Surface Concept HVPS-HC User manual

19“ HVPS-HC Module

1Channel/2Channel

(Release R012)

Manual

2

email:

User Manual for the

19” HVPS-HC Module 1Channel/2Channel

Release: R012

Manual Version 2.3

Printed on 2021-06-11

19“ HVPS-HC Module R012 Manual | Surface Concept GmbH

Surface Concept GmbH

Am Saegewerk 23a

55124 Mainz

Germany

phone: +49 6131 62716 0

fax: +49 6131 62716 29

email: info@surface-concept.de

web: www.surface-concept.de

All rights reserved. No part of this manual may

be reproduced without the prior permission

of Surface Concept GmbH.

3

Manual 19“ HVPS-HC Module

19“ HVPS-HC Module R012 Manual | Surface Concept GmbH

1 Table of Contents

1 Table of Contents ................................................................................................................................................3

2 Introduction..........................................................................................................................................................5

2.1 General Information...........................................................................................................................5

2.2 Safety Instructions..............................................................................................................................5

2.3 General Overview ...............................................................................................................................6

3 Introduction..........................................................................................................................................................7

3.1 Initial Inspection..................................................................................................................................7

3.2 Installation.............................................................................................................................................7

4 Device Layout & Operation .............................................................................................................................9

4.1 Device Layout.......................................................................................................................................9

4.2 General Device Operation ............................................................................................................10

4.3 Schematic Layout of the 19”HVPS-HC Module R012..........................................................11

4.4 Floating Operation .......................................................................................................................... 12

4.5 Limitations Floating Operation................................................................................................... 12

5 List of Figure..................................................................................................................................................... 13

419“ HVPS-HC Module R012 Manual | Surface Concept GmbH

This side has been left blank on purpose.

5

Manual 19“ HVPS-HC Module

19“ HVPS-HC Module R012 Manual | Surface Concept GmbH

2 Introduction

2.1 General Information

This manual is intended to assist users in the installation, operation and maintenance of Release Version

012 of the 19” HVPS-HC Module. It is divided into 5 chapters.

2.2 Safety Instructions

Please read this manual carefully before performing any electrical or electronic operations and strictly

follow the safety rules given within this manual.

The following symbols may appear throughout the manual:

The“caution symbol”marks warnings, which are given to prevent an accidental damaging

of the device. Do NOT ignore these warnings and follow them strictly. Otherwise no

guarantee is given for arose damages.

Note

The “note symbol” marks text passages that contain important information/hints about

the operation of the device. Follow this information to ensure a proper operation of the

device.

The “high voltage symbol” marks warnings, given in context with the description of the

operation/use of high voltage supplies and/or high voltage carrying parts.

Hazardous voltages are present that can cause serious or fatal injuries. Therefore only

persons with the appropriate training are allowed to carry out the installation, adjustment

and repair work.

619“ HVPS-HC Module R012 Manual | Surface Concept GmbH

2.3 General Overview

The Surface Concept 19” HVPS-HC Module R012 is a high voltage module especially designed for the

Surface Concept 19”Basic Unit, a modular supply system.

The 19”HVPS-HC Module R012 comes as a 1 channel/ 2 channel version, which provides one/two separate

high voltages with a switchable polarity (must be manually switched by the user). It also provides the

capability to oat on a reference potential. Hereby each channel has its own, individual reference input. For

the 2 channel version, the both channels work absolutely independent on reference potential and output

polarity.

Depending on the maximum output voltage the 19” HVPS-HC Module R012 comes with either SHV

connectors (maximum output voltage <= 5kV) or with 10kV LEMO connectors type ERA.1S.405.CTL

(maximum output voltage > 5kV).

The device can produce lethal high voltages of up to several kV. Hazardous voltages are

present, therefore only persons with the appropriate training are allowed to carry out

the installation, adjustment and repair work.

Do not open the power supply, while it is in operation. Hazardous voltages are present.

In case that the device must be opened, turn o the device rst AND pull out the power

plug.

Note

The 19” HVPS-HC Module R012 is available with dierent output voltages and dierent

maximum oating voltages. Check the specication sheet of your specic 19” HVPS-HC

Module R012 for detailed information on those parameters.

