Tar River Implements PRZ-3100 User manual

TAR RIVER –401 JEFFREYS ROAD 278404 ROCKY M. –NASH COUNTY (NC)

PRZ-3100

Hay Tedder

OPERATOR’S MANUAL

Rev (07/08/22)

TAR RIVER –401 JEFFREYS ROAD 278404 ROCKY M. –NASH COUNTY (NC)

3

TABLE OF CONTENTS

A

INTRODUCTION

5

A1

INFORMATIONS ABOUT THE MANUAL

5

A2

IDENTIFICATION AND EC CERTIFICATION

5

A3

MAIN COMPONENTS AND TECHNICAL DATA

6

B

SAFETY

7

B1

GENERAL RULES

7

B2

TRANSPORT, INSTALLATION AND MOVEMENTS

7

B3

INTENDED USE AND WARNINGS OF EMPLOY

8

B4

REASONABLY FORESEEABLE MISUSE AND LIMIT OF EMPLOY

10

B5

RESPONSIBILITY OF THE OPERATOR

11

B6

SAFETY LABELS

11

B7

NOISE LEVEL

12

B8

RESIDUAL RISKS

12

C

INSTALLATION

13

C1

HAY TEDDER ASSEMBLY

13

C2

PREPARINF THE TRACTOR

13

C3

HITCHING TO THE TRACTOR

13

C4

CARDAN SHAFT ADAPTATION AND INSTALLATION

14

C5

REMOVAL

14

C6

STORAGE OF HAY TEDDER

14

D

OPERATION AND USE

15

D1

PRELIMINARY INFORMATIONS

15

D2

WORKING CONFIGURATION

15

D3

WORKING PROCESS

15

D4

ADJUSTMENT OF ROTARY UNIT TILT

16

D5

CHANGE OF DIRECTION OF REVERSE

16

D6

END OF WORK

16

E

MAINTENANCE

17

E1

PRECAUTIONS DURING MAINTENANCE

17

E2

MAINTENANCE TASKS

17

E3

TINE REPLACEMENT

18

E4

INSTALLATION OF TINE-HOLDER CLAMP (OPTIONAL)

18

E5

TROUBLESHOOTING

18

E6

MATERIAL DISPOSAL IN CASE OF DEMOLITION

19

4

5

A. INTRODUCTION

A.1 About the manual

The TAR RIVER firm (“Manufacturer”) designed

and created the device in accordance with the

associated safety standards to ensure the safety of

personnel and the entire operating system.

Each hey tedder is supplied with a copy of this

manual which the operator must read in full before

using the equipment. The manual contains all

information relating to transportation, use and

maintenance of the equipment, as well as safety

instructions.

Poor knowledge of the operating system can lead

to accidents and therefore damage to the

equipment. Although the Manufacturer provides the

Customer with all information relating to the hey

tedder operation, use and maintenance, the

Customer is still expected to read this manual and

take note of all the instructions herein.

The manual provides all the necessary instructions

on how to ensure optimal working order and safety.

The manual was drawn up according to the current

technical and structural characteristics of three

models of hey tedder and does not cover previous

similar models. The Manufacturer therefore

reserves the right to modify models in production in

the interest of improvement or due to any new

legislation (Machinery Directive), without being

obliged to modify previous models.

This manual is integral to the hey tedder and must

therefore be kept intact, clean and in good

condition. It should also be in a container, either on

the frame of the hey tedder or in the tractor cabin,

where it can be easily accessed for consultation.

The manual must be kept in its container if the hey

tedder is taken out of service. Ask the Manufacturer

for a duplicate copy if the original manual is lost.

Please contact the TAR RIVER Dealer for any

clarifications relating to the instructions in this

manual.

Symbols used in this manual:

HAZARD or DANGER

Indicates an imminently hazardous situation

that, if not avoided, will result in death or

serious injury;

WARNING

Indicates a potentially hazardous situation that, if

not avoided, could result in death or

serious

injury. It is also used to alert against unsafe

practices.

CAUTION

Indicates a potentially hazardous situation that,

if not avoided, may result in minor or

moderate

injury. It is also used as a reminder of good

safety practices.

IMPORTANT

The operator must take the respective information

into account.

Note indicates that the information referred to can

facilitate the operator work.

