Tapeswitch CKP/S1 User manual

1

IMPORTANT

This manual must accompany the product throughout its working

life. Those persons responsi le for the use of the product must ensure

that all persons involved in the installation, commissioning, operation,

maintenance and servicing of the product have access to all the

information supplied y the manufacturers of the machine and its

safety system.

WARNING

Tapeswitch safety mat systems are intended to protect operators

working at or near dangerous machinery. They can only perform this

function if they are correctly fitted and interfaced to a suita le

machine. It is essential that the full contents of this manual and all the

authoritative documents referred to herein are fully understood

efore any attempt at installation is made. If in dou t contact

Tapeswitch or your Tapeswitch distri utor.

TAPESWITCH

SAFETY MATS-

CKP/S1 Sensors

with PRSU/4 control units

TECH ICAL MA UAL 343181-09

English

2

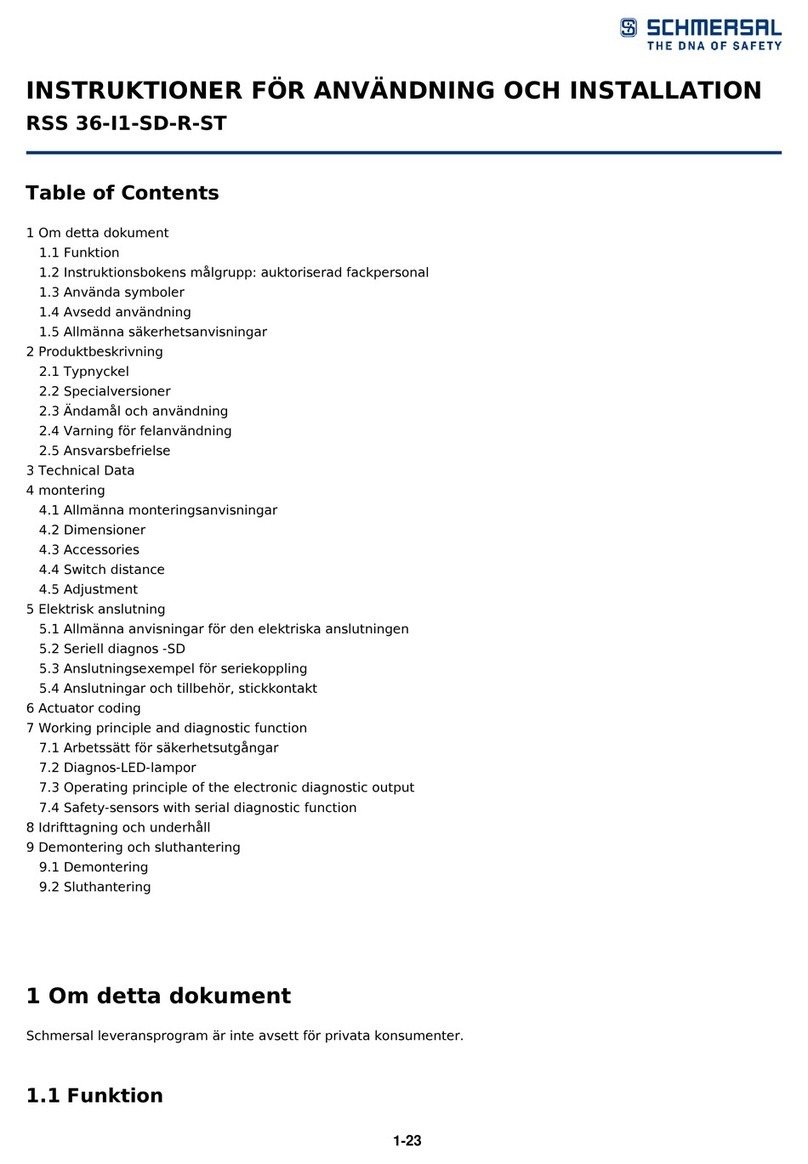

CO TE TS

1. I TRODUCTIO

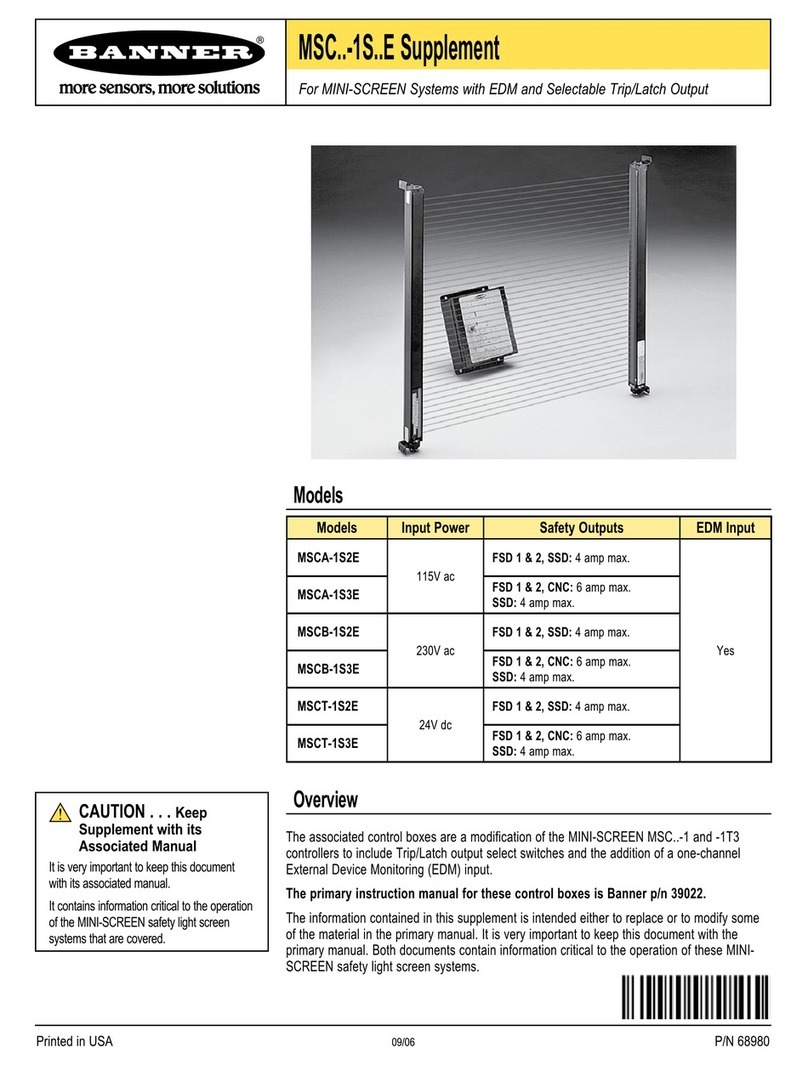

1.1 PRODUCT DESCRIPTION

1.2 PRODUCT RANGE

1.3 PRODUCT FEATURES

1.4 PRODUCT APPLICATION

1.5 STANDARDS AND SAFETY INTEGRITY

1.6 SPECIFICATION AND ORDERING INFORMATION

2. TECH ICAL DESCRIPTIO

2.1 SYSTEM OVERVIEW

2.2 SENSORS

2.3 CONTROL UNIT

3. I STALLATIO

3.1 GENERAL

3.2 SENSOR INSTALLATION

3.3 CONTROL UNITS

3.4 INITIAL CHECKING

4. PERIODIC CHECKI G

4.1 GENERAL

4.2 COMMISSIONING CHECKS

4.3 SIX MONTHLY CHECKS

