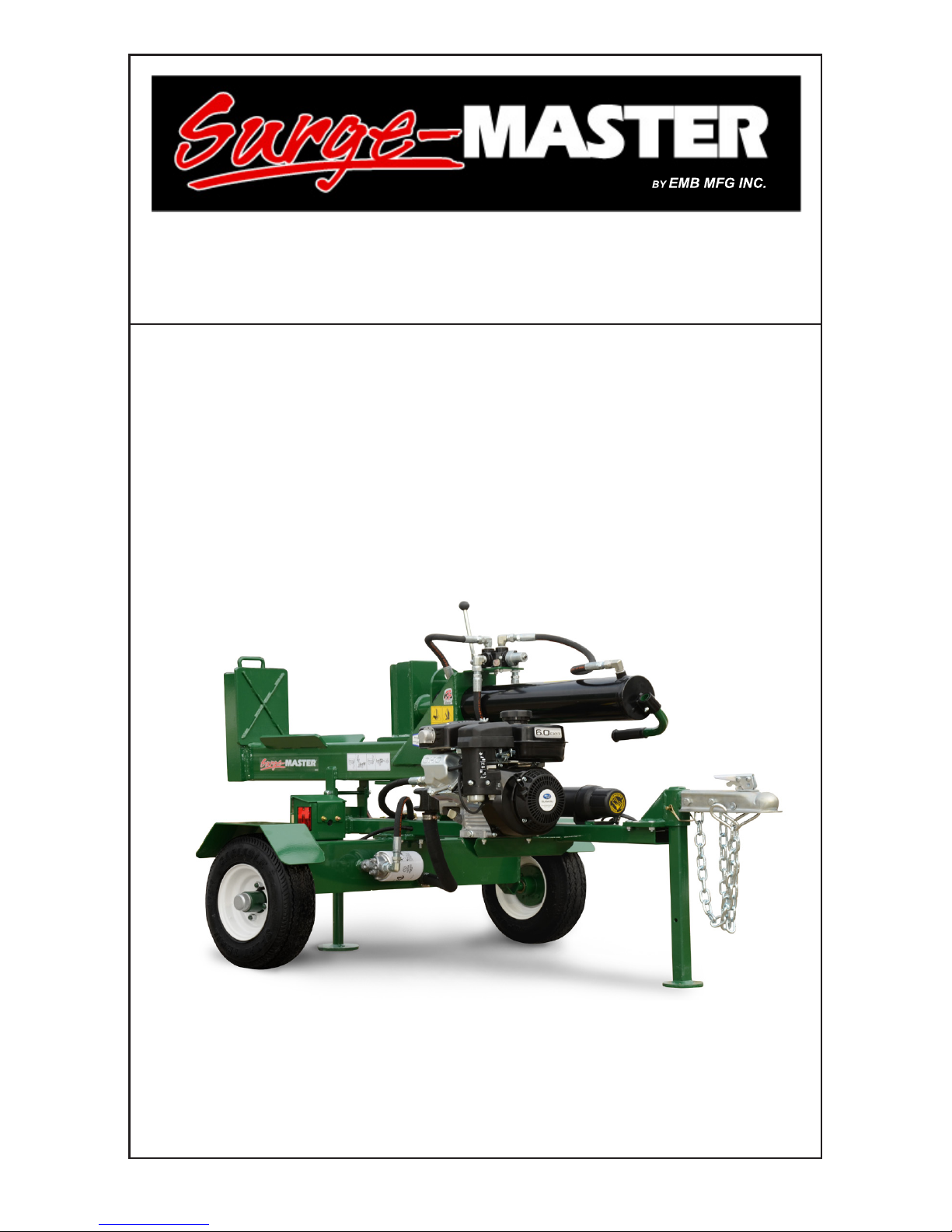

SURGEMASTER SL606S User manual

Horizontal and Vertical Splitting

EMB Manufacturing Inc.

4144 Boomer Line · St. Clements, On · N0B 2M0 · Canada

Ph: (519) 699-9283 · Fax: (519) 699-4146

www.surgemaster.ca www.embmfg.com

PRINTED IN CANADA

Rev: 290312

SL606S Woodsplitter

Operator’s Manual

WARRANTY

Effective on products retailed on or after September 1, 2011.

Register your product online at www.surgemaster.ca within 30 days of purchase to activate warranty.

This product is warranted to be free of defects in materials and workmanship under normal use and service, for a period of

from the date of purchase, when operated and maintained in accordance with the Operating and Maintenance Instructions

supplied with this unit. Warranty is limited to the repair of the product and/or replacement of parts.

This warranty does not cover the following items:

1) Parts lost or damaged during shipment,

2) Normal maintenance or adjustments

3) Normal replacement of service items.

4) Accessory items / parts not supplied by EMB MFG INC.