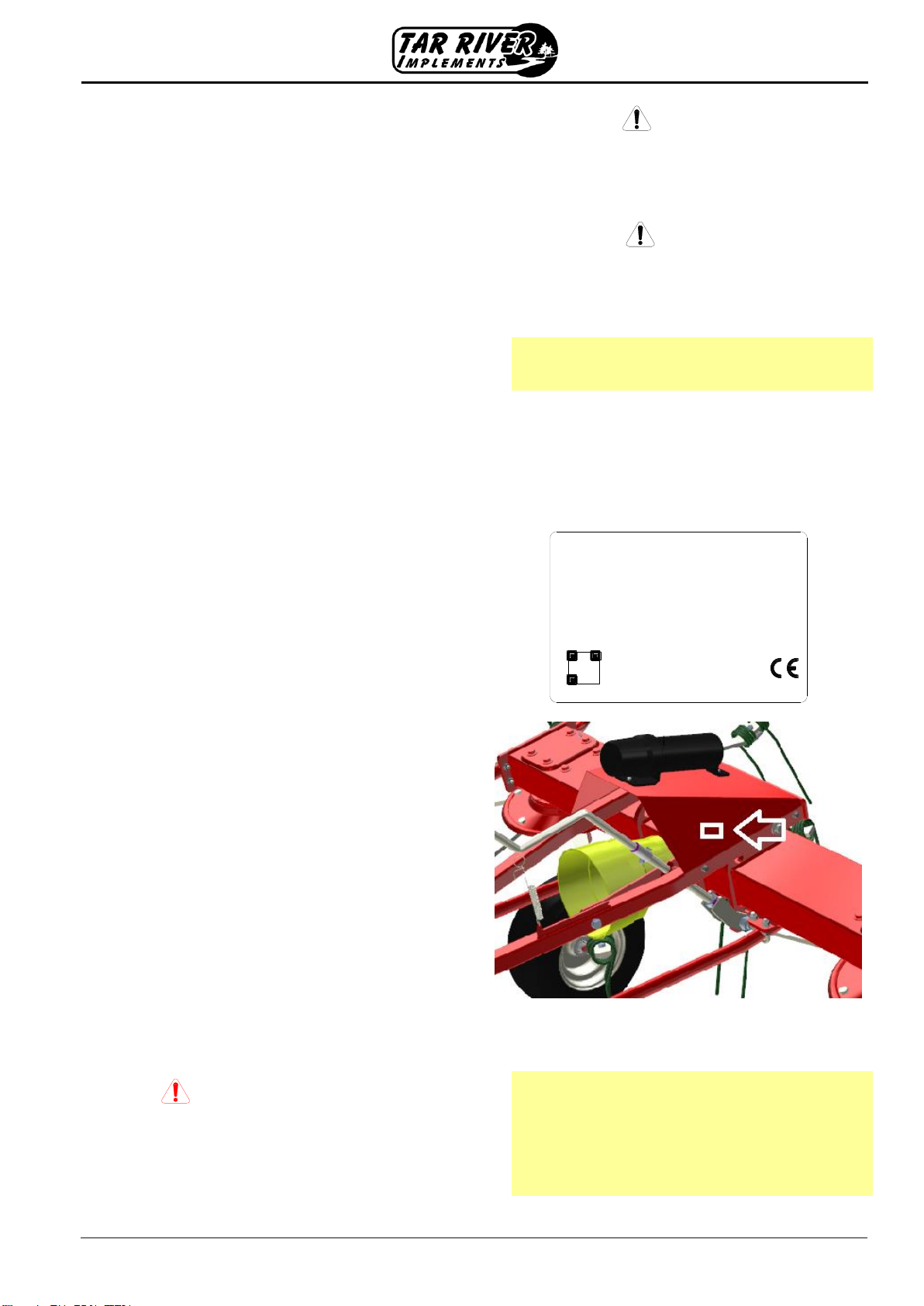

A.2 Identification

An identification plate is affixed to each machine:

Type: XXXXXXXX Model

Serial N. XXXXXXX-XX

MFG: 2015 DEL: 2015

You must have this information at hand when

requesting assistance and spare parts.

IMPORTANT

It is strictly forbidden to alter and/or eliminate the

data on the serial plate. The operator must check

the legibility of the data on a regular basis and

inform the Manufacturer if it becomes in any way

illegible. The Manufacturer will then replace the old

plate with a new one bearing the same data.

6

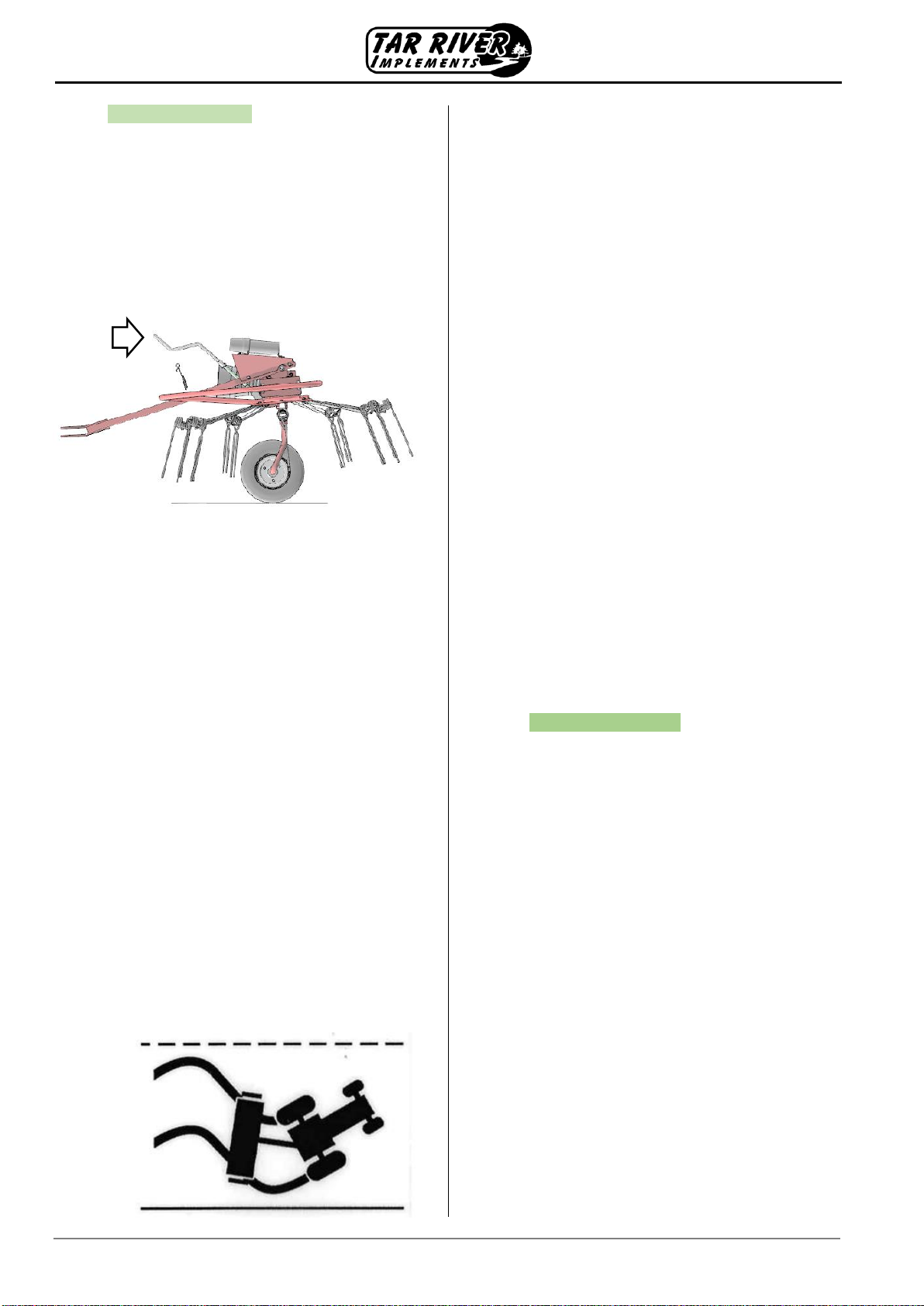

A.3 Main components and technical data

1.

