Systematics, Inc. West Chester, PA. 19380

MANUFACTURER’S LIMITED WARRANTY

This equipment is warranted against defects in materials

and workmanship for a period of two years from the date of

purchase.

EXCEPTION: THE MIG TORCH IS WARRANTED FOR A

PERIOD OF 30 DAYS FROM THE DATE OF PURCHASE.

Should the equipment become defective for such reason,

the Manufacturer will repair it without charge, if it is returned

to the Manufacturer’s factory, freight prepaid. This warranty

does not cover: (1) failure due to normal wear and tear; (2)

consumable parts, such as, but not limited to, torch contact

tips, gas cups and insulating bushings; (3) damage by

accident, force majeure, improper use, neglect, unauthor-

ized repair or alteration; (4) anyone other than the original

purchaser.

THIS LIMITED WARRANTY IS IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED. THE MANUFAC-

TURER SHALL NOT BE LIABLE FOR ANY INJURY TO

PERSONS, INCLUDING DEATH; OR LOSS OR DAMAGE

TO ANY PROPERTY, DIRECT OR CONSEQUENTIAL,

INCLUDING, BUT NOT LIMITED TO, LOSS OF USE,

ARISING OUT OF THE USE, OR THE INABILITY TO USE,

THE PRODUCT. THE USER ASSUMES ALL RISK AND

LIABILITY WHATSOEVER IN CONNECTION WITH THE

USE OF THE PRODUCT, AND BEFORE DOING SO,

SHALL DETERMINE ITS SUITABILITY FOR HIS IN-

TENDED USE, AND SHALL ASCERTAIN THE PROPER

METHOD OF USING IT.

SOME STATES DO NOT ALLOW LIMITATIONS ON

HOW LONG AN IMPLIED WARRANTY LASTS, OR THE

EXCLUSIONS OR LIMITATIONS OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES. SO THE ABOVE LIMITA-

TIONS OR EXCLUSIONS MAY NOT APPLY TO YOU. THIS

WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, AND

YOU MAY HAVE OTHER RIGHTS WHICH MAY VARY

FROM STATE TO STATE.

ARC WELDING CAN BE INJURIOUS TO OPERA-

TOR AND PERSONS IN THE WORK AREA -——

CONSULT INSTRUCTION MANUAL BEFORE

OPERATING.

ELECTRIC SHOCK can kill.

•Do not touch electrodes or other electrically live parts.

•Insulate yourself from work and ground.

•Install and ground machine in accordance with the National

Electical Code and local code(s). Read Operating Manual

before installing or operating.

•Do not operate with protective covers, panels, or guard

removed.

•Disconnect input power before servicing.

•Only qualified personnel should install, use, or service this

equipment.

ARC RAYS can injure your eyes and burn

skin.

•Wear correct eye, ear, and body protection while welding.

FUMES AND GASES can be dangerous to your

health.

•Use enough ventilation and/or exhaust at the arc.

•Keep your head out of fumes.

•Do not breathe fumes.

READ AND UNDERSTAND THE

MANUFACTURER’S INSTRUCTIONS AND

YOUR EMPLOYER’S SAFETY PRACTICES.

See American National Standard Z49.1, “Safety in

Welding and Cutting”, published by the American

Welding Society, 2501 N.W. 7th St., Miami, Florida

33125; OSHA Safety and Health Standards, 29 CFR

1910 available from U.S. Dept. of Labor, Wash.,

D.C. 20210.