5) Damages resulting from:

• misuse, negligence, accident, theft or re

• use of improper or insufcient fuel, uids or lubricants

• use of parts or after market accessories other than genuine EMB MFG INC. parts

• modications, alteration, tampering or improper repair performed by parties other than an authorized servicer

• any device or accessories installed by parties other than an authorized EMB servicer

Engines are covered by the manufacturer of the engine and covered by the warranty period specied by that manufacturer.

Engine warranty must be registered at the engine manufactures website. For service contact your local engine dealer.

Under no circumstances will the manufacturer be liable for any consequential damage or expense of any kind, including loss

of prots. The manufacturer is under no circumstances liable for tow vehicle of any kind. The manufacturer is not liable for

the maintenance of the product.

This warranty is extended only to the original purchaser and is not transferable. Warranty is void if repairs are attempted by

anyone other than an authorized service centre.

If a difculty develops with the product, contact EMB MFG INC. Only our authorized service centres may make repairs to

the product or affect the replacement of defective parts, which will be done at no charge within a reasonable time after the

receipt of the product. Unit or parts shall be returned at the customer’s expense to the authorized service centre. Damage

in transit is not covered by warranty. Include the original purchase receipt with any claim (keep a copy of the receipt

for your les).

The distributor’s liability under warranty is limited to the repair of the product and/or replacement of parts and is given to the

purchaser in lieu of all other remedies including incidental and consequential charges. There are no warranties, expressed

or implied, other than those specied herein.

EMB MFG Inc

4144 Boomer Line, St Clements, ON N0B 2M0 Canada

Phone: 519-699-9283 Fax: 519-699-4146 : attention to Warranty Dept

Email: [email protected]

WARRANTY IS VOID IF NOT REGISTERED

Three (3) Years for Consumer

One (1) Year for Commercial/Rental

rev.091111

Valuable Information for Your Records

Date of Purchase: __________________________________

Dealer Where Purchased: ___________________________________

___________________________________

Woodsplitter Model Number: ________________________________

Woodsplitter Serial Number: ________________________________

Notes

Safety Instructions

Keep hands, feet, and clothing away from engine and all moving

parts.

Never allow your hands, arms, or legs to come between the

cutting edge of the woodsplitter and the moving block pusher.

Children and pets must be kept away from the area of operation

due to possible injury from falling wood or moving woodsplitter

components.

Conrm that all hydraulic lines, ttings, and couplers are tight

and not leaking before starting machine.

Never try to split wood crosswise. The wood may jump out and

cause serious injury.

Always be careful and concentrate fully while the woodsplitter is

in operation.

When towing, always be sure to use the safety chains and to

secure all safety locks.

Before each use, conrm that the woodsplitter is free of damage

and effects of misuse. Failure to keep the woodsplitter in proper

condition may lead to serious injury.

SAFETY

YOU are responsible for the SAFE operation and maintenance of

your Surge-Master Trailer Woodsplitter. YOU must ensure that you

and anyone else who is going to operate, maintain or work around the

Woodsplitter be familiar with the operating and maintenance procedures

and related SAFETY information contained in this manual. This manual

will take you step-by-step through your working day and alerts you to

all good safety practices that should be adhered to while operating the

Woodsplitter.

Remember, YOU are the key to safety. Good safety practices not only

protect you but also the people around you. Make these practices a

working part of your safety program. Be certain that EVERYONE op-

erating this equipment is familiar with the recommended operating and

maintenance procedures and follows all the safety precautions. Most

accidents can be prevented. Do not risk injury or death by ignoring good

safety practices.

• Woodsplitter owners must give operating instructions to operators or

employees before allowing them to operate the machine, and at least

annually.

• The most important safety feature on this equipment is a SAFE op-

erator. It is the operator’s responsibility to read and understand ALL

Safety and Operating instructions in the manual and to follow these.

Most accidents can be avoided.

• A person who has not read and understood all operating and safety

instructions is not qualied to operate the machine. An untrained

operator exposes himself and bystanders to possible serious injury

or death.

• Do not modify the equipment in any way. Unauthorized modication

may impair the function and/or safety and could affect the life of the

equipment.

• Think SAFETY! Work SAFELY!

Although there are no operational restrictions on the Trailer Woodsplitter

when used for the rst time, it is recommended that the following me-

chanical items be checked:

A. After Operating For 1 and 5 Hours:

1. Check all nuts, bolts and other fasteners. Tighten to their speci-

ed torque level.

2. Check hydraulic system for leaks. Tighten all leaking ttings and

replace any leaking components.

3. Check machine uid levels: Fuel, engine oil, and hydraulic oil

reservoir. Top up as required.

4. Check for entangled material. Remove all entangled material

before resuming work.

5. Check tire pressure. Inate as required.

6. Review your engines instruction manual for specic instruc-

tions / requirements

B. After Operating For 10 Hours:

1. Repeat steps 1 through 5 listed above.

2. Go to the normal servicing and maintenance schedule as dened

in the Maintenance Section.

