Manual to personal carriage decoder

WD-PW115, WD-PW 170, WD-PW-230, WD-

PW260, WD-PW290

Document: SW 3.0 / 01www.tec4trains.deSeite 9 from 42

Revolutionen im kleinen Maßstab

handle economically with energy. Today LED are available in all colours, also many white shades.

Do not use electric light bulbs. In particular with long trains it can come to the overload of the train

bus and with it to the compulsive disconnection. T4T offers suitable luminous means for 16 - 20 V.

If LED's are connected, a preresistor has to be switched in series. Resistance values in the area of

from 1 to 5 kOhm are suitable according to the LED model.

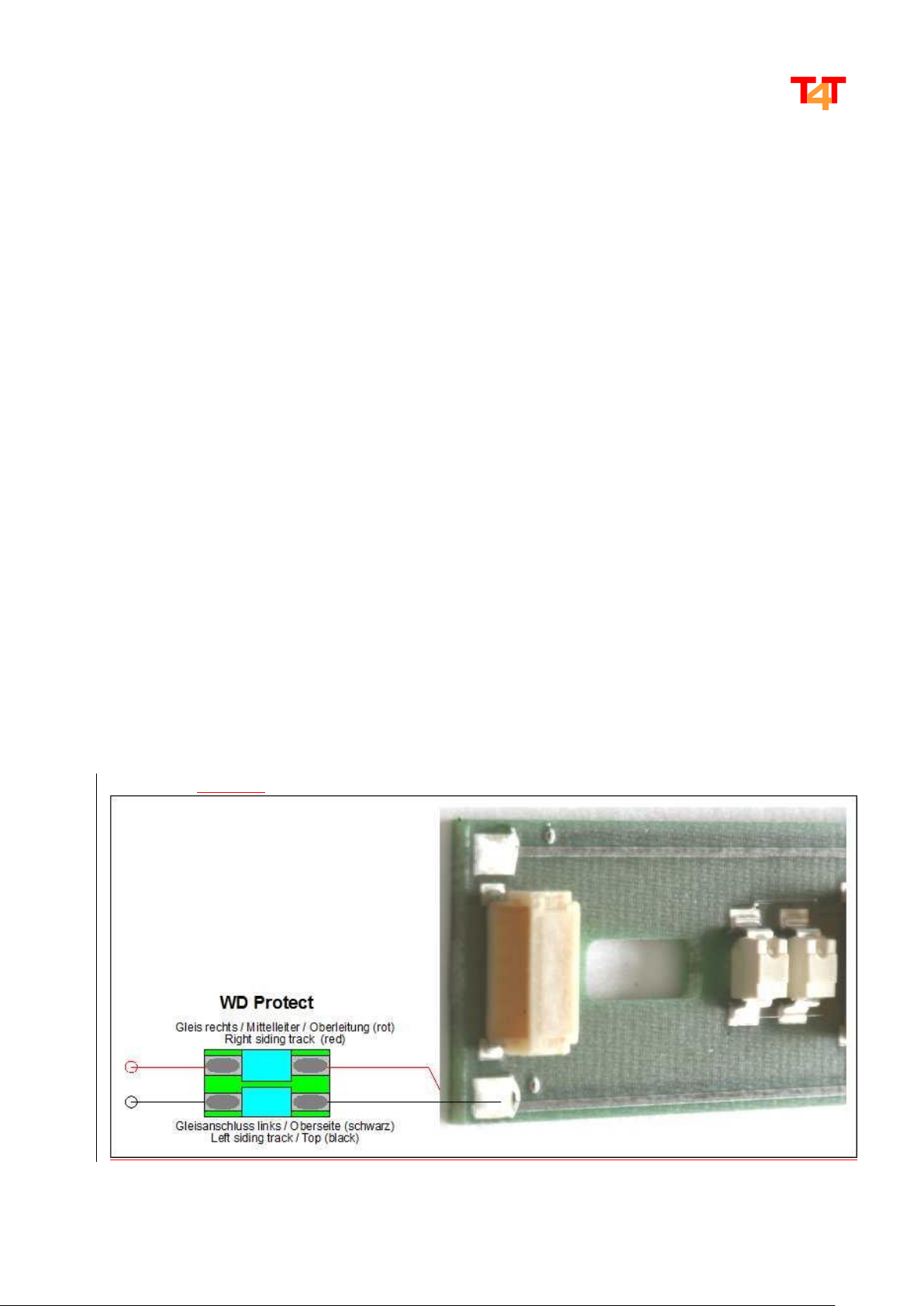

WD-PWxxx and the DCC Protocol

The WD-PWxxx series decoders are not necessary directly connected to the track. They are con-

nected to the coupling TC-H0 via the T4T train bus. This happens simply by hitching the wagon up

to a locomotive fitted with a TC-H0 coupling. In order to activate the functions of the WD-GWx

there are 2 DCC compatible procedures available, which can be activated by any good DCC system.

The exact functionality becomes in the chapter"WD-PWxxx and the T4T Train Automation

(TCCS)"from page 19 described.

WD-PWxxx and running in km/h

The set speed limits in CVs 136 to 139 (SW 2 and higher) for each wagon are read and processed

according to driving direction via the lead locomotive through TCCS. The locomotive will run at

the set speed limit despite the controller having a high speed. This way the derailing of wagons can

be avoided. Wagons which can only run in one direction (e.g. track cleaning wagons) require a 0 to

be entered into both respective CVs for the forbidden direction. To restrict running in the „white

coupling“ direction, a value of 0 must be entered into CV 136/137; for the „yellow coupling“ direc-

tion, write 0 in CV 138/139. Speed limits are programmed separately.

The programming process for wagon decoder CVs is described in the locomotive LD-1x manual.

WD-PWxxx and the automatic train (TCCS)

WD-PWxxx can do more than just mechanically and electrically connect your wagon with the train.

In conjunction with the automatic coupling TC-H0 and the respective locomotive decoders LD-1x,

your entire train can be automated using the DCC protocol - with any DCC capable control system.

The coupling TC-H06 establishes a 2-pin, conductive connection that can be disconnected at any

position of the train set.

The coupling made for the NEM 362 pocket (main coupling method used

by major manufacturers for H0 gauge) supplies the whole train with power. There is no need for

pickups to be made for the wagons.

We call this system TCCS – TrainCoupling&CommunicationSystem

In this way the wagon decoder gets its power via the TC-H0 and handles the supply for internal

lighting. It automatically switches the rear lighting on the end wagon, ensuring flicker-free lighting

and other similar features.

For PC-controlled systems the IR feedback system TRAM (SW 2 and higher) calculates the train

length, identifies each individual wagon for monitor tracking and totals the full length and weight of

the train.

TC-H0 corresponds with regard to all dimensions the recommendation according to standards of

European model railways 362 and is suitable for close coupling, i.e. contrived for the prototypical

driving buffer in buffer.