6/12

be laid separately from the power cables.

- Always connect the protection fuse (or equivalent device) in series with the power

supply for each device.

- Always connect the protection fuse (or equivalent device) in series to the safety

electrical contacts.

- During and after the installation do not pull the electrical cables connected to the

device. If excessive tension is applied to the cables, the device may be damaged.

7.5 Additional prescriptions for safety applications with operator protection

functions

Provided that all previous requirements for the devices are fulfilled, for installations

with operator protection function additional requirements must be observed.

- The utilization implies knowledge of and compliance with following standards:

EN ISO 13849-1, EN 62061, EN 60204-1, EN ISO 12100.

- In the risk analysis, take into account that in manual start mode a possible sticking of

the start button can lead to an immediate activation of the module.

- If expansion modules or external contactors are used, make sure that they have

forcibly guided contacts and connect in feedback an NC contact of each device.

7.6Limitsofuse

- Use the device following the instructions, complying with its operation limits and the

standards in force.

- The devices have specific application limits (min. and max. ambient temperature,

maximum currents, IP protection degree, etc.) These limitations are met by the device

only if considered individually and not as combined with each other.

- According to EU directives, this device is not intended for private use.

- The manufacturer’s liability is to be excluded in the following cases:

1) Use not conforming to the intended purpose.

2) Failure to adhere to these instructions or regulations in force.

3) Fitting operations not carried out by qualified and authorized personnel.

4) Omission of functional tests.

- For the cases listed below, before proceeding with the installation contact our as-

sistance service (see paragraph SUPPORT):

a) In nuclear power stations, trains, airplanes, cars, incinerators, medical devices or

any application where the safety of two or more persons depend on the correct opera-

tion of the device.

b) Applications not contemplated in this instruction manual.