3. Review your engines instruction manual for specic instruc-

tions / requirements

C. After Operating For 20 Hours:

1. Change engine oil: Review your engines instruction manual

for specic instructions / requirements

Hydraulic Oil ll

tube & dipstick

Hydraulic Valve

Control

Before Starting

Before beginning operation of your woodsplitter be sure to read

and understand operating and safety instructions as outlined in the

woodsplitter and engine operator’s manuals.

Starting Operation

For engine starting instructions, see applicable engine operator’s

manual. Before operating the woodsplitter check hydraulic oil level and

check to make sure wedge slide is free from all obstructions and debris.

Never run woodsplitter inside without adequate ventilation as it will

cause carbon monoxide poisoning. Never permit a minor or incompetent

operator to operate machine.

Woodsplitter Operation

When machine is in desired location, set adjustable back leg (2) to

stabilize machine. To operate in horizontal position, simply start engine

and machine is ready to work. The wedge will move the same

direction as the valve lever (1) is pushed. To split a log, push forward

on the lever to extend cylinder and wedge. When log is split, pull lever

back until you feel it lock into the valve detent and it will return and stop

automatically. Woodsplitter can also be used in the vertical position

by releasing spring latch and lifting it to upright position. Always keep

sliding wedge mechanism free of all foreign material.

(A)

Maintenance

Always keep the oil reservoir lled within the at area on the dipstick

(A). Your woodsplitter comes shipped from the factory with Dexron III

transmission uid installed because it easily handles a wide range of

temperatures. Change oil if it becomes discoloured or every 500 hours

of use. The oil lter should be changed at least every 500 hours of

operation. Oil capacity of the reservoir is approximately 13 litres. Keep

wheel bearings well greased.