4.4 DAILY/SETTING CHECKS

5. OPERATIO , MAI TE A CE A D SERVICI G

5.1 OPERATION

5.2 MAINTENANCE

5.3 SERVICING

6. TECH ICAL SPECIFICATIO

6.1 SYSTEM

6.2 SENSORS

6.3 MATERIAL SPECIFICATION

6.4 CONTROL UNIT

7. CO TACTS

3

1.2 PRODUCT RA GE

1.2.1 SENSORS

1.2.1.1 SENSOR SHAPES AND SIZES

Mat sensors can be produced in any shape and

size which meets the following restrictions:

- all corners, internal or external, should be

90 degrees.

- the maximum possible width of a mat is

1200 millimetres.

- the maximum possible length of a mat is

2 00 millimetres.

- the maximum total area is 2.88m².

Rectangular shapes are preferred although any

shape which meets the restrictions outlined

above is possible.

The dimensions of sensors and their layout

must be such access to the machine is not

possible without stepping on a sensor. It should

not be possible to move the sensors or bridge

them using boards, plates etc. Further guidance

is given in section 1.6.

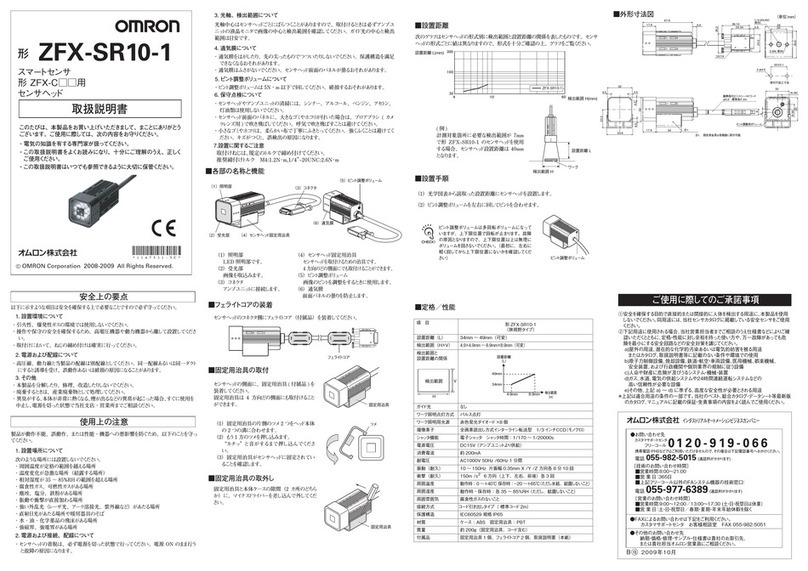

NOTE: CKP/S1 sensors have an inactive area

around the outer edges. This inactive area is 30

millimetres wide which means that the

dimensions of the active area (i.e. the zone

within which the application of pressure will

actuate the sensor) is 60 millimetres less than

the overall dimensions of the mat as shown in

Figure 1. This should be borne in mind when

specifying the size of mat for a particular

application. See section 1.6 for further

guidance on determining sensor dimensions.