Three-point universal hitch

2.

Cardan shaft coupling

3.

Protective lateral screens

4.

Rotary unit

5.

Tine holder arms

6.

Bearing wheel

7.

Tine

8.

Chassis

9.

Bearing foot

10.

Grade adjusting lever

11.

Towing bar

12.

Manual holder

TECHNICAL SPECIFICATIONS

PRZ 3100

Working width

cm./ ft

310 / 10.2

Transport width

cm./ ft

250 / 8.2

Tine holder arms

nr.

12

Tines - Total

nr.

12

PTO speed

rpm

540

Tractor power

Hp

20

Tractor working speed

km/h

5÷10

Cardan shaft with torque limiter

Nm

600

Tires mounted on chassis - Ballon 15.600-6

nr.

2

Weight

Kg / lbs

193 / 425

7

SAFETY

B.1 General rules

This manual describes the safety regulations to

be followed when using hey tedder. As most

work-related accidents occur due to non-

compliance with the most basic of safety

regulations, it is obligatory to read this manual

before using the hey tedder and to follow all the

instructions.

The equipment must be used by qualified adult

personnel trained in its use. The Manufacturer

cannot be held liable for accidents due to the

operator's negligence and/or non-compliance

with the safety instructions. In this case the

Manufacturer assumes no responsibility and

the warranty is forfeited.

B.2 Transportation, Installation and Movement

Transportation (delivery): the device is fully

dismantled and placed in a crate for

transportation. The TAR RIVER Dealer can

then re-assemble the parts quickly and easily

on receipt, following the detailed instructions.

-In the first case, the equipment used must

have suitable characteristics and slings to

support the hay tedder, which total weight

is indicated on the identification plate.

Trained personnel will perform the

operations, holding the equipment on the

points marked on the frame and provided

for that purpose.

Note: in order to preserve the frame

integrity we recommend holding the hay

tedder with approved straps instead of

chains. However, on the

points where it should be

held an adhesive label

was applied, containing a

hook (as shown in the

figure), to highlight the

use.

-in the second case, by using a forklift or

a tractor, the equipment is pushed, in

reverse, on the vehicle platform

In both cases, the equipment, once placed on

the truck, will be anchored to its structure and

equipped with all the safety gear needed for

transport.

IMPORTANT

Do not forget that, for transportation and

handling, the hey tedder must be in its

transport configuration as described in the

chapter “Moving the hey tedder”.

HAZARD

Loading and unloading operations always

represent situations of danger, is

therefore necessary that the operators,

always act with caution.

Always take the following precautions:

-Loading/unloading must be carried out

on a flat surface and at a safe distance

from slopes or ditches;

-Always make sure the ramps are strong

enough to withstand the hey tedder

weight (see the specification table shown

in this manual), are firmly attached to the

vehicle and are parallel to each other and

perpendicular with the edge of the

vehicle;

-Ensure the ramps are clean, without any

traces of oil, grease or ice;

-Never change direction when moving hey

tedder onto or off the vehicle. If

necessary, move hey tedder back down

the ramp to turn it around.

For long distances travels the equipment is

dismantled and lies within a wooden casing.

Detailed instructions allow the Customer,

upon receiving the parts, to assemble the

hay tedder with ease and speed. So, if the

machinery is to be sold or transferred to

another user, for disassemble operations just

follow the instructions in reverse order.

Installation: the hay tedder must only ever

be attached to an agricultural tractor with

hitch, auxiliary universal three-point coupling

and hydraulic lift.

IMPORTANT

The tractor must also, by law, be fitted with a

protective roll-bar or ROPS or FOPS cabin. It

is strictly forbidden to install the rake on a

tractor without the required protection

equipment.

Prior to installation, however, the Customer

must check the tractor operating and

maintenance manual to make sure the tractor

is compatible with rake, and whether ballasts

are needed to prevent unbalance that could

cause it to tip over..

For the hay tedder installing instructions and

any hydraulic and electrical connections refer

to the relative sections described below.

For the cardan shaft instructions, refer to the

ones attached to the part.

8

Movement on road: the hay tedder must be

hitched to the back of an agricultural tractor.

The complete vehicle (the tractor with hay

tedder) does not require any luminous or

acoustic signalling devices or panels when

used in cultivated fields. However, you must

do the following for road circulation:

-tine positioning: by turning the lever

counter to reset the rotary unit tilt in

respect to the ground;

-warning lights: the tractor must

obligatory have the beacon warning light

(yellow or orange) always activated. In

addition, if the hay tedder bulk hides the

visual signalling and lighting devices on

the tractor, they must be duplicated,

applying a special bar at the back of the

machinery;

-hay tedder weight and tractor speed: it

is necessary consider the total weight of

the machinery (tractor and hay tedder)

and its load (hay tedder). The tractor

must be heavy and powerful enough with

special braking power for the towed load.

Ensure the load does not exceed the

recommended weigh ratio. Add ballast to

recommended maximum for tractor,

lighten the load or get a heavier towing

unit;

Stopping distance increases with speed

and weight of towed load and,

particularly, on slopes. Towed loads (with

or without brakes) can be both heavy for

the tractor and towed fast. In both cases

they can cause loss of control.

Follow to:

if towed equipment does not have

brakes, the tractor speed cannot

exceed more than 32 km/h (20 mph)

and the tow-load weight cannot

exceed more than 1.5 times of

tractor’s;

if towed equipment has brakes, the

tractor speed cannot exceed more

than 40 km/h (25 mph) and the tow-

load weight can not exceed more

than 4.5 times of tractor’s.

Use additional caution when towing loads

under adverse surface conditions, when

turning and on slopes.

