After installation and maintenance activities, observe

the system operation to verify that the fan coil is

operating normally before leaving equipment to operate

unattended.

Only use Surna supplied or recommended equipment

with the Surna wall fan coil.

CAUTION: Care must be taken when handling sheet

metal. Sheet metal parts have sharp edges and could

cause injury.

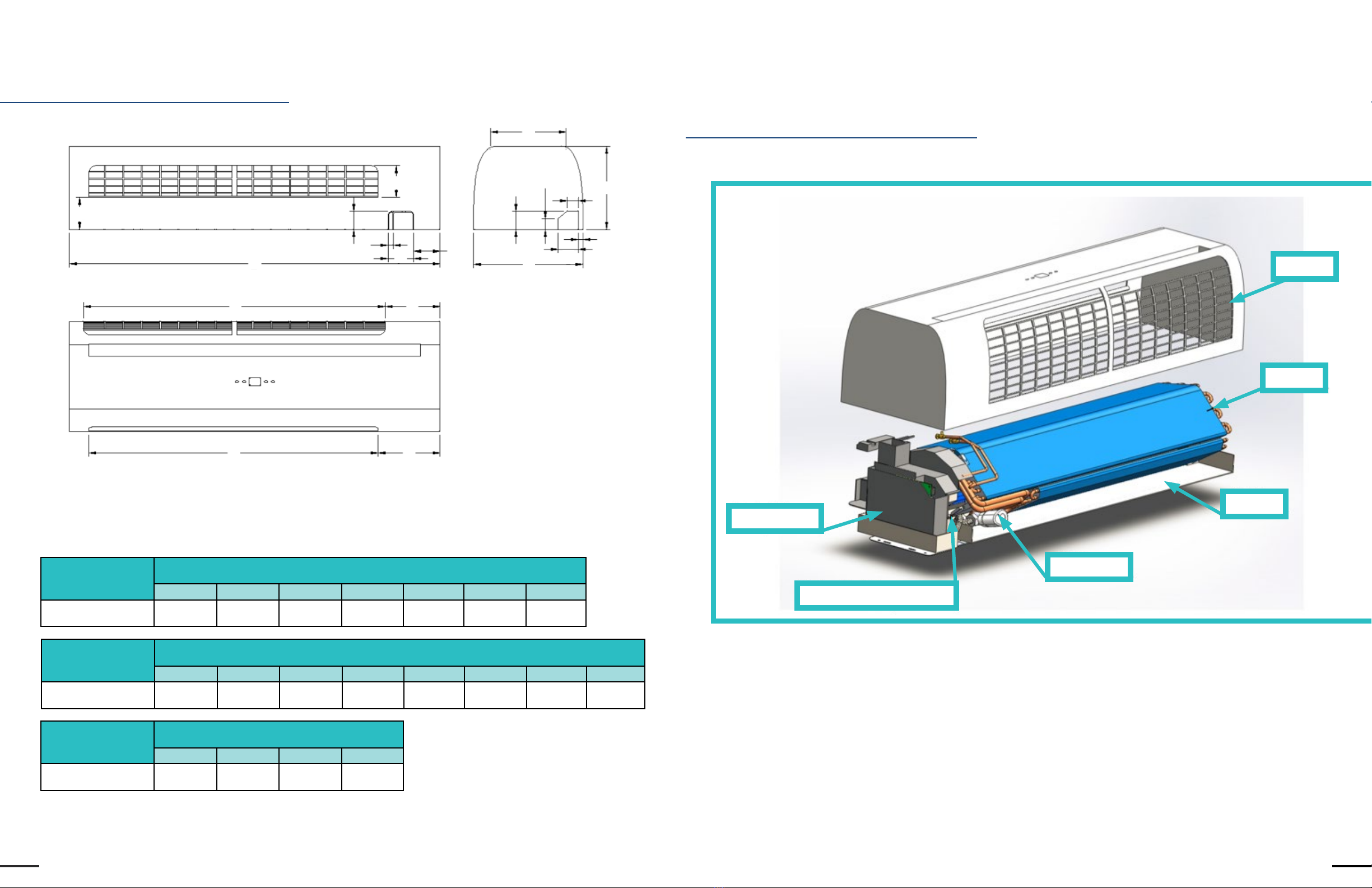

The components of this fan coil have been inspected at

the factory and readied for shipment. Upon receiving the

shipment, a visual inspection of the packaging must be

performed.

