PROBABLE CAUSE

Incorrect starting procedures.

Incorrect carburettor mixture adjustment

setting.

Fouled spark plug

Fuel filter blocked.

Incorrect lever position on choke.

Dirty spark arrester screen.

Dirty air filter.

Incorrect carburettor mixture adjustment

setting.

Incorrect carburettor mixture adjustment

setting.

Incorrectly gapped spark plug.

Incorrect carburettor mixture adjustment

setting.

Incorrect fuel mixture.

Chain brake is engaged.

Chain brake engaged.

Incorrect chain tension.

Chain incorrectly fitted.

Blocked passages.

Oil leaking from unit after use.

Oil comming out of cap.

3

GENERAL SAFETY RULES AU

WARNING! When using petrol tools, basic safety precautions, including the following, should always be followed to

reduce the risk of serious personal injury and/or damage to the unit.

Read all these instructions before operating this product and save these instructions.

1. DO NOT operate a chain saw with one hand! Serious

injury to the operator, helpers, bystanders, or any

combination of these persons may result from one-

handed operation. A chain saw is intended for two-

handed use.

2. DO NOT operate a chain saw when you are fatigued.

3. Use safety footwear, snug-fitting clothing, protective

gloves, and eye, hearing and head protection

devices.

4. Use caution when handling fuel. Move the chain saw

at least 10 feet (3m) from the fueling point before

starting the engine.

5. DO NOT allow other persons to be near when start-

ing or cutting with the chain saw. Keep bystanders

and animals out of the work area.

6. DO NOT start cutting until you have a clear work

area, secure footing, and a planned retreat path from

the falling tree.

7. Keep all parts of your body away from the saw chain

when the engine is running.

8. Before you start the engine, make sure that the saw

chain is not contacting anything.

9. Carry the chain saw with the engine stopped, the

guide bar and saw chain to the rear, and the muffler

away from your body.

10. DO NOT operate a chain saw that is damaged,

improperly adjusted, or not completely and securely

assembled. Be sure that the saw chain stops mov-

ing when the throttle control trigger is released.

11. Shut off the engine before setting the chain saw

down.

12. Use extreme caution when cutting small size brush

and saplings because slender material may catch the

saw chain and be whipped toward you or pull you off

balance.

13. When cutting a limb that is under tension, be alert for

springback so that you will not be struck when the

tension in the wood fibers is released.

14. Keep the handles dry, clean, and free of oil or fuel

mixture.

15. Operate the chain saw only in well-ventilated areas.

16. DO NOT operate a chain saw in a tree unless you

have been specifically trained to do so.

17. All chain saw service, other than the items listed in

the user manual safety and maintenance instructions,

should be performed by competent chain saw service

personnel.

18. When transporting your chain saw, use the appropri-

ate guide bar scabbard.

19. DO NOT operate your chain saw near or around

flammable liquids or gases whether in or out of doors.

An explosion and/or fire may result.

20. Do not lubricate, fill with fuel or oil when the chain

saw engine is running.

21. USE THE RIGHT TOOL: Cut wood only. Do not use

the chain saw for purposes for which it was not

intended. For example, do not use the chain saw for

cutting plastic, masonry, or nonbuilding materials.

Kickback may occur when the nose or tip of the guide bar

touches an object, or when the wood closes in and pinch-

es the saw chain in the cut. If the bar tip contacts, it may

cause a lightning-fast reverse reaction, kicking the guide

bar up and back towards the operator. Pinching the saw

chain along the top of the guide bar may push the guide

bar rapidly back towards the operator. Either of these

reactions may cause you to lose control of the saw, which

could result in serious personal injury. Do not rely exclu-

sively upon the safety devices built into your saw. As a

chain saw user, you should take several steps to keep

your cutting jobs free from accident or injury.

1. With a basic understanding of kickback, you can

reduce or eliminate the element of surprise. Sudden

surprise contributes to accidents.

2. Keep a good firm grip on the saw with both hands,

the right hand on the rear handle, and the left hand

on the front handle, when the engine is running. Use

a firm grip with thumbs and fingers encircling the

chain saw handles. A firm grip will help you reduce

kickback and maintain control of the saw. Don’t let

go.

3. Make sure that the area in which you are cutting is

free from obstructions. Do not let the nose of the

guide bar contact a log, branch, or any other obstruc-

tion which could be hit while you are operating the

saw.

KICKBACK SAFETY PRECAUTIONS

TROUBLESHOOTING AU

Read the user manual before using the machine

Whenever the machine is in use, safety goggles

must be worn to safeguard against flying objects,

as must ear protectors such as a sound proof hel-

met, in order to protect the operators hearing.

Wear gloves to protect your hands.

Wear safety boots to protect your feet.

Do not operate unit in the rain.

Danger! Beware of kickback!

