SySTIUM®TECHNOLOGIES MotherBoard ReadyTM System • MODEL 515

Copyright © 2013, SySTIUM® Technologies, LLC

PN: 91454-01Rev 03

ASSEMBLY GUIDE

Assembly Safety Instructions

Assembly of a computer system using this product shall be

assembled only by technically qualified personnel. Follow the

instructions in the document “Model 515 Maintaining Regulatory

Compliance” to meet and maintain the safety and product

regulatory compliance of this product when assembling a

computer system using this product.

WARNINGS

Read and adhere to all of these instructions and

instructions supplied with this assembly. Failure to follow

these instructions will result in voiding the product

regulatory compliance statements. The computer system

will most likely be noncompliant with other regional

product laws and regulations.

The procedures in this document assume familiarity with the

general terminology associated with personal computers and with

the safety practices and regulatory compliance required for using

and modifying electronic equipment.

WARNINGS

TO PREVENT ACCESS TO HIGH ELECTRICAL

ENERGY PARTS, DO NOT REMOVE THE

COVERS WHILE THE SYSTEM IS POWERED ON!

Do not open the power supply. The power supply in this

computer contains no user-serviceable parts. To avoid

personal injury or damage to your equipment, refer repair

or replacement of the power supply to qualified technical

personnel only. All other areas and components of this

computer are considered user-accessible.

CAUTIONS

Electrostatic discharge (ESD) can damage disk drives,

add-in cards, and other components. Do the procedures

described in this chapter only at an ESD workstation. If

such a station is not available, you can provide some ESD

protection by wearing an anti-static wrist strap and

attaching it to a metal part of the chassis.

Add-in cards can be extremely sensitive to ESD and

always require careful handling. After removing the card

from its protective wrapper or from the computer, place the

card flat on a grounded, static-free surface, component

side up. Use a conductive foam pad (f available, but not

the board wrapper Do not slide the board over any

surface.

For proper cooling and airflow, always close the chassis

before turning on the computer system. Operating the

computer system without the chassis closed can damage

system parts.

Before You Begin

1. Be sure to follow each procedure in the correct order.

2. Set up an equipment log to record the computer’s model

and serial numbers, all installed options, and other

information about the computer. This information must be

saved as a record of the product’s configuration and

compliance with the allowable configuration options.

3. We recommend that you use an anti-static wrist strap and a

conductive foam pad when working on the computer.

4. You will need a Phillips (#1 and #2 bits) screwdriver and

Needle Nose Pliers.

NOTE

The integration kit provides screws for the following:

• Slim DVD Drive Bracket

• Eight 6-32 Phillips Screws (motherboard & 3.5” HDD)

• Eight M3 Phillips screws (Peripheral)

• One Plastic Tie-wrap

• Four Stick-on Rubber Feet

Assembly Notes for Different Motherboards

The Model 515 supports a number of different motherboards. A

number of the assembly step details are different for each

specific motherboard. This manual describes the steps required

to complete the base system assembly task. Any steps or figures

specific to a particular motherboard are noted with a reference to

the assembly instructions specific to that motherboard. If no other

board instructions are present, then the assembly step is

consistent for all motherboards.

NOTE

If the manual does not include information for your specific

motherboard check the Systium Technologies web site

www.Systium.com, Tech Support for updates to this manual.

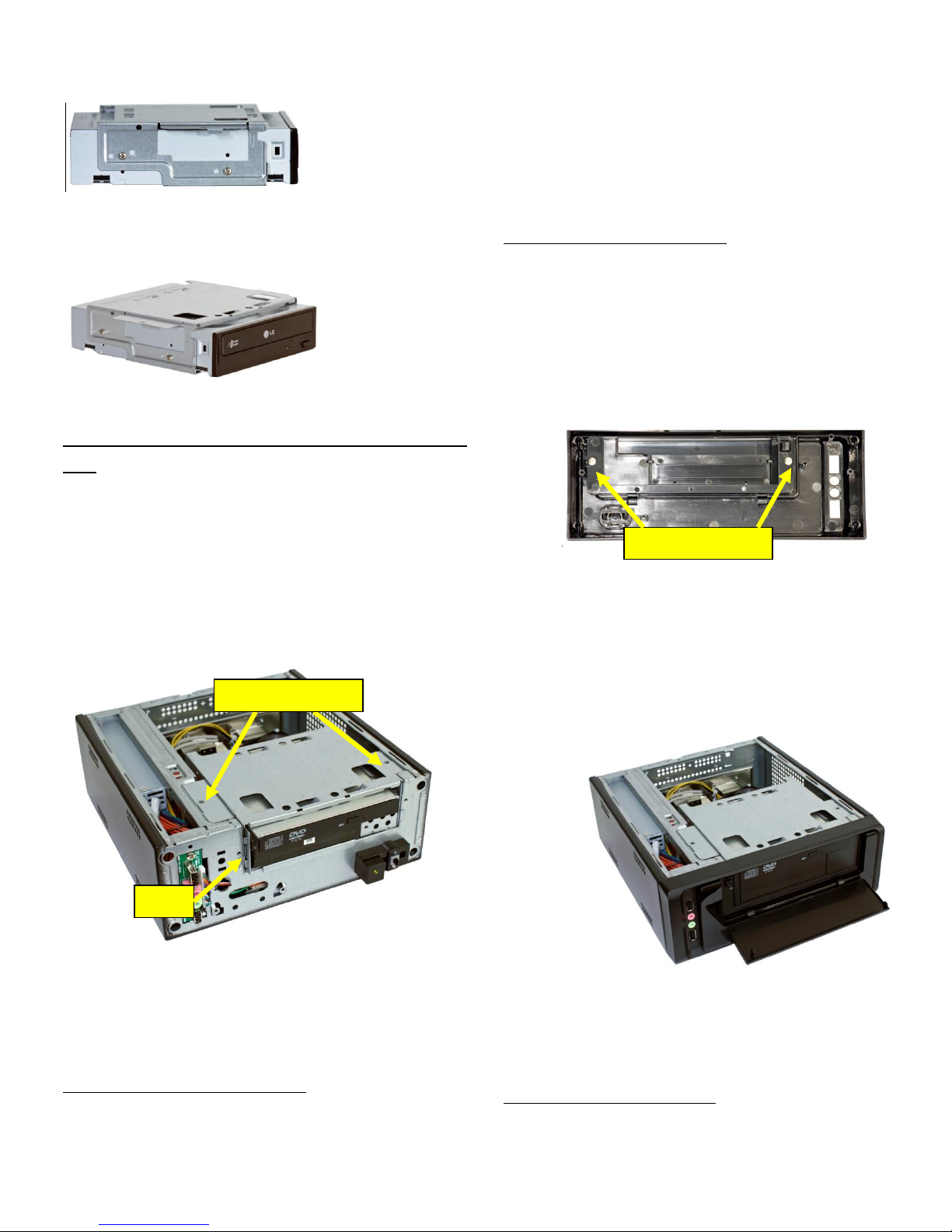

Unpack the System

Systium Technologies offers MotherBoard Ready products in two

packaging configurations. The first is a reusable “End-User”

ready single package. The second is a hi-volume bulk package.

The instructions detailed are for the single package. Any

differences in procedures between the single package and bulk

package are noted within each section. The integration kits are

the same for the single or bulk package MotherBoard Ready

Systems.

CAREFULLY UNPACK THE COMPUTER. Save the box and

packaging material for shipment to the customer. If components

are missing please contact your supplier or Systium

Technologies.

BULK PACKAGE