-Laws: you should know and comply with

the laws on road circulation in your

country

When circulating on road with the operating

machine (tractor with hay tedder), the

operator in the cabin must always observe

the following precautions:

-do not carry passenger on the tractor;

-do not carry on the equipment people,

animals or things;

-PTO must always be disengaged.

Movement on field: when on fields with the

operating machine (tractor with hay tedder)

there is no need to turn on any lights or

sound or to display any type of panel.

B.3 Intended use

The hay tedder is an agricultural equipment used

to spread, aerate and turn over any type of

previously cut forage, so as to allow an early and

uniform drying of the product which ensures a

high-quality forage. Once completely desiccated,

it is harvested by a baling press.

The hay tedder operates only if connected the

tractor towing hook. Both models operate in result

to the tractor drag effect that pulls them and to

the rotation effect of the working units, provided

by a cardan shaft applied to the tractor PTO.

Each of rotating working units (two) is composed

by six arms on which working tools or tines are

installed. The units rotate, one in opposition to

the other, with a pronounced tilt toward the front

(7 ÷ 10°), so that the product is harvested from

the tines and thrown up in the back spreading on

the land.

9

The movement of the side sections (from the

working configuration to the transport one) is

obtained by hydraulic cylinders. The adaptation

to the ground of the tines (smaller or greater

forward grade of the six units) is performed by a

hydraulic cylinder. In this case, the cylinder is

supplied by the auxiliary hydraulic circuit of the

tractor, through piping equipped with quick

couplings, and therefore controlled by a

correspondent lever in the cabin.

The hay tedder must be used only by qualified

operators and trained for its use and operation.

Safety is of prime importance for the personnel

who use the equipment or who perform repairs or

maintenance. Given that the provided

instructions cannot cover all possible working

situations and related dangers, personnel should

always use caution and common sense.

The operator (tractor driver) must always check

that no people or animals go in the dangerous

zones of the equipment (shown in figure),

because they are not conscious of possible

dangers.

Before starting the tractor and begin working,

it is important:

-verify that the equipment has been correctly

installed on the tractor;

-verify that all locking and safety devices are

present and undamaged;

. -verify that the power takeoff is disengaged

and that the tractor PTO number of

revolutions per minute is 540 and that the

sense of rotation is clockwise;

IMPORTANT

The power takeoff must never be engaged

when the engine is switched off and if

between two cardan universal joints

(tractor /hay tedder) there is a grade more

than 10°;

-verify that the cardan shaft is properly

installed and that all blocking and safety

devices are present and integral. If one of

these was not integral or a not approved

device was installed, the Manufacturer

cautions the Customer in not using that

shaft since it is prohibited;

-do not use the equipment if there are broken

or damaged parts, especially of protective

ones;

-perform the daily maintenance (as described

in the relative paragraph). Concerning this,

remember that any type of task (control,

adjustment, maintenance or other) should

always be performed with the equipment

not in motion, the PTO disengaged and

the tractor engine switched off;

-check the tine grade in respect to the ground.

If any adjustment is required, refer to the

specific sections described below;

-hay tedder operations are allowed in good

visibility conditions. In the event that

these conditions were absent, even

partially, operations should be interrupted

since even the normal safety conditions are

absent. The operations can be resumed

10° max

TRACTOR

PTO

EQUIPMENT

PTO

DANGEROUS

ZONE

DANGEROUS ZONE

DANGEROUS ZONE

DANGEROUS

ZONE

10

only if good visibility conditions are

restored.

Precautions when using:

-the tractor must proceed in straight line,

avoiding abrupt movements (sudden

accelerations and/or changes of direction).

The tractor speed must not exceed the

limit of 10 - 12 km/h (6.2 - 7.46 MPH);

-any adjustment, check, control and

maintenance task must be performed with

the tractor stopped, with its engine off and

with the ignition key removed from the

dashboard;

-the operator in the tractor cabin must never

abandon the tractor leaving its engine on.

Even for short working breaks, they must

always stop the tractor, switch off its engine

and remove the ignition key from the

dashboard;

-before reversing with the tractor or for

direction changes at the end of the field, the

operator must necessarily place the

equipment in transport configuration, lifting

the tines of central rotary units from ground.

The hay tedder could suffer serious damage

if the teeth were not raised (see also section

“Change of direction or reverse”);

-the hay tedder operation does not produce

enough noise to allow the use of the

acoustic protections (earplugs, earphones,

etc.), instead the tractor can produce it.

Therefore, consult the use and maintenance

manual of the tractor;

-the vibrations that the equipment may

produce and transmit to the operator are of

low intensity and the frequency is below

human tolerability levels. However, it is

good always to keep the transmission

and the gears well lubricated.

Immediately interrupt work operations if:

-you are in proximity of resistant objects,

such as manholes, wells, trees, etc. since

contact could break the tines, and projected

the pieces all around at high speed;

-noisy vibrations coming from the equipment

are heared. To avoid possible damages, the

operator should stop the tractor, disengaged

the PTO, switched off the engine and if

possible, identify and remedy the situation,

always in respect with safety regulations.

B.4 Reasonably foreseeable misuse and limit of

employ

A different use from that one described in the

previously paragraph is considered improper

and therefore forbidden. In addition, the

technical characteristics of the equipment must

not be modified in any way to alter its

performance. In this case, both the equipment

warranty and the Manufacturer liability would

immediately become void.

Visibility: in conditions of insufficient visibility

(fog, dust, smoke or other): it is advisable to stop

the tractor and to wait until that fog, dust or other

goes away. If this must not occur it is necessary

that the working process is interrupted and the

tractor goes in a parking place by using its

lighting devices. Operate at the same way in

case of rain.

Changes of direction or reverse: when to the

end of the field the machinery must invert the

traveling direction, the operator in cabin

must stop the tractor and then to provide to

put the equipment in transport configuration

and to carry out the manuever of travel

reversal.

Slope: a high slope can cause the tractor

rollover. Do not work on grounds with slope

greater than 15 degrees because it is very

dangerous.

Vibrations: it is important to keep the

transmission devices and the gears always

lubricated. Furthermore, it is opportune to verify

often that the bolts are tightened so as to avoid

vibrations.