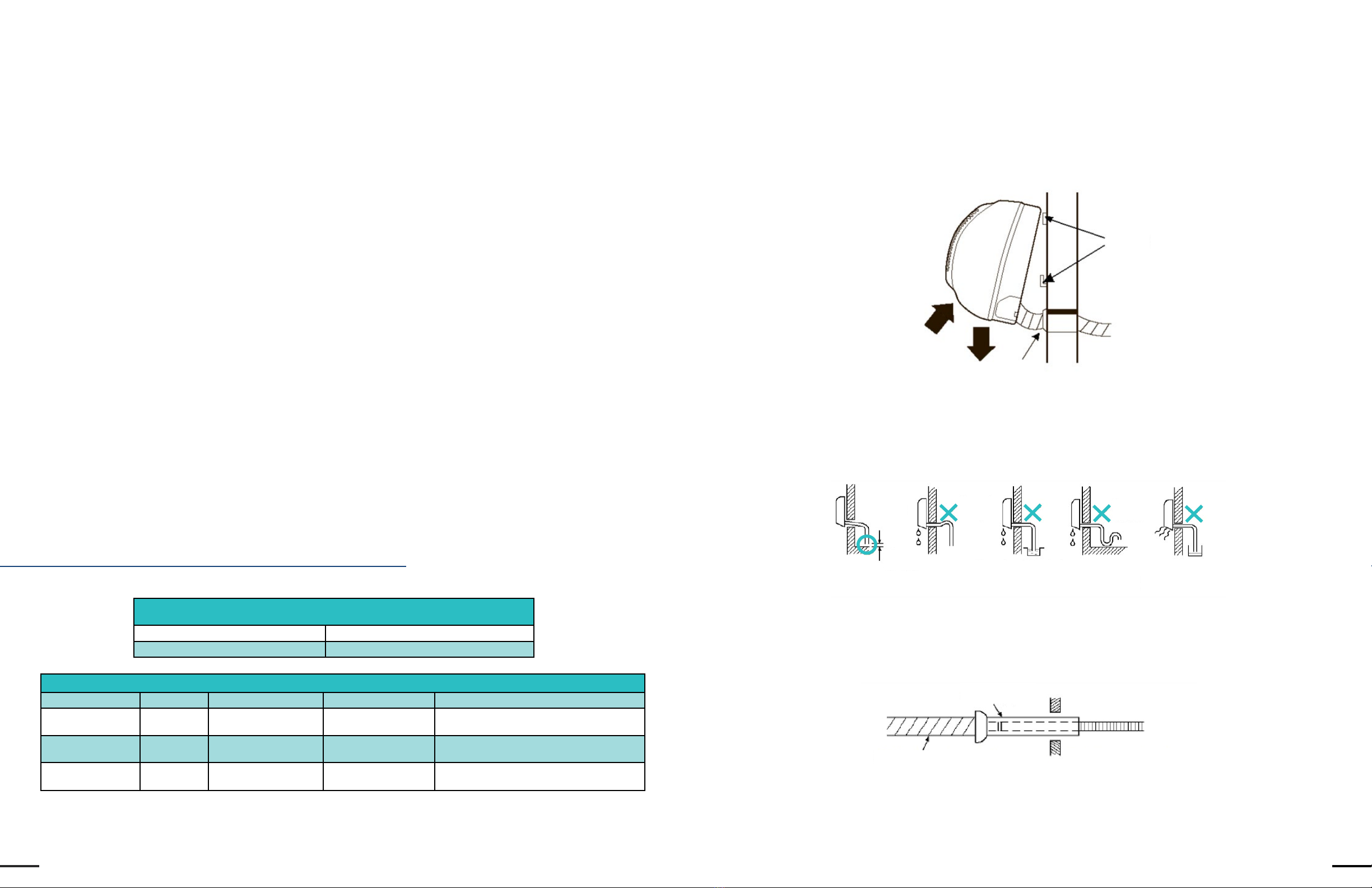

Care must be taken to ensure the structural integrity of

the supporting members when mounting these devices.

