© 2015 Taco Electronic Solutions, Inc. 1

Application Guide 505-035

HPU3 Water Source Heat Pump Controller

Self-Contained Interoperable Controller Model UCP-1 for Software Version 2

SUPERSEDES: December 15, 2014 EFFECTIVE: June 30, 2015

Plant ID: 001-4056

Table of Contents

HPU3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Purpose of This Guide . . . . . . . . . . . . . . . . . . . . . . . . . 3

Representations and Warranties . . . . . . . . . . . . . . . . . 4

Applicable Documentation . . . . . . . . . . . . . . . . . . . . . . 4

Installation Instructions . . . . . . . . . . . . . . . . . . . . . . 5

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Static Electricity . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

FCC Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Before Installing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

About this Document . . . . . . . . . . . . . . . . . . . . . . . . 5

Inspecting the Equipment . . . . . . . . . . . . . . . . . . . . 5

What is Not Included with this Equipment . . . . . . . . 6

Equipment Location . . . . . . . . . . . . . . . . . . . . . . . . . 6

Selecting a Power Source . . . . . . . . . . . . . . . . . . . . 6

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Mounting the Device . . . . . . . . . . . . . . . . . . . . . . . . 6

Routing Cabling to the Device . . . . . . . . . . . . . . . . . 7

Grounding the Device . . . . . . . . . . . . . . . . . . . . . . . 7

Wiring Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Connecting Input Devices . . . . . . . . . . . . . . . . . . . . 9

Connecting Output Devices . . . . . . . . . . . . . . . . . . 10

Other Connections . . . . . . . . . . . . . . . . . . . . . . . . . 11

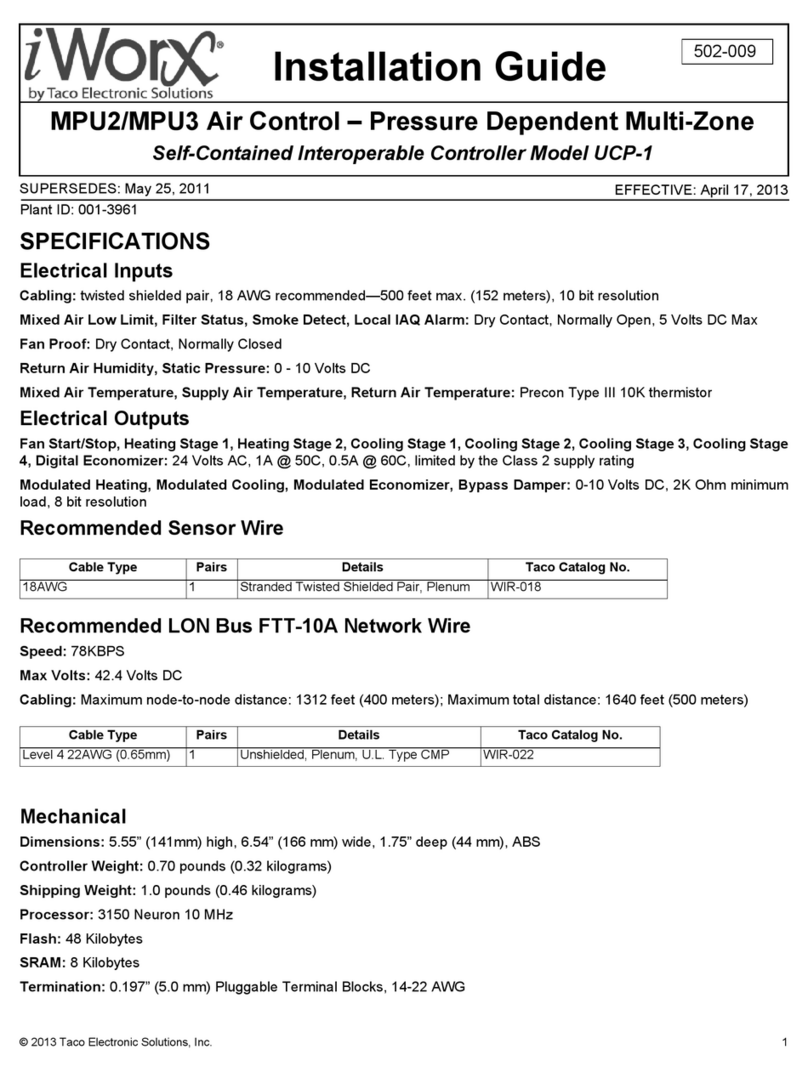

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Mechanical. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Application Description . . . . . . . . . . . . . . . . . . . . . . . . 13

Sequence of Operation . . . . . . . . . . . . . . . . . . . . . . . 14

Setpoints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Heating Sequence . . . . . . . . . . . . . . . . . . . . . . . . . 16

Cooling Sequence . . . . . . . . . . . . . . . . . . . . . . . . . 18

Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Fan Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Dehumidification with Reheat . . . . . . . . . . . . . . . . 20

Auxiliary Heat. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Global Unit Enable. . . . . . . . . . . . . . . . . . . . . . . . . 21

Humidification . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Thermostat. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Local Backup Schedule . . . . . . . . . . . . . . . . . . . . . 21

Runtime Accumulation. . . . . . . . . . . . . . . . . . . . . . 21

Reversing Valve. . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Supply Air Temperature Fan Modulated Output . . 22

Alarms and Events. . . . . . . . . . . . . . . . . . . . . . . . . 22

Hydronic Zone Interaction . . . . . . . . . . . . . . . . . . . 23

Automatic Configuration . . . . . . . . . . . . . . . . . . . . 23

Communication with Associated Controllers . . . . . 23

Controller Identification . . . . . . . . . . . . . . . . . . . . . . . 23

Network Inputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Inputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Diagnostic LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Troubleshooting Tips . . . . . . . . . . . . . . . . . . . . . . . 32