Dangerous zone: if, during the working process,

a people or an animal go in one of the

dangerous zone (see previously paragraph), the

tractor driver must immediately stop the working

process and provide to distance the intruder. At

the same way, during the adjusting and/or

maintenance tasks, the outsiders must not stay

or move in the proximity of the equipment.

Do not use the machinery if:

The cut product is wet or damp. Under these

conditions, it becomes sticky and easily

accumulates on tines, limiting them operational

function.

11

HAZARD

No operations should take place in masonry

proximity. In these cases apart from the

possibility to damage the tines could also be a

dangerous projection of relative residues.

For any doubt about the use of the hay tedder and

not included in this manual please contact the

Manufacturer.

B.5 Responsibility of the operator

Each operator becomes liable for the damages

caused to themself, others, animals or damages

to the things if they proceed with an incorrect use

of the equipment and/or not conform to the

instructions contained in this manual.

Consequently, the responsibility of the

Manufacturer would immediately be void if

the operator:

-use the equipment in improper or incorrect

way;

-has not been property trained or has not

read the operator instructions in this manual;

-use the equipment while under the influence of

alcohol, drugs, or in a state of tiredness or

sickness

-does not respect the current road norms;

-not having previously verified the required

requirements, the coupling of the equipment

to the tractor is not suitable (different power

or characteristics to the those ones

indicated in the table of the technical data);

-has not performed the foreseen

maintenance tasks;

-has modified the equipment;

-has used non original spare parts or not

right for the model.

-do not wear radio or music headphones

while operating machine;

-wear close fitting clothing and safety

equipment appropriate to the job.

HAZARD

Each operator must know that the direct

contact and/or exposure to hazardous

chemical (as lubricants, coolants, paint and

adhesive) can cause

serious injury.

A Material Safety Data Sheet (MSDS) provides

specific details on chemical products: physical

and health hazards, safety procedures and

emergency response techniques.

Before starting any job

using a chemical product of

these above mentioned,

each operator must consult

the MSDS to know exactly

the associated risks and

how to do the job safely.

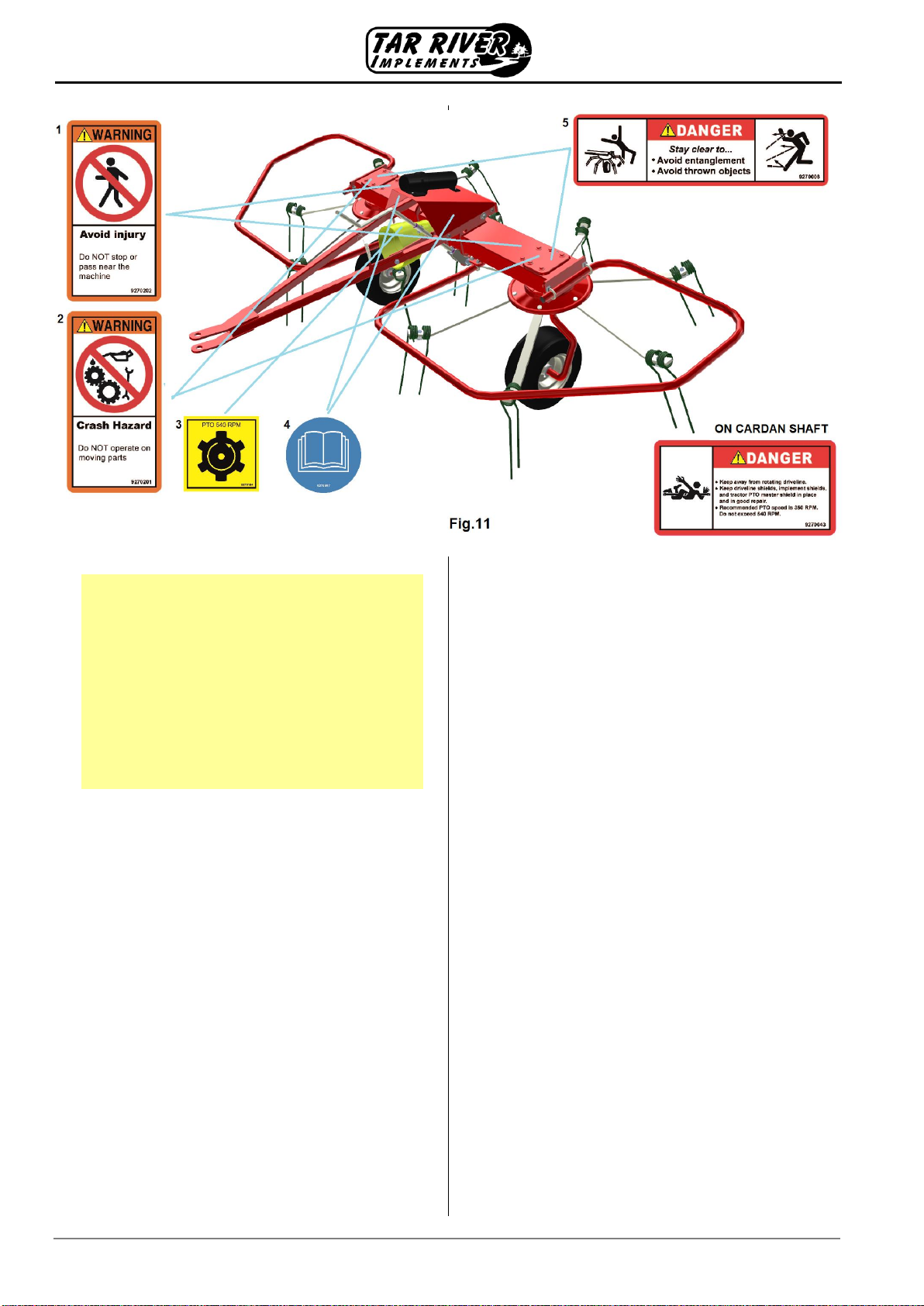

B.6 Safety labels

In addition to the instructions contained in this

manual, adhesive labels have been applied on

various parts of the equipment to help operators.

These labels illustrate the safety rules that

should be observed.

