For information on Taco’s Switching Relays (SR)

including catalog sheet, instruction sheets, Visio

stencils and our highly praised Zone Controls

Wiring Guide, scan the QR code to the left or go

to our website: http://www.taco-hvac.com.

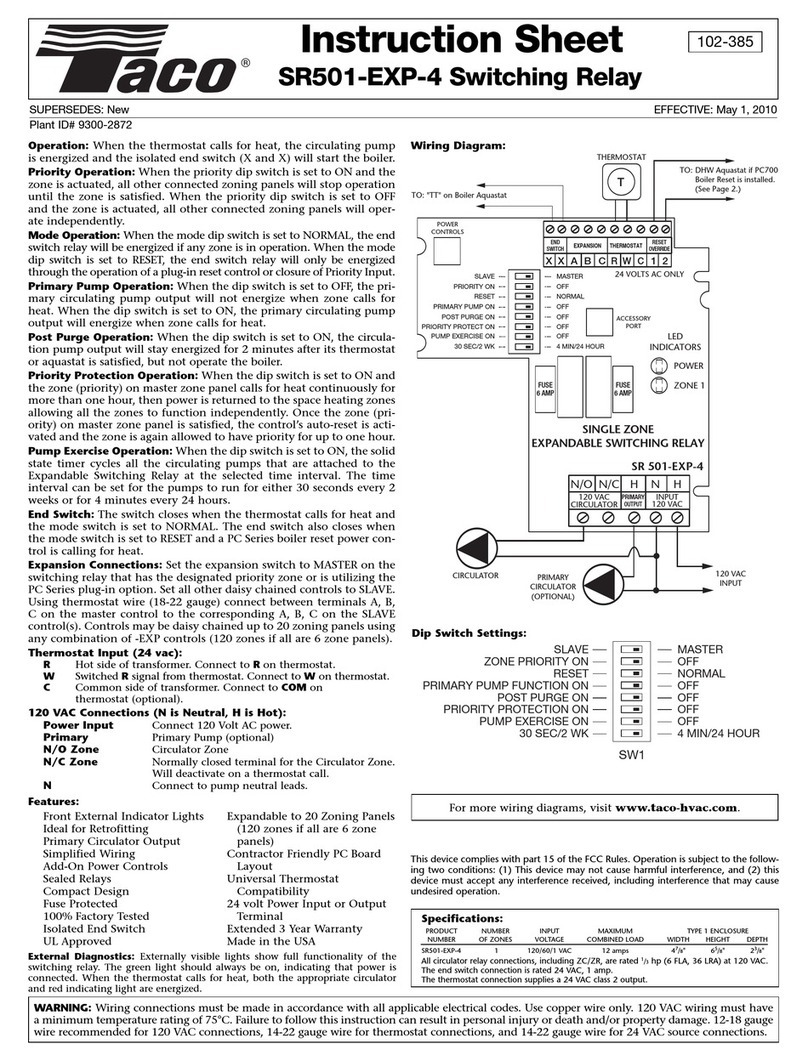

Priority Oper tion: When the priority dip switch is set to ON and the

priority zone is actuated, all other zones will stop operation until pri-

ority zone is satisfied. When not switched to priority, all zones will

operate independently.

Mode Oper tion: When the dip switch is set to NORMAL, the end

switch relay will be energized if any zone is in operation. When the switch

is set to RESET, the end switch relay will only be energized if the priority

zone is in operation, or through the operation of a plug-in reset control.

Prim ry Pump Oper tion: When the dip switch is set to OFF, the pri-

mary circulating pump output will energize when any zone calls for heat,

except the priority zone. When the dip switch is set to ON, the primary

circulating pump output will energize when any zone calls for heat.

Post Purge Oper tion: When the dip switch is set to ON, the priority

zone output will stay energized for 2 minutes after its thermostat or

aquastat is satisfied, but not operate the boiler.

Priority Protection Oper tion: When the dip switch is set to ON,

and if the priority zone calls continuously for more than one hour,

power is returned to all the other zones, allowing each zone to function

independently. Once the priority zone is satisfied, the control's auto-

reset is activated and the priority zone is again allowed to have priority

for up to one hour starting from when it calls next.

Pump Exercise Oper tion: When the dip switch is set to ON, the

solid state timer cycles all the circulating pumps that are attached to

the Expandable Switching Relay at the selected time interval. The time

interval can be set for the pumps to run for either 30 seconds every 2

weeks or for 4 minutes every 24 hours.

Low Limit (ZC) Oper tion: When the dip switch is set to ON and the

boiler drops below the set low limit (terminal ZC connected to boiler),

all zone circulating pumps will stop. When the boiler rises above the

set low limit, the zone circulating pumps are allowed to operate.

End Switches (Dry Cont cts): The main end switch closes when any

zone thermostat calls for heat and the mode switch is set to NORMAL.

The main end switch also closes when the mode switch is set to RESET

and a PC Series boiler reset power control is calling for heat. The priority

end switch closes only when the priority zone thermostat or aquastat is

calling for heat.

