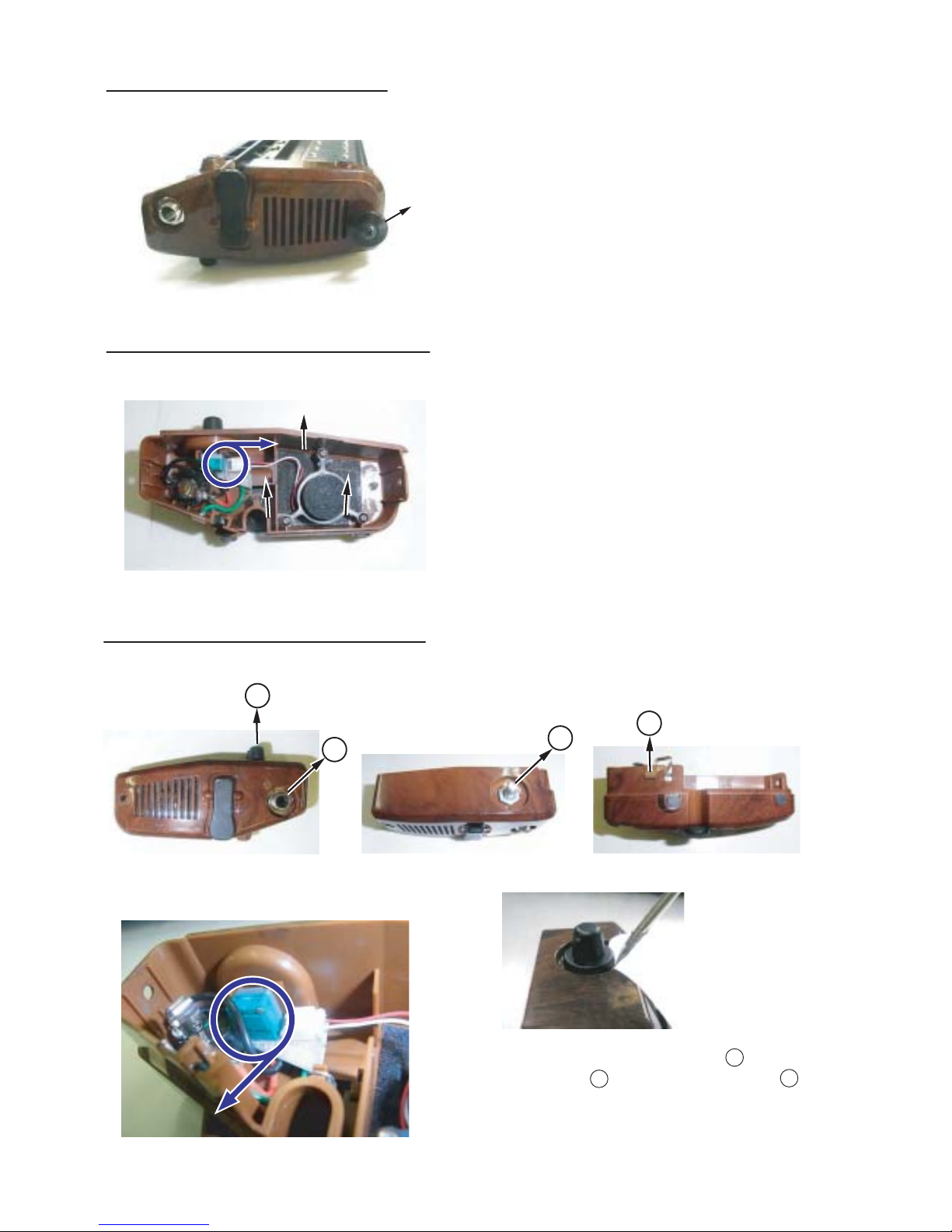

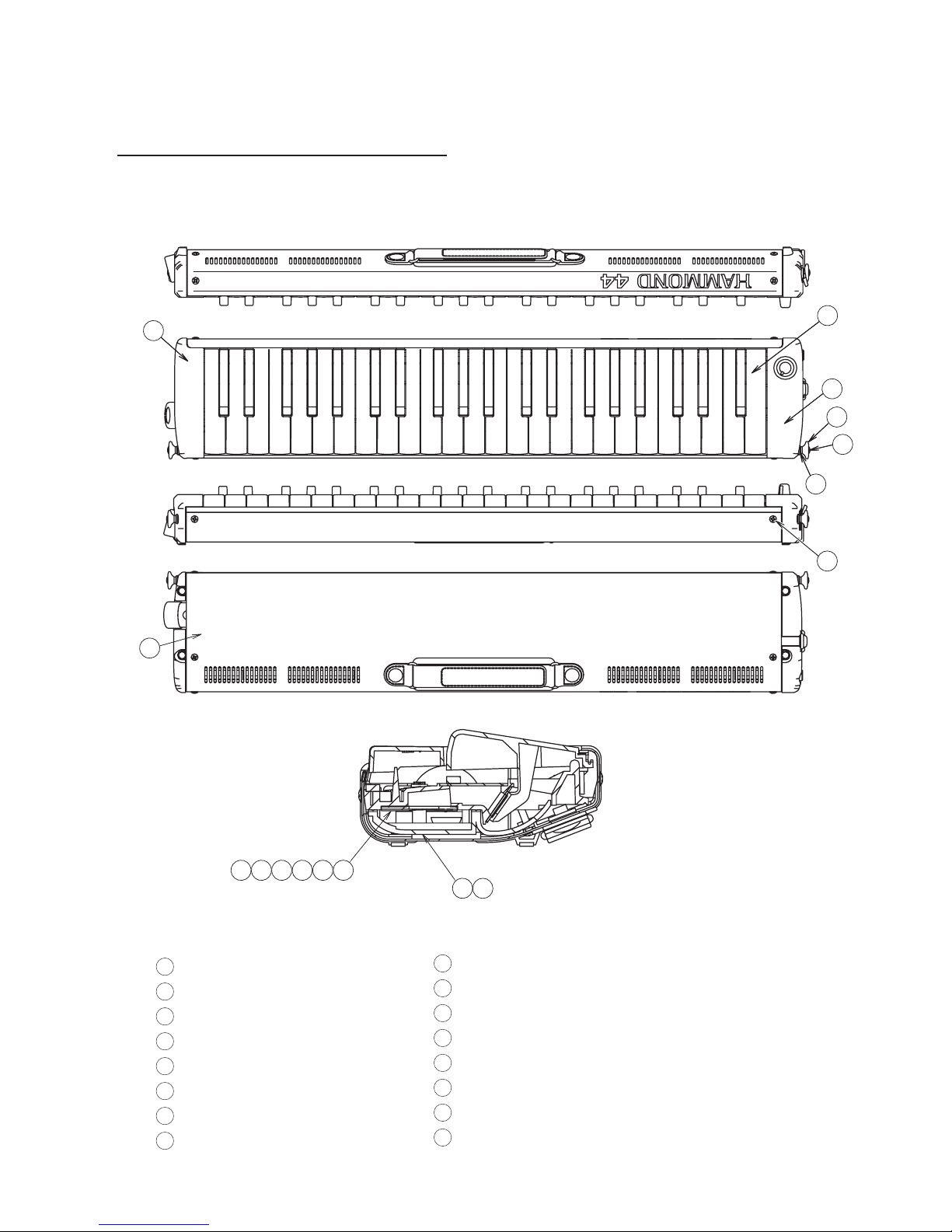

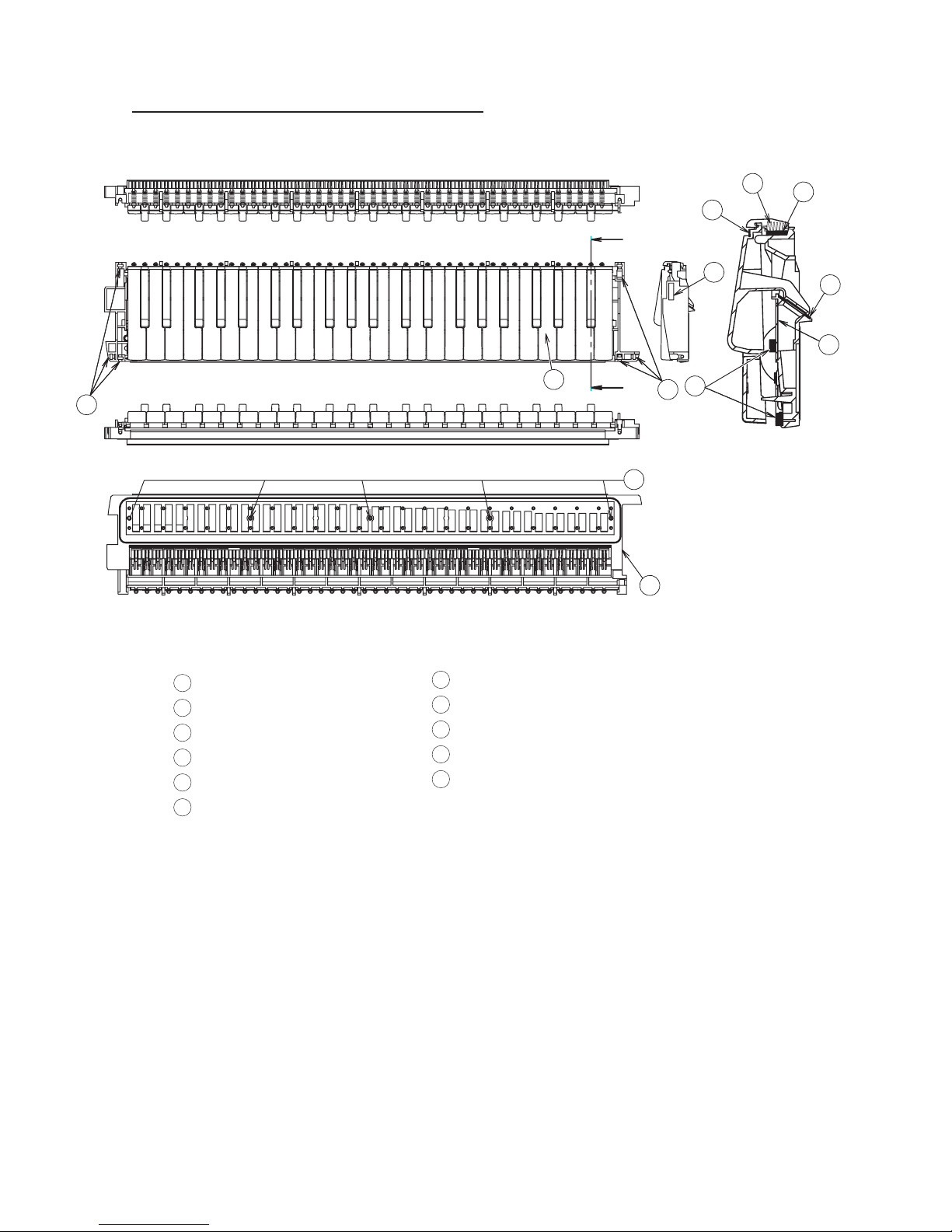

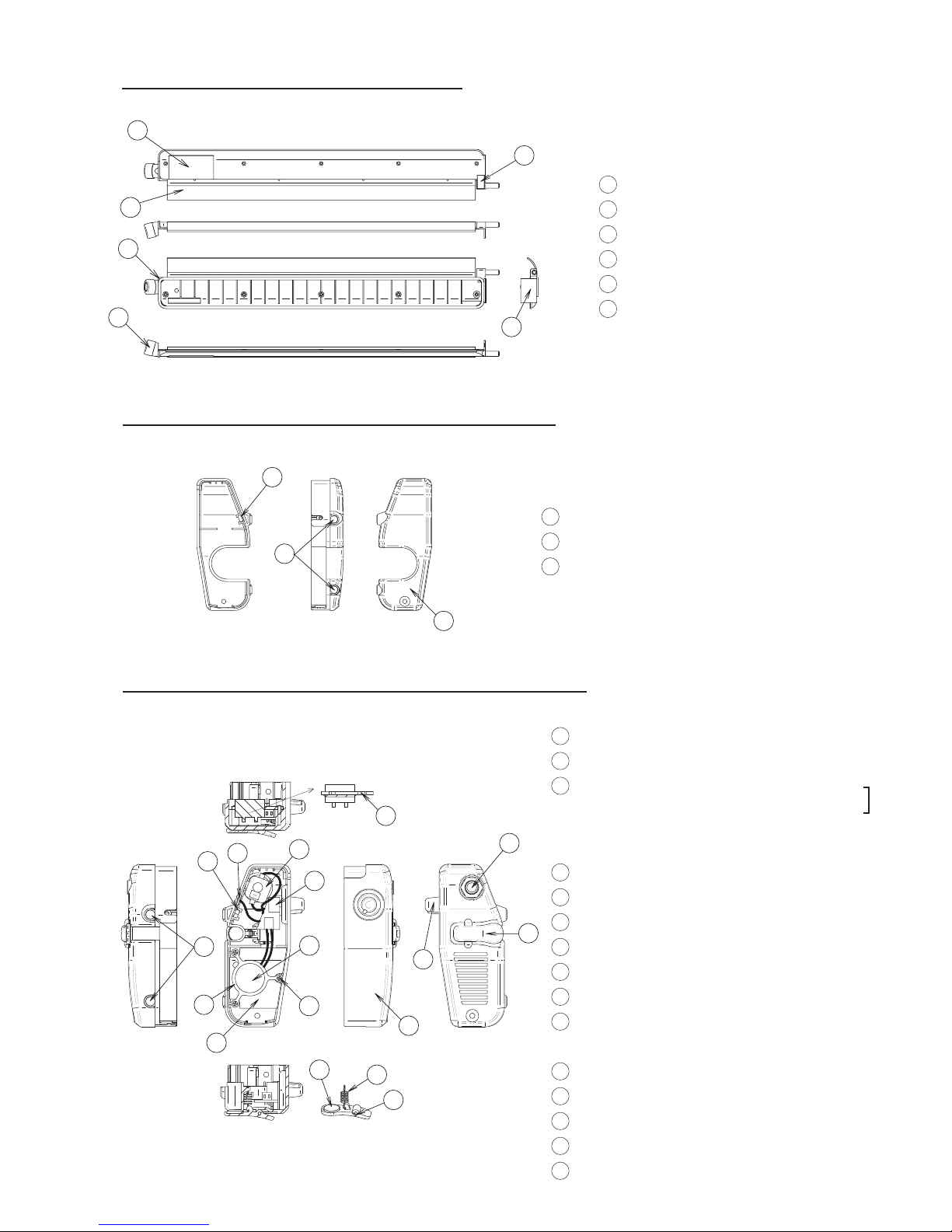

2.INSPECTION SPECIFICATION

0. Required Equipment

0-1 Mixer and Headphone (You need a equipment which you can listen to the

microphone sound with a headphone)

or

Amplifier (which produces the bigger sound than live sound, and also the

microphone level is available)

1. Sound Inspection

1-1 Insert a mouthpiece into Hammond 44.

1-2 Insert the plug into Hammond 44’s jack output and connect to the above equipment

(0-1) at input terminal.

1-3 Turn Hammond 44’s volume to max.

1-4 Blow kind of strongly without pressing any key and make sure there is no air

leakage.

1-5 Check each key from bass to treble with kind of strong and stable blow.

Is there hollow sound?

Is there strange sound?

Check if the volume is too small by each key, or if overtone is unstable by each key.

2. Key sound Inspection

2-1 Hold a mouthpiece in your mouth without blowing, and press each key from bass

to treble. Check if there is any unexpected sound or clang.

3. Reed Inspection

3-1 Hold blowing kind of strongly and fillip strongly each key from bass to treble.

Check if there is any clink besides overtone.

3-2 In case you find a wrong key, check that key and next key alternately with blowing

gently. If there is no clink besides overtone, it is OK.

4. Tuning Inspection

4-1 Play in octave unison from bass to treble, and check if undulation is not too fast.

2-1