1

GENERAL SAFETY RULES GB

WARNING! When using gas tools, basic safety precautions, including the following, should always be followed to reduce

the risk of serious personal injury and/or damage to the unit.

Read all these instructions before operating this product and save these instructions.

WARNING • PLEASE READ

For your own safety please read this manual before attempting to operate your new unit. Failure to follow instructions

can result in serious personal injury. Spend a few moments to familiarize yourself with your trimmer before each use.

MODEL NO. AEA002

SAFETY

OPERATION

MAINTENANCE

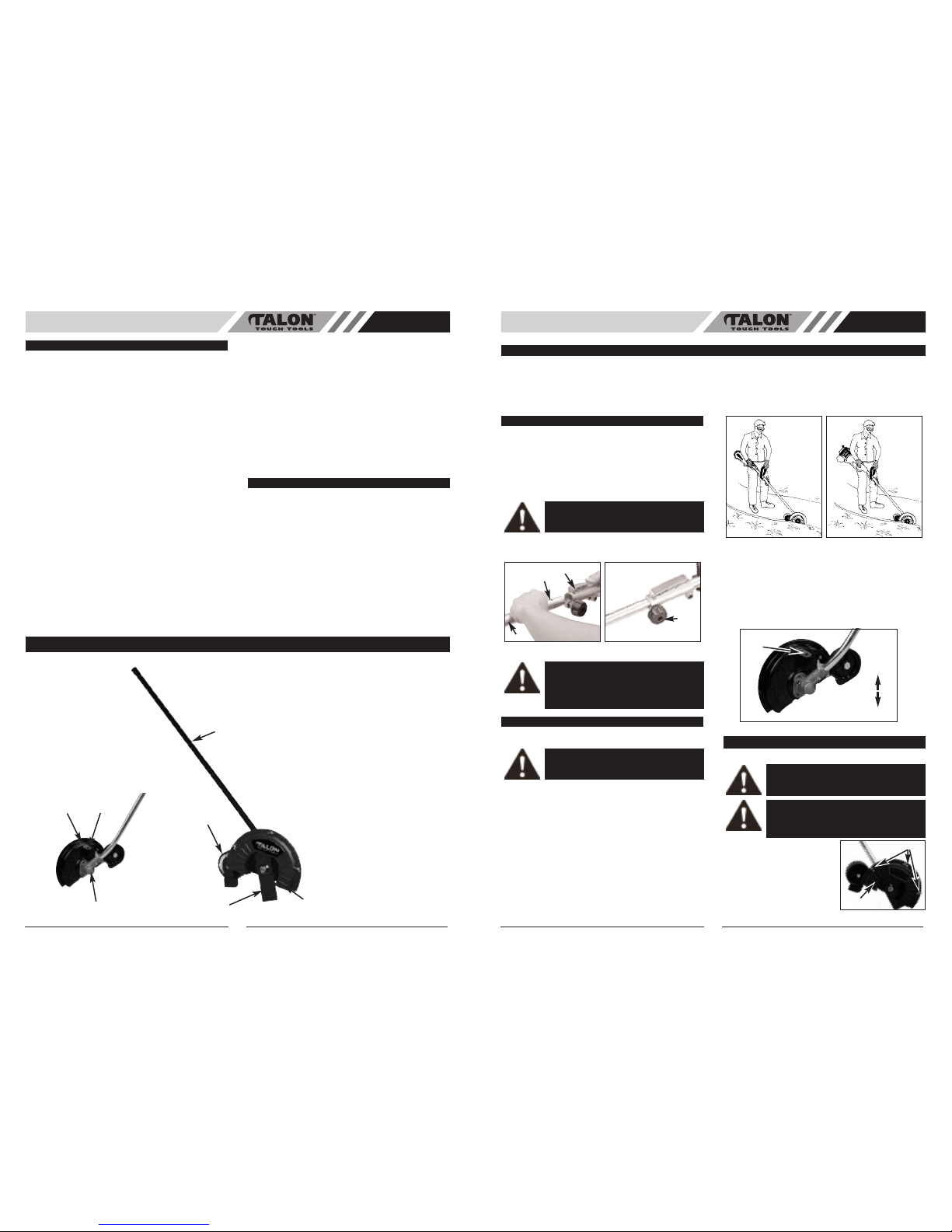

Edger Attachment

USER MANUAL

Meaning of symbols marked on the product

Read the user manual before using the machine

Wear safety goggles to protect your eyes

Wear ear protection to protect against noise

Wear dust mask to protect against dust

Wear gloves to protect your hands

Wear safety boots to protect against electric shock

READ YOUR USER MANUAL AND ALL SUPPLE-

MENTS (IF ANY ENCLOSED) THOROUGHLY BEFORE

OPERATING YOUR UNIT.

