6Series 8HPH Weld Head User’s Manual

Installing the Weld Head

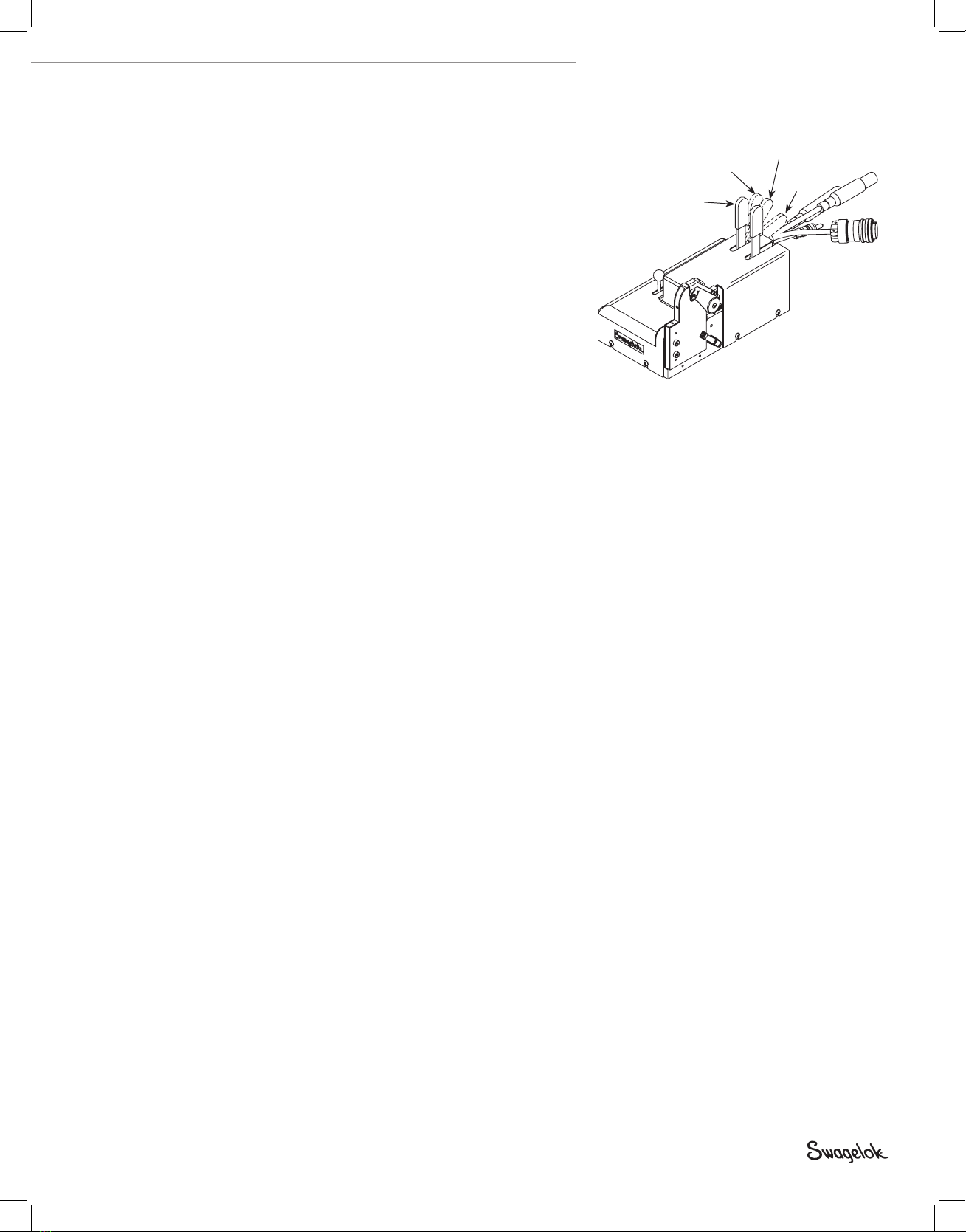

Connecting the Extension Cable to the Weld Head

The four connectors on the cable are:

• threaded multi-pin connector

• electrode (red)

• work (green)