1. I TRODUCTIO

1.1 PRODUCT DESCRIPTIO

Tapeswitch safety mat systems are pressure

sensitive safety devices designed to protect

operators working at or near dangerous

machinery. A system consists of a pressure

sensitive sensor and a control unit. When

correctly installed at and interfaced to a suitable

machine the system will:

(a) detect a person present in the dangerous

area and prevent dangerous motion from

occurring.

( ) detect a person entering the dangerous

area and cause dangerous motion to cease

before the person can reach the dangerous

parts.

(c) a combination of (a) and ( ).

Pressure sensitive sensors are fixed to the floor.

The area covered by the sensor depends on

which of the functions (a), (b) or (c) is to be

performed. When a person steps onto a sensor

a signal is transmitted to the control unit which

will in turn transmit a stop signal to the

machine control system.

Figure 1 - Dimensions of the inactive area

around outer edge of sensor

ACTIVE

AREA

30 30

30 30

4

1.2.1.2 SENSOR OPTIONS

CKP/S1 sensors can be supplied with two 2-

core leads or a single -core lead. Where a

single mat sensor is used a single -core lead

is most practical. Where several mats are

connected in series to form a larger sensor two

2-core leads should be specified.

1.2.2 PRSU/4 CONTROL UNIT

The PRSU/ control unit is designed to

monitor -wire safety sensors. The unit

provides monitoring of a sensor (or a number

of sensors connected in series), auto or

manual reset function and 3 safety outputs.

1.2.3 ACCESSORIES

Aluminium edging is available for fixing the

sensors in position. This edging consists of

two interlocking aluminium extrusions, a base

and a cover. The edging can accommodate the

mat wiring and provides a 20 degree ramp to

prevent a tripping hazard at the mat edge.

1.3 PRODUCT FEATURES

1.3.1 SENSORS

* Tapeswitch internal switching elements.

* Sealed to IP65.

* 2 volt operation.

* Low pressure actuation.

* Heavy duty, abrasion and chemical resistant

materials.

* Multiple sensors can be connected to one

control unit.

1.3.2 CONTROL UNIT

* Cross-monitored safety output relays

with force guided contacts.

* Auto or manual reset function

* DIN rail mounting enclosure.

* Simple, reliable, proven technology.

*One control unit capable of monitoring

multiple sensors.

* Built in diagnostic indication.

* 2 Vdc supply.

NOTE: The external 2 Vdc power supply

must either be provided from a safety

transformer meeting EN607 2 or from a

battery. Cables feeding the supply should be

run separately and should be protected against

damage.

5

1.4 PRODUCT APPLICATIO

1.4.1 GENERAL

Tapeswitch safety mat systems can be used

either to provide primary guarding where

other types of guarding are impractical or to

provide secondary guarding where the

primary guarding method cannot protect all

danger areas. Safety mats are particularly

useful for protecting operators who may be

inside large machines and for awkwardly

shaped machines. Applications include:

* Robot cells

* Tube bending machines

* Carton folding/gluing machines

* Punching machines

1.4.2 FACTORS AFFECTING

SUITABILITY

1.4.2.1 PERSONS TO BE PROTECTED

CKP/S1 safety mats are not suitable for use

where children are to be protected.

1.4.2.2 MACHINE CONTROL FACTORS

The machine control system must satisfy the

following requirements:

(a) The dangerous motion of the machine

must be electrically controllable.

( ) The machine response/stopping

performance must be adequate and consistent.

(c) It must be possible to stop the dangerous

motion of the machine at any point in its

operation.

(d) The control system as a whole must be

constructed to provide the level of safety

integrity determined by a risk assessment as

described in section 1. .2.2.

1.4.2.3 RISK FACTORS

Every machine has its own unique hazards. In

order to determine the level of risk in a

particular application a risk assessment must

be performed. In many countries methods

have been developed and published, usually

by the organisations responsible for industrial

safety, to enable a systematic risk assessment

to be carried out.

The guidance available in a particular country

may take the form of national, European or

international standards. Persons responsible

for selecting safety devices should be familiar

with the guidance available in his country

before specifying particular safety devices. In

most current guidance the factors considered

in risk assessment are:

(a) the severity of possible injury.

( ) the frequency of exposure to the

hazard.

(c) the possibility of avoiding the hazard.

CKP/S1 mat sensors are suitable for use

in low to medium risk applications where the

following conditions apply:

EITHER

- the severity of possible injury is slight.

OR

- the severity of possible injury could be

serious and

- the frequency of exposure to the hazard is

low and

- the possibility of avoiding the hazard is high.

6

1.4.2.4 ENVIRONMENT FACTORS

The existence of the following factors

may preclude the use of safety mat

systems in particular applications:

(a) risk of injury from thermal or

other radiation.

( ) a tendency for the machine to

eject materials or components.

(c) a need for heavy vehicles to

frequently enter the dangerous area.

(d) continuous or repeated immersion

in water or other fluids.

(e) exposure to damage due to

droppage of heavy or sharp objects.

(f) exposure to spillage of hot and/or

solidifying substances.

(g) exposure to spillage of aggressive

chemicals.