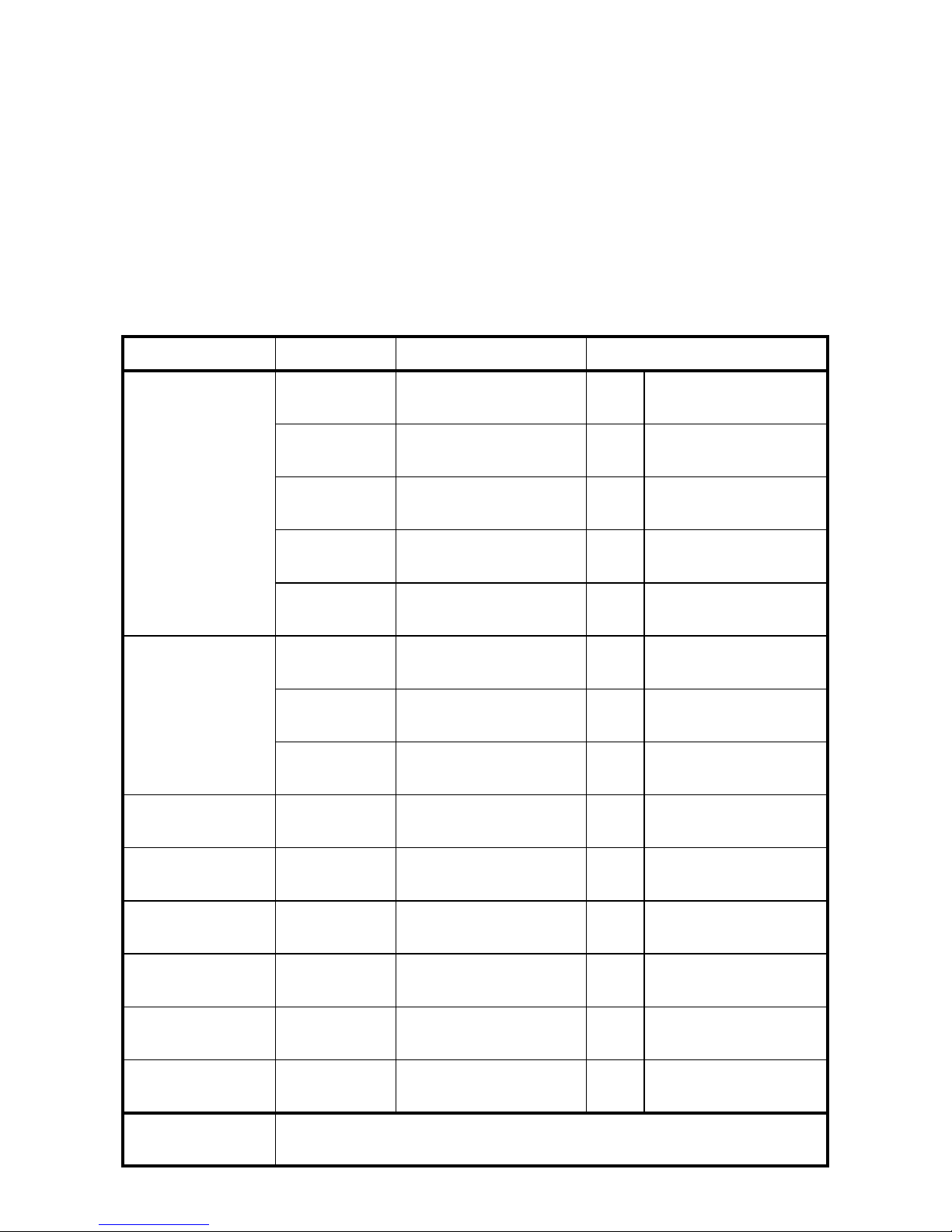

No pressurized

hydraulic oil. Oil filter plugged. Change filter. Ensure machine is off and cooled

down.

No pressurized

hydraulic oil Low hydraulic oil level, top up Ensure machine is off and cooled

down

Wood jammed around

wedge.

Shut machine off and safely remove

wood. Ensure machine is off

Not enough pressure. Call technician, system relief setting

may be low (below 2750 psi).

Ensure machine is off and call

hydraulic technician.

Low engine speed. Check that choke is off, check

throttle is set to maximum.

Detent set too tight.

Call technician, adjustment required

with detent on valve.

Ensure machine is off and call

hydraulic technician.

Hydrualic fluid too

cold. Allow machine to warm up.

Hydrualic fluid is too

old or contaminated. Change hydraulic fluid and filter Ensure machine is off and cooled

down.

CAUTION

Cylinder rod moves slowly or

doesn't move.

Control handle doesn't go to

neutral after rod is fully

retracted.

PROBLEM CAUSE SOLUTION

Control handle goes to

neutral before rod is fully

retracted.

Detent set too loose.

Call technician, adjustment required

with detent on valve.

Ensure machine is off and call

hydraulic technician.

Control handle does't go to

neutral when released.

Control may be

damaged.

Call technician, control may need

service or be replaced.

Ensure machine is off and call

hydraulic technician.

Cylinder stops on contact

with wood.

Second stage on pump

not functioning.

Call technician, pump may need

service or be replaced.

Ensure machine is off and call

hydraulic technician.

Wedge jumps. Wedge frame

jamming. Lubricate wedge frame wear plates. Ensure machine is off.

Leaking hydraulic hose. Hose worn or

damaged. Replace hose. Ensure machine is off and cooled

down.

Leaking cylinder. Seals worn. Call technician, seal replacement

may be required.

Ensure machine is off and call

hydraulic technician.

Engine related issues. Refer to your engine instruction manual for specific trouble shooting instructions / requirements.

TROUBLE SHOOTING

The Surge-Master Trailer Woodsplitter uses hydraulic power to move a

hydraulic cylinder to split wood or logs. It is a simple and reliable system

that requires minimal maintenance.

In the following chart, we have listed many of the problems, causes and

solutions to the problems that you may encounter.

If you encounter a problem that is difcult to solve, even after having

read through this trouble shooting section, please call your local dealer,

distributor or Surge-Master. Before you call, please have this Operator's

Manual and the serial number from your Woodsplitter ready.

Product Specications

Surgemaster Model SL606S 25 Ton Woodsplitter

• Powered by 5.7 hp Subaru EX17 engine

• Two stage hydraulic pump producing 11 gpm ow

• 4.5” bore, 24” stroke cylinder

• 3 position, auto return valve

• 50,000 lb. splitting capacity

• Heavy-duty tubular frame construction

• Splits wood in either horizontal or vertical position

• Comes with 2” ball hitch, safety chains, signal lights, and 4.80 x

8 highway towable wheels

• Measures 80” long, 48’ wide, and 40” high.

• Each unit comes lled with oil and is fully tested at factory before

delivery.

• Optional 4 way Splitter availalble

Table of contents

Other SURGEMASTER Log Splitter manuals

Popular Log Splitter manuals by other brands

DR

DR DUAL-ACTION ELECTRIC Safety & Operating Instructions

The Handy

The Handy THPLS7TE instruction manual

Central Machinery

Central Machinery 62291 Owner's manual & safety instructions

Scheppach

Scheppach Compact 8t Translation of original instruction manual

GÜDE

GÜDE DHH 1250/12 T Translation of the original instructions

MTD

MTD 24BF572B729 Operator's manual

MTD

MTD 630 Series Illustrated parts list

Scheppach

Scheppach HL710 Translation from the original instruction manual

Scheppach

Scheppach Ox 3-1200 instruction manual

MTD

MTD 24632-8 owner's guide

Greyhound

Greyhound GREYHOUND 56072 Set up and operating instructions

Avantco

Avantco A413195 Operator's manual for Attachment