INDUSTRY STANDARD INTERFACE

COMPATIBILITY

Both drives are compatible with controllers that use an

ST506/412 industry standard interface.

FRONT PANEL

Front panels equipped with an activity indicator are

available for each

of

the drives.

AIR FILTRATION

A self-contained, recirculating air filtration system sup-

plies clean air through a 0.3-micron filter. A secondary

breather filter is provided to allow pressure equaliza-

tion with the ambient atmosphere without contamina-

tion. The entire head-disk-actuator compartment is

maintained at a slightly positive pressure

to

further en-

sure an ultraclean environment.

1.4

FUNCTIONAL DESCRIPTION

The functional characteristics

of

the TM362 and

TM262 drives are identical. The drives are fully self-

contained and require no operator intervention during

normal operation. During the power-up sequence, the

spindle motor reaches 3,568 RPM, and the position-

ing mechanism recalibrates the recording heads back

to Track

0.

If

the spindle motor does not get up to speed

within

15

seconds, the drivers to the spindle motor will

be

turned off. A new power up sequence will be at-

tempted when the power is momentarily removed and

then restored.

The drives are designed to optimize

MFM

write and

read data recording methods,

as

specified

by

the

ST506/412 interface. Data recovery electronics include

1-2

a low-level read amplifier, differentiator, a zero-

crossover detector, and digitizing circuits. No data en-

coding or decoding features are provided on the drives.

The heads are positioned over the desired track

by

means

of

a stepper motor and a rack and pinion

mechanism. Servo positioning pulses are recorded on

the final segment

of

each Head 0 track, and,

by

con-

tinuously monitoring the location

of

the heads in rela-

tionship to those pulses, the drive is able to maintain

highly accurate servo positioning.

The onboard microprocessor monitors all functions that

could affect drive performance.

If

a problem exists, the

drive will abort its power-up sequence

or

(after achiev-

ing a Ready state) declare a fault condition.

A parking zone is provided for the read/write heads

at cylinder 663. The parking function is under the con-

trol

of

the drive controller.

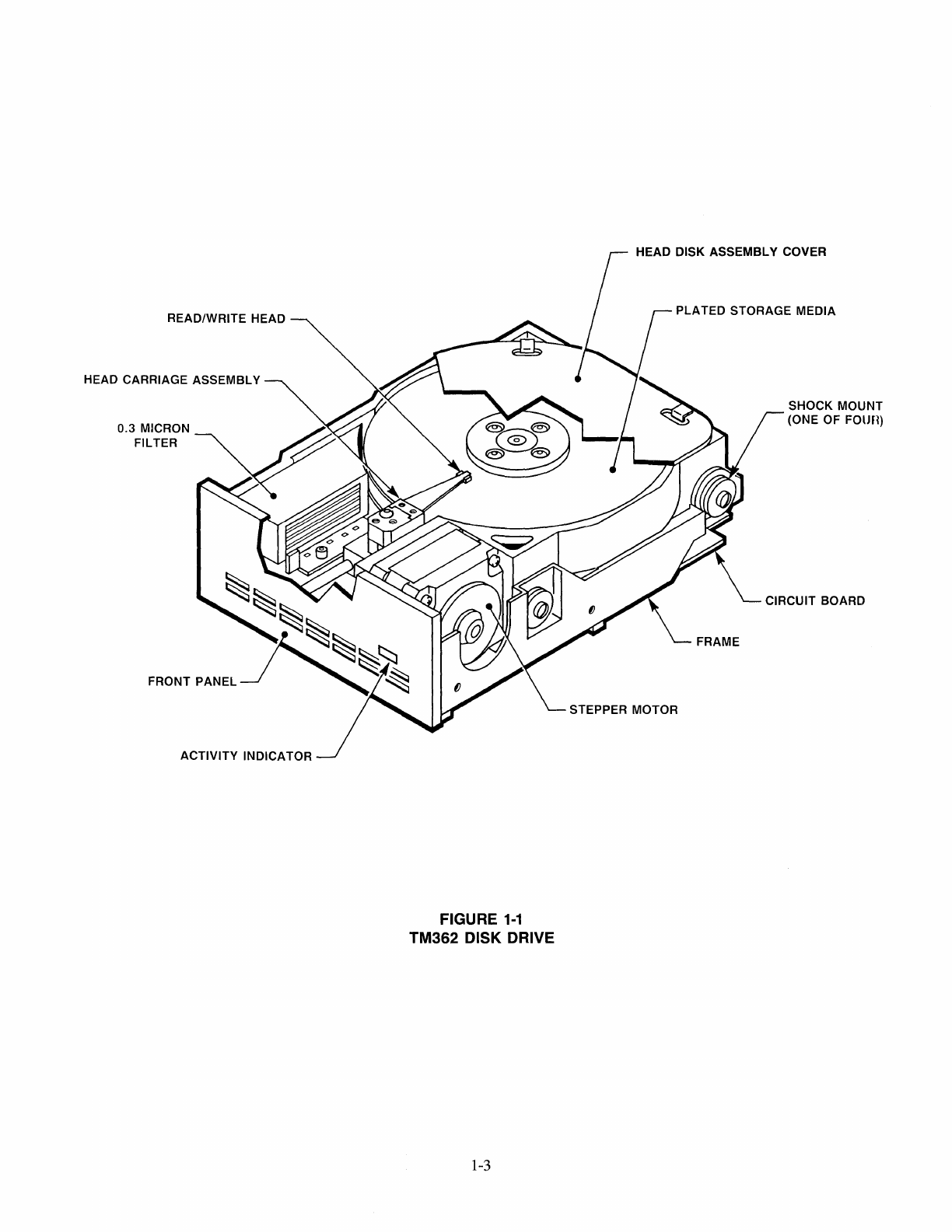

1.5 PHYSICAL DESCRIPTION

The TM362 and TM262 drives differ only in the

physical dimensions

of

their frames. The TM362 uses

the smaller frame, and the TM262 the larger.

The TM362 drive

is

shown in Figure

1-1

and the TM262

drive in Figure

1-2.

Both drives contain 3.5-inch storage

media.

The

head

disk

assembly

and the

read/write

preamplifiers are enclosed in a sealed cast aluminum

housing, which includes an air

fil~ration

system

to

en-

sure a contamination-free environment. The housing

is shock mounted to a metal frame. A front panel may

be attached to either drive. Threaded holes are provid-

ed on the sides and bottom

of

the frame for mounting

the drive onto a chassis.

In addition, both drives include read/write control elec-

tronics and servo spindle control electronics.