Consult Tapeswitch or your Tapeswitch

agent if in doubt.

1.5 STA DARDS A D SAFETY

1.5.1 GENERAL

Tapeswitch CKP/S1 safety mat systems

have been designed to meet the

requirements of the European Standard

EN 13856-1 "Safety of Machinery.

Presssure-sensitive protective device.

General principles for the design and

testing of pressure-sensitive mats and

floors".

They also conform to Performance

Level PLd of EN138 9-1 "Safety of

machinery. Safety-related parts of

control systems. General principles for

design" when used with a Tapeswitch

PRSU/ control unit. In this case the

probability of dangerous failures per

hour, PFHd , is 1.03 x 10-7

As a component only, the B10d lifespan

value for the mat sensor is .0 x 106

cycles.

7

1.6 SPECIFICATIO A D

ORDERI G I FORMATIO

1.6.1 DETERMINING SENSOR

DIMENSIONS

1.6.1.1 GENERAL

The dimensions of the dangerous area depend

on the particular application. The parameters

to be considered include:

- speed of walk or arm movement

(typically 1,6m/s)

- arm length (typically 0,85m)

- length of stride (typically 0,7m)

- response time of system

- position of inactive areas

- overtravel of dangerous parts after stop

signal is generated

A Tapeswitch pressure sensitive safety mat

system can be used as:

(a) a combined trip and presence sensing

device - the device is positioned such that it

will be activated when a person enters a

dangerous area and remains activated whilst

the person is inside the dangerous area.

( ) a presence sensing device - the sensor is

positioned such that it will be actuated by a

person who is inside a dangerous area.

(c) a trip device - the sensor is positioned

such that it will detect a person entering a

dangerous area.

NOTE: Tapeswitch CKP/S1 safety mats

have an inactive area around the outer

edges. This inactive area is 30

millimetres wide which means that the

dimensions of the active area (i.e. the

zone which must cover the dangerous

area) will be 60 millimetres less than the

overall dimensions of the mat, as shown

in Figure 2. This should be borne in mind

when specifying the size of mat for a

particular application.

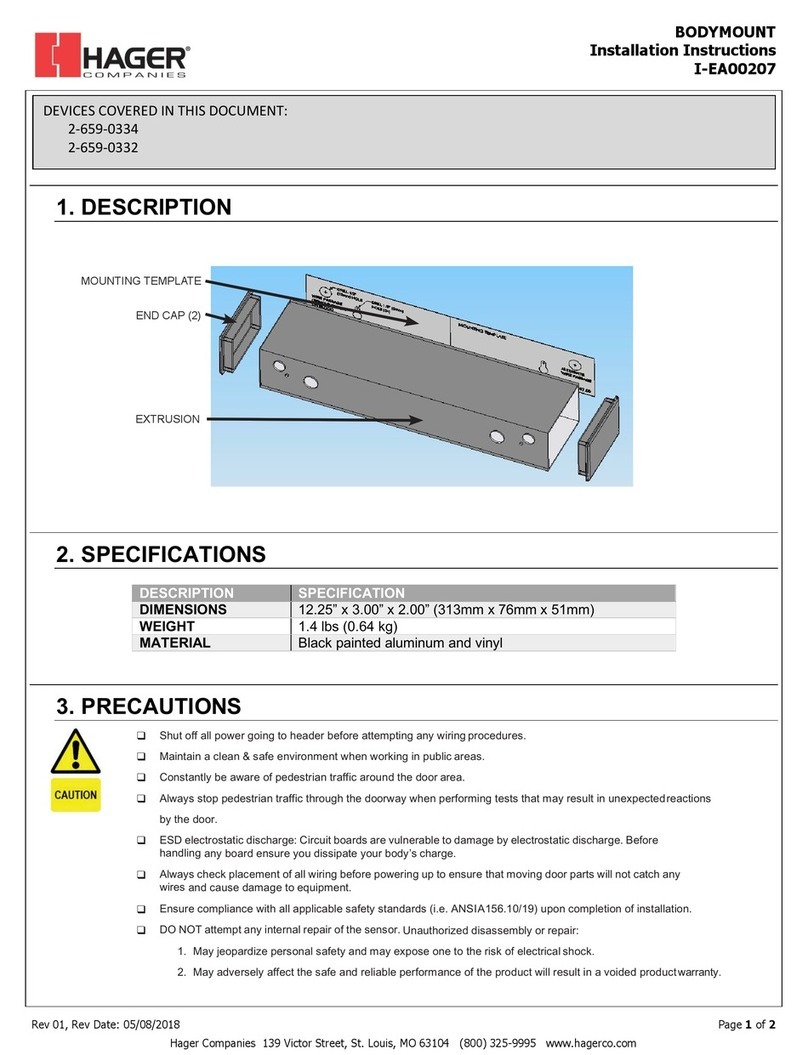

A1

B1

C1

A1

B1

C1

Active Area = A1 x A2

Overall Mat Dimensions = B1 x B2

Area Covered with Edging = C1 x C2

C1 =B1 + 126mm

C2 =B2 + 126mm

B1 =A1 + 60mm

B2 =A2 + 60mm

Figure 2 - Sensor Dimensions

8

Where possible, the shape and size of the

dangerous area should be designed such

that a single rectangular sensor,

preferably of a standard size, can be used.

