B15 and

3each - B30-001 w/6” tube & B30-043

ACCESSORIES

P07362

Filling/Measuring Device 32

ounce capacity - Heavy Duty

Polyethylene container with

brass mesh screen and easy fill

spout.

REPAIR PROCEDURES

The following is the correct order and way to

remove and reassemble all the parts on the Model

“B” Sprayer.

a) ALWAYS DEPRESSURIZE SPRAYER

BEFORE REMOVING ANY PARTS. See page

1. #1.

b) Removethe complete top assembly from the

canister once all the air has been let out of the

sprayer. Do this by grasping the body in one

hand and the canister in the other and unscrew-

ing counterclockwise completely.

c) Unscrew the valve head from the body.

d) Remove the valve and B14 o’ring from the body.

e) Remove the 7/16” hex air filler (B11) assembly

from the side of the body.

NOTE: The B11W teflon washer will be left in the

recessed threaded area on the body where the air

filler assembly was just removed. The B11W must

be removed and replaced.

f) Remove the o’ring from the body.

g) The Model “B” sprayer is completely unassem-

bled.

h) To reassemble, start by reassembling the o’ring

to the body.

i) Take a new B11W Teflon® washer and insert

into the recessed threaded area on the side of

the body.

j) Take the 7/16” hex air filler (B11) assembly and

screw on by hand. Tighten with wrench.

NOTE: Be careful to only tighten until snug. DO

NOT OVERTIGHTEN.

k) Assemble B14 o’ring to valve and reposition on

top of body.

l) Take B25 valve head and secure valve and

o’ring in place. Firmly hand tighten only.

m) Take the completed top assembly and screw it

clockwise into top of the canister. Firmly hand

tighten only.

n) Pressurize and check for leaks. If leaks are

found retighten the loose part or parts until

leaks stop. Depressurize and follow steps

#1 - #7 on page 1.

DO NOT PRESSURIZE SPRAYER WITHOUT

B25 VALVE HEAD IN PLACE AND TIGHTENED

MAXIMUM PRESSURE — 200 PSI

TROUBLE SHOOTING

Normal maintenance includes replacing the

B15/B16 valve

THE B15/B16 VALVE WILL NEED TO BE

PERIODICALLY REPLACED. THE LONGEVITY OF

EACH VALVE DEPENDS ON THE PRODUCT

BEING SPRAYED AND THE AMOUNT OF

SEDIMENT OR DIRT THAT GETS INSIDE THE

SPRAYER WHILE FILLING.

Four fillings is the average before the valve needs

to be replaced. But it is not uncommon to get more

than four filings out of each valve.

THE STANDARD MODEL B UNITS COME WITH

VITON® O’RINGS, A B15 VITON® VALVE,

AND B12 VITON® VALVE CORE. NOT ALL

PRODUCTS ARE COMPATIBLE WITH VITON®.

There are a variety of o’rings available (Viton®,

Neoprene, Buna & Ethylene Propylene). There are

three different valves (B15 Viton®, B15N Neoprene

&B16-Buna). There are two different valve cores

(B12 - Viton® &B12N - nitrile).

If the standard Viton® o’rings and seals are not

compatible with the product being sprayed please

checkwith the chemical supplier for compatibility

with the other o’rings and seals that are available.

Viton® o’rings and seals are standard on Model “B”

sprayers because they are compatible with the

widest range of sprayable products.

Problem: Leaks from around B25 valve head.

Reason/Solution

1) B25 valve to loose. Firmly tighten by hand only.

2) B14 o’ring is crimped or has some loose

particles on it. Depressurize sprayer and

remove B25 valve head. Remove valve and

check o’ring. Clean away any loose particles

and wet o’ring. Reassemble and repressurize.

TROUBLE SHOOTING

Problem: Pin Stream only.

Reason/Solution

1) Liquid is too thick. Thin with proper diluent until

sprayable. Consult your chemical supplier for

correct thinning procedures.

2) Too little air pressure. You must have at least 80

psi to spray full contents of sprayer.

3) Pin Stream nozzle in operating position.

Remove. Replace with a spray nozzle. (regular,

fine, medium & coarse)

Problem: Air filler assembly won’t accept air or

leaks

Reason/Solution

1) Air filler assembly has been damaged. Replace.

2) Valve core is swollen. Replace.

3) Chemical is attacking valve core. Replace B11

with an alternative valve core.

Problem: Will not spray at all.

Reason/Solution

1) Nozzle is completely clogged. Replace

2) Valve is completely clogged. Replace.

3) No Air pressure. Pressurize with at least 80 psi

4) Sprayer is full to top with liquid not allowing

room for compressed air.

Problem: Leaks from valve stem/nozzle.

Reason/Solution

1) Valve worn or swollen. Replace. Standard

valve has a Viton® seal. Valves also available

in neoprene and buna for chemicals not

compatible with Viton®.

Problem: Leaks from between body and canister.

Reason/Solution

1) O’ring is dirty. Clean and wet.

2) O’ring is swollen. Replace. Standard o’ring is

Viton®. Neoprene, ethylene propylene, and

buna, are available for chemicals that are not

compatible with Viton®.

WARNING * WARNING * WARNING

Sprayer Units returned to the factory containing ANY LIQUIDS will be returned to sender at their expense.

WARRANTY

SURE SHOT SPRAYERS, Parts and Accessories are guaranteed against defective materials and workmanship

under normal conditions of use and service for a period of ninety days from date of sale to the consumer or nine

months from date of shipment from the factory, whichever transpires first. The obligation of the Company (Milwaukee

Sprayer Mfg. Co., Inc.) shall be limited to repairing or replacing any sprayer, part or accessory which is

found by the Company to be defective, provided that a written claim covering such defect is submitted within the

warranty period. The Company shall in no event be liable for consequential damages arising out of a defect or

failure in any sprayer, part or accessory, or for any loss arising from the use or resale of any such materials, the

Company’s liability being limited to repair or replacement of defective components as aforesaid. This warranty shall

not apply to defects resulting from accident, alterations, abuse or misuse, including solutions not recommended for

use with the materials used in the manufacturing of this unit. Although it shall be the policy of the Company to be

liberal in making adjustments,the settlement of claims regarding product defects will be governed by the provisions

of this warranty. No other warranty, expressed or implied, is made by Milwaukee Sprayer Mfg. Co., Inc. with respect

to anysales or products referred to herein.

Milwaukee Sprayer puts everything within reach. Learn more about air tools & compressors we have.

This manual suits for next models

11

Table of contents