7

Manual 19“ HVPS-HC Module

19“ HVPS-HC Module R012 Manual | Surface Concept GmbH

3 Introduction

3.1 Initial Inspection

Visual inspection of the system is required to ensure that no damage has occurred during shipping. If

there are any signs of damage, please contact SURFACE CONCEPT immediately. Please check the delivery

according to the packing list (see Table 1) for completeness.

• 1x 19“ HVPS-HV Module R012

• 1x Termination Plug (SHV or LEMO 1S) per channel

Table1: Packing list for the 19“ HVPS-HC Module R012.

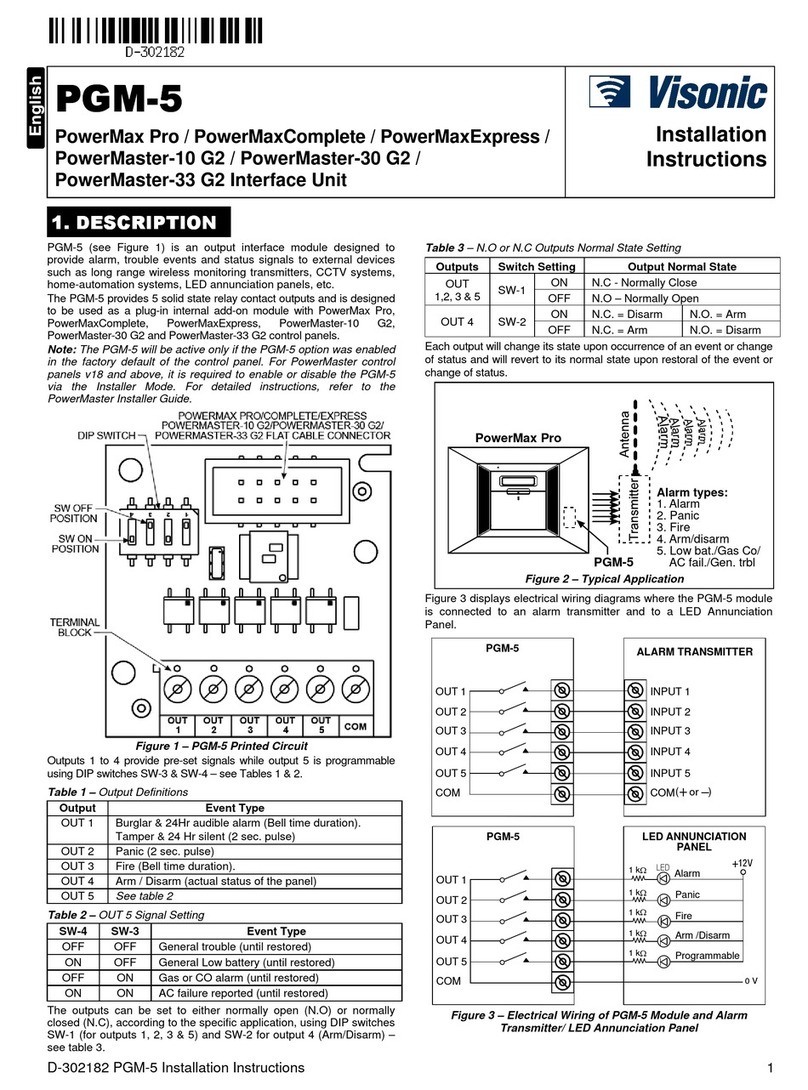

3.2 Installation

The general connection scheme of the 19”HVPS-HC Module R012 is as follows:

Figure 1: Exemplary basic connection scheme of a 2 channel Module R012 with SHV connectors.

819“ HVPS-HC Module R012 Manual | Surface Concept GmbH

The 19” HVPS-HC Module R012 is specied for the operation with an external reference

voltage. Please check the specication sheet of your specic module for the maximum

allowed reference voltage.

All 19” HVPS-HC Module R012 with a maximum output voltage <= 5kV come with SHV

connectors, independent on their maximum oating voltage.

Therefore it must be taken care o, that the sum of the module output voltage and the

applied oating voltage is not exceeding 5kV in total.

In cases that no reference voltage is applied to the device, the termination plug must

be used to ground the reference input of the 19” HVPS-HC Module R012. With a missing

reference potential the device is not providing any output voltage.

Finish the complete cabling of the 19”HVPS-HC Module R012 before switching on the 19”

Basic Unit and switch o the device rst before performing any changes to the cabling.