Exp nsion Connections: Set the expansion switch to MASTER on the

switching relay that has the designated priority zone or is utilizing the

PC Series plug-in option. Set all other daisy chained controls to SLAVE.

Using thermostat wire (18-22 gauge) connect between terminals A, B,

C on the master control to the corresponding A, B, C on the SLAVE

control(s). Controls may be daisy chained up to 20 zoning panels using

any combination of -EXP controls (120 zones if all are 6 zone panels).

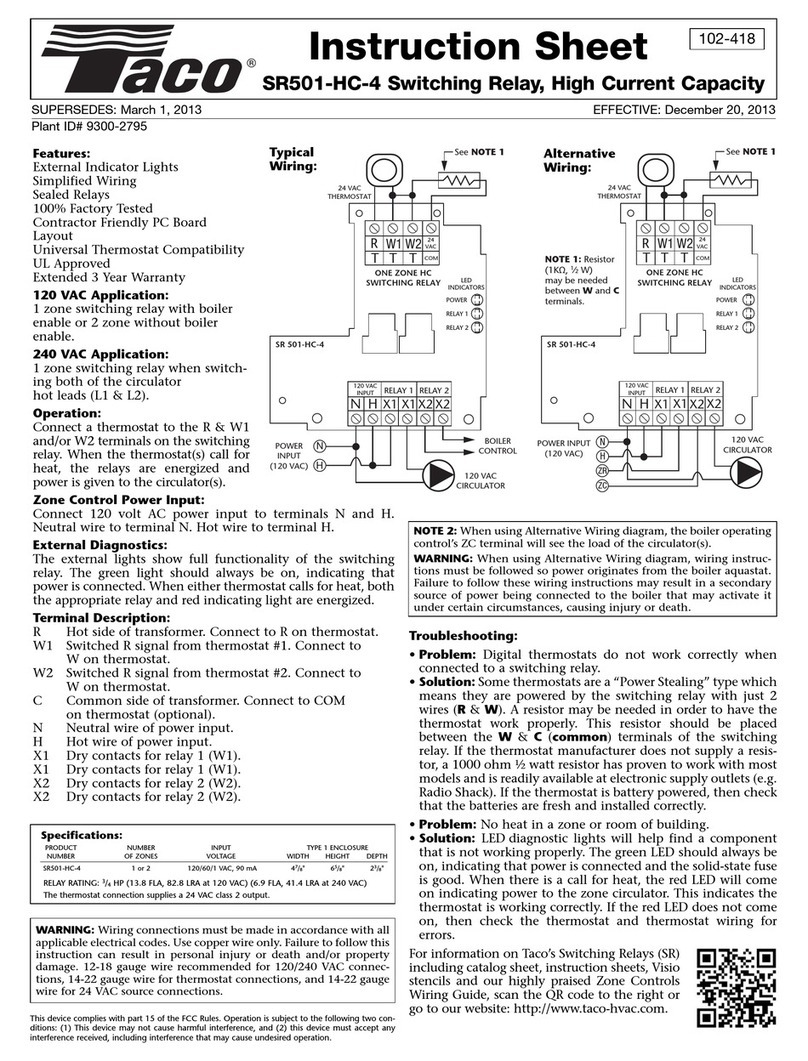

Thermost t Input (24 v c):

R Hot side of transformer. Connect to Ron thermostat.

W Switched R signal from thermostat. Connect to W on thermostat.

C Common side of transformer. Connect to COM on

thermostat (optional).

NET Network terminals 1 & 2 are tied together for wiring convenience

when using communicating style thermostats (optional).

120 VAC Connections (N is Neutr l, H is Hot):

Power Input Connect 120 Volt AC power

Prim ry Primary Pump (optional)

Zone 1-3 Circulator Zones

Priority Zone 4 Priority Zone (if enabled) or Zone 4

N/C Zone 4 Normally closed terminals for the Priority Zone.

Will deactivate on a Priority Zone call.

