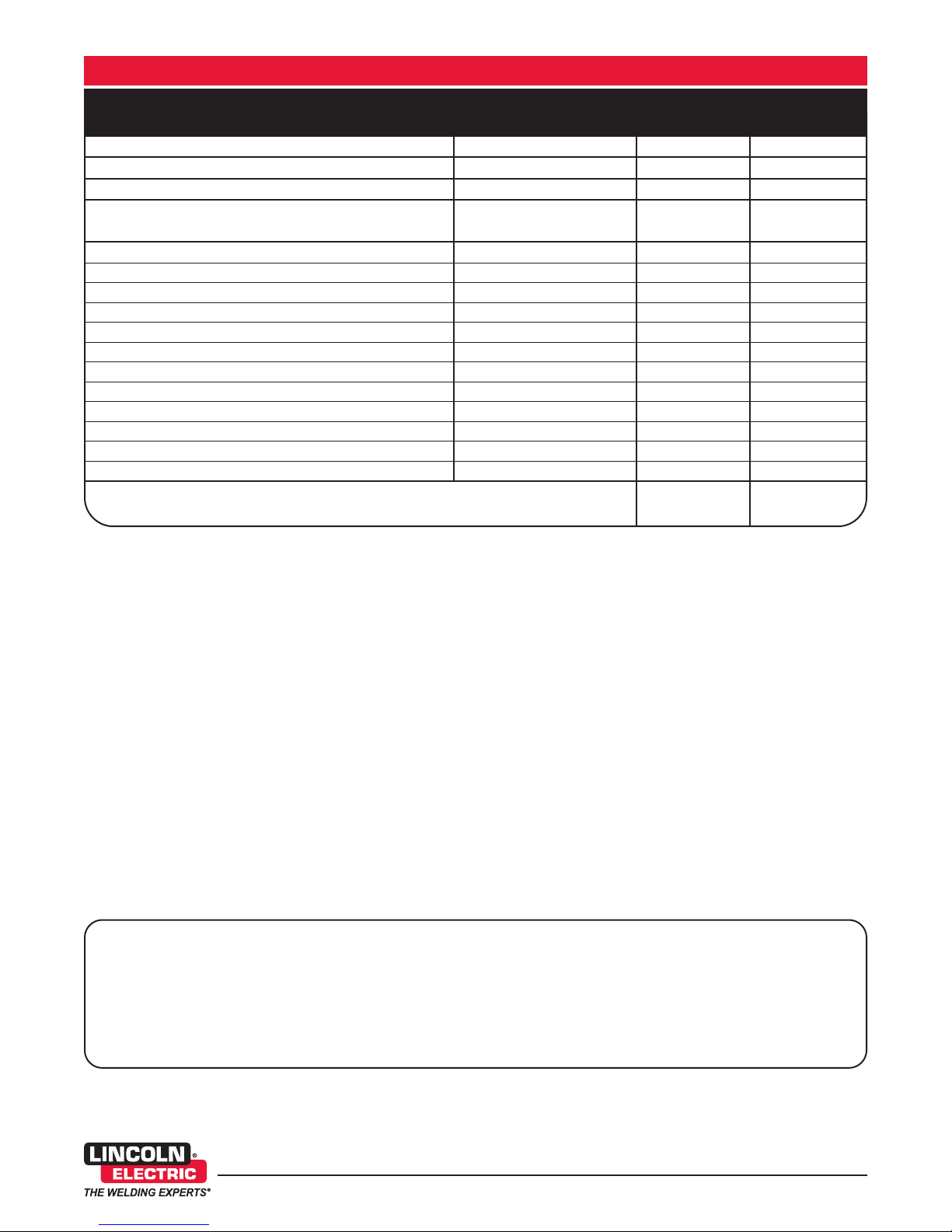

Lincoln Electric POWER MIG 255XT User manual

Other Lincoln Electric Welding System manuals

Lincoln Electric

Lincoln Electric INVERTEC 160 TPX User manual

Lincoln Electric

Lincoln Electric INVERTEC V145-S User manual

Lincoln Electric

Lincoln Electric POWER-ARC 4000 User manual

Lincoln Electric

Lincoln Electric RED-D-ARC FX450 User manual

Lincoln Electric

Lincoln Electric SQUARE WAVE TIG 275 IM609-B User manual

Lincoln Electric

Lincoln Electric RANGER 275 User manual

Lincoln Electric

Lincoln Electric IDEALARC CV 505 User manual

Lincoln Electric

Lincoln Electric FLEXTEC 500 P User manual

Lincoln Electric

Lincoln Electric POWER MIG 215 MPi User manual

Lincoln Electric

Lincoln Electric POWERTEC i380C ADVANCED User manual

Lincoln Electric

Lincoln Electric REDI-MIG Plus 215C User manual

Lincoln Electric

Lincoln Electric 10993 User manual

Lincoln Electric

Lincoln Electric LN -15 WIRE FEEDER IM823-A User manual

Lincoln Electric

Lincoln Electric WELDMARK 135 PLUS IM789 User manual

Lincoln Electric

Lincoln Electric CITOTIG 200 AC/DC User manual

Lincoln Electric

Lincoln Electric POWER MIG SVM167-A User manual

Lincoln Electric

Lincoln Electric CLASSIC 11572 User manual

Lincoln Electric

Lincoln Electric POWER WAVE IM716 User manual

Lincoln Electric

Lincoln Electric Harris 62-E User manual

Lincoln Electric

Lincoln Electric FLEXCUT 125 CE Mounting instructions