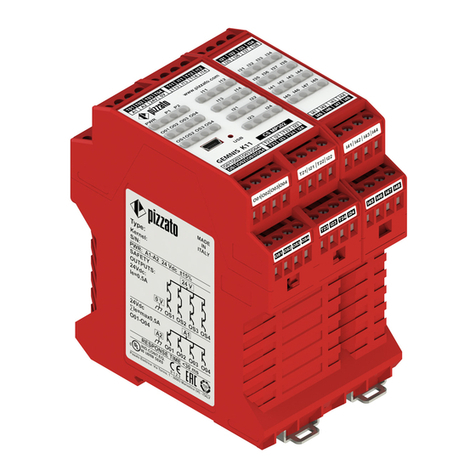

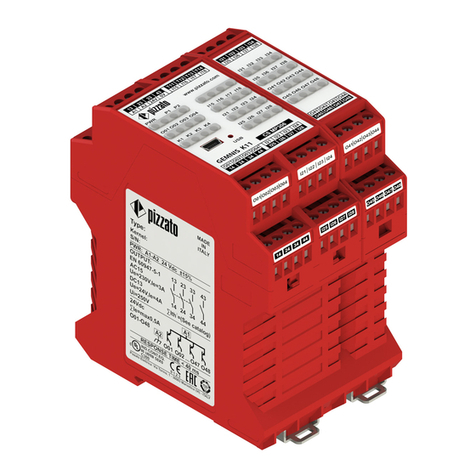

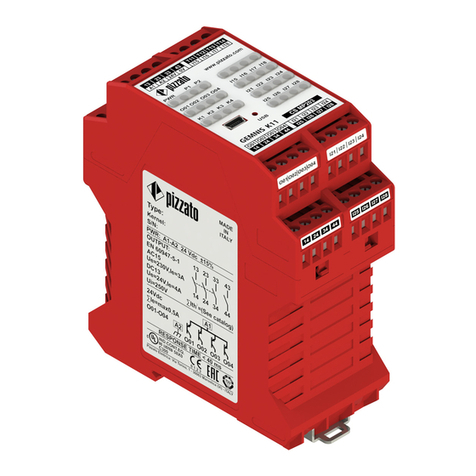

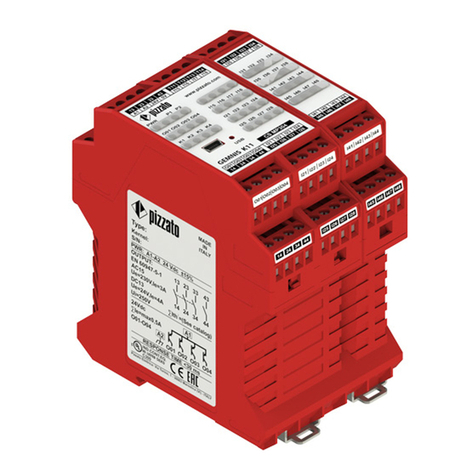

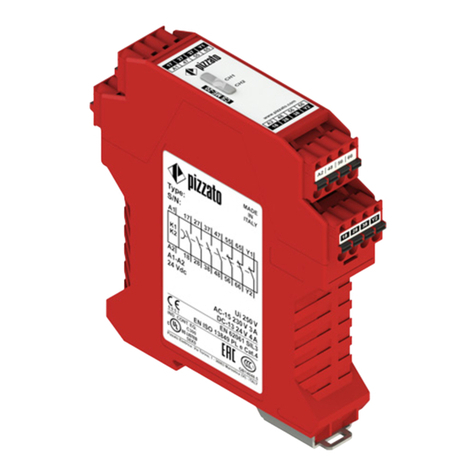

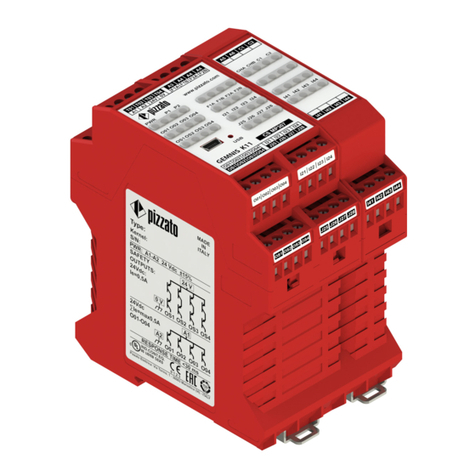

8 MARKINGS

The outside of the device is provided with external marking positioned in a visible

place. Marking includes:

- Producer trademark

- Product code

- Batch number and date of manufacture. Example: CS1-123456 (A19). The last part

of the production batch refers to the month of manufacture (A = January, B = February,

etc.) as well as the year of manufacture (19 = 2019, 20 = 2020, etc.).

9 TECHNICAL DATA

9.1 Housing

Material: Polyamide PA 66, self-extinguishing V0 acc. to UL 94

Protection degree: IP40 (housing), IP20 (terminal strip)

Cable cross section: 0.2 … 2.5 mm2 (24 … 12 AWG)

Terminal tightening torque: 0.5 … 0.6 Nm

9.2 General data

SIL (SIL CL): Up to SIL CL 3 acc. to EN 62061

Performance Level (PL): Up to PL e acc. to EN ISO 13849-1

Safety category: Up to cat. 4 acc. to EN ISO 13849-1

MTTFD: 152 years

DC: High

PFHD: 1.84 E-10

Mission time: 20 years

Ambient temperature: -25°C … +55°C

Storage temperature: -25°C … +70°C

Mechanical endurance: > 10 million operating cycles

Electrical endurance: > 100,000 operating cycles

Pollution degree: external 3, internal 2

Impulse withstand voltage Uimp: 4 kV

Rated insulation voltage Ui: 250 V

Overvoltage category: II

Air and surface distances: acc. to EN 60947-1

9.3 Power supply

Rated supply voltage Un: 24 Vac/dc; 50…60 Hz (articles CS AR-•••024)