Where this is not possible, non-standard

rectangular shapes, irregular shapes and

combinations of sensors will be required.

The range of standard sizes and the

restrictions on size and shape for

individual sensors are given in section

1.2.

Where a combination of sensors is

required the following considerations

apply:

(a) If possible all mat sensors in a

combination should be the same shape

and size. This makes it possible for the

user organisation to hold spare sensors

and simplifies the ordering of

replacements.

( ) If possible the mat sensors should be

arranged in a single row with joints

perpendicular to the normal direction of

approach of the operator as illustrated in

Figure 3.

(c) When mats must be arranged in an

array, one side of the array must not

exceed two mats as shown in Figure .

Figure 3 - Arrangement of mat joints

MACHI E

JOI T OF MATS

PERPE DICULAR

TO DIRECTIO OF

APPROACH

DIRECTIO OF

APPROACH

MAT 1

MAT 2

1.6.1.2 USE AS A COMBINED TRIP AND

PRESENCE SENSING DEVICE

When a system is used as a combined

trip and presence sensing device it will

normally be the sole means of guarding

at that particular part of the machine. In

this case it is necessary to ensure that

the dimensions of the sensor(s) are such

that the machine will be brought to rest

before an approaching person can reach

the dangerous parts and that the sensor

covers all of the dangerous area. It

should not be possible for a person to

stand anywhere between the front edge

of the active zone of the mat, and the

machine without standing on the mat.

In order to determine the position of the

front edge of the active zone it is

necessary to consider the stopping

performance of the machine.

Any machine, regardless of the

efficiency of its braking system, will

take a certain time to come to rest after

a stop signal is generated.

Figure 4 - Mat array requirements

2 MATS WIDE

9

From the instant that a persons foot

touches the mat to the instant that

dangerous motion actually ceases is

called the overall system response time.

The overall system response time, T, is

given by the following calculation:

T = t1 + t2

where t1 = the maximum response time

of the safety device between

the actuation of the sensor and

the generation of the stop

signal = 30ms

and t2 = the response time of the

machine between receiving a

stop signal from the safety

device and the dangerous

parts coming to rest.

The dangerous parts will obviously

continue to move during this time. The

sensor must therefore be dimensioned

such that the nearest point at which a

person could first touch the mat is at a

certain minimum distance from the

dangerous parts, to prevent the person

from reaching the dangerous parts

before they have stopped.

This must take into account the worst

case conditions illustrated in Figure 5

where a person could be a full stride

onto the sensor before the sensor is

actuated. This means that a certain

distance from the front edge of the

sensor and the nearest dangerous parts

must be maintained.

MINIMUM SEPARATION

DISTANCE S

DANGEROUS

PARTS

WORST CASE

POINT OF

DETECTION

Figure 5—Minimum separation distance

BEST CASE

POINT OF

DETECTION

NEAREST DANGER POINT

FRONT EDGE OF ACTIVE ZONE

10

This distance is the minimum separation

distance. All possible directions of

approach must be considered. The

minimum separation distance, S, can be

calculated using the following formula:

S = (1600 x T) + 1200

The overall system response time, T,

should be measured several times and the

highest value recorded, plus a suitable

allowance for brake deterioration, should

be used in the calculation of the

minimum separation distance.

1.6.1.3 USE AS PRESENCE SENSING

DEVICE

When the system is used solely as a

presence sensing device it is normally

used as a secondary guarding device in

conjunction with a separate primary

guarding device. The primary guarding

device would normally, as a minimum,

operate as a trip device. The position of

the trip device should be determined

according to the manufacturers

instructions. The primary guarding device

could be an interlocking fence, photo-

electric curtain or similar device.

In this case it is necessary to ensure that

the dangerous area, between the primary

guarding device and the machine is

completely covered by the active area of

the sensor(s), such that it is impossible

for a person to stand between the primary

guarding device and the dangerous parts

of the machine without standing on the

active area of the mat(s).

1.6.1.4 USE AS A TRIP DEVICE

When the system is used solely as a trip

device the minimum separation distance,

i.e. the distance from the front edge of the

active zone of the mat to the nearest

dangerous parts should be calculated as

described in section 1.6.1.2.

The minimum width of the active zone of

the mat should be 750 mm (i.e 810 mm

overall) to ensure that an operator cannot

inadvertently step over the mat into the

dangerous area without actuating the mat.

See Figure 6.

MACHI E

750mm

MI

MI SEPARATIO DISTA CE (S)

Figure 6—Mat solely used as a trip device

11

1.6.2 ORDERING INFORMATION

1.6.2.1 MAT SENSORS

When ordering mat sensors the following order code should be used. See Figure 7 for

lead position details:

Figure 7 - Lead position options

1.6.2.2 CONTROL UNIT

When ordering control units simply use

the control unit type designation i.e.

PRSU/ .

1.6.2.3 AE-13 MAT EDGING

AE-13 Mat Edging is for use with the

CKP/S1 Mats. The edging can be

supplied in kit form already prepared,

or in D-I-Y form for the edging to be

prepared when the mat is being

installed.

