Tar River Implements RR-248 User manual

Dec. 2023

Rotary Rake

RR-248

Operator’s Manual

2

Rotary Rake RR-248

Page left blank intentionally

3

Rotary Rake RR-248

TO THE DEALER:

Assembly and proper installation of this product is the responsibility of the Tar River dealer. Read manual

instructions and safety rules. Make sure all items on the Dealer’s Pre-Delivery and Delivery Check Lists in the

Owner’s/Operator’s Manual are completed before releasing equipment to the owner.

TO THE OWNER:

Read this manual before operating your Tar River equipment. The information presented will prepare you to

do a better and safer job. Keep this manual handy for ready reference. Require all operators to read this manual

carefully and become acquainted with all the adjustment and operating procedures before attempting to

operate. Replacement manuals can be obtained from your selling dealer. The equipment you have purchased

has been carefully engineered and manufactured to provide dependable and satisfactory use. Like all

mechanical products, it will require cleaning and upkeep. Lubricate the machine as specified. Observe all

safety information in this manual and safety decals on the equipment. For service, your authorized Tar River

dealer has trained mechanics, genuine Tar River service parts, and the necessary tools and equipment to handle

all your needs. Use only genuine Tar River service parts. Substitute parts will void the warranty and may not

meet standards required for safe and satisfactory operation.

Record your machine model and serial number in the space provide below. Your dealer will need this

information to give you prompt, efficient service.

Model Number: ______________________________________

Serial Number: _______________________________________

Date Purchased: ______________________________________

4

Rotary Rake RR-248

Introduction …………………………………………………………………………………………….. 5

Technical Specifications ……………………………………………………………………………….. 5

Safety …………………………………………………………………………………………………… 6

Safety Signal Words ……………………………………………………………………………………. 6

General Safety Guidelines ……………………………………………………………………………… 7

Safety Decal Care ………………………………………………………………………………………. 7-8

Before Operation ……………………………………………………………………………………….. 8

During Operation ……………………………………………………………………………………….. 9

Highway And Transport Operations …………………………………………………………………… 10-11

Assembly Instructions…………………………………………………………………………………... 12-14

Attaching to tractor……………………………………………………………………………………... 15-16

PTO Instructions……………………………………………………...………………………………… 17

Operating Instructions…………………………………………...……………………………………… 18-22

Inspection & Maintenance……………………………………………………………………………… 23

Lubrication…………………………………………………………………………………………… 24

Trouble Shooting……………………………………………………………………………………….. 25

Torque Specifications ………………………………………………………………………………….. 26

Parts Breakdown ……………………………………………………………………………………….. 29-39

Warranty ………………………………………………………………………………………………... 40

Table of Contents

5

Rotary Rake RR-248

Thank you for purchasing the RR-248 Rotary Rake. The RR-248 was designed with the needs of the small hay

farmer in mind. With a 98” working width, this rotary rake is capable of delivering an excellent quality or

performance while still being compact enough to be used with a 20 HP tractor.

The high-quality but affordable materials makes this rake durable and a great choice for budget farms. With

the RR-248’s combination of performance, durability, and affordability, it is the nest-best-thing for small hay

farms.

Technical Specifications

Introduction

RR-248

Weight 364 lbs.

Working width 98”

# of Tine arms 6

# of Tines 12

6

Rotary Rake RR-248

Safety

It is important that you read the entire manual and to become familiar with this product before you begin using

it. This product is designed for certain applications only. The manufacturer cannot be responsible for issues

arising from modification. We strongly recommend this product not be modified and /or used for any

application other than that for which it is designed. If you have any questions relative to a particular

application, DO NOT use the product until you have first contacted us to determine if it can or should be

performed on the product.

Read and understand this manual and all safety signs before operating and maintaining. Review the safety

instructions and precautions annually.

Safety Signal Words

TAKE NOTE! This safety alert symbol found though out this manual is used to call you attention to

instructions involving you personal safety and the safety of others. Failure to follow these instructions

can result in injury or death.

This symbol means:

Attention!

Become alert!

Your safety is involved!

