SurfPrep SPPV15-A/E User manual

September 2019

WARNING

SAFETY LEGEND

• A HEPA Filter must be installed in this vacuum at all times

• If this vacuum is used to collect hazardous material, personal protective equipment should be used when opening the vacuum or

emptying its contents

• If this vacuum is intended for Dust Ignition Proof Operation, it must be used with supplied or recommended accessories from

SurfPrep Associates

• Any alteration to this equipment by a third party will nullify its warranty

Hearing protection is recommended

when operating this equipment.

Respiratory protection is recommend-

ed when operating this equipment.

Read and understand operator’s man-

ual before using this equipment.

Eye protection is required when oper-

ating this equipment.

WARNING WARNING

WARNING

WARNING

Safety – Operation – Maintenance

Keep this document in a safe place

Read and understand this manual before operating your vacuum

SurfPrep Vacuum System

120V with Electric/Pneumatic Tool Sync

Model: SPPV15-A/E

• Designed for general cleanup, housekeeping, vacuum sanding

• Dry Recovery Only

IMPORTANT SAFETY INSTRUCTIONS

READ ALL INSTRUCTIONS BEFORE USING THIS APPLIANCE

When using an electrical appliance, basic precautions should always be followed, including the following:

WARNING

• To reduce the risk of fire, electric shock, or injury:

• Do not leave appliance when plugged in. Unplug from outlet when not in use and before servicing.

• This unit is to be used only indoors and in a dry location.

• Use only as described in this manual. Use only manufacturer’s recommended attachments.

• Do not use with damaged cord or plug. If appliance is not working as it should, has been dropped, damaged, left outdoors,

or dropped into water, return it to a service center.

• Handle provided on power head is used only for removal of power head during maintenance.

• Before separation of power head from tank, users must disengage draw latches on tank.

• Do not pull or carry by cord, use cord as a handle, close a door on cord, or pull cord around sharp edges or corners.

• Do not run appliance over cord. Keep cord away from heated surfaces.

• Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

• Do not handle plug or appliance with wet hands.

• Do not put any object into openings. Do not use with any opening blocked; keep free of dust, lint, hair, and anything that may

reduce air flow.

• Keep hair, loose clothing, fingers, and all parts of body away from openings and moving parts.

• Turn off all controls before unplugging.

• Do not use to pick up flammable or combustible liquids, such as gasoline, or use in areas where they may be present.

• Connect to a properly grounded outlet only. See Grounding Instructions.

• Do not pick up anything that is burning or smoking, such as cigarettes, matches, or hot ashes.

• Do not use without all filters in place.

• Do not allow to be used as a toy. Close attention necessary when used by or near children.

SAVE THESE INSTRUCTIONS

EARTHING/GROUNDING INSTRUCTIONS

This appliance must be earthed/grounded. If it should malfunction or breakdown, earthing/grounding provides a path of least

resistance for electric current to reduce the risk of electric shock. This appliance is equipped with a cord having an equipment-

earthing/grounding conductor and earthing/grounding plug. The plug must be inserted into an appropriate outlet that is properly

installed and earthed/grounded in accordance with all local codes and ordinances.

WARNING – Improper connection of the equipment-earthing/grounding conductor can result in a risk of electric shock. Check with

a qualified electrician or service person if you are in doubt as to whether the outlet is properly earthed/grounded. Do not modify

the plug provided with the appliance – if it will not fit the outlet, have a

proper outlet installed by a qualified electrician.