12

2. TECH ICAL DESCRIPTIO

2.1 SYSTEM OVERVIEW

A Tapeswitch safety mat system consists

of two elements: a sensor and a control

unit. The sensor may consist of a single

mat sensor or a combination of mat

sensors. When a person stands on the

sensor a stop signal is transmitted to the

control unit. On receiving a stop signal

from the sensor the control unit switches

off its output relays causing dangerous

motion to cease or be prevented.

The control unit contains the system

power supply, the sensor monitoring

circuit and the safety output relays. The

safety output relay contacts must be

connected into the machine control

circuit such that when the output relays

are switched off, power to the machine

primary control element(s) is removed.

A machine primary control element or

MPCE is defined as ‘an electrically

controlled element which directly

controls the normal operating motion of a

machine such that it is the last (in time)

to operate when motion is initiated or

arrested’.

NOTE: On low to medium risk machines

a single MPCE is normally used. If two

MPCE’s are provided their function

should be such that each of them is

capable of stopping the machine,

regardless of the state of the other.

2.2 SE SORS

2.2.1 MAT SENSORS

The construction of the CKP/S1 sensor is

shown in figure 8. A network of

Tapeswitch ribbon switching elements is

sandwiched between two thick sheets of

PVC material. The switching elements

are connected in series. The switch

elements are glued to the bottom layer.

The top and bottom layers are sheets of

ribbed, heavy duty matting material. This

material is of laminated construction and

is PVC based with special additives and

fillers to increase its abrasion and

chemical resistance. This material can

withstand years of pedestrian traffic and

is resistant to most chemicals commonly

found in an industrial environment

including water, coolant, oil and

hydraulic fluid. The top sheet is 6.5

millimetres thick and the bottom sheet is

5 millimetres thick.

TOP LAYER

SWITCH LAYER

BOTTOM LAYER

Figure 8 - Construction of CKP/S1 sensor

13

The construction of the Tapeswitch

elements is shown in Figure 9. Each

switching element is a long normally

open switch. The switch consists of two

copper plated steel conductors held apart

at the sides by an insulator. When

pressure is applied to the bead, the two

conductors are forced together in the

centre, closing the switch.

All the upper conductors of all the switch

elements are connected together and all

lower conductors are connected together,

effectively creating a single normally

open switch. Heavy gauge copper-plated

steel wire is used for all internal wiring

and all connections to the switching

elements are direct solder joints. The

switches are self-bottoming and as a

result they can withstand very high loads

and repeated operation. Several million

operations is typical.

PVC SLEEVE

PVC SLEEVE

UPPER CO DUCTOR

PVC SLEEVE

UPPER CO DUCTOR

LOWER CO DUCTOR

LOWER CO DUCTOR

2.2.2 COMBINATION OF SENSORS

When a number of mat sensors are used

in combination, sensors with two 2-core

leads should be used. The sensors should

be connected in series such that the

control unit ‘sees’ a single normally open

switch. One of the 2-core cables can be

considered to be the inlet cable and the

other the outlet cable. When connecting a

number of sensors together the outlet

cable of the first sensor is connected to

the inlet cable of the second sensor and

so on. This leaves the inlet cable of the

first sensor and the outlet cable of the last

sensor to be connected to the control unit

as illustrated in Figure 10.

Figure 9 - Construction of Tapeswitch

elements

Figure 10-Construction of sensors in series

TO

CO TROL

U IT

TO

CO TROL

U IT

MAT

SE SOR

MAT

SE SOR

14

3. I STALLATIO

WARNING

TAPESWITCH SAFETY MAT SYSTEMS ARE DESIGNED TO PROTECT

OPERATORS WORKING AT OR NEAR DANGEROUS MACHINES. THEY CAN

ONLY PERFORM THAT FUNCTION IF THEY ARE CORRECTLY FITTED AND

INTERFACED TO A SUITABLE MACHINE. EVERY EFFORT HAS BEEN MADE

IN THE PRODUCTION OF THIS MANUAL TO PROVIDE COMPREHENSIVE

AND ACCURATE INFORMATION. IT IS THE RESPONSIBILITY OF THE USER

TO ENSURE THAT ALL PERSONS INVOLVED IN THE INSTALLATION OF THE

PRODUCT HAVE THE KNOWLEDGE, TRAINING AND EXPERIENCE

NECESSARY AND THAT THEY ARE FULLY CONVERSANT WITH ALL LAWS,

RULES, REGULATIONS AND CODES OF PRACTICE PERTAINING TO THEIR

TASK.

3.1 GE ERAL

The attention of the installer is drawn to

following general requirements for the

installation of a Tapeswitch safety mat system:

(a) The machine must be electrically

controllable.

( ) It must be possible to stop the

dangerous motion of the machine at any

point in its operation, in any operating

mode.

(c) The control system as a whole must

be designed to provide the level of safety

integrity determined by the risk

assessment.

(d) Steps must be taken to prevent

access to the dangerous parts of the

machine from any direction not covered

by the sensor. Such steps could include

fixed or interlocking fences or screens,

additional pressure sensitive mats or

photo-electric devices.

(e) Steps must be taken to prevent a

person standing in the dangerous area

without standing on the sensor. The inner

surfaces of fixed mechanical fencing

should be designed

such that there are no ledges or steps on

which a person could stand and thereby

avoid the sensor. It may be necessary to

fit additional mechanical barriers, covers

etc. to cover any surfaces within the

dangerous area on which a person could

stand, such as the feet of the machine.