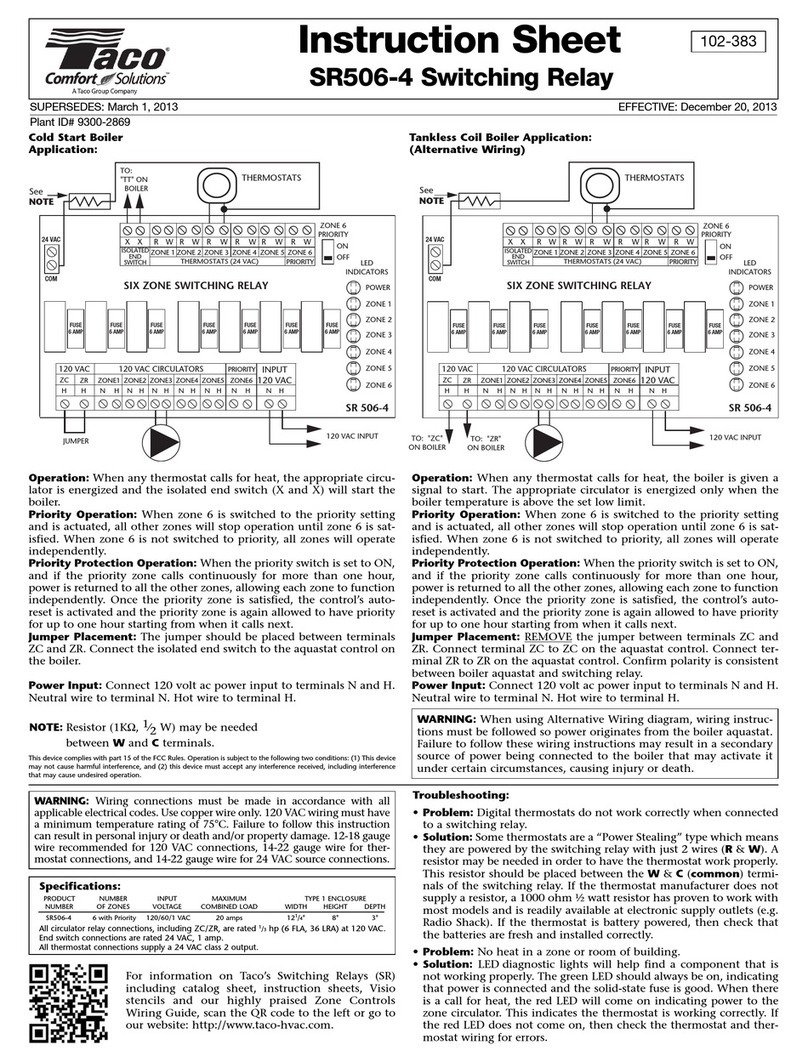

Cold St rt Boiler

Applic tion:

T nkless Coil Boiler

Applic tion: (Altern tive Wiring)

Instruction Sheet

SR504-EXP-4 Switching Relay

102-389

SUPERSEDES: December 20, 2013 EFFECTIVE: January 18, 2017

Plant ID# 9300-2874

For Both Cold St rt Boiler Applic tion nd T nkless Coil Boiler Applic tion (Altern tive Wiring)

For Cold St rt Boiler Applic tion

Oper tion: When any thermostat calls for heat, the appropriate circu-

lating pump is energized and the isolated end switch (X and X) will

start the boiler.

For T nkless Coil Boiler Applic tion (Altern tive Wiring)

Oper tion: When any thermostat calls for heat, the boiler will be enabled

and appropriate circulating pump is energized when the boiler tempera-

ture is above the set low limit and low limit (ZC) dip switch is set to on.

ZC nd ZR Termin ls: Connect terminal ZC to ZC terminal on the aqua-

stat control. Connect ZR to ZR terminal on the aquastat control. Confirm

polarity is consistent between boiler aquastat and switching relay.

WARNING: When using Alternative Wiring diagram, wiring instruc-

tions must be followed so power originates from the boiler aquastat.

Failure to follow these wiring instructions may result in a secondary

source of power being connected to the boiler that may activate it

under certain circumstances, causing injury or death.

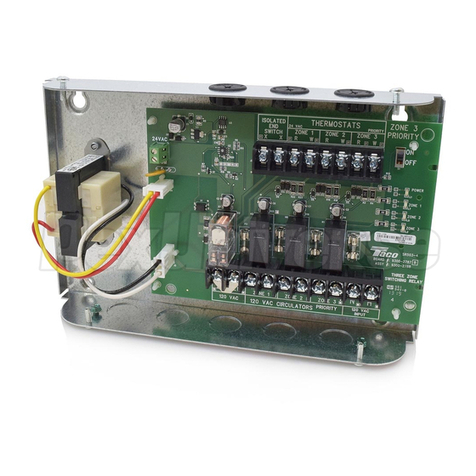

Specific tions:

P ODUCT NUMBE INPUT MAXIMUM TYPE 1 ENCLOSU E

NUMBE OF ZONES VOLTAGE COMBINED LOAD WIDTH HEIGHT DEPTH

S 504-EXP-4 4 with Priority 120/60/1 VAC 20 amps 121/4" 8" 3"

All circulator relay connections, including ZC/Z , are rated 1/3hp (6 FLA, 36 L A) at 120 VAC.

End switch connections are rated 24 VAC, 1 amp.

All thermostat connections supply a 24 VAC class 2 output.

For more wiring diagrams, visit www.taco-hvac.com.

WARNING: Wiring connections must be made in accordance with all

applicable electrical codes. Use copper wire only. 120 VAC wiring must have

a minimum temperature rating of 75 C. Failure to follow this instruction

can result in personal injury or death and/or property damage. 12-18 gauge

wire recommended for 120 VAC connections, 14-22 gauge wire for thermo-

stat connections, and 14-22 gauge wire for 24 VAC source connections.