See Power Head Name Plate for electrical requirements

USA 120V

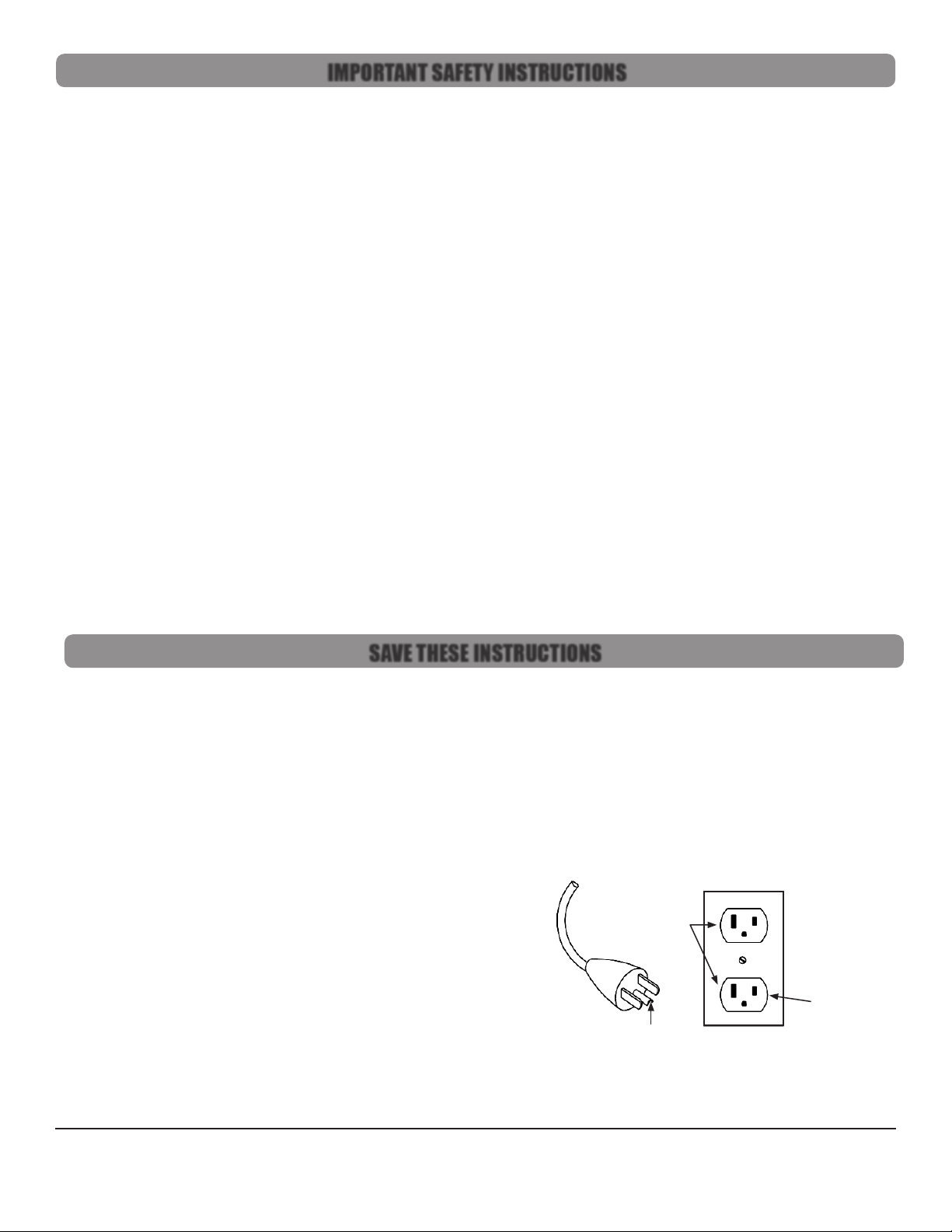

This appliance has a earthing/grounding attachment plug

that looks like the plug illustrated in Figure 1. Make sure that the

appliance is connected to an outlet having the same configuration as

the plug. No adapter should be used with this appliance.

International 120V

This appliance has a IEC 60309 125V earthing/grounding attachment

plug. Make sure that the appliance is connected to an outlet having the

same configuration as the plug. No adapter should be used with this

appliance

Earthed/Grounded

Outlet

Repair or Warranty Contact SurfPrep •571 Birch Street •Lake Elsinore, CA 92530 •P.+1-951-245-4200 F.+1-951-245-4299

www.SurfPrepSanding.com

Page 2

Figure 1: Earthed/Grounded Outlet and Plug

Earthed/Grounded

Outlet Box

TABLE OF CONTENTS

APPLICATIONS & ENVIRONMENTS

• Designed for general cleanup and housekeeping

• Dry Recovery Only

Do not use this equipment for cleaning or extracting fuel residues from any vehicle or equipment

Do not use this equipment for cleaning or extracting live sparks or burning embers

WARNING

Important Safety Instructions ............................................................................. 2

Save These Instructions...................................................................................... 2

Table of Contents .............................................................................................. 3

Applications & Environments ............................................................................. 3

What’s Included................................................................................................. 4

Specifications & Requirements........................................................................... 4

Getting Started ................................................................................................. 4

Compressed Air Fittings..................................................................................... 5

Pneumatic Tool Sync.......................................................................................... 6

Electric Tool Sync .............................................................................................. 7

Before Each Use ................................................................................................8

Bag Filter Change.............................................................................................. 9

Pre-Filter Change .............................................................................................10

HEPA Filter Change..........................................................................................10

Illustrated Parts Breakdown................................................................................11

