Boiler Operation:

The supply water temperature from a boiler can be controlled by

cycling the boiler on and off. Modulation of the boiler’s operating

temperature in hot water heating systems not only provides more

comfort but also offers significant energy savings. The cooler the

boiler runs, the more efficient it is due to less heat losses up the flue

and reduced boiler jacket losses.

Differential

An on / off boiler must be operated with a differential in order to pre-

vent short cycling. When the supply water temperature drops below

the bottom rail of the differential, the boiler is turned on. The boiler is

then kept on until the supply water temperature rises above the top

rail of the differential. If the differential is too wide, there can be large

supply water temperature swings; however, if the differential is too

narrow, the boiler short cycles and operates inefficiently. This control

can be set for two different boiler differentials, 10°F (6°C) or 20°F

(12°C). This setting will help to achieve an appropriate balance

between temperature swings and boiler efficiency.

Minimum Boiler Supply

Most boilers require a minimum supply water temperature in order to

prevent corrosion from flue gas condensation. The control should

therefore only modulate the boiler supply water temperature down to

the boiler manufacturer’s minimum recommended operating temper-

ature. Some boilers are designed to condense and should be oper-

ated at low water temperatures as much as possible for maximum

efficiency.

SUPPLY WATER TEMPERATURE

TIME

Differential = 10°F (5°C

)

165

°F(74°C)

155°F (68°C)

160°F (71°C)

BOILER ON BOILER ON

BOILER OFF BOILER OFF

OUTDOOR AIR TEMPERATURE

50

(10)

30

(-1)

10

(-12)

-10

(-23)

70

(21)

90

(32)

WWSD

TEMPERATURE

°F(

°C)

SUPPLY WATER TEMPERATURE

110 (43)

70 (21)

90 (32)

210 (99)

170 (77)

150 (65)

130 (54)

190 (88)

RESET

RATIO

BOILER

MINIMUM

SEQUENCE OF OPERATION:

Powering Up the Control:

After the SR501-OR is powered up, the green power LED light will be on.

Heating Demand:

The SR501-OR receives a heating demand from thermostat or zone

control end switch closure on the R and W thermostat terminals. The

thermostat red LED light will also be turned on. The control can be

setup for boiler temperature reset or ON – OFF boiler operation.

Reset Demand:

When the SR501-OR receives a heating demand the controls enable

the boiler based on the reset curve. The Boiler Relay red LED light

will be turned on when the boiler relay is energized.

DHW Demand:

When the SR501-OR receives a DHW demand the controls enable

the boiler and ignore the boiler reset curve. The DHW Override red

LED light will also be turned on.

Warm Weather Shut Down (WWSD):

When the outdoor temperature rises above 70°F (21°C), the control

turns off the boiler and blinks the Thermostat LED light. This function

only applies for space heating and does not affect DHW operation.

Boiler Operation:

When the SR501-OR has a reset demand, the system supply water

temperature is controlled by turning the boiler on and off. The control

calculates the target supply water temperature based on the outdoor

temperature, and the settings that were entered. The boiler operates

around a differential that is manually set by dip switch number 2. The

control includes a minimum on and off time for the boiler, in order to

minimize short cycling.

Maximum Boiler Supply

The SR501-OR does not allow the boiler target temperature to

exceed the boiler design temperature setting plus 10°F (6°C) up to a

maximum of 225°F (107°C).

Minimum Boiler Supply

The SR501-OR has a 140°F minimum boiler setting which is used in

order to prevent corrosion from flue gas condensation. During mild

outdoor conditions, the boiler cycles around the minimum boiler set-

ting. This programmed function can be set to the OFF setting for

condensing and electric boilers.

• The sensor should be mounted on a wall which best represents

the heat load on the building (i.e. a northern wall for most build-

ings and a southern facing wall for buildings with large south

facing glass areas). The sensor should not be installed near heat

sources such as ventilation or window openings.

• The sensor should be installed at an elevation above the ground

that will prevent accidental damage or tampering.

• Install the Outdoor Sensor and run the wiring back to the con-

trol mounting location.

Installing the Boiler Sensor

Note: This sensor is designed to mount on a pipe or in a tempera-

ture immersion well.

• The sensor can be strapped directly to the pipe using the cable

tie provided. Insulation should be placed around the sensor to

reduce the effect of air currents on the sensor measurement.

• The Boiler Sensor should be placed downstream of a pump or

after an elbow or similar fitting. This is especially important if

large diameter pipes are used because the thermal stratification

within the pipe can result in erroneous sensor readings. Proper

sensor location requires that the fluid is thoroughly mixed with-

in the pipe before it reaches the sensor.