Verify that the load bearing capacity of any mounting

surface is rated for the load of the fan coil.

DO NOT use ethylene glycol with this system. Only

propylene glycol is to be used.

Adequate clearance shall be provided around the unit

for regular servicing. After installation, service and

maintenance personnel shall be able to access the power

supply, coil connections and condensate drain.

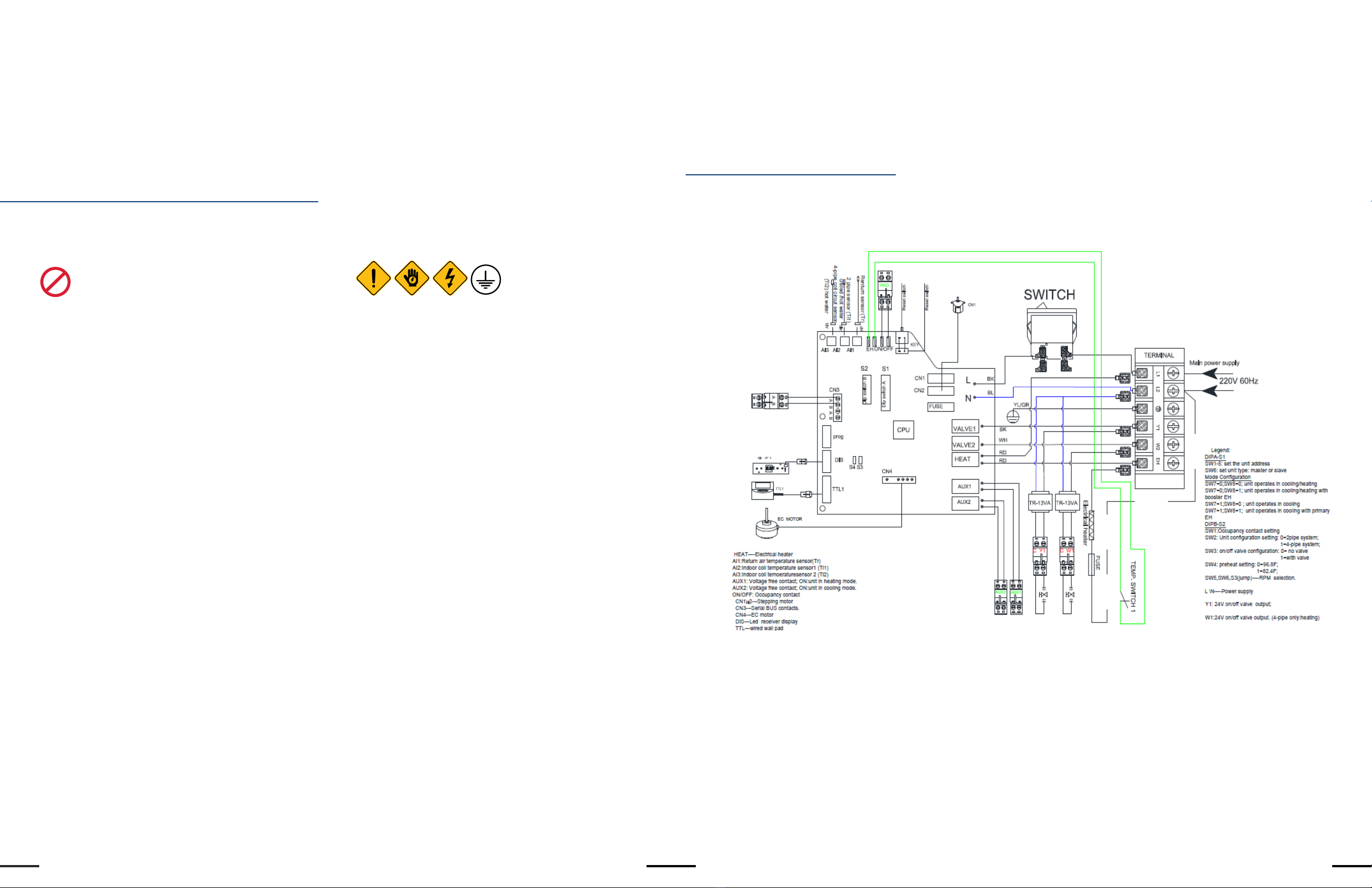

This unit must be connected to a protective earthing

system prior to operation. DO NOT remove the

grounded connection while power is being supplied to

the Surna wall fan coil. Doing so presents an electric

shock hazard to users and service personnel.