Particular attention should be paid to the

edge of the mat nearest to the machine.

Ensure that a person tip-toeing at the

front of the machine will still be standing

on the active area of the mat. See Figure

11.

(f) Wherever possible rectangular mats

of standard sizes should be used. Where

this is not possible, due to obstructions,

mats with edge or corner cutouts and

even with holes can be specified. This

should only be done where the

obstructions are permanent.

(g) Under no circumstances should a

mat sensor be cut or drilled. It is not

possible for the user to modify the size or

shape of a mat sensor.

15

(h) Great care should be taken when

handling mat sensors. Never pick the

sensor up or drag it around using the

cables. Never bend a mat at a radius less

than 300 millimetres. Keep mat sensors

flat whenever possible. Always store

flat. Mat sensors with one edge longer

than 1 metre should be handled by two

people.

(i) No devices other than those

specified in this manual should be

connected to the internally generated

power supply of the system.

(j) After installation the machine/mat

system must be commissioned in

accordance with section of this

manual.

(k) Any covers removed dur ing

installation must be replaced as soon as

possible.

3.2 SE SOR I STALLATIO

3.2.1 SENSOR MOUNTING SURFACE

The surface on which the sensor is

mounted must be sound and reasonably

flat. The sensor can tolerate minor

irregularities but sharp edges or

projections greater than 1mm may cause

premature degradation. Where the surface

is rough, cracked or breaking up, it

should be treated using proprietary

sealing and levelling compounds.

3.2.2 SENSOR FI ING

The sensor(s) must be fixed permanently

in position. Tapeswitch aluminium

edging should be used around the outer

edge of the sensor. This specially

designed edging comes in two parts, a

base and a cover. The cover provides a 20

degree ramp to prevent a tripping hazard

at the outer sensor edges. The base can

accommodate sensor wiring which

protects the cables from damage and acts

as a conduit to route the cables to the

control unit. Type AE-13 edging is

illustrated in Figure 12 and AE-C corner

pieces in Figure 13. At the junction of

several mats, the mats should be fixed to

the floor using double sided tape.

SLOPI G SKIRT

FIXED TO MACHI E

MAT

OPERATOR O

TIPTOE ALWAYS O

ACTIVE ZO E OF

SE SOR

Figure 11 - Ensure operator is always

standing on active area of sensor

71

8

17

Figure 12 - AE-13 Sensor Edging

16

3.2.3 INSTALLATION PROCEDURE

Step 1 - Plan the layout. Mark out on the

floor the position and size of each

sensor. Take care to use the overall

dimensions of mat sensors.

Step 2 - Cut all edging to size. Remove

any burrs and sharp edges with a file.

Note: If AE-C corner pieces are used

then:

the cut length = mat dimension - 12mm

of AE-13

Step 3 - Mark the positions of the sensor

cables and cut slots in the inner face of

the edging base extrusion to allow access

for the sensor cables.

Figure 13 - AE-C Corner piece

94

69

32

32

69

94

17

Step 4 - Position the base sections around

the mat and fit AE-C corner pieces as

shown in figure 1 . Drill pilot holes

through each corner piece and holes in

the base sections if applicable. Remove

base sections / corner pieces and drill and

plug the floor. Refit base sections and

corner pieces and secure in position with

the screws provided, ensuring the cable

exits neatly through the slot(s) in the base

section.

Figure 14 - AE-13 & AE-C Installation

Step 5 - In the case of a combination of

sensors connect the sensors in series as

shown in Figures 15 and 16. Special

grease filled waterproof connectors are

available from Tapeswitch Ltd. for this

purpose. If necessary cut the cables to

length. Always leave some slack in the

cables in order that a sensor can be

disconnected and reconnected at a later

date. The connectors are fitted using a

pair of pliers. Make sure that they are

fully mated.

NOTE: MAT SENSORS MUST BE

FITTED WITH THE LABEL SIDE UP.

17

Step 6 -Route the cable(s) to the control

unit. The cable(s) should exit from the

edging as close to the control unit

position as possible. The cables should

be protected in suitable conduit between

the edging and the control unit. Protect

any edges over which the cables pass

with grommet strip or similar.

Step 7 - Fit the cover extrusion of the

edging using suitable self-tapping

screws.

SEE FIGURE 17

SEE FIGURE 17

Figure 15 - Connection of sensors in series

Figure 16 - Wiring of two mat sensors each with 2 x 2 core ca les

GREASE-FILLED

TERMI ALS

OTE: CO ECT THE CABLES

COLOUR TO COLOUR USI G THE

GREASE-FILLED TERMI ALS

MAT SE SOR MAT SE SOR

18

3.3 CO TROL U IT

3.3.1 GENERAL

The connections for the PRSU/ control unit are shown in Figure 17. Crimped

ferrules should be fitted on all stranded wires. It is recommended that electrical

installation is performed in the order described below.

3.3.2 SENSOR CONNECTION

Connect the sensor cables to the control unit according to Table 1, taking particular

care that there are no stray strands which could cause a short between adjacent

terminals.

3.3.3 POWER CONNECTION

Connect +2 V to terminal A1 and 0V to terminal A2 as shown in Figure 17. The

maximum power consumption is 5VA.

