TECHNICAL CHARACTERISTICS

POWR-FLITE PREDATOR 32” AUTOSCRUBBER MODEL PA S 3 2 S H P

• CAUTION: Operators must read and understand this manual

completely before operating this equipment.

• CAUTION: Make sure key switch is in the “OFF” position

before installing pad.

• CAUTION: Loose objects on the floor can become danger-

ous projectiles if struck by the high-speed pad.

Remove them before operating this machine.

• CAUTION: Keep hands and feet away from revolving pad.

• CAUTION: Keep machine moving to prevent damage to

finish or floor.

• CAUTION: Make sure key switch is turned “OFF” and

battery connector is unplugged from machine

before performing any maintenance procedures.

• CAUTION: Maintenance and repairs must be performed by

authorized personnel.

• CAUTION: Battery acid can cause burns. When working on

or around batteries, wear protective clothing and

safety glasses. Remove metal jewelry. Do not lay

tools or metal objects on top of batteries.

• CAUTION: Do not operate this equipment in bare feet or

with open-toed shoes or sandals.

• CAUTION: Charging batteries generate explosive gases.

NO SMOKING OR OPEN FLAMES OR SPA R K S .

Make sure the charger has turned off before

disconnecting it from the batteries. Charge

batteries in a well-ventilated area with the tanks in

the raised and locked position.

• CAUTION: Store or park this machine on a level surface

only. Remove key from switch if machine is left

unattended.

• CAUTION: Do not operate machine or charger in areas

where flammable liquids or gases are present.

Do not use or pick up flammable chemicals or

liquids with this machine.

• CAUTION: Make sure all caution, warning and instructional

decals are in place and legible. Replace

d a m aged or missing labels.

• CAUTION: These machines are designed for level floor

operations only. DO NOT OPERAT E ON RAMPS

OR INCLINES unless adequate personnel are

available for assistance.

• CAUTION: Do not expose electrical components to water or

other liquids. To clean machine wipe down with

a damp cloth.

IMPORTANT SAFETY INSTRUCTIONS

All operators must read, understand and practice the following safety instructions.

They will be repeated occasionally throughout this manual, and additional cautions may be added for specific causes.