!WARNING

TABLE OF CONTENTS

INTRODUCTION ........................................................................... 1

DESCRIPTION, SPECIFICATIONS .............................................. 2

CHECK LIST (CONTENTS) .......................................................... 3

INSTALLATION & ELECTRICAL REQUIREMENTS .................... 3

OPERATION ................................................................................. 7

MAINTENANCE .......................................................................... 12

TROUBLE SHOOTING CHART .................................................. 14

CONNECTING TIG PACK OR SPOOL GUN ............................. 19

LINER INSTALLATION ............................................................... 20

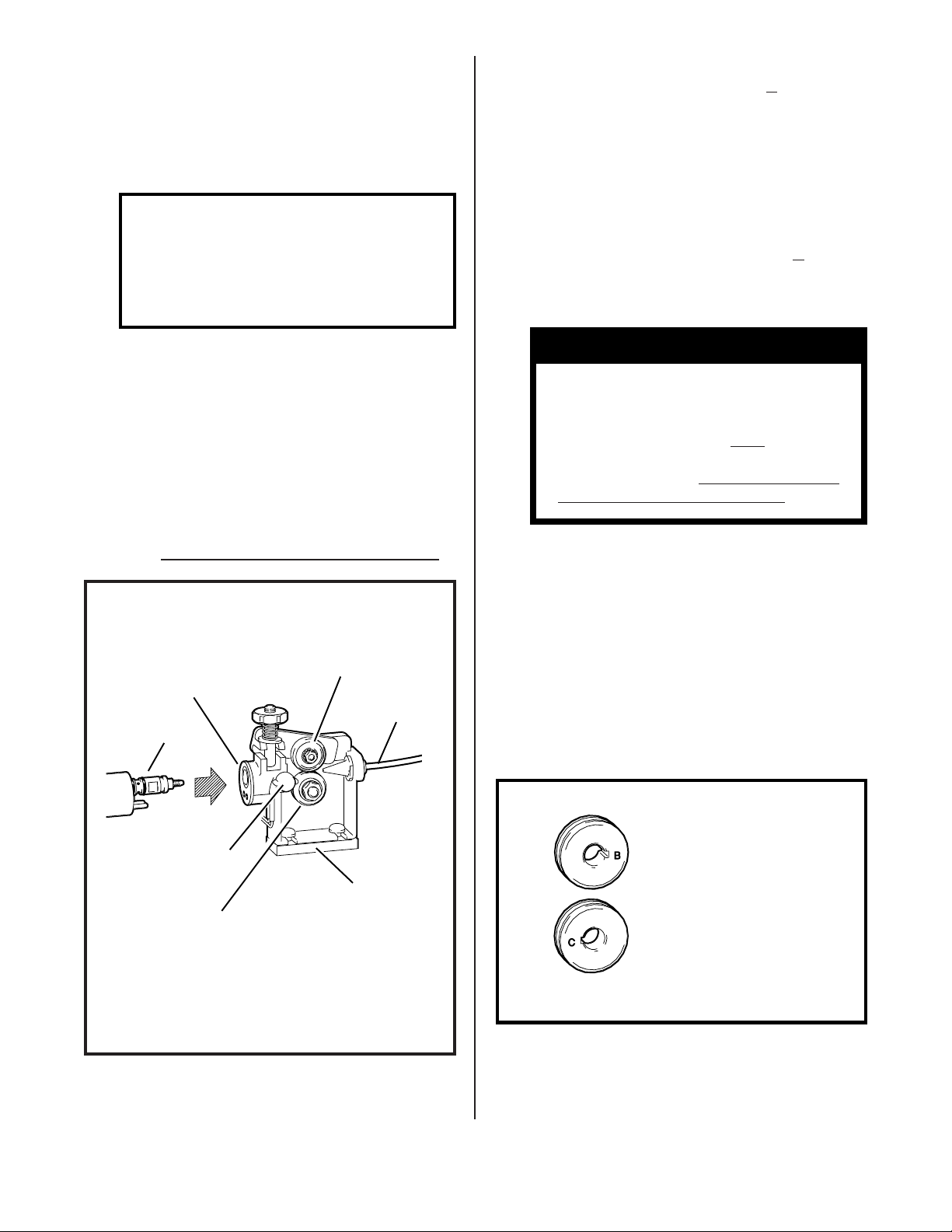

PARTS BREAKDOWN - MIG TORCH ........................................ 21

OPTIONS - TIG PACK OR SPOOL GUN ................................... 23