TABLE OF CONTENTS

TABLE OF CONTENTS ...................................................................................................... i

LAUNCHING AND RIGGING .........................................................................................1

RUDDER AND TILLER...................................................................................................1

OUTBOARD MOTOR AND BRACKET..........................................................................2

CRANE LAUNCH ........................................................................................................2

TRAILER LAUNCH........................................................................................................3

RIGGING KIT...............................................................................................................4

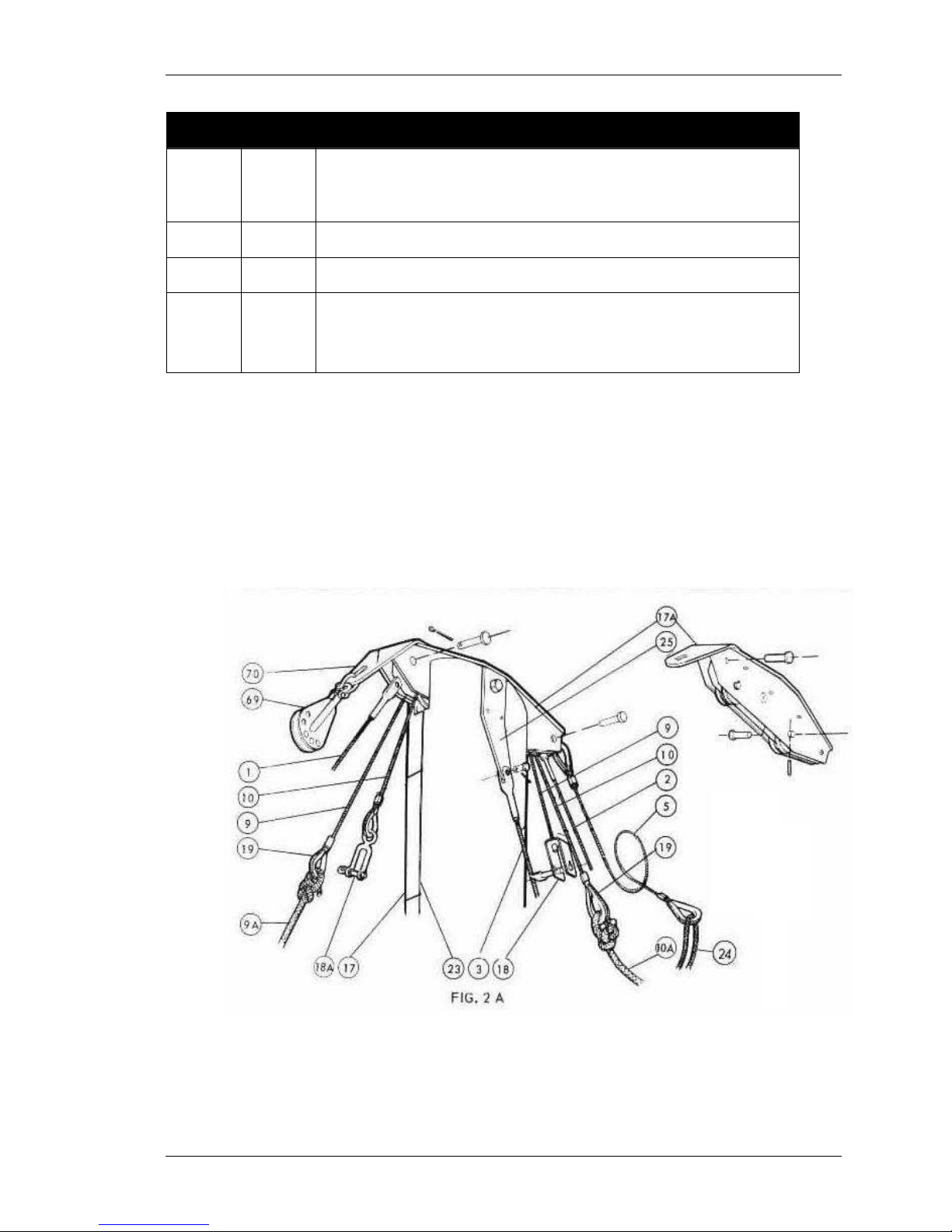

RIGGING AND STEPPING THE MAST..........................................................................5

BOOM VANG...........................................................................................................13

MAINSAIL..................................................................................................................13

OUTHAUL ..................................................................................................................14

CUNNINGHAM.........................................................................................................15

MAINSHEET TRAVELLER ............................................................................................16

MAIN SAIL COVER ...................................................................................................16

SPINNAKER GEAR.....................................................................................................17

BOW PULPIT, LIFELINES & STERN RAIL.......................................................................19

ANCHOR WELL HATCH............................................................................................20

HOISTING SAIL..............................................................................................................21

MAINSAIL..................................................................................................................21

JIB .............................................................................................................................21

GENOA.....................................................................................................................23

SPINNAKER ...............................................................................................................24

REEFING .......................................................................................................................25

ROLLER REEFING ......................................................................................................25

JIFFY REEFING...........................................................................................................25

ACCESSORIES..............................................................................................................26

FOREHATCH VENTILATOR ........................................................................................26

SCREENS...................................................................................................................26

COCKPIT AWNING...................................................................................................27

MARINE TOILET .........................................................................................................27

PORTABLE TOILETS....................................................................................................28

ICE BOX ....................................................................................................................28

ELECTRICAL SYSTEM ....................................................................................................29

MAINTENANCE ............................................................................................................32

ANTI-FOULING..........................................................................................................32

FIBERGLASS SURFACES.............................................................................................32

GELCOAT REPAIRS...................................................................................................33

TEAK..........................................................................................................................34

STANDING AND RUNNING RIGGING......................................................................34

FITTINGS ....................................................................................................................34

THROUGH HULL FITTINGS .........................................................................................34

CARE OF SAILS .........................................................................................................35

CENTERBOARD ASSEMBLY.......................................................................................36

WINCHES ..................................................................................................................36

ADDITIONS ...................................................................................................................38