2

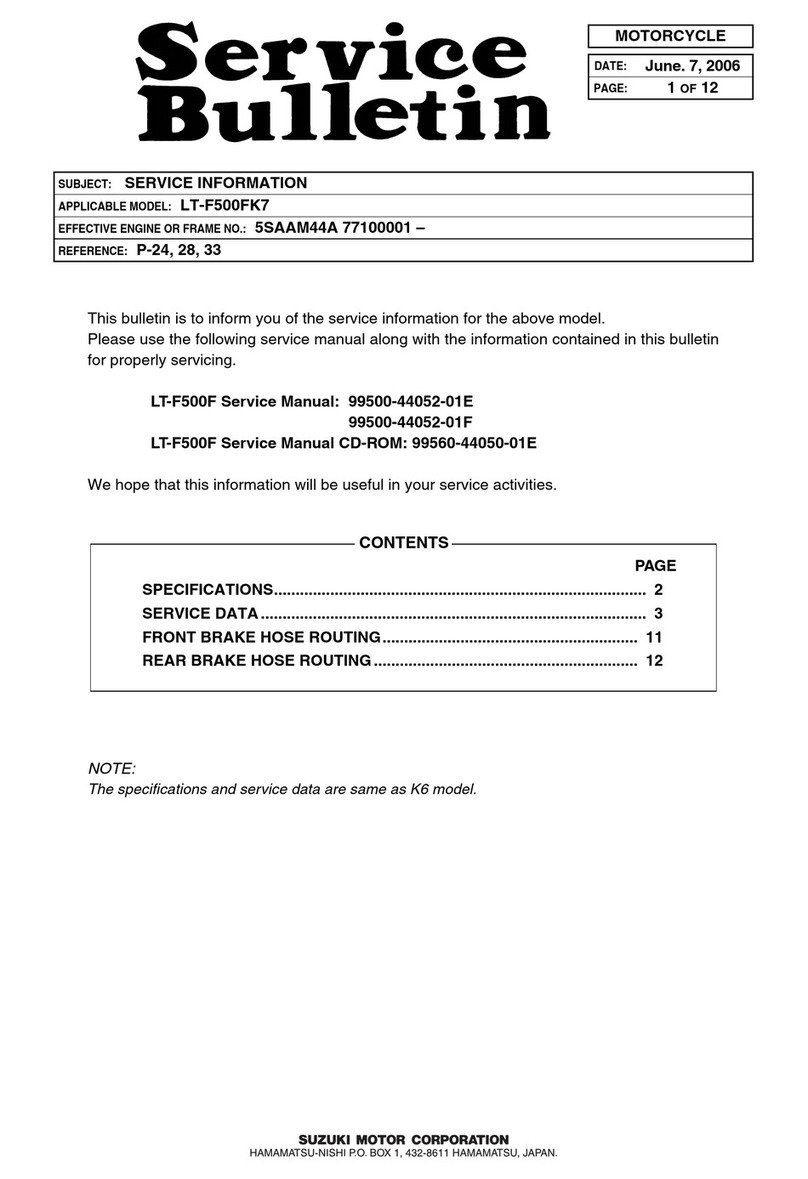

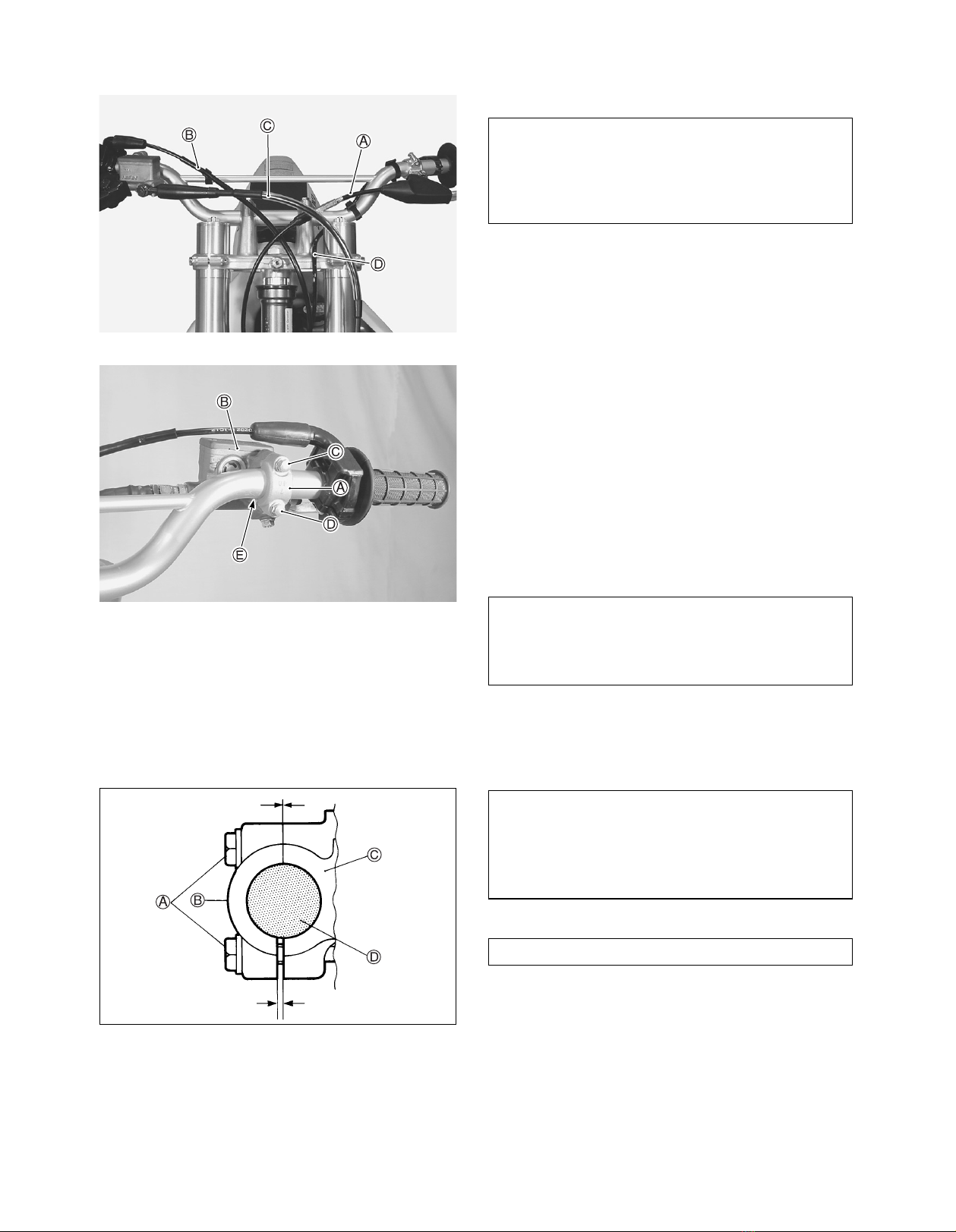

Parts listed above are installed respectively into the positions as follows.