The shape and color of the labels vary based on

the rules. In addition to containing a danger or

prohibition sign, other rectangular labels provide

additional information about the safety rules that

must be observed. The rules illustrated by the

labels affixed to the equipment (fig.11) are as

follows:

1. Prohibition of stopping or transit. It is

prohibited to others than authorized

personnel to stop or transit in the hay tedder

proximity, when it is running. Remain at a

safe distance (m. 20);

2. prohibition to perform repairs or

maintenance with parts in motion. It is

absolutely forbidden to adjust, lubricate,

repair or replace parts in motion. These tasks

must be performed with the P.T.O.

disengaged, the tractor engine off and the

ignition keys removed from the dashboard;

3. verify that the number of revolutions at

the tractor PTO exit is of 540 rpm and that

the rotation is clockwise;

4. obligation of reading the use and

maintenance manual;

5. danger to be hooked or to get caught on.

With the rotation of arms, the tines may hook

clothes or other objects worn by staff. -

danger of flying objects. With the rotation

of arms, the tines could pick up and throw

objects form the working site. Minimum

safety distance m.20

12

IMPORTANT

The safety and instruction labels must be

replaced before they become illegible. If this

happens, the operator cannot use the hay tedder

until a new label is applied. Similarly it is utterly

forbidden to remove the safety or instruction

labels placed on the machine. In any

circumstances in which this occurs the

Manufacturer disclaims all responsibility because

the machine would not meet the safety

standards with which it was designed and

Manufactured.

The labels similar to these present on the

equipment are available from the Manufacturer.

Call the Customer service of TAR RIVER Dealer

to ask for replacements. It is advisable, during

the equipment delivery verify the presence and

the status of the labels.

B.7 Noise levels

The device produces little noise other than that

of its moving mechanical parts and has no

motor. Therefore, the operator does not need

any acoustic protection (ear plugs, muffs, etc.).

As for the noise produced by the tractor, to

consult the proper operator’s manual.

B.8 Residual risks

Lower limbs and/or bodily injuries: loss of

stability in phase of parking caused by the non-

installation of the bearing feet.

13

C. INSTALLATION

C.1 Hay tedder assembly

As already said, the hay tedder is fully

dismantled for delivery to the Customer. The hay

tedder can be assembled quickly and easily

following the relative instructions (at the end of

this manual). Assembly must be performed on a

flat surface prepared especially for the purpose.

The hay tedder, once it has been assembled,

can be installed or hitched to a tractor.

C.2 Preparing the tractor

The hay tedder can be attached to any tractor

having a drawbar that conforms to ASAE-SAE

standards of 330 to 559 mm (13 to 22 in.)

(fig.12-A) from the ground.

C.3 Hitching to the tractor

The operator must move the hay tedder slowly to

a position where the joints can be easily aligned

(fig.13-3.1).

IMPORTANT

The holes in the tractor attachment must be

aligned with those on the hay tedder attachment

with maximum care and attention.

When the tractor is near the hay tedder coupling

point, an operator on ground, manually raises or

lowers the hay tedder coupling point in order to

make it horizontally coincide with the tractor.

After the coupling, the operator inserts the

locking pin (3.2) in the corresponding holes of

coupling point, as shown in the figure, and then

secures it with the safety pin (3.3).

C.4 Cardan shaft adaptation and installation

Installation: follow thoroughly the installation

instructions reported on its own use and

maintenance manual.

IMPORTANT

Before installing the cardan shaft make certain

that it suits the requirements concerning the

type and the power to be transmitted

depending on the tractor’s PTO speed. If

necessary also check the tractor’s user

manual.

When not utilized, i.e. when not attached to

the tractor PTO but only to the hay tedder,

place the shaft on the support provided for

this purpose on towing hook bar.