• weld head shielding gas

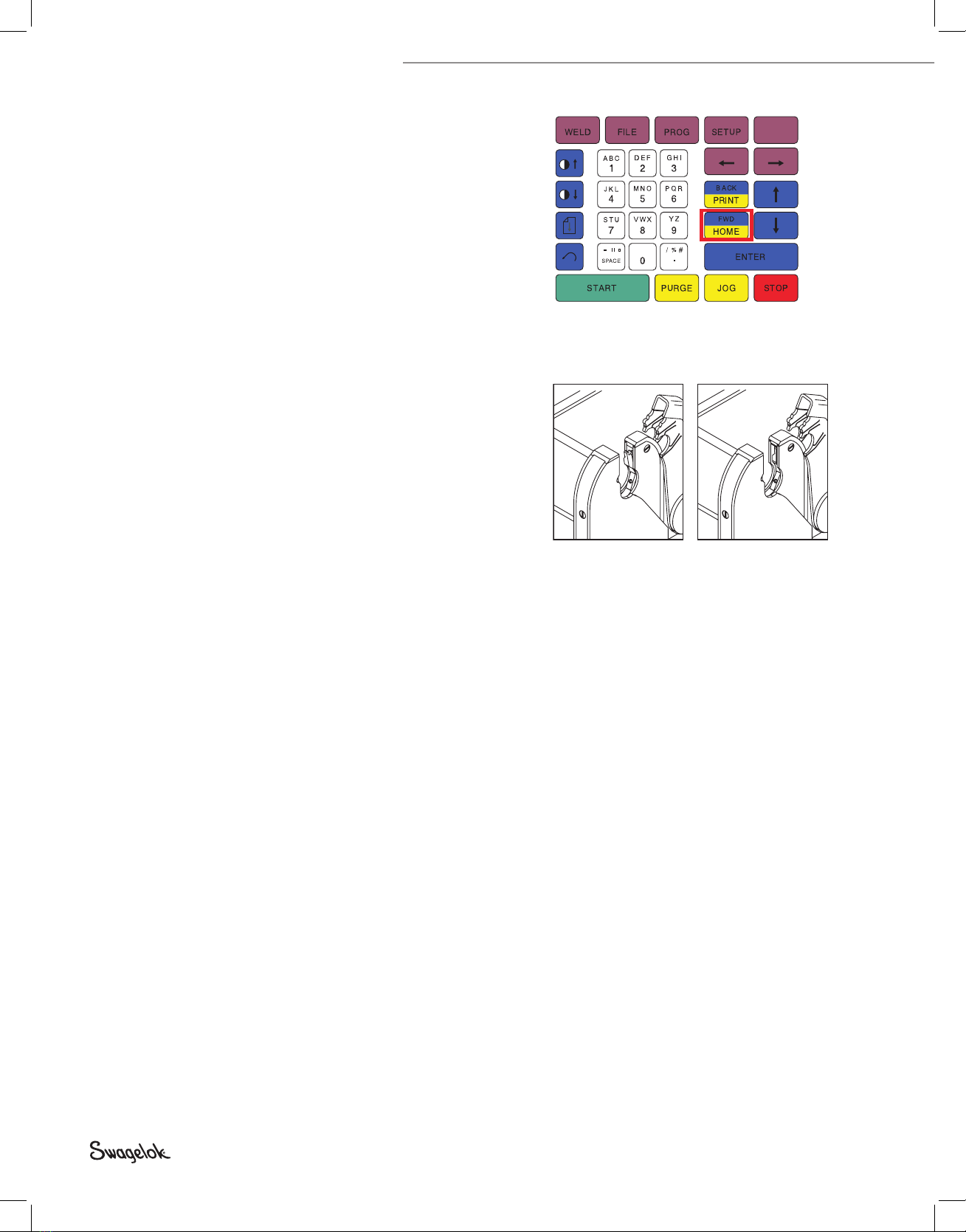

1. Align the notch on the threaded multi-pin connector of the weld

head cable with the small tab in the mating socket of the extension

cable. Insert the threaded connector and screw on the weld head

cable by turning clockwise until it is tight.

2. Align the arrow on the female socket of the weld head electrode

cable (red) with the arrow on the male connector (red) of the

extension cable. With the arrows aligned, insert and fully seat the

red male connector of the extension cable into the red female

socket of the weld head cable. Twist the connector one-quarter

turn clockwise to lock into place.

3. Align the arrow on the male connector of the weld head work

cable (green) with the arrow on the female socket (green) of the

extension cable. With the arrows aligned, insert and fully seat the

green male connector of the weld head cable into the green female

socket of the extension cable. Twist the connector one-quarter

turn clockwise to lock into place.

4. Insert the male shielding gas connector of the weld head cable into

the female Swagelok quick-connect body of the extension cable.

Align bodies and stems when coupling or uncoupling.

Figure 5 Connecting the Weld Head

to the Extension Cable

Caution!

Do not rotate quick-connects while

coupled. Do not insert foreign

object into uncoupled bodies or

stems.

Figure 6 Connecting the Weld Head to the

Extension Cable

13-170.indb 6 2/1/13 1:45 PM