1. Wear close fitting, tough work clothing that will

provide protection, such as long slacks or trousers,

safety work shoes, heavy duty work gloves, hard hat,

a safety face shield, or safety glasses for eye protec-

tion and a good grade of ear plugs or other sound

barriers for hearing protection.

2. Store in a safe place.

Open fuel cap slowly to release

any pressure which may have formed in fuel tank. To

prevent a fire hazard, move at least 10 feet (3 meters)

from fuelling area before starting.

3. Turn unit off before setting it down.

4. Always hold unit firmly with both hands, the

thumb and fingers encircling the handles.

5. Keep all screws and fasteners tight. Never operate

your equipment when it is improperly adjusted or not

completely and securely assembled.

6. Keep handles dry, clean and free of fuel mixture.

7. Keep stringhead as close to ground as practical.

Avoid hitting small objects with stringhead. When cut-

ting on a slope, stand below stringhead. NEVER cut

or trim on a hill or slope, etc. if there is the slightest

chance of slipping, sliding or losing firm footing.

8. Check area you will be trimming for debris that

may be struck or thrown during operation.

9. Keep all parts of your body and clothing away

from stringhead when starting or running engine.

Before starting engine, make sure stringhead will not

come in contact with any obstacle.

10. Stop engine before examining cutting line.

11. Store equipment away from possible flammable

materials, such as gas-powered water heaters,

clothes dryers, or oil-fired furnaces, portable

heaters, etc.

12. Always keep the debris shield, stringhead, and

engine free of debris build-up.

13. Operation of equipment should always be restricted

to mature and properly instructed individuals.

WARNING: Gasoline is highly flammable, and its vapours

can explode if ignited. Take the following precautions:

1. Store fuel only in containers specifically designed and

approved for the storage of such materials.

2. Always stop the engine and allow it to cool before fill-

ing the fuel tank. Never remove the cap of the fuel

tank, or add fuel, when the engine is hot. Never oper-

ate the unit without the fuel cap securely in place.

Loosen the fuel tank cap slowly to relieve any pressure

in the tank.

3. Mix and add fuel in clean, well-ventilated area out-

doors where there are no sparks or flames. Slowly

remove the fuel cap only after stopping engine. Do not

smoke while fuelling or mixing fuel. Wipe up any spilled

fuel from the unit immediately.

4. Avoid creating a source of ignition for spilled fuel. Do

not start the engine until fuel vapours dissipate.

5. Move the unit at least 10 feet (3m) from the fuelling

source and site before starting the engine. Do not

smoke, keep sparks and open flames from the area

while adding fuel or operating the unit.

6. Never start or run the unit inside a closed room or

building. Breathing exhaust fumes can kill. Operate

this unit only in a well ventilated area outdoors.

1. WARNING: To reduce the risk of electrical shock, use

only extension cords approved for outdoor use.

2. CORDS SETS: Make sure your cord set is in good

condition. When using a cord set, be sure to use a cord

that is heavy enough to carry the current that your unit

will draw. An undersized cord set will cause a drop in

line voltage resulting in loss of power and overheating.

See the operator’s manual for the unit that will power

this attachment for the recommended cord size.

3. Inspect all extension cords and the unit power connec-

tion periodically. Look closely for deterioration, cuts or

cracks in the insulation. Also inspect the connections

for damage. Replace the cords if any defects or dam-

age appear.

4. Avoid creating a source of ignition for spilled fuel. Do

not start the engine until fuel vapours dissipate.

5. Do not use the unit in the rain.

6. Do not handle the plug or unit with wet hands or stand-

ing on any wet surfaces.

7. Do not leave the unit plugged in when not in use,

changing attachments or add-ons, or while being serv-

iced.

WARNING: Keep children, bystanders, and

animals 50 feet (15 meters) away. If

approached stop unit immediately.

SAFETY WARNINGS FOR GAS EDGERS

SAFETY WARNINGS FOR ELECTRIC EDGERS