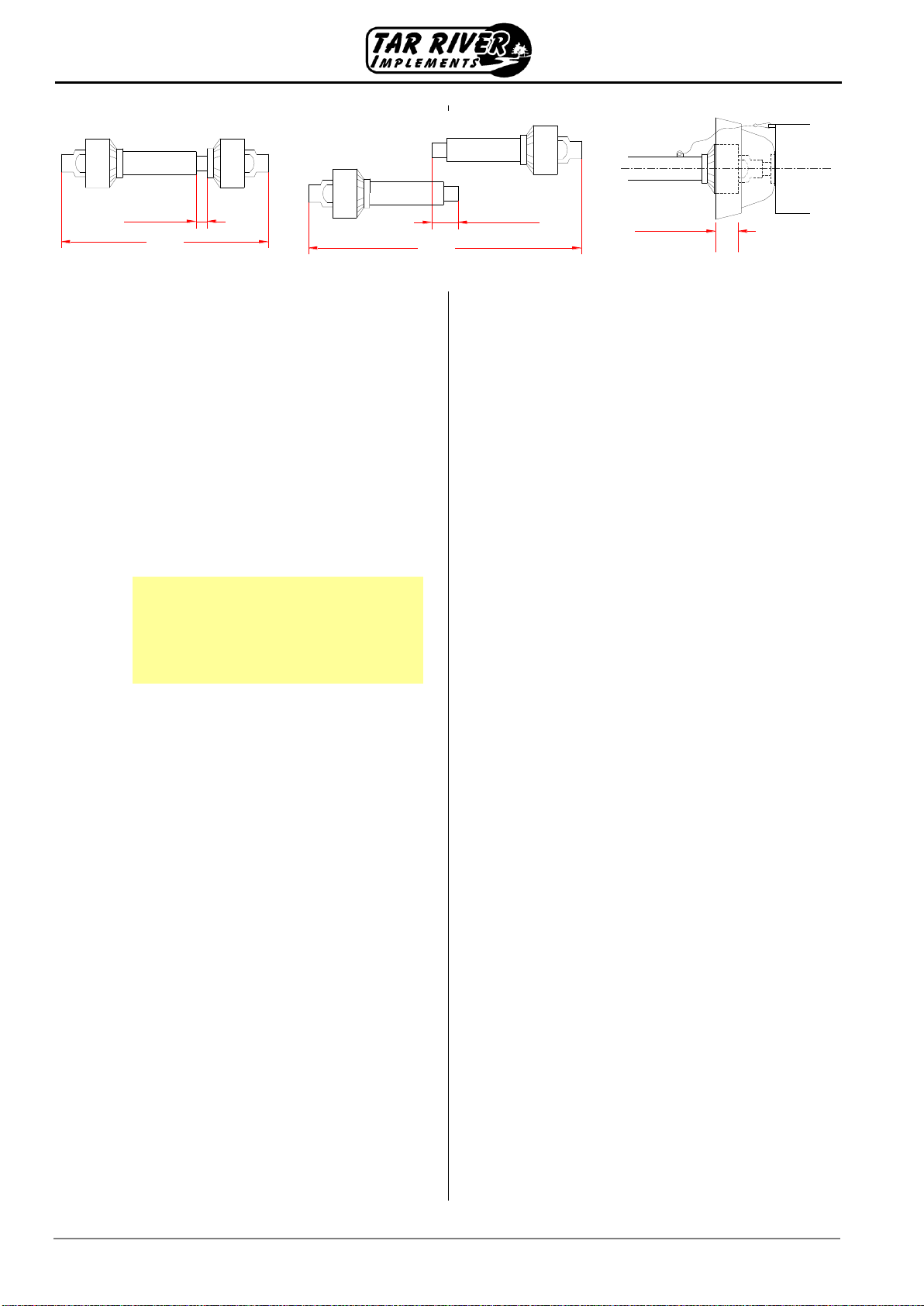

Adaptation: the cardan shaft (either

supplied with the equipment or sold

separately as an accessory) is standard

length. It is therefore necessary to adapt it

according to the tractor on which the hay

tedder will be installed. For this operation,

proceed as follows:

Fig.12

3.1

3.3

3.2

Fig.13

Fig.13

14

-remove the cardan shaft protections;

-pull out the two halves that make up the

shaft and attach one half to the hay

tedder PTO, triggering the safety spring

pin, and the other half to the tractor PTO,

also triggering the safety spring pin;

-place the two halves one next to the

other and find the minimum flowing

length (L). If the shaft is too long, first cut

in equal measures the two external

plastic protection tubes and then the

internal metal ones. File the cut parts

and lubricate the internal parts.

IMPORTANT

When the cardan shaft is pulled out to the

maximum, the two tubes must overlap by

at least 15 cm. When it is inserted at the

maximum, the minimum backlash

allowed must be 4 cm.

-remove the two halves of the cardan shaft

from their joints (on the tractor and on the

hay tedder) and reconstruct the shaft,

putting one half in the other completely;

-connect again each end of the cardan

shaft to the respective PTO triggering their

safety spring pins;

-block the protection tubes with the special

chains, respectively, on the hay tedder

and on the tractor in order to prevent

them from rotating. The overlap between

the guard and the cardan shaft must not

be less than 5 cm.

At this point, without activating the tractor PTO,

the equipment can be transported to the place of

use.

Note: if the equipment is used with a different

using the tractor, the cardan shaft may need a

readjustment. Proceed with the instructions

described in this paragraph.

C.5 Removal

For the hay tedder removal from the tractor follow

the instructions contained in the previous

paragraph, in reverse order.

C.6 Storage of hay tedder

The Customer must provide, within his company,

the equipment storage area, making sure it has a

wide and easy access. For the hay tedder

storing, the following interventions are needed:

-if not already done, place the hay tedder into

transport configuration;

-put the bearing feet (front and rear) for the

parking phase;

-park the equipment in a safe and secluded

area, on a flat and solid surface;

-remove the tractor from the hay tedder;

-protect the equipment with a cloth.

MAX

MIN

Min 4 cm Min 15 cm cm 5

15

D. OPERATION and USE

D.1 Preliminary informations

An appropriate and optimal use of the hay tedder

serves not only to prevent damage and/or injury,

but is the only way to get the same high

performance and to discover its true potential

and performance.

Before each start-up of the tractor, it is important

to scrupulously follow the precautions described

in the chapter “Safety”. Remember that the hay

tedder is to be used by a qualified operator, of

age and trained for its use and operations.

Consequently, he must know perfectly the

instructions in this manual, all those reported on

the adhesive labels and all the safety regulations

for his and others' safety and to safeguard the

equipment.

D.2 Working configuration

The hay tedder will be driven to the workplace

according to the regulations described in the

chapter “Safety”, and

before using the

equipment, verify that

the tractor PTO is

disengaged. Rotation

speed: 540 rpm.

IMPORTANT

The PTO should never

be engaged while the

engine is off;

After that, the operator provides to:

-verify the tine inclination in respect to the

ground is correct. For any adjustments

consult the paragraph “Adjustment of rotary

unit tilt (page 16);

-verify that NO people or animals in one of the

equipment dangerous areas (or range), if not

provide to send them away;

-Get back on the tractor, start the engine and

release the parking brake and by acting on the

corresponding lever, engage the PTO..

D.3 Working process

With the tractor proceeding and the rotation of

working rotary units and therefore of the tines,

the hay aeration process begins.

The tines skims and scrapes the ground surface

and harvests the cut crop pushing it rear upwards

in order to spread it evenly. For best results the

rotary units

must operate at an angle to the ground, which

can vary from 7 to 10°, as shown in figure.

Operate for a few meters and then check the

result of the process. If the operator deems

appropriate to increase or decrease the angle of

the rotary groups to the ground so as to improve

the working process, follow the relative

instructions in the next paragraph.

In presence of a lot of forage and/or of damp

forage adjust the rotary groups to the maximum

inclination B. Use the inclination Ain presence of

little forage and/or dry.

16

During operations, always maintain the tractor

speed within 5÷10 km/h. The optimum number of

PTO revolution is around 450 rpm.

IMPORTANT

Except for cases where otherwise specified, all

adjustments must be performed with the tractor

engine off, the PTO disengaged, the parking

bhey tedder pulled and the ignition key removed

from the dashboard.

