CONTENTS

Page

Number

SECTION

I--GENERAL

INFORMATION

1.1

Scope

1-1

1.2

Introduction

....•.•...............•.•.•

1-1

1.3

Disk

Drive

Performance

Characteristics.

1-1

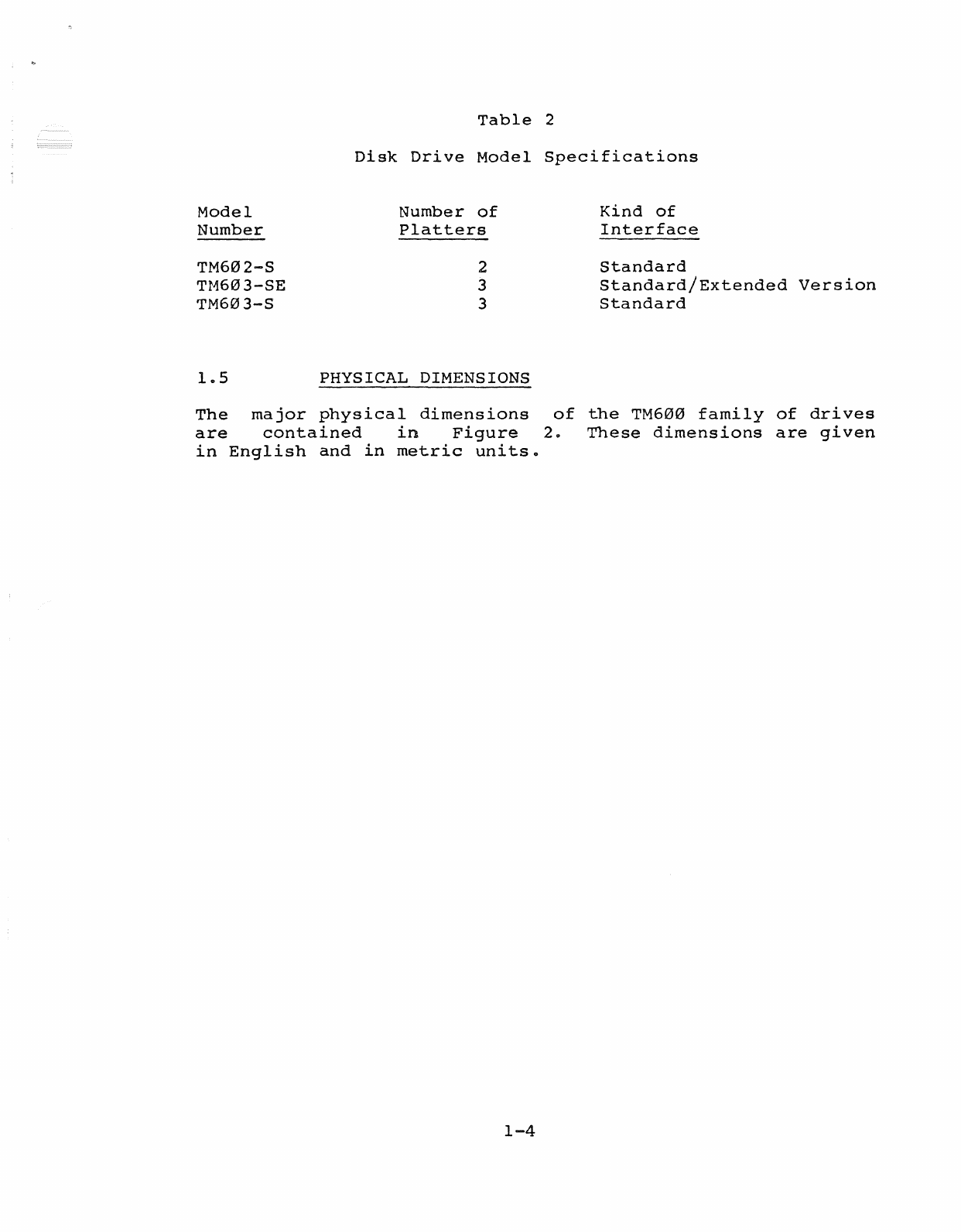

1.4

Disk

Drive

Model

Specifications

.•••.•••

1-1

1.5

Pqysical

Dimensions

••..•...•.••.•.•..••

1-4

SECTION

II--INSPECTION,

INSTALLATION,

AND

INTERFACES

2.1

Introduction

••••••••••.••..•.••.•.•..••

2-1

2.2

Unpacking

and

Inspection

•••••••••••.•.•

2-1

2.3

Mounting

Characteristics

•••••••••••••.•

2-3

2.4

Power

Cabling

•••••••••••.••.•••••••••••

2-3

2.5

Standard

Interface

••••••••••.•.••••••••

2-3

SECTION

III--THEORY

OF

OPERATION

3.1

3.2

3.2.1

3.2.2

3.2.3

3.2.4

3.2.5

3.2

..

6

3.3

3.3.1

3.3.2

3.3.3

3.3.4

3.3.5

3.3.6

3.4

3.4.1

3.4.2

Introduction

.•..•.•••.••.•••••.••••.•••

3-1

Input

Control

Lines

••.•••••..••••••••••

3-2

Reduced

Write

Current

.•••.•••..••••.••.

3-2

Write

Gate

••••••.•••••••.•••••••••.••••

3-2

Head

Select

••••••••••.•••.•••••••••••••

3-3

Step

Interface

•••••••••••••••••••••••••

3-3

Di

rect

i

on

In

•••••••••••••••••.•••••••••

3-4

Drive

Select

••••••••••••.•••.••••••••••

3-4

Output

Control

Lines

••••.•••••••••••••••

3-5

Drive

Selected

•••••••••••••••••••••••••

3-5

Seek

Complete

••••••••••••••••••••••••••

3-5

Track

00eJ

••••••••••••••••••••••••••••••

3-5

Fault

0

••••••••••••

,.

••••

3-6

Line

Ready

•••••••••••••••••••••••••.•••

3-6

Index

3-6

Data

Transfer

Lines

••••••••••••••.•••••

3-6

MFM

Write

Data

•••••••••.••••••.••••.•••

3-6

MFM

Read

Data

••••••••••••••••••••••••••

3-7