Item Part Name Q’ty Remarks

A

Number plate 1

Flange bolt 1 6 × 20 mm

Washer 1 OD:14.0 ID:6.5

B Radiator louver 1

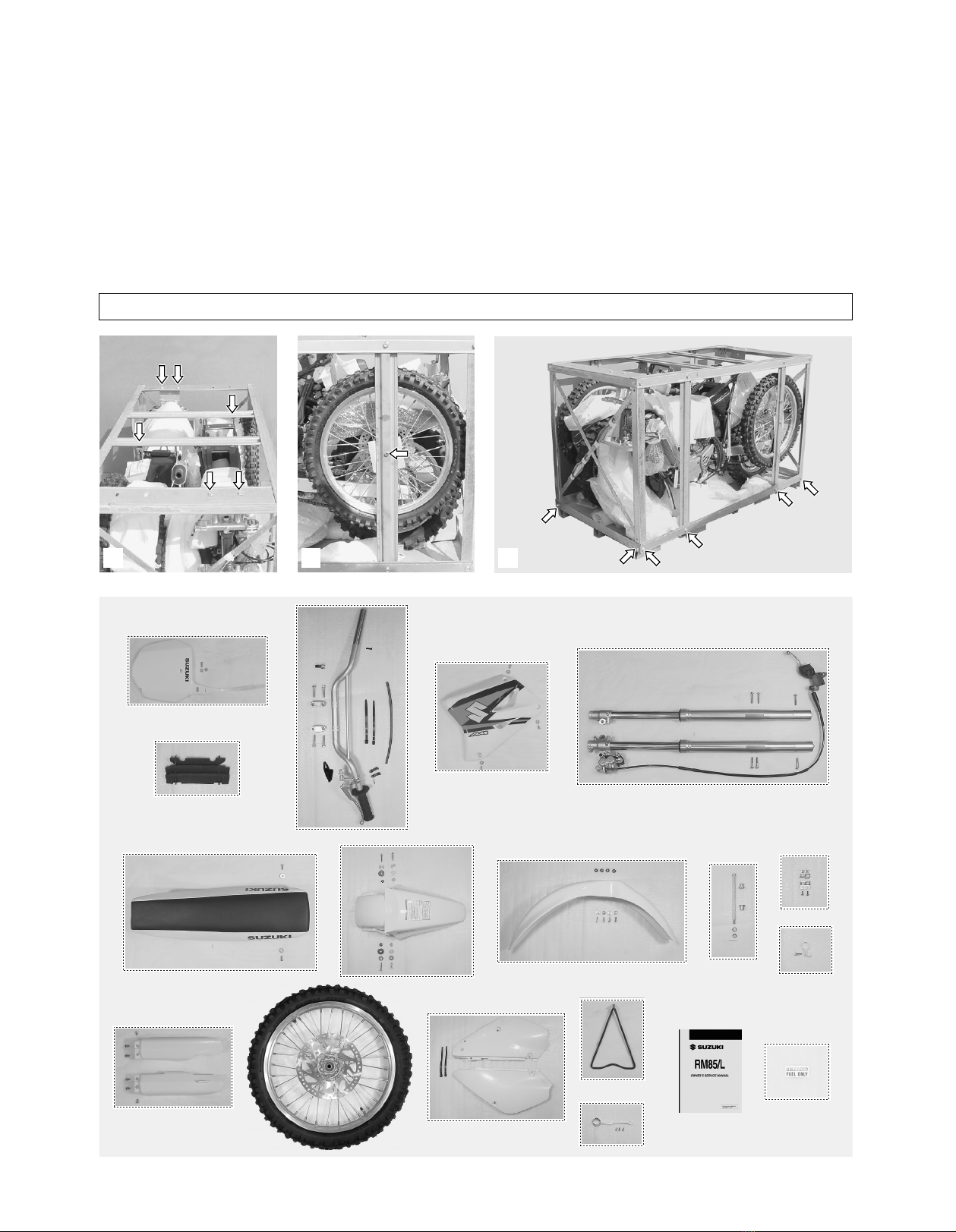

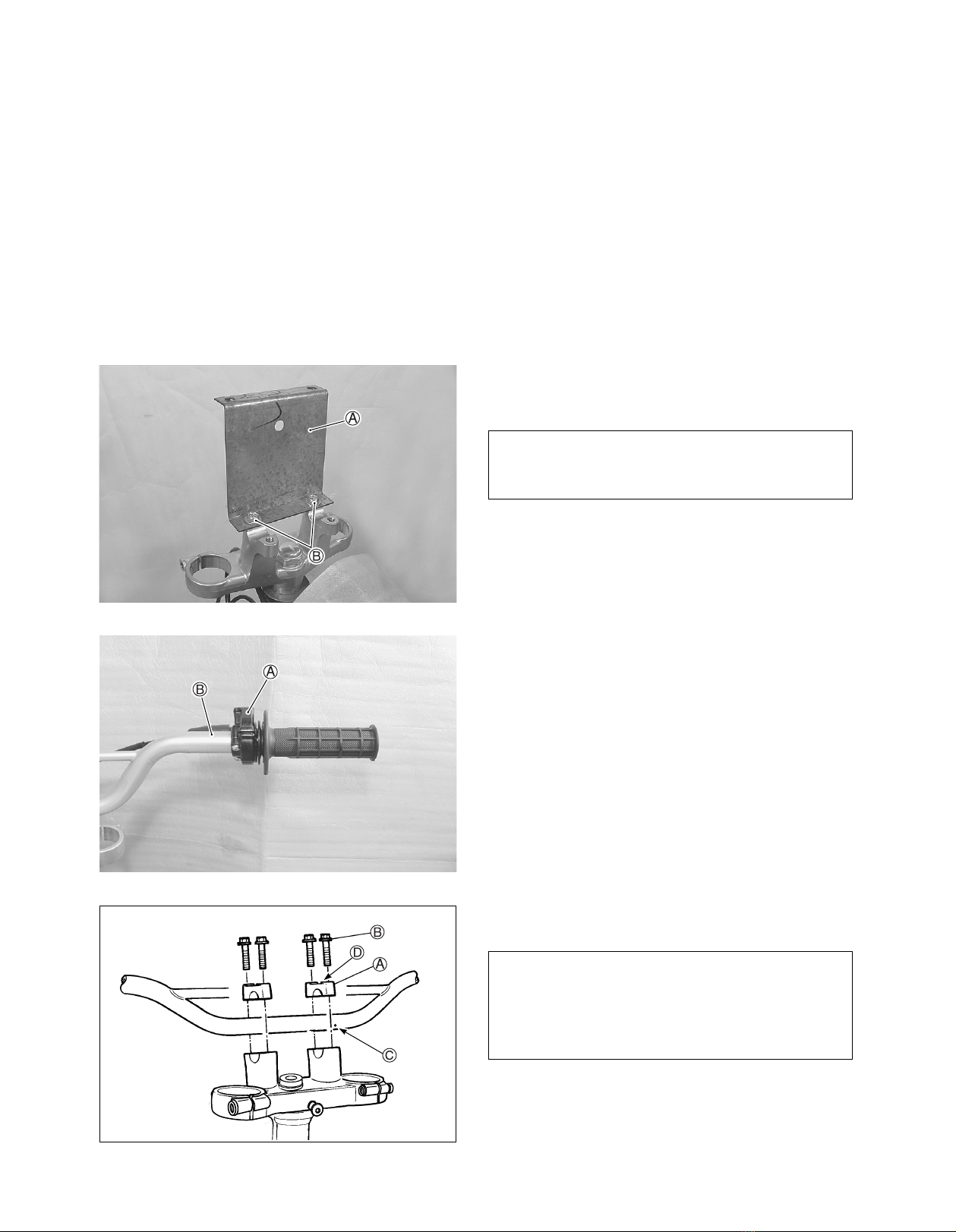

C

Handlebars assembly 1

Clamp 2

Flange bolt 4 8 × 35 mm

Clutch lever cover 1

Fuel tank vent hose 1

Screw 1 5 × 16 mm

For throttle assembly

Clamp 1 For throttle cable

Strap 2 L:120

Engine stop switch holder 2 Upper and lower

Screw (with lock washer) 1 3 × 14 mm

D

Radiator cover 1

Flange bolt 3 6 × 12 mm

Stepped washer 3 OD:16.0 ID:6.5 T:3.5

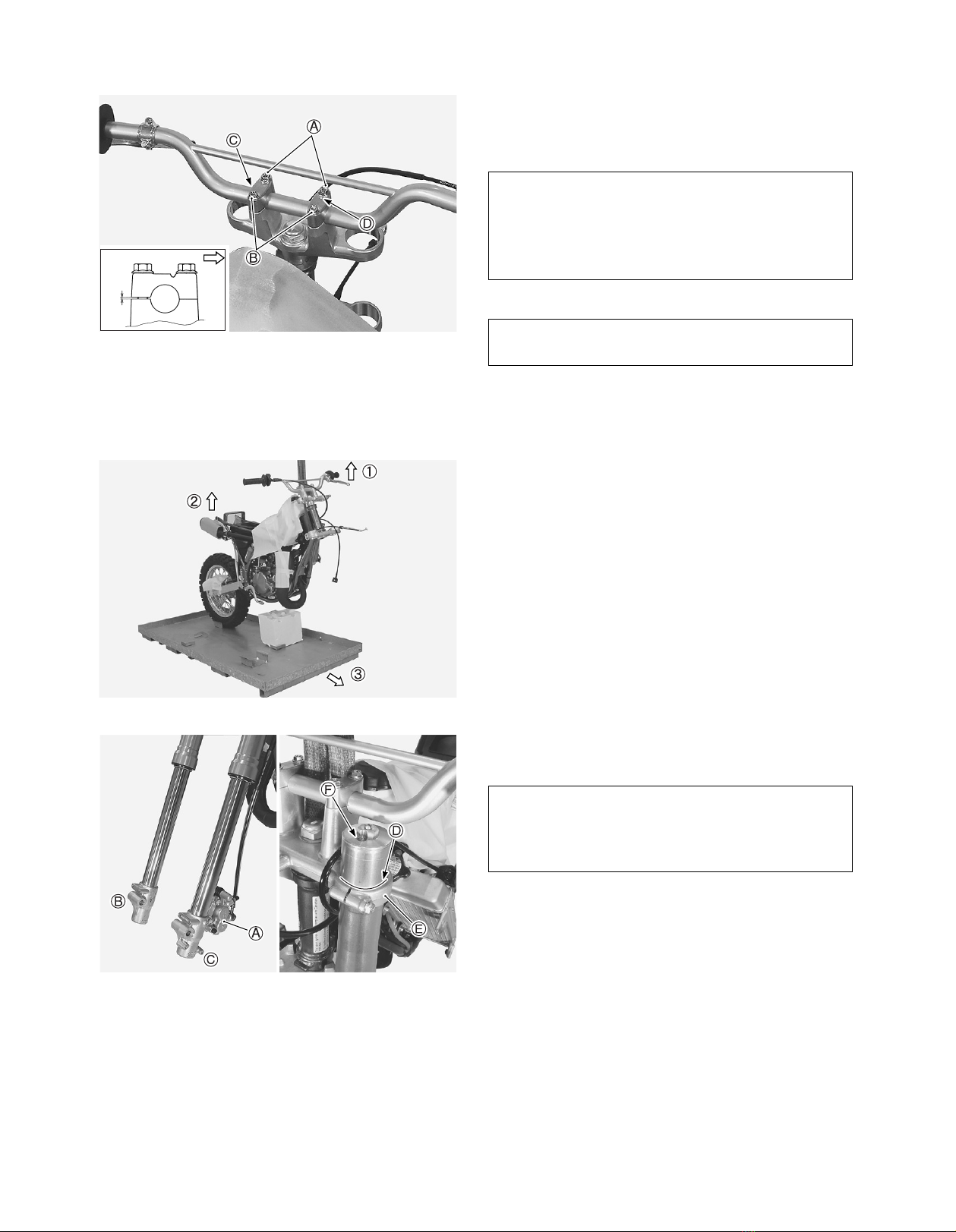