D.4 Adjustment of rotary unit tilt

To modify the rotary unit tilt in respect to the

ground operate on the special adjusting lever, as

shown in figure. By turning the lever counter

clockwise (1direction) the inclination increases.

Turning the lever clockwise (2direction) the

inclination reduces.

D.5 Change of direction or reverse

At the end of the field when the tractor with the

hay tedder must reverse the direction of

movement or in the case it has to go for a short

distance in reverse, is essential that the tines are

lifted from the ground and when needed the

equipment has to convert into the transport

configuration (consult the following paragraph).

By turning the lever counter to reset the rotary

unit tilt in respect to the ground.

D.6 End of work

At the end of work, if a tractor has to go back in its

usual parking place, make the hay tedder assume

the transport configuration before moving.

Therefore:

disengaged the P.T.O.;

switch off the tractor engine;

pull the parking bhey tedder;

put the gear lever in neutral position;

remove the ignition key from the dashboard;

For the storage of equipment follow the

instructions described in the related paragraph.

2

1

17

E. MAINTENANCE

E.1 Warnings during maintenance

The hay tedder is agricultural equipment that

does not require special maintenance, nor

relative programs. However, there is a regular

intervention, described below, which, if done with

care by the Client, will keep unchanged the

efficiency and the working capacity of the

machinery avoiding any operating damage.

The operator, which must be of age, qualified and

trained to perform such interventions must

necessarily observe what follows:

HAZARD

-any type of intervention has to be

performed on a flat surface, sufficiently

lit and clear of people, animals or things

that might hinder the manoeuvre. The

equipment must be placed firmly on the

ground, the tractor blocked, the parking

brake pulled, the engine switched off and

the ignition key removed from the

dashboard. Should it be necessary to lift

the hay tedder, it is appropriate to secure

it by placing beneath pieces of wood or

metal, as shown in figure;

-before operating, for his safety and to

prevent damage to the hay tedder, he must

apply, well in view on the tractor dashboard,

the warning sign "Machine under

Maintenance”;

-both maintenance and repair operations,

once started, must always be finished and

never postponed;

-he must rely on his memory, but always read

the instructions in this manual and execute

them accurately;

-the use of equipment to perform

maintenance work is subjected to the

accident prevention.

At the end of maintenance or repair operations,

remove from the area any water, oil, grease oily

rags, tools or other material that may be present.

E.2 Maintenance tasks

The intervention times are for information only

and refer to normal conditions of use. Therefore,

they are subject to changes in relation to the kind

of service, the environment in which the work is

done (more or less dusty) seasonal factors etc.

The more the machinery conditions are

burdensome, the more the interventions must be

increased.

The maintenance tasks to be performed every

week or after 40 operating hours are:

-refuelling of grease by using the specific

pump, in all the grease nipples present on the

equipment and identifiable through the

adhesive labels like the one shown on the side

and sticked in their proximity. Grease agip MU

EP 2;

-check the fastening of nuts and screws that

secure the various parts of the equipment;

-check for the presence of the various safety

pins and R cotter pins that lock the various

parts of the equipment;

-verify that the structural integrity of all the

equipment parts especially those more

subject to wear such as wheels tires;

-check the integrity of the rotary units and that

the transmission gear box does not present

any oil leakage.

Note: all types of hay tedder have an oil

immersed transmission gear box which

means that all internal components operate

immersed in the lubricant..

Consequently, they are subject to a rapid

wear out if the oil runs out and therefore to

seizure. Therefore, if from the box any loss

or leakages are to be verified, it is essential

to check the inside oil level.

To check simply unscrew the cap level on

the side of the head as shown in the figure. If

the oil level does not reach the bottom of the

hole, its quantity is to be considered

insufficient and its refilling must be operated

through the same hole until the oil begins to

overflow.

GREASE

NIPiPLE

LUBRICATING

POINTS

18

Use only ISO VG 320 (ENI BLASIA 320)

gear oil (CINCINNATI MILACRON | DAVID

BROWN S1.53.101 (5E) | DIN 51517 Parte 3

- CLP | ISO L-CKD | U.S. STEEL 224)).

IMPORTANT

To avoid pollution, it is absolutely forbidden to

dispose of oils, lubricants, filter cartridges or

other harmful materials into the environment.

Strictly follow the regulations in force for the

disposal of liquid and solid substances.

For what concerns the cardan shaft interventions,

refer to what is described in its use and

maintenance manual

E.3 Tine replacement

If tine replacement were necessary (worn or

broken), you must completely unscrew the

locking nut (5), extract from its seat the fastening

screw (3) with its tine-stop plate (2) and then pull

the pair of teeth (4) from the equipment arm (1).

Insert a new pair and proceed in reverse order

the phases described for the removal.

E.4 Installation of tine-holder clamp (optional)

Protective clamp in case of breaking up of a tine.

To insert the clamp (1) from the lower part, to

position it after the bending of the tines (as in

figure) and to stop it with the respective locking

screws and nuts (2).

E.5 Troubleshooting

FAILURES

CAUSES

REMEDIES

Partial or insufficient forage harvesting

Tines too high from the ground

Adjust working rotary unit tilt (see

paragraph page 16)

Tines rapid wear out

The tines are continuously in contact

with the ground

Adjust working rotary unit tilt (see

paragraph page 30)

1

2

19

E.6 Material disposal in case of demolition

When the hay tedder is placed out of service, we

need to make harmless the parts that could

become dangerous for people, animals and

the environment, if dispersed. The materials of

the equipment, which are subjected to a separate

subdivision are:

iron

lubricating oil

rubber

Disposal of these materials must be done

according to the regulations of applicable law, in

force in each Country.

20

Table of contents

Other Tar River Implements Farm Equipment manuals

Popular Farm Equipment manuals by other brands

Maschio

Maschio RHINO Use and maintenance / spare parts

Frontier

Frontier RT 1142 Operator's manual

REIST INDUSTRIES

REIST INDUSTRIES RR72 Operator and parts manual

Landoll

Landoll 2131 Operator's manual

pronovost

pronovost SilaTube P-6500 Operator and parts manual

New Holland

New Holland BR6080 Operator's manual