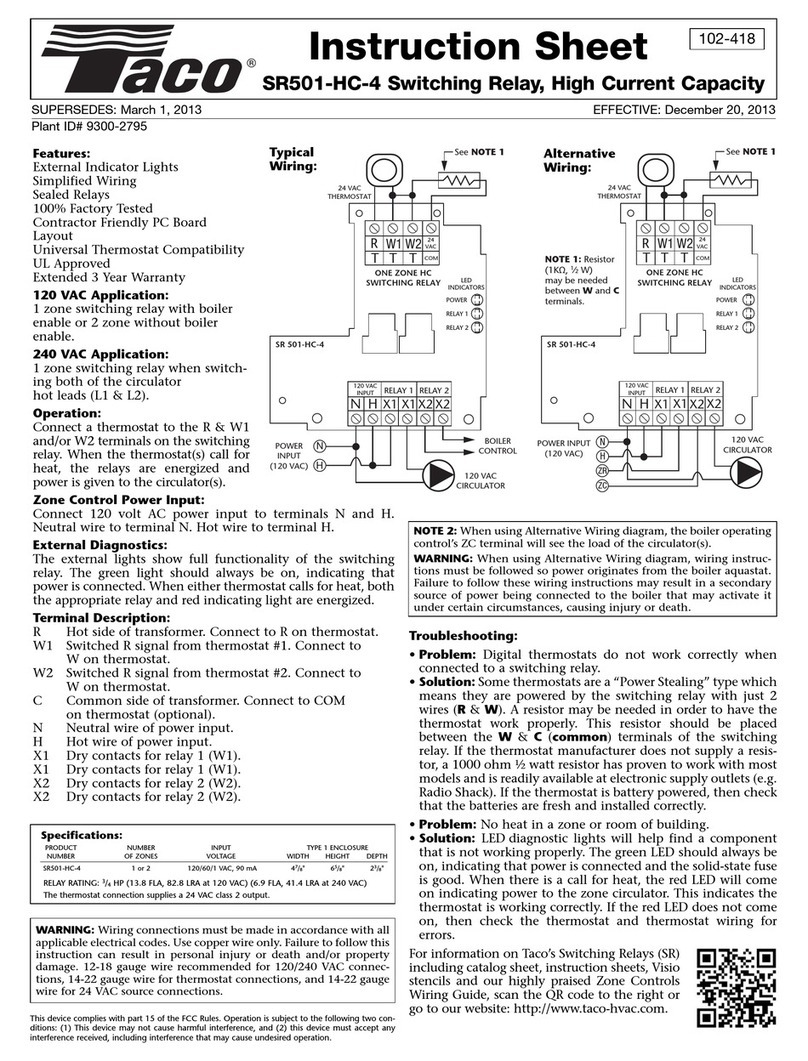

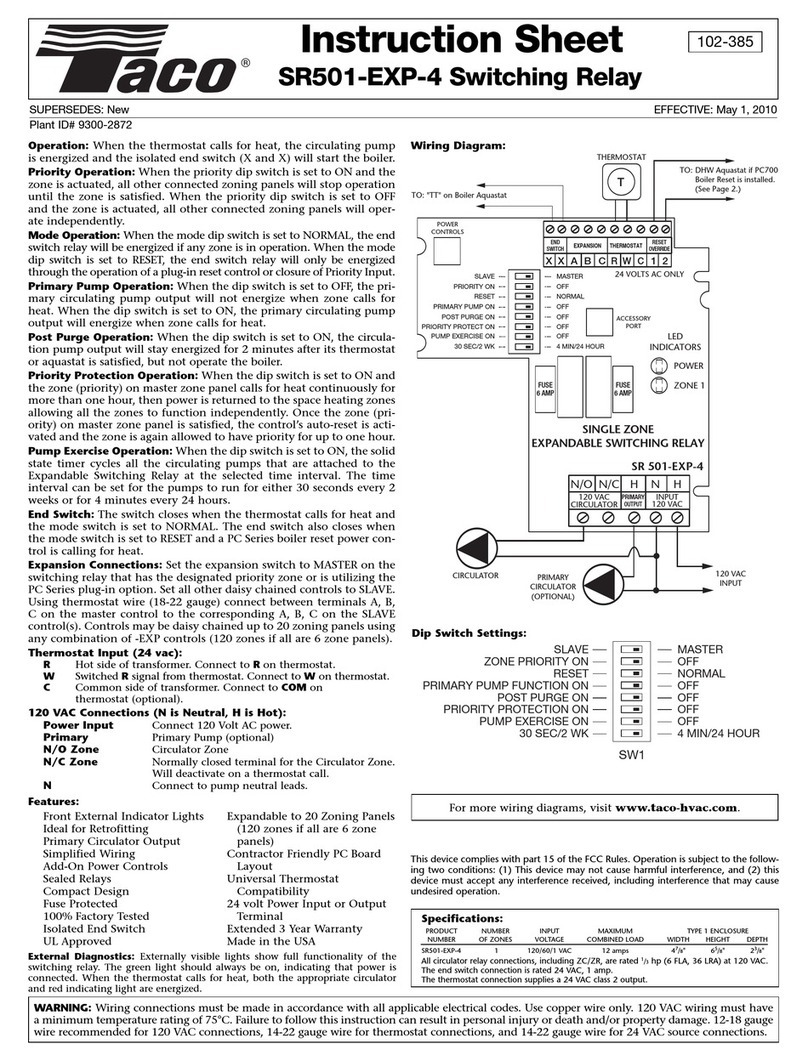

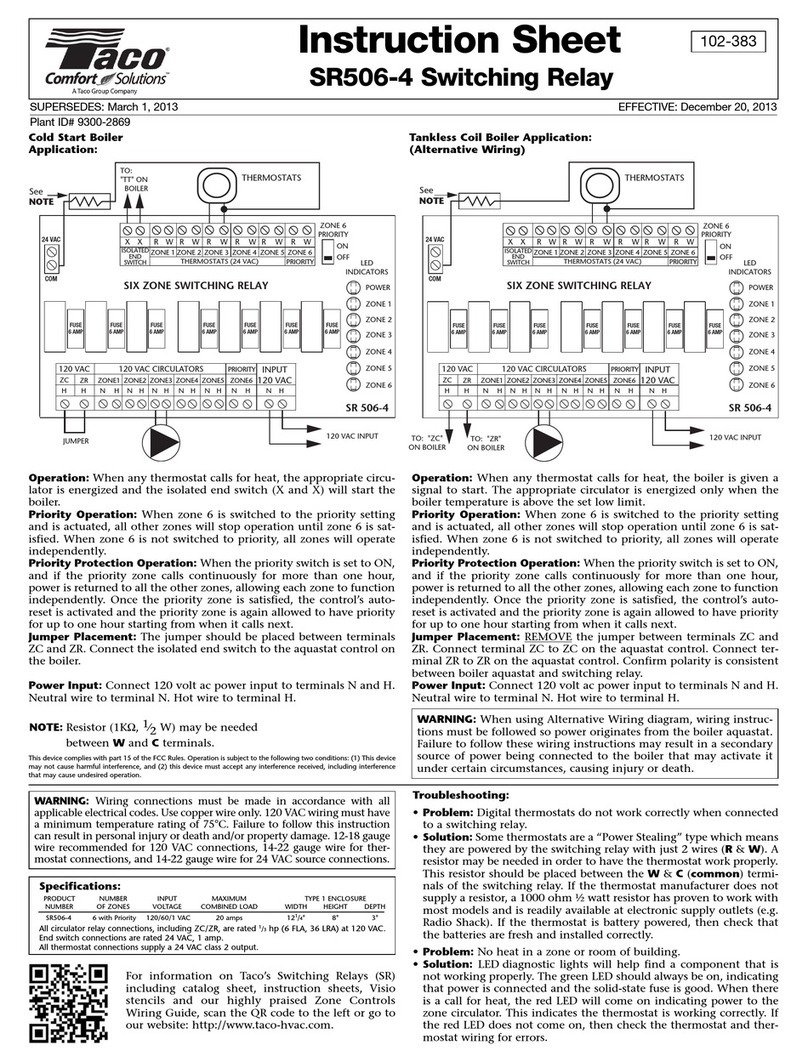

Step Three:

Wiring to the Zone Control

Line Voltage Connections –

Connect 120VAC incoming line voltage; Hot to the H terminal and

Neutral to the N terminal.

Connect 120VAC circulator; HOT lead of circulator to Zone H ter-

minal and Neutral lead of circulator to Zone N terminal.

Low Voltage Connections –

Connect thermostat or zone control end switch to the R and W

thermostat terminals.

Connect the DHW aquastat to the R and W DHW override terminals

(optional).

Connect boiler’s T and T terminal to the X and X boiler end switch

terminals.

Wiring the Sensors

Do not apply power to these terminals as this will damage the

control.

Outdoor Sensor

Connect the two wires from the Outdoor Sensor to the Outdoor

Sensor terminals. The Outdoor Sensor measures the outdoor air

temperature.

Boiler Sensor

Connect the two wires from the Boiler Sensor to the Supply

Sensor terminals and insulate. The Boiler Sensor measures the

supply water temperature going from the boiler to the system.

