2Need help? Give us a call on 0330 026 6273 and speak to one of our trained advisors.

Important Safety Informaon

Need help? Give us a call on 0330 0267 658 and speak to one of our trained advisors.

Please read these instrucons thoroughly and retain for future use.

All products supplied by Swan are safe provided they are installed, used correctly and receive regular maintenance in accordance with these

instrucons. If you are in any doubt about your ability to install this product safely you must employ the services of an experienced qualied

plumber.

Remove all packaging and check the components for damage before starng installaon. Before starng any installaon please consider the

following:

Prior to drilling into walls, check that there are no hidden electrical wires, cables or water supply pipes. This can be checked with the aid of an

electronic detector.

If power tools are used do not forget to:

- Wear eye protecon

- Unplug equipment aer use

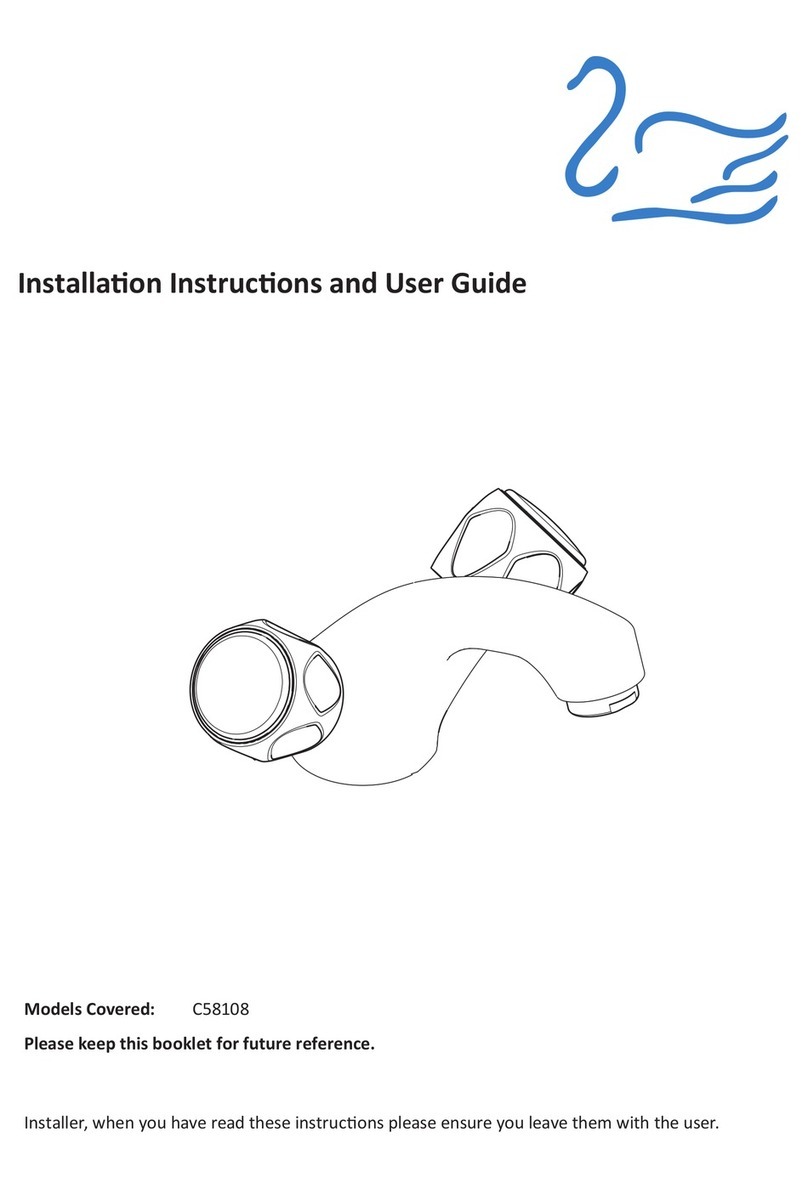

1. Idenfy all components before ng.

- 1 x Tap Body

- 2 x Rubber Washers

- 2 x Fixing Nuts

- 1 x Tap Base Washer

- 1 x Hose

- 1 x Handset

- 1 x Bracket

- 1 x Bracket Fixings

2. Fit the tap to the bath using xing

nuts supplied. The rubber washer

goes between the xing nut and the

underside of the bath.

3. Connect the hot and cold supplies.

4. Fit the bracket using the xings

supplied.

5. Connect the hose to the tap body and

handset.

6. Fully open both valves, leng them

run for a few minutes to ush out

the system. Check all joints and

connecons for leaks.

Working Pressure Range: Min 0.2 bar, Max 5.0 bar

Maximum Stac Pressure: 10 bar

BS 6700 recommends the temperature of stored water

should never exceed 65°C. A stored water temperature of

60°C is considered sucient to meet all

requirements and will minimise the build up of limescale

in hard water areas.

Specicaons

Installaon Steps

This product needs to be installed in accordance with, and meet the

requirements of the Water Supply (Water Fings) Regulaons 1999

and current byelaws. For full Installaon Requirements & Notes

(IRN) please visit www.wras.co.uk/directory.

Isolaon valves must be ed to the inlet water supplies to ensure

ease of future maintenance. Full access must be made available for

future maintenance/servicing purposes. Before installing this

product the water supply must be thoroughly ushed in order

to remove any swarf, solder etc.

This product must not be modied in any way as this will

invalidate the guarantee.

If in doubt, contact a registered plumber or your Local Water

Authority or the Secretary of the Instute of Plumbing,

address as follows:-

The Instute of Plumbing,

64 Staon Lane,

Hornchurch,

Essex,

RM12 6NB, Tel: 01708 472791

Installaon

Tap Body

Tap Base

Washer

Rubber

Washer

Fixing Nut

Hose

Handset Bracket

Bracket

Fixings