120 Vac; 50…60 Hz (articles CS AR-•••120)

230 Vac; 50…60 Hz (articles CS AR-•••230)

Supply voltage tolerance: ±15% of Un

Max. DC residual ripple in DC: 10%

Power consumption AC: < 5 VA

Power consumption DC: < 2 W

9.4 Control circuit

Protection against short circuits: PTC resistance, Ih = 0.5 A

PTC times: Response time > 100 ms, release time > 3 s

Maximum resistance per input: ≤50 Ω

Current per input: < 40 mA

Min. duration of start impulse tMIN: > 100 ms

Response time tA: < 150 ms

Release time tR1: < 15 ms

Release time

in absence of power supply tR: < 70 ms

Simultaneity time tC: unlimited

9.5 Output circuit

Output contacts: 3 NO safety contacts

1 NC auxiliary contact

Contact type: forcibly guided

Material of the contacts: gold-plated silver alloy

Maximum switching voltage: 230/240 Vac; 300 Vdc

Max. current per contact: 6 A

Conventional free air thermal current Ith: 6 A

Max. total current ΣIth2: 64 A2

Minimum current: 10 mA

Contact resistance: ≤100 mΩ

External protection fuse: 4 A

Maximum switching load: 1380 VA/W

Utilization categories acc. to EN 60947-5-1:

AC15 (50 … 60 Hz) Ue = 230 V, Ie = 3 A

DC13 (6 op. cycles/minute) Ue = 24 V, Ie = 4 A

Utilization category acc. to UL 508: C300

9.6Compliancewithstandards

EN 60204-1, EN ISO 13855, EN ISO 14118, EN ISO 12100, EN ISO 13850, EN 60529,

EN 61000-6-2, EN 61000-6-3, EN 61326-1, EN 60664-1, EN 60947-1, EN IEC 63000,

EN ISO 13849-1, EN ISO 13849-2, EN 62061, UL 508, CSA C22.2 n° 14-95,

GB/T14048.5-2017

9.7 Compliance with directives

Machinery Directive 2006/42/EC, EMC Directive 2014/30/EU, RoHS Directive

2011/65/EU.

10 SPECIAL VERSIONS ON REQUEST

Special versions of the device are available on request.

These special versions may differ substantially from the indications in these operating

instructions.

The installer must ensure that he has received written information regarding the use

of the special version requested (see paragraph SUPPORT).

11 DISPOSAL

At the end of service life product must be disposed of properly, according to the

rules in force in the country in which the disposal takes place.

12 SUPPORT

The device can be used for safeguarding people’s physical safety, therefore in case of

any doubt concerning installation or operation methods, always contact our technical

support service:

Pizzato Elettrica Srl

Via Torino, 1 - 36063 Marostica (VI) - ITALY

Telephone +39.0424.470.930

E-mail tech@pizzato.com

www.pizzato.com

Our support service provides assistance in Italian and English.

13 EC CONFORMITY DECLARATION

I, the undersigned, as a representative of the following manufacturer:

Pizzato Elettrica Srl - Via Torino, 1 - 36063 Marostica (VI) – ITALY

hereby declare that the product is in conformity with whatever prescribed by the

2006/42/EC Machine Directive. The complete version of the present conformity

declaration is available on our website www.pizzato.com

Marco Pizzato

DISCLAIMER:

Subject to modifications without prior notice and errors excepted. The data given in this sheet

are accurately checked and refer to typical mass production values. The device descriptions and

its applications, the fields of application, the external control details, as well as information on

installation and operation, are provided to the best of our knowledge. This does not in any way mean

that the characteristics described may entail legal liabilities extending beyond the “General Terms of

Sale”, as stated in the Pizzato Elettrica general catalogue. Customers/users are not absolved from

the obligation to read and understand our information and recommendations and pertinent technical

standards, before using the products for their own purposes. Taking into account the great variety of

applications and possible connections of the device, the examples and diagrams given in the present

manual are to be considered as merely descriptive; the user is deemed responsible for checking that

the specific application of the device complies with current standards. This document is a translation

of the original instructions. In case of discrepancy between the present sheet and the original copy,

the Italian version shall prevail. The present manual may not be reproduced, in whole or in part,

without the prior written permission by Pizzato Elettrica.

© 2019 Copyright Pizzato Elettrica. All rights reserved.