Figure 17 - Control unit connection

SE SOR CO ECTIO

S11 S21 S12 S22

Single Lead -wire Brown Blue or

Green

Black or

Yellow

White

Dual Lead -wire Brown 1 White 1 Brown 2 White 2

SE SOR TYPE

Ta le 1

19

3.2.4 RESET INPUT CONNECTION

For auto reset mode connect a link across terminals S33 & S3 as shown in Figure 18.

For manual reset mode connect a normally-open switch across terminals S33 & S3 as

shown in Figure 19

If the machine has two MPCEs, a pair of normally-closed auxiliary contacts from each

MPCE can be connected in series with the reset input as shown in Figure 20. This

provides cross-monitoring of the MPCEs such that if they are in disparity due to a

fault, reset will be prevented until the fault is rectified

Figure 18 - Auto Reset

Figure 19 - Manual Reset

Figure 20– Cross Monitoring of

MPCEs

RESET TERMI ALS

RESET TERMI ALS

RESET TERMI ALS

20

3.2.5 SAFETY OUTPUT CONNECTION

Three normally-open safety outputs are provided. In low to medium risk applications

the machine is normally provided with a single MPCE.

In such cases both safety outputs should be connected in series with the MPCE coil as

shown in Figure 21. If the machine is fitted with two MPCEs, one safety output should

be connected in series with each MPCE coil as shown in Figure 22.

To protect the contacts of the safety output relays from the effects of switching

inductive loads, it is recommended that arc suppressors should be fitted in parallel

with the MPCE coils as shown Figures 21 and 22. Arc suppressors must not be fitted

across the safety relay contacts.

To protect against the possibility of both safety outputs welding in, due to an

overcurrent fault in the machine circuit, 2A fuses should be fitted in series with the

MPCE coils as shown in Figure 21 and 22. This limits the current through the safety

output contacts to well below that which could cause the contacts to weld.

Figure 21– Safety Output Connection (single MPCE)

Figure 22– Safety Output Connection (Two MPCEs)

Table of contents

Other Tapeswitch Accessories manuals

Popular Accessories manuals by other brands

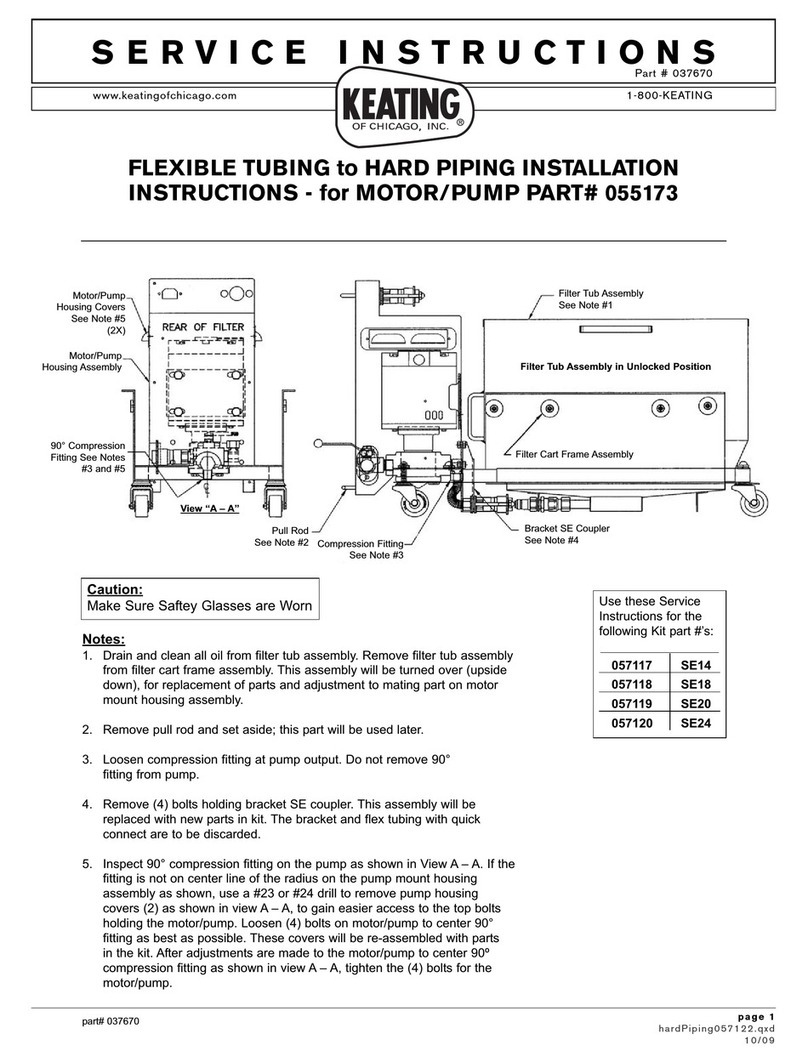

Keating Of Chicago

Keating Of Chicago Flexible Tubing to Hard Piping 055173 Service instructions

IFM

IFM TS502A operating instructions

Kübler

Kübler IN8 Series installation instructions

Franklin Fueling Systems

Franklin Fueling Systems FMP-HFS2 installation guide

ab

ab AB-UVC-STRL user manual

Martin Yale

Martin Yale 1648 user manual