NOTE: SOMFY motors conform to IP44 requirements and

as such must be protected against direct weather elements

such as rain, sleet,...etc.

2

1

3

4

5

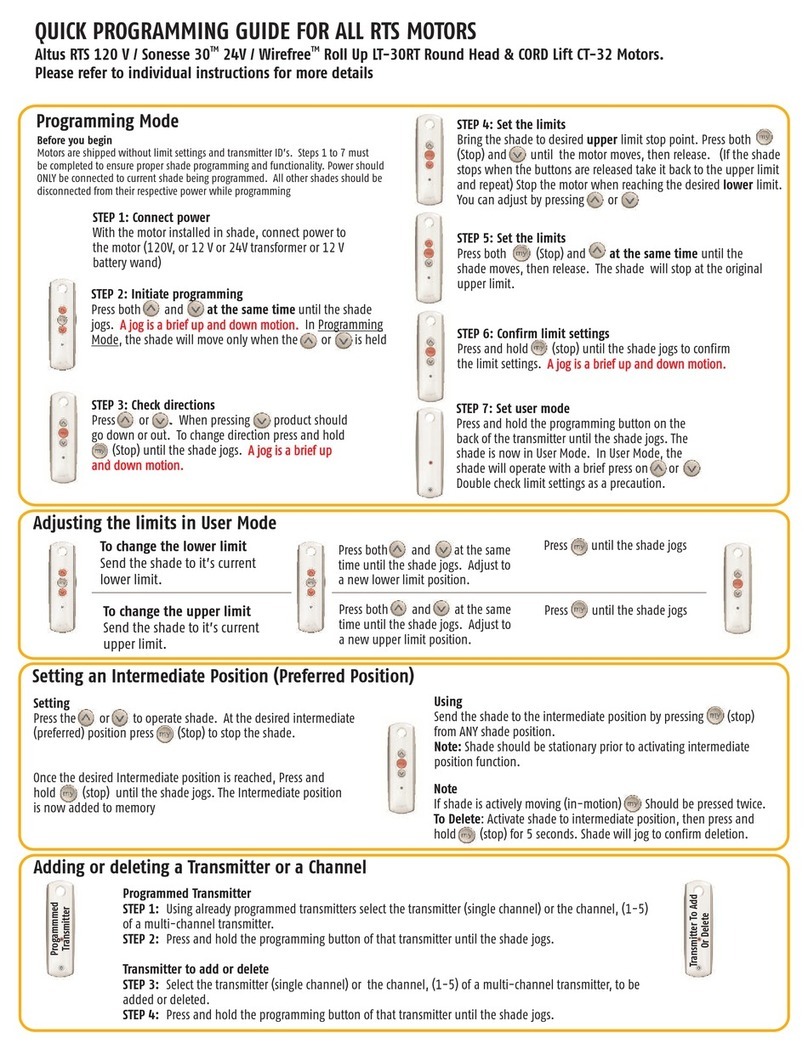

Ensure the tester cable switch is in the center "OFF" position,

and connect T.C. to motor leads by matching color codes.

Identify the UP recessed limit screw by finding the arrow on

the motor head which points in the direction that retracts (rolls

up) the system.

Turn the power on to ensure that the switch is operating

properly (UP-raises, DOWN-lowers). If not, turn the power off

and simply reverse the black and red motor leads.

Flip the tester cable switch in the UP direction. If the system

stops before its UP limit, turn the UP screw to " " until

necessary. If the system does not stop at its UP limit, flip the

tester cable switch in the DOWN direction and turn the UP

screw to " ". Repeat this until the correct setting is achieved.

Flip the tester cable switch in the DOWN direction. If the

system stops before its DOWN limit, turn the DOWN limit

screw to " ". If not, flip the tester cable switch in the UP

direction and turn the DOWN limit screw to " ". Repeat this until

the correct setting is achieved.

+

-

+

-

NOTE: 7 turns of Hex Screws equals 1 turn of roller tube.

NOTE: Recessed thumbscrews can accommodate a flat

head screwdriver (4mm wide max.), SOMFY's Allen wrench

(Cat. No. 6500258) or Flexible limit switch adjuster (Cat.

No. 6500091).

6. TROUBLESHOOTING GUIDE

SYSTEM DOES NOT RESPOND

- Is the power supply switched on - check any fuses in the

system?

- Is control switch wired correctly? Refer to instructions.

- Are limit switches set properly? Review limit switch

settings.

- The thermal protective device may have shut the motor off.

Wait for the motor to cool down.

- Check the wiring between the motor & the switch.

- Disconnect the switch & test the motor with a tester cable.

THE SYSTEM IS NOT STOPPING

- Are limit switches set properly? Review limit switch settings.

- Is the limit switch crown wheel being driven by the tube (has tube

profile been properly notched)?

- Is motor drive wheel securely fastened to the tube?

NOTE: if the motor is tested outside the tube, the crown wheel

has to be manually turned in order to stop the rotation of the

output shaft.

SOMFY SYSTEMS, INC. reserves the

right to update, change or modify

these instructions without prior notice.

REF. NO. 4500047/900246A

SOMFY SYSTEMS, INC.

47 Commerce Drive

Cranbury, NJ 08512

SOMFY CANADA

6315 Shawson Drive, Unit #1

Mississauga, Ontario L5T1J2

SOMFY MEXICO S.A. De C.V.

Calle 3 No. 47, Loc. E-5

Fracc Ind. Alce Blanco

Nau., Edo. de Mex C.P. 53370

5. WIRING/INSTALLATION RECOMMENDATIONS

A. All wiring must conform to NEC (National Electrical Code)

and local codes

B. Do not wire two or more motors to one SPDT (single pole

double throw switch-NO PARALLEL WIRING).

C. Do not use light switches to control SOMFY motors.

D. Do not wire two or more switches to one motor, without

using SOMFY's multi switch command. Cat. No. 6300427.

NEUTRAL

LINE

GROUND

Power

120VAC 60Hz

DECORATOR PADDLE/

TOGGLE SWITCH

** See note above

BLACK

GROUND

CONNECTED TO BOX

RED*

BROWN*

GREEN

BLACK

BLACK

* - reverse the brown

and red wire if the UP

and DOWN movement

do not correspond to the

UP and DOWN of the switch.

RED

BROWN

** The motor cable should not act

as a direct conduit for the water to

enter the head of the motor (form

drip loops).

Adjustment of Upper and Lower Positions for the LS40

Motor on Left

(Black Wire Direction)

Motor on Left

(Red Wire Direction)

Tester Cable Switch

Cat. No. 6020086

HOOD

Motor on Right

(Red Wire Direction)

Motor on Right

(Black Wire Direction)

Stop Position 2

+

+

+

+

-

-

-

-

Stop Position 1

SOMFY reserves the right to void the motor warranty if the wiring recommendations are not followed.

c SOMFY SYSYTEMS, INC., FEBRUARY 2000

NOTE: Tubular motors are not continuously rated. They

have a built-in thermal overload device which limits their

operation to approximately 5 minutes. A maximum 15

minute cool down period is required if the motor reaches

thermal overload.