Note the use of the signal words, DANGER, WARNING and CAUTION with the safety messages.

The appropriate signal word for each has been selected using the following guidelines:

DANGER: Indicates an imminently hazardous situation that, if not avoided, will result in death or

serious injury. This signal word is to be limited to the most extreme situations typically for machine

components which, for functional purposes, cannot be guarded.

WARNING: Indicates a potentially hazardous situation that, if not avoided, could result in death or

serious injury, and includes hazards that are exposed when guards are removed. It may also be used

to alert against unsafe practices.

CAUTION: Indicates a potentially hazardous situation that, if not avoided, may result in minor or

moderate injury. It may also be used to alert against unsafe practices.

Important Safety Information

7

Rotary Rake RR-248

General Safety Guidelines

Safety of the operator is one of the main concerns in designing and developing a new piece of equipment.

Designers and manufacturers build in as many safety features as possible. However, every year many accidents

occur which could have been avoided by a few seconds of thought and a more careful approach to handling

equipment. You, the operator, can avoid many accidents by observing the following precautions in this section.

To avoid personal injury, study the following precautions and insist those working with you, or for you, follow

them.

Replace any DANGER, WARNING, CAUTION or instruction safety decal that is not readable or is missing.

Location of such decals are indicated in this manual. Do not attempt to operate this equipment under the

influence of drugs or alcohol.

Review the safety instructions with all users annually.

This equipment is dangerous to children and persons unfamiliar with its operation. The operator should be a

responsible adult familiar with farm machinery and trained in this equipment’s operations. Do not allow

persons to operate or assemble this machine until they have read this manual and have developed a

thorough understanding of the safety precautions and of how it works.

To prevent injury of death, use a tractor equipped with a Roll Over Protection System (ROPS). Do not paint

over, remove or deface any signs or warning decals on your equipment. Observe all safety signs and practice

the instructions on them.

Never exceed the limits of a piece of machinery. If its ability to do a job, or to do so safely, is in question -

Don’t try it!

• Keep safety signs clean and legible at all times.

• Replace safety signs that are missing or have become illegible.

• Replaced parts that displayed a safety sign should also display the current safety sign

• Safety signs are available from your Distributor or Dealer Parts Department or the factory.

Safety Decal Care

Important Safety Information

8

Rotary Rake RR-248

How to Install Safety Signs

• Be sure that the installation area is clean and dry.

• Decide on the exact position before you remove the backing paper.

• Remove the smallest portion of the split backing paper.

• Align the decal over the specified area and carefully press the small portion with the exposed sticky

backing in place.

• Slowly peel back the remaining paper and carefully smooth the remaining portion of the decal in place.

• Small air pockets can be pierced with a straight pin and smoothed out using the piece of decal backing

paper.

• Carefully study and understand this manual.

• Do not wear loose-fitting clothing, which may catch in moving parts.

• Always wear protective clothing and substantial shoes.

• Assure that all tires are inflated evenly.

• Give the machine a visual inspection for any loose bolts, worn parts or cracked welds, and make necessary

repairs. Follow the maintenance safety instructions included with this manual.

• Be sure that there are no tools lying on or in the equipment.

• Do not use the machine until you are sure that the area is clear, especially of children and animals.

• Don’t hurry the learning process or take the machine for granted. Ease into it and become familiar with

your new equipment.

• Practice operation of your equipment and its attachments. Completely familiarize yourself and other

operators with its operation before using.

• Use a tractor equipped with a Roll Over Protection System (ROPS) and fasten your seat belt prior to

starting engine.

• The manufacturer does not recommend usage of tractor with ROPS removed.

• Move tractor wheels to the widest recommended settings to increase stability.

• Securely attach to towing unit. Use a high strength, appropriately sized hitch pin with a mechanical retainer

and attach safety chain.

• Do not allow anyone to stand between the tongue or hitch and the towing vehicle when backing up to the

equipment.

Important Safety Information

Before Operation

9

Rotary Rake RR-248

• Children should not be allowed on the product.

• Clear the area of small children and bystanders before moving the machine.

