iWorx® HPU Series

2 502-025, Effective: April 17, 2013

© 2013 Taco Electronic Solutions, Inc.

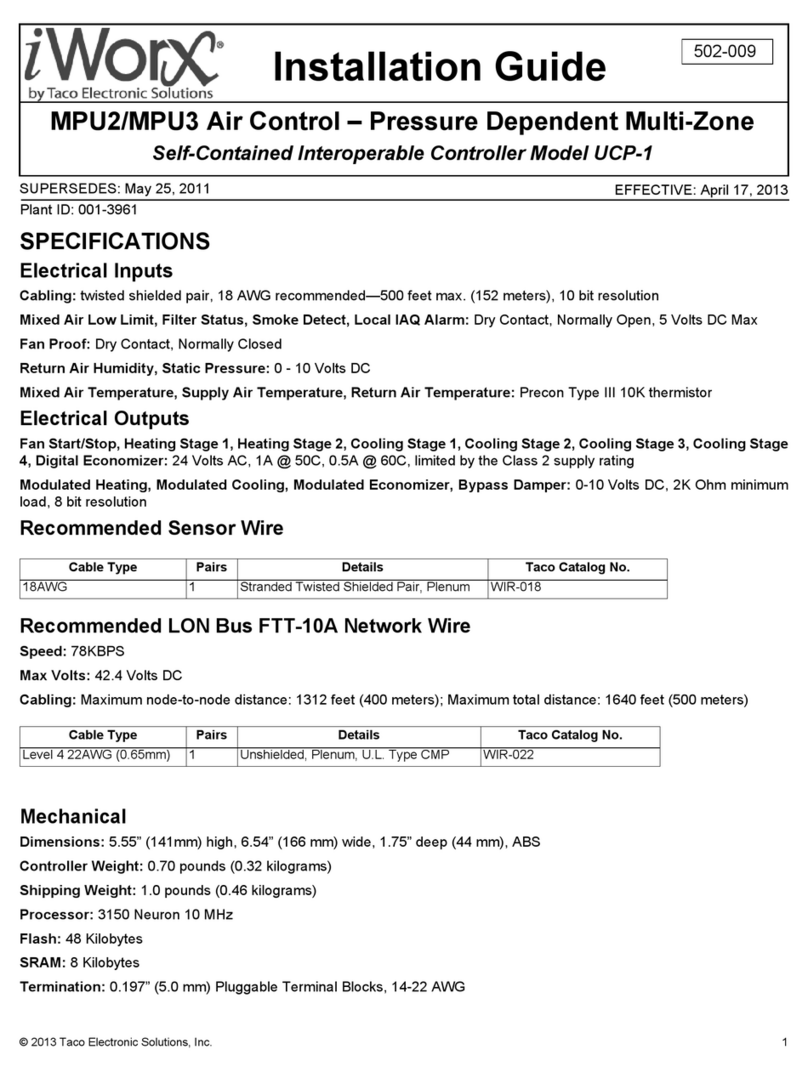

SRAM: 8 Kilobytes

Termination: 0.197” (5.0 mm) Pluggable Terminal Blocks, 14-22 AWG

Temperature: 32 °F to 140 °F (0 °C to 60 °C)

Humidity: 0 to 90%, non-condensing

UL Listed for US and Canada, Energy Management Equipment PAZX and PAZX7

FCC Part 15 Class A compliant

Equipment Location

Abide by all warnings regarding equipment location provided in this document. This equipment is suitable for

indoor use only. Preferably, or as required by National Electrical Code, the unit is intended to be installed within

an electrical control enclosure. Operate where ambient temperatures do not exceed 140 °F (60 °C) or fall

below 32 °F (0 °C) and relative humidity does not exceed 90%, non-condensing.

If the equipment is to be installed outdoors, it must be contained within a protective enclosure that maintains internal tem-

perature and humidity within the ranges specified for this equipment.

The equipment must be installed within 500 feet of all input peripherals (smoke detectors, sensors, etc.) that are connected

to the equipment.

Avoid locations where corrosive fumes, excessive moisture, vibration or explosive vapors are present.

Avoid electrical noise interference. Do not install near large contactors, electrical machinery, or welding equipment.

Selecting a Power Source

This equipment requires a UL recognized Class 2 external power source (not supplied) to operate. The controller power

input requires a voltage of 24 Volts AC.

To calculate power source current requirements, add the power consumption of all peripheral devices to that of the control-

ler.

The controller and sensor power supplies can use the same power source. If both are using the same power source, the

loads must have EMF protection. This protection can be integral to the load, or installed in the 24 VAC wiring across the

load’s coil.

To provide necessary RFI and transient protection, the controller’s ground (GND) pin (T40) must be connected to earth

ground or the earth ground of the packaged unit’s enclosure ground. Failure to properly ground the controller may cause it

to exceed FCC limits. Excessive noise could also produce inaccurate sensor data. The power source must be capable of

operating with this connection to ground.

INSTALLATION PRECAUTIONS

General

CAUTION: This symbol is intended to alert the user to the presence of important installation and maintenance

(servicing) instructions in the literature accompanying the equipment.

CAUTION: Risk of explosion if battery is replaced by an incorrect type. Contains lithium type battery; dispose

of properly.

WARNING: Electrical shock hazard. Disconnect ALL power sources when installing or servicing this equip-

ment to prevent electrical shock or equipment damage.

Make all wiring connections in accordance with these instructions and in accordance with pertinent national and local elec-

trical codes. Use only copper conductors that are suitable for 167 °F (75 °C).