• Install the 19” HVPS-HC Module R012 into a free slot of the 19”Basic Unit (if not already installed).

• Use appropriate cables (SHV or LEMO 1S) to connect the outputs with the corresponding polarity

suitable for your application.

• Use the termination plugs (SHV or LEMO 1S) to terminate the output with the opposite polarity to GND

(e.g. terminate the negative output of channel 1 in case that the positive output of channel 1 should

be used).

• Alternatively an external reference potential can be applied instead of using the termination plug for

a termination to GND.

9

Manual 19“ HVPS-HC Module

19“ HVPS-HC Module R012 Manual | Surface Concept GmbH

4 Device Layout & Operation

4.1 Device Layout

The layout of the 19” HVPS-HC Module R012 is given below.

SHV connector for output of operation

voltage with positive polarity for the rst/

second HV channel.

(Must be terminated to GND or to an external

reference potential when using the output

voltage with negative polarity.

Check the specication sheet for the

maximum allowed reference voltage).

SHV connector for output of operation

voltage with negative polarity for the rst/

second HV channel.

(Must be terminated to GND or to an external

reference potential when using the output

voltage with positive polarity.

Check the specication sheet for the

maximum allowed reference voltage).

Figure 2: Layout of the 19”HVPS-HC Module R012.

1(+)/2(+)

1(-)/2(-)

10 19“ HVPS-HC Module R012 Manual | Surface Concept GmbH

4.2 General Device Operation

After switching on the 19” Basic Unit, the display shows the “Surface Concept” animated logo, while the

device is scanning for the 19” HVPS-HC Module R012 and its specic settings. This can take up to several

seconds. If the 19”Basic Unit is ready for operation, it switches into the standby mode and shows an empty

mask for the voltage adjustment (see Figure 3).

Push the“Start/Standby” button in the lower left

corner of the display to switch on the high

voltage.

Alternatively one can press the“Channel”control

knob.

After switching on the high voltage the device

is in the so called operation mode. In operation

mode the display shows the name of the selected

channel in the top line (in this case“HV 1”) as well

as the output voltage of that channel.

The dierent HV channels can be selected by

turning the “Channel” control knob.

Figure 3: Standby mode.

Figure 4: Operation mode.

Figure 5: Operation mode – voltage adjustment.

The “Adjust” control knob is used to adjust

the output voltage. Turn the “Adjust” control

knob clockwise/counter-clockwise to increase/

decrease the value of the output voltage in a step

width as dened in the line “edit step”.

The line “set value” displays the nominal value

for the output voltage as adjusted by the user.

Voltage adjustment can only be made in this line.

11

Manual 19“ HVPS-HC Module

19“ HVPS-HC Module R012 Manual | Surface Concept GmbH

The line “actual” displays the actual value for the output voltage on the output connector as measured by

the device. The device always regulates the actual value of the output voltage to t to the nominal value

as set by the user. Hereby the voltage measurement is always a relative measurement between the two

HV outputs of one channel. Additional reference voltages (e.g. in oating operation) are not measured

and therefore are also not displayed (see the manual of the specic module for further details). Turn the

“Adjust” control knob clockwise/counter-clockwise while pushing it to increase/decrease the step width

in the line “edit step”.

Push the„Start/Standby“-button in the lower left corner of the display again to switch back to the“Standby”

mode.

4.3 Schematic Layout of the 19” HVPS-HC Module R012

Figure 6 shows the schematic layout of the 19” HVPS-HC Module R012 and especially the layout of the HV

outputs. An internal controller measures the output voltage and regulates it to the nominal value entered

by the user or set as default value within the device. Hereby the voltage measurement is always a relative

measurement. The output polarity is xed dened (see the specic specication sheet for details on the

max. output voltage and the polarity). Figure 6 also shows the internal load and measuring resistors.

Figure 6: Schematic layout of the 19“ HVPS-HC Module R012.

12 19“ HVPS-HC Module R012 Manual | Surface Concept GmbH

when a HV module with oating capability is stacked on top of a reference voltage, then it can happen that

the oating,“upper” HV module “pulls up” the reference voltage of the “lower” reference HV module when

operating. This “pulling up” eect is caused by cross current ows from the one to the other HV module

and it depends on the output voltage of the oating HV module in respect to the output voltage of the

reference HV module as well as on the internal resistances to ground within the dierent modules and on

the polarity of the output voltages of the both HV modules (e.g. the“pulling up”eect is much stronger for

dierent polarities between the both modules then when both polarities are the same).