Meaning of symbols marked on the product

2

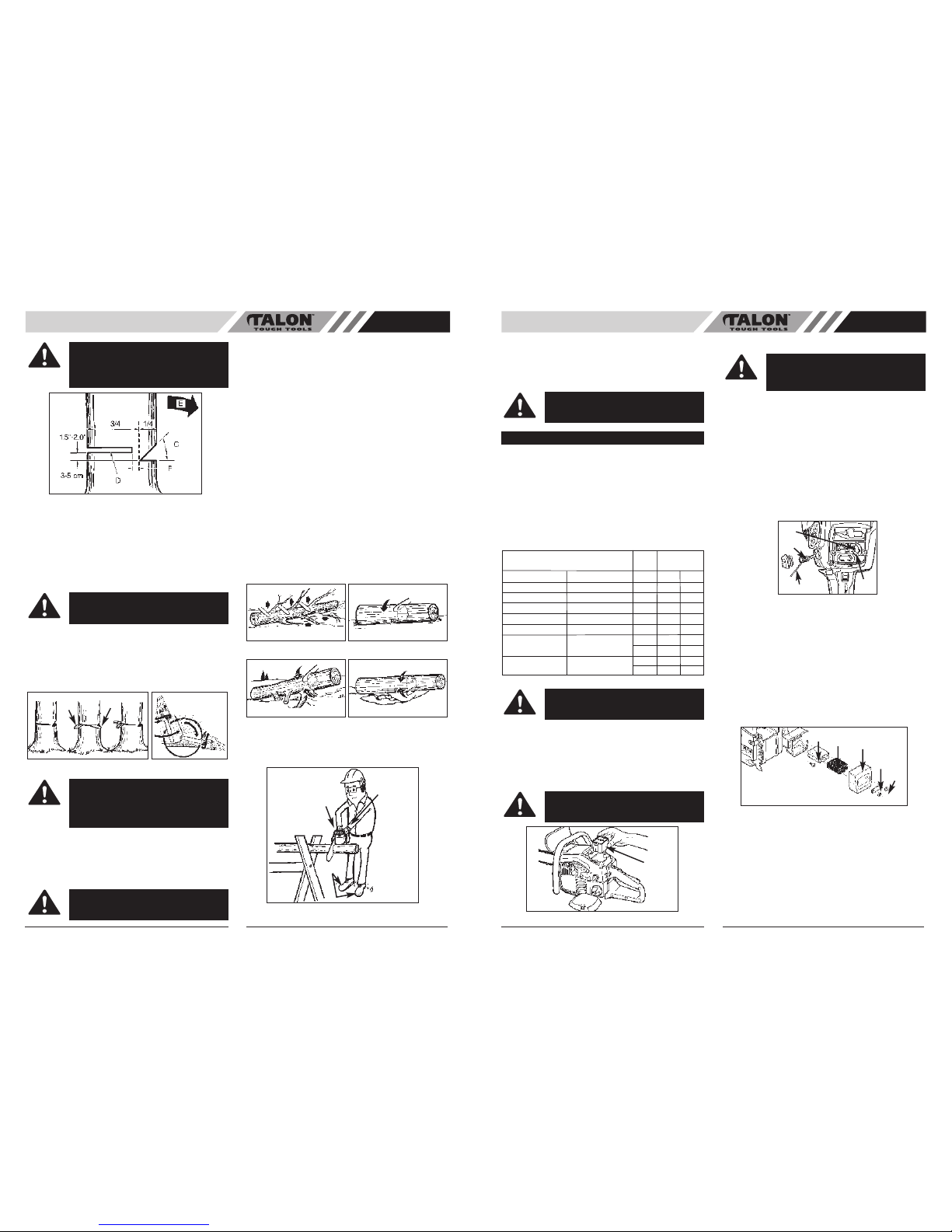

TROUBLESHOOTING THE ENGINE

PROBLEM

Unit won’t start or starts but will not run.

Unit starts, but engine has low power.

Engine hesitates.

No power under load.

Runs erratically.

Smokes excessively.

Cannot remove chain sprocket cover

Unit does not cut properly.

Chain oil not feeding or leaking from unit.

CORRECTIVE ACTION

Follow instructions in the User Manual.

Have carburettor adjusted by an Authorized

Service Center.

Clean / gap or replace plug.

Replace fuel filter.

Move to RUN position.

Replace spark arrester screen.

Remove, clean and reinstall filter.

Have carburettor adjusted by an Authorized

Service Center.

Have carburettor adjusted by an Authorized

Service Center.

Clean / gap or replace plug.

Have carburettor adjusted by an Authorized

Service Center.

Use properly mixed fuel (25:1 mixture).

Disengage chain brake.

Disengage chain brake. Unit will “smoke” if

chain brake is engaged while trying to run.

Adjust chain tension.

Cutting edges of chain should face forward

on top of chain bar.

Remove sprocket cover and ensure the

area around the sprocket and bar are clean

and free of saw dust.

A small amount of oil will always discharge

from the unit after use. This is the oil remain-

ing in the lines after use.

Clean oil passages. Oil passages that are

blocked will build up pressure in tank thus

forcing oil out of cap.

The cap seal maybe faulty. Exchange oil

filler cap.

The following basic trouble shooting checks can be easily carried out to determine whether or not the unit is running

properly. If the unit will not operate after these checks then the product should be taken to an authorised service agent

for further inspection.

Ensure a small amount of fresh 2 stroke fuel (25:1 fuel:oil) is either in the tank or available for use during trouble shoot-

ing.