EFront fork assembly 2 Right and Left

Flange bolt 6 8 × 40 mm

F

Seat assembly 1

Flange bolt 2 6 × 16 mm

Washer 2 OD:20.0 ID:6.5 T:1.6

G

Rear fender 1

Washer 2 OD:26.0 ID:6.5

Flange bolt 3 6 × 30 mm

Washer 4 OD:20.0 ID:6.5 T:1.2

Self-lock nut 2 6 mm

Flange bolt 1 6 × 20 mm

Washer 2 OD:18.0 ID:6.5 T:1.6

Flange self-lock nut 2 6 mm (Black)

Item Part Name Q’ty Remarks

H

Front fender 1

Flange bolt 4 6 × 20 mm

Stepped washer 4 OD:16.0 ID:6.5 T:3.5

Stepped washer 4 OD:17.0 ID:6.5 T:7.0

I

Front axle 1

Front wheel spacer 2

Washer 1 OD:20.0 ID:12.5

Axle nut 1 12 mm

Cotter pin 1 L:27.0

JFront brake hose clip 2 Inner and Outer

Flange bolt 2 6 × 16 mm

KFront brake hose guide 1

Flange bolt 1 6 × 20 mm

LFront fork protector 2 Right and Left

Flange bolt 6 6 × 10 mm

M Front wheel assembly 1

NFrame cover 2 Right and Left

Strap 2 L:140

OStand 1

P

Main jet 3 Exchanging parts

Spark plug and spoke

nipple wrench 1

Q Owner’s manual 1

R Fuel label 1 For limited market

OD : Outside diameter (mm)

ID : Inside diameter (mm)

L : Length (mm)

T : Thickness (mm)

TL

OD ID

NOTE:

The parts shown as Item R in the above table are supplied for limited markets.

N

EL

I

A C

ID

RFGKEHL

BJMO

N