20 Year Limited Warranty Terms and Conditions................................................15

Repair or Warranty Contact SurfPrep •571 Birch Street •Lake Elsinore, CA 92530 •P.+1-951-245-4200 F.+1-951-245-4299

www.SurfPrepSanding.com

Page 3

Repair or Warranty Contact SurfPrep •571 Birch Street •Lake Elsinore, CA 92530 •P.+1-951-245-4200 F.+1-951-245-4299

www.SurfPrepSanding.com

Page 4

WHAT’S INCLUDED

GETTING STARTED

1. The Vacuum Power Head and the Vacuum Tank ship in separate boxes

2. Unbox the Vacuum Power Head

3. Visually inspect Power Head to ensure that no parts are missing or damaged

4. Familiarize yourself with the Power Head

Power Cord

Filter Adapter

Pneumatic

Tool Sync Gauge

Pneumatic

Tool Sync Adjustment

Compressed Air Plug

(Air In)

HEPA Wire Lock

Hex Stando

HEPA Wire Lock

Hex Stando

Power Switch

Compressed

Air Coupler

(Tool Air Out)

125V

(Tool Power Out)

Compressed

Air Coupler

(Tool Air Out)

125V

(Tool Power Out)

SurfPrep Power Heads ship with the following items:

• SurfPrep Power Head

• HEPA 12 Month Timer Card

SurfPrep Vacuum Tanks ship separately and include

Bags, Filters, and other components.

These instructions

assume you have both a Power Head and one of

the following SurfPrep Vacuum Tanks

SPECIFICATIONS & REQUIREMENTS

Weight ............................................................................................................. 21.7 lbs (9.8 kg)

Dimensions............................................................. 17.5 x 17.5 x 12 in (44.5 x 44.5 x 30.5 cm)

HEPA Filter Eciency....................................................................... 99.995% @ 0.3 μm (H14)

Filter Bag Eciency......................................................................................95% @ 0.5 micron

Sounds Pressure Level ................................................................................................<70 dBA

Compressed Air Consumption.................................................................... Determined by Tool

Compressed Air Supply Pressure..................................................... 90-120 PSI (6.2 - 8.3 bar)

Power Consumption .........................................................................................120VAC~ 14.5A

Vacuum Flow ..........................................................................................120 CFM (204 SCMH)

Vacuum Suction......................................................................................... 120 in/H

2

O (30 kPa)

COMPRESSED AIR FITTINGS

The vacuum has the following Compressed Air Requirements to function properly.

• Compressed air must be clean, dry, and oil free to prevent blockage of the pneumatic system

• Compressed air line and ttings must have a minimum diameter of 1/4in (7mm)

Compressed Air Plug (air in)

• The Vacuum is supplied with a 1/4in (7mm) industrial interchange compressed air plug for connection to your compressed air supply

The Compressed Air Plug may be changed to another nominal 1/4in (7mm) style if required.

• Hold the brass bulkhead tting with a 1in (26mm) open end wrench

• Remove the compressed air plug with either a 9/16in (15mm)deep socket or 9/16in (15mm)open end wrench

• Install a new compressed air plug

Compressed Air Coupler (air out)

• The Vacuum is supplied with two 1/4in (7mm) brass high ow compatible industrial interchange compressed air couplers

• This coupler provides convenient pass through compressed air for an air tool connected to the vacuum

The Compressed Air Coupler may be changed to another nominal 1/4in (7mm) style if required.

• Hold the brass bulkhead tting with a 1in (26mm) open end wrench

• Remove the compressed air coupler with a 3/4in (19mm) open end wrench

• Install a new compressed air coupler

WARNING

Repair or Warranty Contact SurfPrep •571 Birch Street •Lake Elsinore, CA 92530 •P.+1-951-245-4200 F.+1-951-245-4299

www.SurfPrepSanding.com

Page 5

5. Power Head Vents

• NEVER BLOCK THE POWER HEAD VENTS

• NEVER WRAP THE POWER CORD AROUND THE POWER HEAD VENTS

GETTING STARTED

Vents

Preparing the Vacuum for Use

1. Install a Filter Bag

• Unfold and u a new Filter Bag

• Push the inlet tube into the hole on the cardboard collar of the Filter Bag

• Grasp the sides of the cardboard collar and push it all the way on to the inlet tube

• Ensure the bottom of the collar is past the opening on the underside of the inlet tube

2. Unbox a new HEPA Filter

• Remove the HEPA Timer Card from the box and set aside

• Remove the HEPA Cable Lock from the box and set aside

• Remove the HEPA Filter from the box and remove from plastic bag

3. Install a new HEPA Filter

• Holding the power head on its side, screw the new HEPA Filter onto the threaded nipple

• Ensure the white inner ring of the HEPA Filter is in contact with the underside of the power head

• If it is not, turn it clockwise until it comes in contact with the underside of the power head

• See the instructions included with the HEPA Cable Lock

4. Attach the Power Head

• Sit the Power Head on the tank

• Rotate the Power Head so that the switch on the Power Head is in line with the inlet port on the vacuum tank

• Latch the Power Head to the tank

Table of contents

Other SurfPrep Vacuum Cleaner manuals