4.4 Floating Operation

For the 2 channel version of the 19” HVPS-HC Module R012, one can not only use external HV supplies

to provide a reference voltage, but also one of the both channels of the R012 can be used as reference

potential for the other HV channel.

The connection scheme of one HV channel of the 19” HVPS-HC Module R012 in oating operation in

reference to the second HV channel is shown in Figure 7.

Figure 7: Connection scheme for oating operation of one HV channel of Module R012in respect to the second HV

channel.

4.5 Limitations of Floating Operation

13

Manual 19“ HVPS-HC Module

19“ HVPS-HC Module R012 Manual | Surface Concept GmbH

This eect occurs independent on using an external HV module or using the second HV channel of the

R012.

This “pulling up” eect can be minimized by installing an addition resistance to ground on the HV output

of the reference HV module, to create an additional current ow out of the reference HV module.The value

of the resistance depends on the necessary current ow, which should be larger than the current ow out

of the oating HV module (a typical resistance values for the oating operation of MCP based detectors is

10MOhms).

External resistances in a compact housing with SHV connectors are available from Surface Concept to

connect in between the HV line of the reference HV module.

The connection scheme of the 19”HVPS-HC Module R012 in oating operation with such external resistance

is given in Figure 8.

Figure 8: Connection example for the oating operation of HV

channel 2 with positive polarity in reference to the negative

output of HV channel 1 with an external resistance to ground

connected to minimise the“pulling up”eect.

14 19“ HVPS-HC Module R012 Manual | Surface Concept GmbH

This side has been left blank on purpose.

15

Manual 19“ HVPS-HC Module

19“ HVPS-HC Module R012 Manual | Surface Concept GmbH

Figure 1: Exemplary basic connection scheme of a 2 channel Module R012 with SHV connectors...............................7

Figure 2: Layout of the 19”HVPS-HC Module R012...........................................................................................................................9

Figure 3: Standby mode........................................................................................................................................................................... 10

Figure 4: Operation mode....................................................................................................................................................................... 10

Figure 5: Operation mode – voltage adjustment............................................................................................................................ 10

Figure 6: Schematic layout of the 19“ HVPS-HC Module R012. ................................................................................................. 11

Figure 7: Connection scheme for oating operation of one HV channel of Module R012in respect to the second HV

channel. ......................................................................................................................................................................................................... 12

Figure 8: Connection example for the oating operation of HV channel 2 with positive polarity in reference to the

negative output of HV channel 1 with an external resistance to ground connected to minimise the “pulling up”

eect............................................................................................................................................................................................................... 13

5 List of Figure

16

Surface Concept GmbH

Am Sägewerk 23a

55124 Mainz

Germany

phone: +49 6131 62716 0

fax: +49 6131 62716 29

email: info@surface-concept.de

web: www.surface-concept.de

Manufacturer

Product

Model

High Voltage Power Supply

19” HVPS-HC Module

The above named products comply with the following European directive:

89/336/EEC Electromagnetic Compability Directive, amended by 91/263/ EEC

and 92/31/ EEC and 93/68/EEC

73/23/EEC Low Voltage Equipment Directive, amended by 93/68/EEC

The compliance of the above named product to which this declaration relates is in conformity with the

following standards or other normative documents where relevant:

EN 61000-6-2:2005+AC:2005 Electromagnetic compatibility (EMC):

Generic standards - Immunity for industrial environments

EN 61000-6-4:2007+A1:2011 Electromagnetic compatibility (EMC):

Generic standards - Emission standard for industrial environments

EN 61010-1: 2010 Safety Requirements for Electrical Equipment for Measurement,

Control and Laboratory Use

This declaration does not represent a commitment to features or capabilities of the instrument.The safety notes and regulations

given in the product related documentation must be observed at all times.

For and on behalf of Surface Concept GmbH

Mainz,……01.10.2019………. Legal Signature…………………………………………

(Date) (Dr. Andreas Oelsner)

email:

EC Declaration of Conformity

19“ HVPS-HC Module R012 Manual | Surface Concept GmbH

Other manuals for HVPS-HC

2

Table of contents

Other Surface Concept Control Unit manuals