Installing and servicing fan coil unit should be performed

by qualified personnel only.

Equipment manufactured by Surna (“Company”), the

warranty shall exist for a period of twelve (12) months from

initial start-up or eighteen (18) months from date of

shipment, whichever period is shorter, against failure due to

defects in material and/or manufacturing and warranted to

the capacities and ratings set forth in Company’s catalogs

and bulletins (“Warranty”).

Equipment, material, and/or parts that are not

manufactured by Company are not warranted by Company

and carry such warranties as may be extended by the

respective manufacturer.

Exclusions from this Warranty include damage or failure

arising from: wear and tear; corrosion, erosion,

deterioration; modifications made by others to the

Equipment; repairs or alterations by a party other than

Company that adversely aect the stability or reliability of

the Equipment; vandalism; neglect; accident; adverse

weather or environmental conditions; abuse or improper

use; improper installation; commissioning by a party other

than Company; unusual physical, electrical or mechanical

stress; lack of proper startup or maintenance as

recommended by Company; operation with any accessory,

equipment or part not specifically approved by Company.

Company shall not be obligated to pay for the cost of lost

product or any other direct, indirect, or consequential

damages. Company’s obligations and liabilities under this

Warranty are limited to furnishing replacement equipment

or parts, at its option, FCA (Incoterms 2000) factory or

warehouse (f.o.b. factory or warehouse for US domestic

purposes) at Company-designated shipping point, freight

allowed to Company’s warranty agent’s stock location, for

all non-conforming Company manufactured Equipment

which have been returned by Customer to Company.

Returns must have prior written approval by Company and

are subject to restocking and replacement charges where

applicable.

No warranty liability whatsoever shall attach to Company

until Customer’s complete order has been paid for in full

and Company’s liability under this Warranty shall be limited

to the purchase price of the Equipment shown to be

defective.

Additional warranty and service protection is available on

an extra-cost basis and must be in writing and agreed to by

an authorized signatory of the Company.

The warranty excludes: (a) labor, transportation and related

costs incurred by the Dealer or Customer; (b) re-installation

costs of repaired equipment; (c) re-installation costs of

replacement equipment; (d) removal costs of equipment; (e)

consequential damages of any kind; and, (f) reimbursement

for loss caused by interruption of service.

EQUIPMENT MANUFACTURED BY COMPANY THAT

INCLUDES A REQUIRED START-UP AND SOLD IN NORTH

AMERICA WILL NOT BE WARRANTED BY COMPANY

UNLESS COMPANY OR ITS AUTHORIZED AGENT

PERFORMS THE EQUIPMENT STARTUP.

COMPANY MAKES NO REPRESENTATION OR

WARRANTY, EXPRESS OR IMPLIED, REGARDING

PREVENTION OF MOLD/MOULD, FUNGUS, BACTERIA,

MICROBIAL GROWTH, OR ANY OTHER CONTAMINATES.

EXCEPT FOR COMPANY’S WARRANTY EXPRESSLY SET

FORTH HEREIN, COMPANY DOES NOT MAKE, AND

HEREBY EXPRESSLY DISCLAIMS, ANY WARRANTIES,

EXPRESS OR IMPLIED CONCERNING ITS PRODUCTS,

EQUIPMENT OR SERVICES, INCLUDING, WITHOUT

LIMITATION, ANY WARRANTY OF DESIGN,

MERCHANTABILITY OR OF FITNESS FOR A PARTICULAR

PURPOSE, OR OTHERS THAT ARE ALLEGED TO ARISE

FROM COURSE OF DEALING OR TRADE.

WARRANTY

INFORMATION

1312