5

<400mm

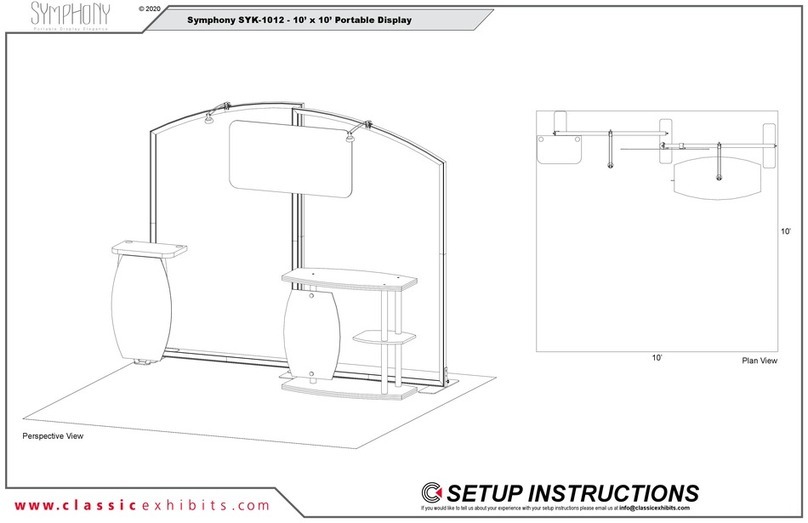

Setting Out

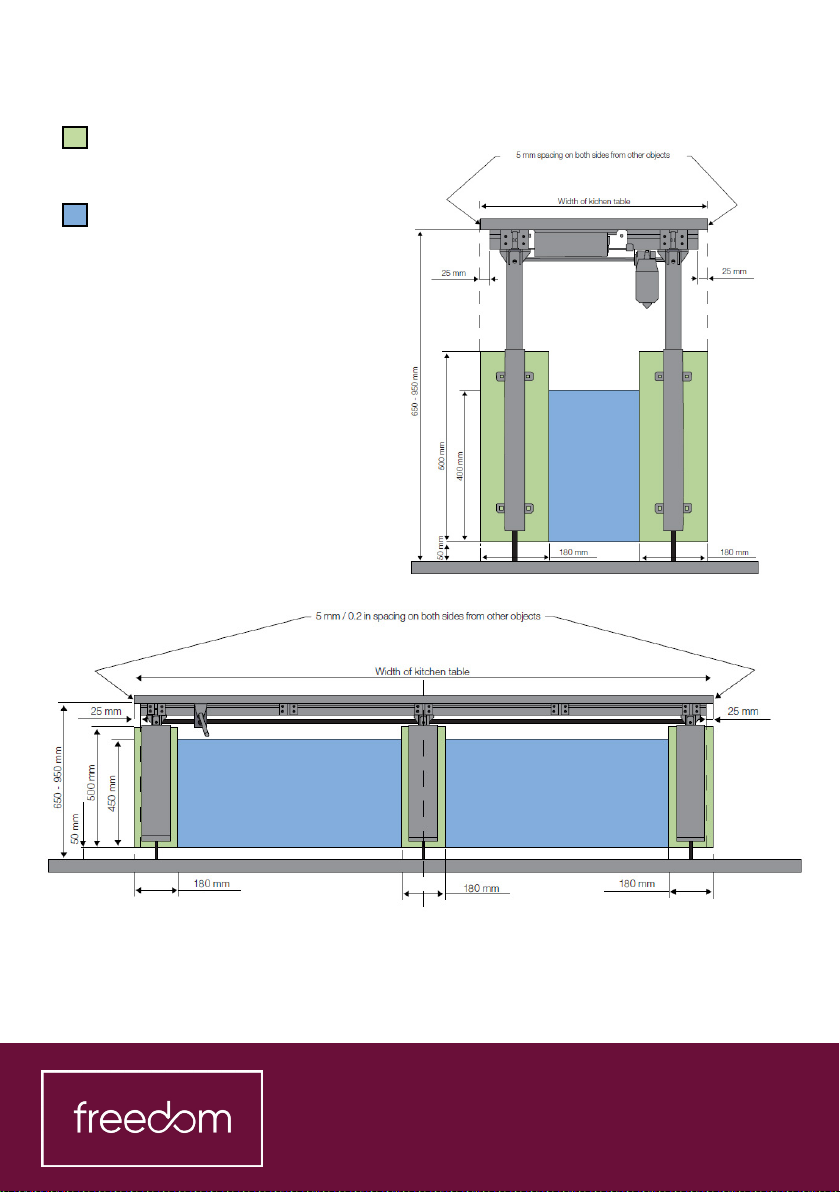

Start with the sink and hob worktop area when setting out and fitting.