- 1 -

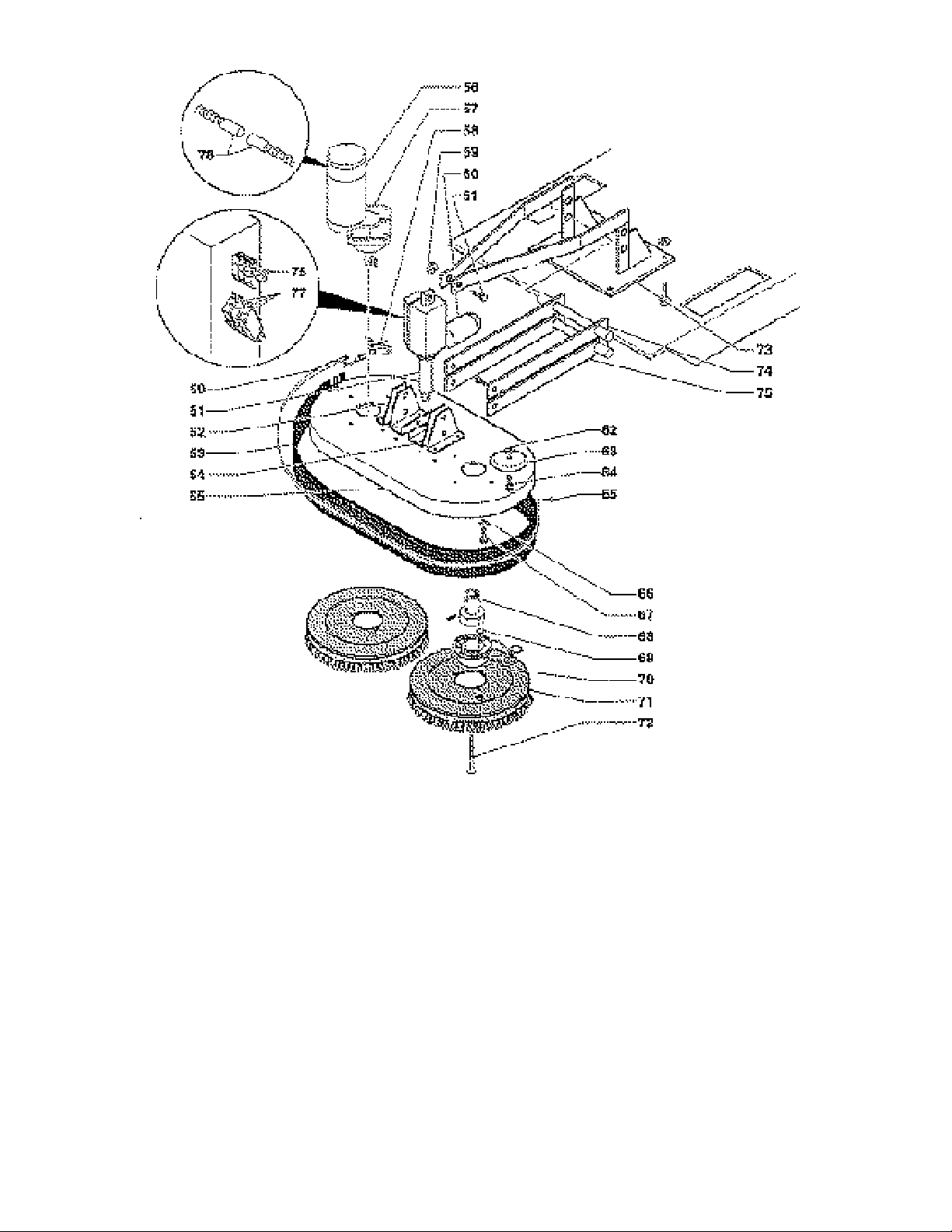

Area per hour . . . . . . . . . . . . . . . . . . 54,000 sq. ft. . . . . . . . . . . . . . . . . . . . . 5016 sq. meters

Solution tank . . . . . . . . . . . . . . . . . . 24 gallons . . . . . . . . . . . . . . . . . . . . . . 100 liters

Recovery tank . . . . . . . . . . . . . . . . . . 24 gallons . . . . . . . . . . . . . . . . . . . . . . 100 liters

Cleaning width . . . . . . . . . . . . . . . . 32 inches . . . . . . . . . . . . . . . . . . . . . . 812 mm

Squeegee Width . . . . . . . . . . . . . . . . . 44 inches . . . . . . . . . . . . . . . . . . . . . . 1117 mm

Brush pressure . . . . . . . . . . . . . . . . . 88 lbs. - 175 lbs. . . . . . . . . . . . . . . . . . 40kg - 80kg

Brush speed . . . . . . . . . . . . . . . . . . . 225 rpm . . . . . . . . . . . . . . . . . . . . . . . 225 rpm

B r u s h e s . . . . . . . . . . . . . . . . . . . . . . 2 ea. 16 inch . . . . . . . . . . . . . . . . . . . . 2 x 406 mm

Brush motor . . . . . . . . . . . . . . . . . . . 2 ea. 3/4 hp . . . . . . . . . . . . . . . . . . . . . 2 ea. 3/4 hp

Brush pressure motor . . . . . . . . . . . . 1-1/4 hp . . . . . . . . . . . . . . . . . . . . . . . 1-1/4 hp

Vacuum motor . . . . . . . . . . . . . . . . . 2 ea. 1/2 hp . . . . . . . . . . . . . . . . . . . . . 2 ea. 1/2hp

Drive motor . . . . . . . . . . . . . . . . . . . 1/2 hp. . . . . . . . . . . . . . . . . . . . . . . . . 1/2 hp.

Tr a n s m i s s i o n . . . . . . . . . . . . . . . . . . helical gear . . . . . . . . . . . . . . . . . . . . . helical gear

Supply voltage . . . . . . . . . . . . . . . . . . 36 volt . . . . . . . . . . . . . . . . . . . . . . . . 36 volt

Continuous operating . . . . . . . . . . . . 6 hours . . . . . . . . . . . . . . . . . . . . . . . . 6 hours

Operating time . . . . . . . . . . . . . . . . . 6 - 8 hours . . . . . . . . . . . . . . . . . . . . . 6 - 8 hours

Battery requirement . . . . . . . . . . . . . 6 - 6 volt- 244 ah . . . . . . . . . . . . . . . . . 6 - 6 volt- 244 ah

Battery storage area LxWxH . . . . . . . . . 21-1/4 x 21-1/2 x 14 1/8 . . . . . . . . . . . . 53.9 cm x 54.6 cm x 35.9 cm

Weight w/o batteries . . . . . . . . . . . . . 440 lbs. . . . . . . . . . . . . . . . . . . . . . . . 200 kgs.