The Orbital/Microplate Shakers have been designed for the speed and time functions

to work independently of one another. The speed can be reset without resetting

the timer and the timer can be stopped and started without interrupting the shaking

function.

1. Getting ready:

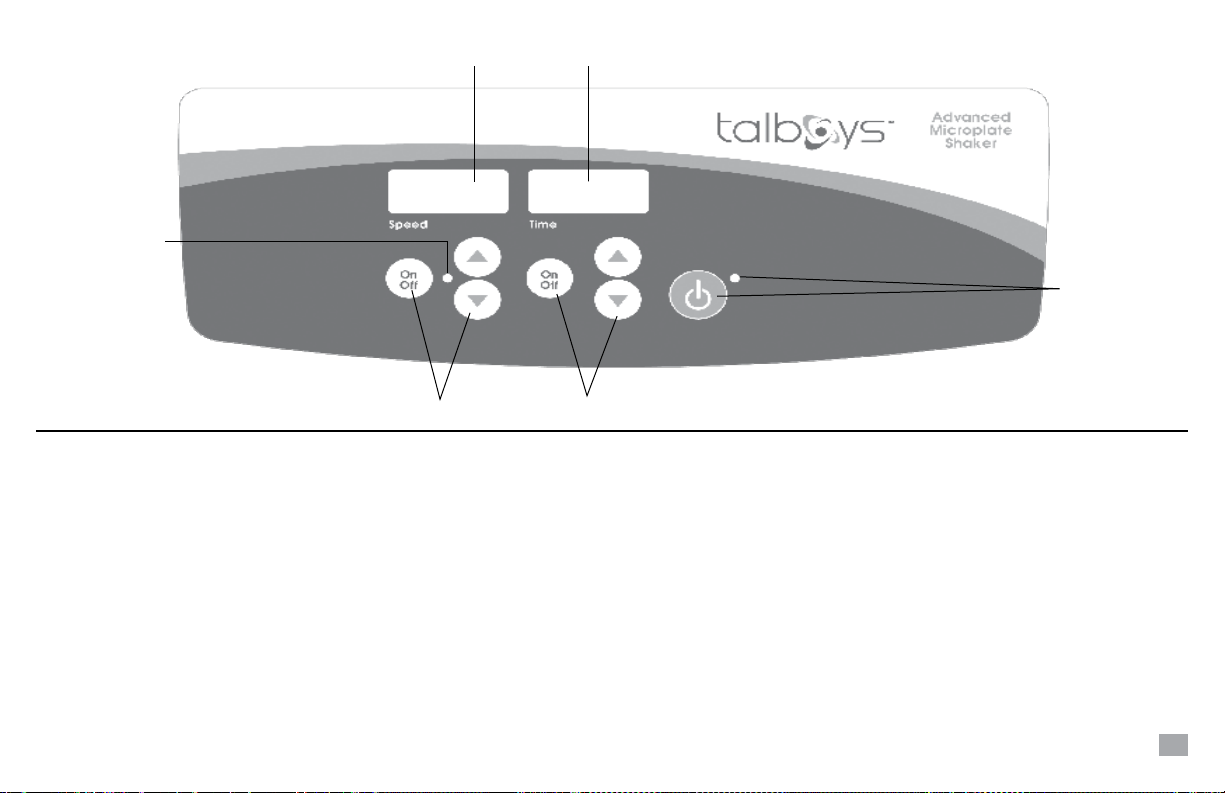

a. Plug the power cord into a properly ground outlet. The standby indicator light

will illuminate, verifying power to the unit.

b. Press the standby button to move the unit from standby mode. The standby

indicator light will turn off and the speed and time displays will illuminate,

displaying previously used settings.

2. Setting speed:

a. Press the up/down arrows below the speed display until you reach the desired

speed. When you release the button, the display will blink off and then on

indicating the new set speed has been accepted.

b. Press the on/off button to start the shaking function. The indicator light below

the speed display will illuminate to indicate the shaking function is in use and

remain lit until shaking has ceased. The microprocessor controlled ramping feature

slowly increases speed until the set-point is reached which helps to avoid

splashing, and provides excellent low end control.

c. Speed adjustments can be made without interrupting shaking by using the up/

down arrows below the speed display. After the change has been made and

you release the button, the display will blink off and then on indicating the new

set speed has been accepted.

d. To stop the shaking function, press the on/off button below the speed display.

The speed indicator light will turn off.

3. Setting time to zero (0:00) and continuous mode: Accumulated time.

a. Press and hold the on/off button below the time display. After three (3) seconds

the display will indicate the previous set time.

b. Simultaneously press both the up and down arrows, the display will indicate

zero (0:00). The unit time is now set to zero (0:00) minutes. Alternately, you can

use the up/down arrows to get to zero (0:00).

c. Press the on/off button below the time display. The display will indicate

accumulated time. The up/down arrows will become inactive. To stop timer,

press the on/off button again. IMPORTANT: This will NOT interrupt the shaking

function. Press the on/off button below the speed display to interrupt the

shaking function.

d. To reset, press and hold the on/off button below the time display. After three (3)

seconds the display will indicate the previous set time, which was zero (0:00).

4. Setting timed mode: Programmed time.

a. Press the up/down arrows below the time display until you reach the desired

time.

b. Start this function by pressing the on/off button below the time display. The unit

will run for the selected time, the up/down arrows will become inactive while the

timer is running. The unit will stop shaking when the time display reaches zero

(0:00). Four (4) audible beeps will indicate the count down function is complete.

The time display will default back to the set time. To repeat for the same time,

simply press the on/off button again.

c. To interrupt an automatic timing cycle before it is completed, press the on/off

button below the time display. The display will flash off and on to indicate the

time function is on “hold”. IMPORTANT: This will NOT interrupt the shaking

function. Press the on/off button below the speed display to interrupt the

shaking function. Restart the timer by pressing the on/off button below the

time display. Unit will continue counting down to zero (0:00). When the display

reaches zero (0:00), you will hear the four (4) audible beeps that indicate the

count down function is complete and shaking function will cease.

aDvanCeD orbital/MiCroPlate shaker oPerating instruCtions

9