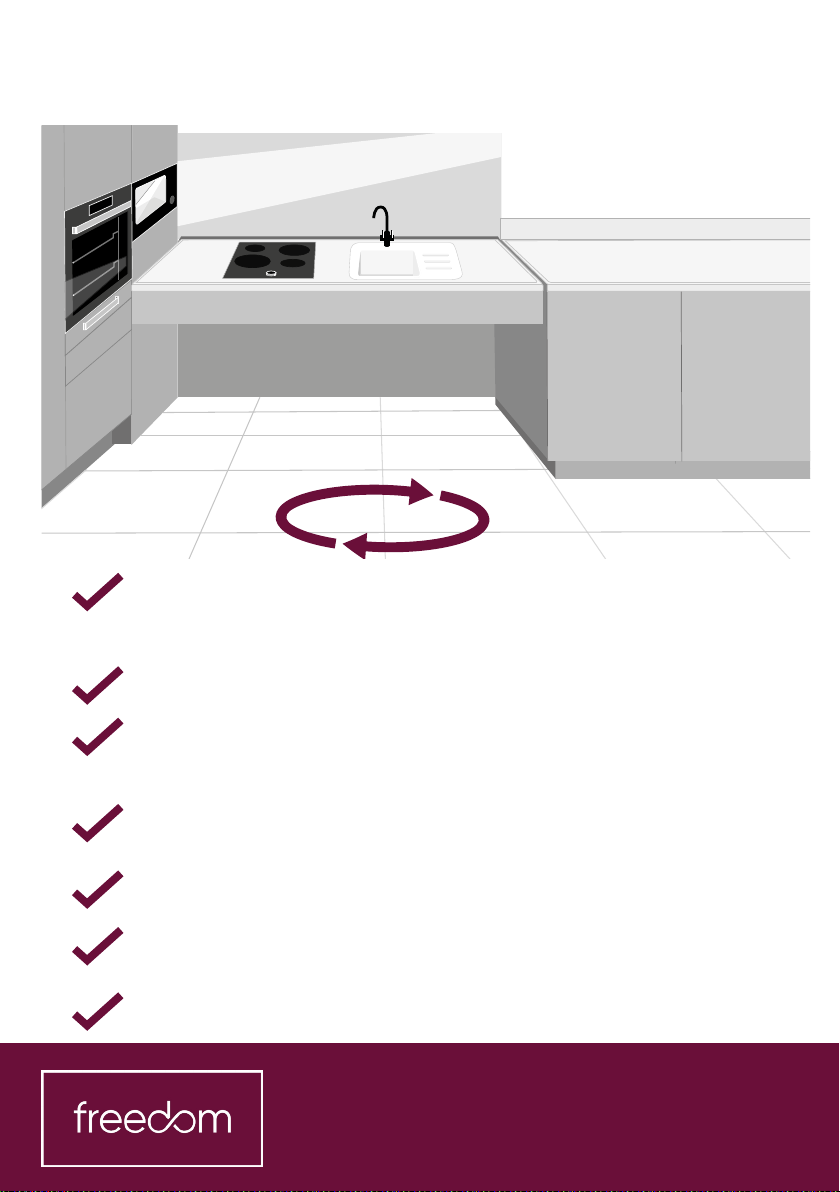

Check that a turning circle of 1.5m x 1.5m can be achieved once all units

are in place.

The angle of the tall units can be adjusted in relation to the wall, after

the sink and hob worktop is set out. This ensures the sink and hob work-

top section is at right angles to the rest of the units.