SETTINGS:

Before adjusting the settings, read through the sequence of operation

to ensure that you understand how the control operates. The follow-

ing page describes how to program these settings into the control

once it has been powered up.

Step Four:

Outdoor Design Temperature

The Outdoor Design setting is the outdoor temperature used in the heat

loss calculation. It is set to the typical coldest outdoor temperature.

Using a small screwdriver adjust the rest ratio knob to appropriate

Outdoor Design Temperature. When set to OFF, the boiler temperature

will not be reset and boiler will fire to high limit when there is a call for

heat.

Boiler Minimum Supply Temperature (Dip Switch #1)

Most boilers require a minimum operating temperature to prevent

corrosion from flue gas condensation. The minimum boiler dip switch

should be set to ON (140°F) supply water temperature so boiler can

operate without causing the boiler flue gases to condense. Consult

the boiler manufacturer for recommended minimum boiler supply

temperatures. The dip switch can also be set to OFF (70°F) when

condensation is not a concern.

Differential (Dip Switch #2)

The differential adjustment sets how far the actual boiler supply

water temperature may deviate from the desired temperature before

the boiler is turned on or off. This is a function of the water content

of the boiler and the flow rate through the system pump relative to

the heat output of the boiler. The differential can be set by dip switch

#2, set to OFF for 10°F (6°C) or set to ON for 20°F (12°C).

Pump Operation (Dip Switch #3)

The pump operation is controlled by dip switch #3. When the dip

switch is set to ON, the pump output will energize when thermostat

or DHW calls for heat. When set to OFF, the pump will only come on

when the thermostat calls for heat not the DHW.

Warm Weather Shut Down

When the outdoor temperature rises above 70°F (21°C), the control

turns off the boiler and blinks the Thermostat LED light. This function

only applies for space heating and does not affect DHW operation.

INSTALLATION:

Step One:

Check the contents of this package. If any of the contents listed are

missing or damaged, please contact your sales representative for

assistance. The SR501-OR includes

SR501-OR Boiler Reset Control and Switching Relay Combination

One Outdoor Sensor

One Strap on Sensor

Instruction Sheet

Replacement sensors are available from Taco, Inc.

Strap on Sensor – 9300-2044RP

Outdoor Sensor – 9300-2052RP

Note: Carefully read the details of the Sequence of Operation section

in this brochure to ensure that you have chosen the proper control for

your application.

Step Two:

Installing the Control

The enclosure is to be mounted flush onto a wall or any ridge sur-

face.

• The mounting holes in the enclosure accept #6 screws.

• Line voltage to enter from bottom of control and low voltage to

enter from top of control.

Installing the Outdoor Sensor

Note: The temperature sensor (thermistor) is built into the enclosure.

• Use one round or pan head screw to attach the base of the sen-

sor to the wall.

• The sensor is wall mounted and the wiring enters through the

bottom of the enclosure. The hole for the cable entry must face

downward in order to prevent water from entering and filling the

enclosure.

CAUTION: Improper installation and operation of this control

could result in damage to the equipment and possibly even

personal injury. It is your responsibility to ensure that this con-

trol is safely installed according to all applicable codes and

standards. This electronic control is not intended for use as a

primary limit control. Other controls that are intended and cer-

tified as safety limits must be part of the control circuit.

TROUBLESHOOTING:

Step Five:

As in any troubleshooting procedure, it is important to isolate a prob-

lem as much as possible before proceeding. The blinking error LED

light greatly simplifies troubleshooting of the SR501-OR. If you sus-

pect a wiring fault, return to step three and carefully check all exter-

nal wiring and wiring connections.

Sensor Errors

• If an outdoor sensor fault occurs, the SR501-OR will assume a

fixed outdoor temperature of 32°F (0°C) and will target the

appropriate supply water temperature. The Boiler light will blink

twice every 5 seconds to indicate the outdoor sensor error.

• If a boiler sensor fault occurs, the SR501-OR turns the boiler off

and the Boiler light will blink once every 5 seconds to indicate

the boiler supply sensor error.

Adjustment of Settings

• If the outdoor temperature is cold and the rooms are cold,

increase the Outdoor Design setting by 5°F (3°C) per day.

• If the boiler is cycling too often, increase the Differential setting.

Testing the Sensors

A good quality test meter capable of measuring up to 5,000 kΩ(1 k =

1000 Ω) is required to measure the sensor resistance. In addition to

this, the actual temperature must be measured with either a good

quality digital thermometer, or, if a thermometer is not available, a sec-

Do not apply voltage to a sensor at any time

as damage to the sensor may result.

Note: When the outdoor temperature rises above 70°F (21°C), the

control turns off the boiler and blinks the Thermostat LED light.

DHW will still operate.