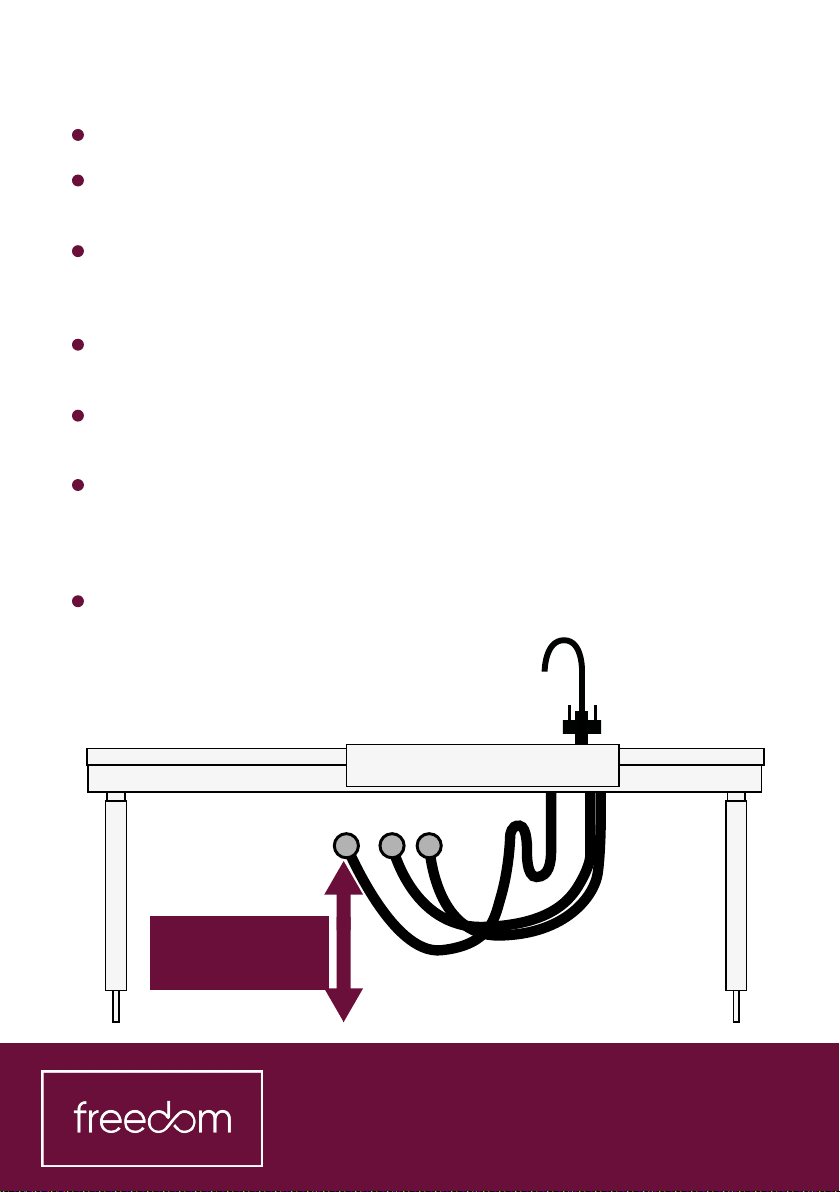

5mm gap required at either end of rise and fall worktops. Ensure this is

allowed for when setting out.

5mm gap required behind rise and fall worktops, once wall covering is

fitted. Allow 13mm gap behind when setting out.

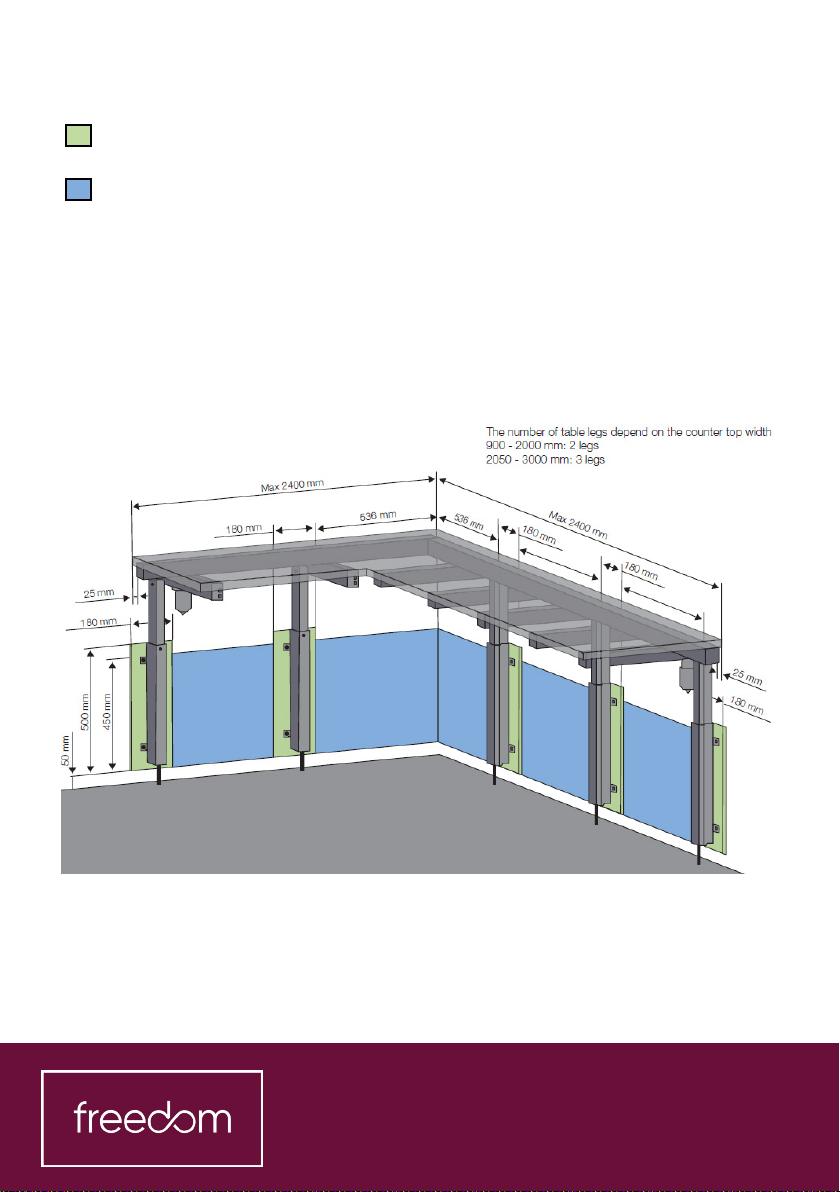

Base units will be shown on the plan as battened o the wall by 50mm,

with 650mm worktops. Ensure this is accounted for when setting out. The

rise and fall worktops will be 637mm, to allow for a 13mm gap behind. The

front of the rise and fall and fixed worktops will be flush with each other.

Fixed worktop brackets should be set at an appropriate height for the

user, or as advised by the site manager. Height from the floor can be

779mm, 819mm, 859mm, 899mm, or 939mm.