• If using a towing unit, securely attach machine by using a hardened 3/4” pin, a metal retainer, and safety

chains if required. Shift towing unit to a lower gear before going down steep downgrades, thus using the

engine as a retarding force. Keep towing vehicle in gear at all times. Slow down for corners and rough

terrain.

• Make sure you are in compliance with all local and state regulations regarding transporting equipment on

public roads and highways. Lights and slow moving signs must be clean and visible by overtaking or

oncoming traffic when machine is transported.

• Beware of bystanders, particularly children! Always look around to make sure that it is safe to start the

engine of the towing vehicle or move the machine. This is particularly important with higher noise levels

and quiet cabs, as you may not hear people shouting.

• NO PASSENGERS ALLOWED! Do not carry passengers anywhere on, or in, the tractor or equipment,

except as required for operation.

• Keep hands and clothing clear of moving parts.

• Do not clean, lubricate or adjust your equipment while it is moving.

• When halting operation, even periodically, set the tractor or towing vehicle brakes, disengage the PTO,

shut off the engine and remove the ignition key.

• Be especially observant of the operating area and terrain. Watch for holes, rocks or hidden hazards. Always

inspect the area prior to operation.

• DO NOT operate near the edge of drop-offs or banks.

• DO NOT operate on steep slopes as overturns may result.

• Operate up and down (not across) intermediate slopes. Avoid sudden starts and stops.

Important Safety Information

Warning: Never backup with the machine on the ground! This will cause dam-

age to the machine. Always lift the machine high enough to clear the ground be-

fore backing up.

During Operation

10

Rotary Rake RR-248

• Adopt safe driving practices.

• Keep the brake pedals latched together at all times. Never use independent braking with machine in tow

as loss of control and/or upset of machine can result.

• Always drive at a safe speed relative to local conditions and ensure that your speed is low enough for an

emergency stop to be safe and secure. Keep speed at a minimum.

• Reduce speed prior to turns to avoid the risk of overturning.

• Avoid sudden uphill turns on steep slopes.

• Always keep the tractor or towing vehicle in gear to provide engine braking when going downhill. Do not

coast.

• Do not drink and drive!

• Comply with state and local laws governing highway safety and movement of farm machinery on public

roads.

• Use approved accessory lighting flags and necessary warning devices to protect operators of other vehicles

on the highway during daylight and nighttime transport. Various safety lights and devices are available

from your dealer.

• The use of flashing amber lights is acceptable in most localities. However, some localities prohibit their

use. Local laws should be checked for all highway and marking requirements.

• When driving the tractor and equipment on the road or highway under 40 kph (20 mph) at night or during

the day, use the amber warning lights and a slow moving vehicle (SMV) identification emblem.

• Plan your route to avoid heavy traffic.

• Be a safe and courteous driver. Always yield to oncoming traffic in all situations, including narrow

bridges, intersections, etc.

• Be observant of bridge loading ratings. Do not cross bridges rated at lower than the gross weight at which

you are operating.

• Watch for obstructions overhead and to the side while transporting.

• Always operate in a position to provide maximum visibility at all times. Make allowances for increased

length and weight of the equipment when making turns, stopping the machine, etc.

• Pick the most level route when transporting across fields. Avoid the edges of ditches or gullies and steep

hillsides.

• Be extra careful when working in inclines.

Important Safety Information

Highway and Transport Operations

11

Rotary Rake RR-248

• Maneuver the tractor or towing vehicle at safe speeds.

• Avoid overhead wires or other obstacles. Contact with overhead lines could cause serious injury or death.

• Avoid loose fill, rocks and holes, they can be dangerous for equipment operation or movement.

• Allow for machine length when making turns,

• Operate the towing vehicle from the operator’s seat only.

• Never stand alongside of machine with engine running or attempt to start engine and/or operate machine

while standing alongside of machine.

• Never leave running equipment attachments unattended.

• As a precaution, always recheck the hardware on equipment following every 100 hours of operation.

Correct all problems. Follow the maintenance safety procedures.

Important Safety Information

Highway and Transport Operations

12

Rotary Rake RR-248

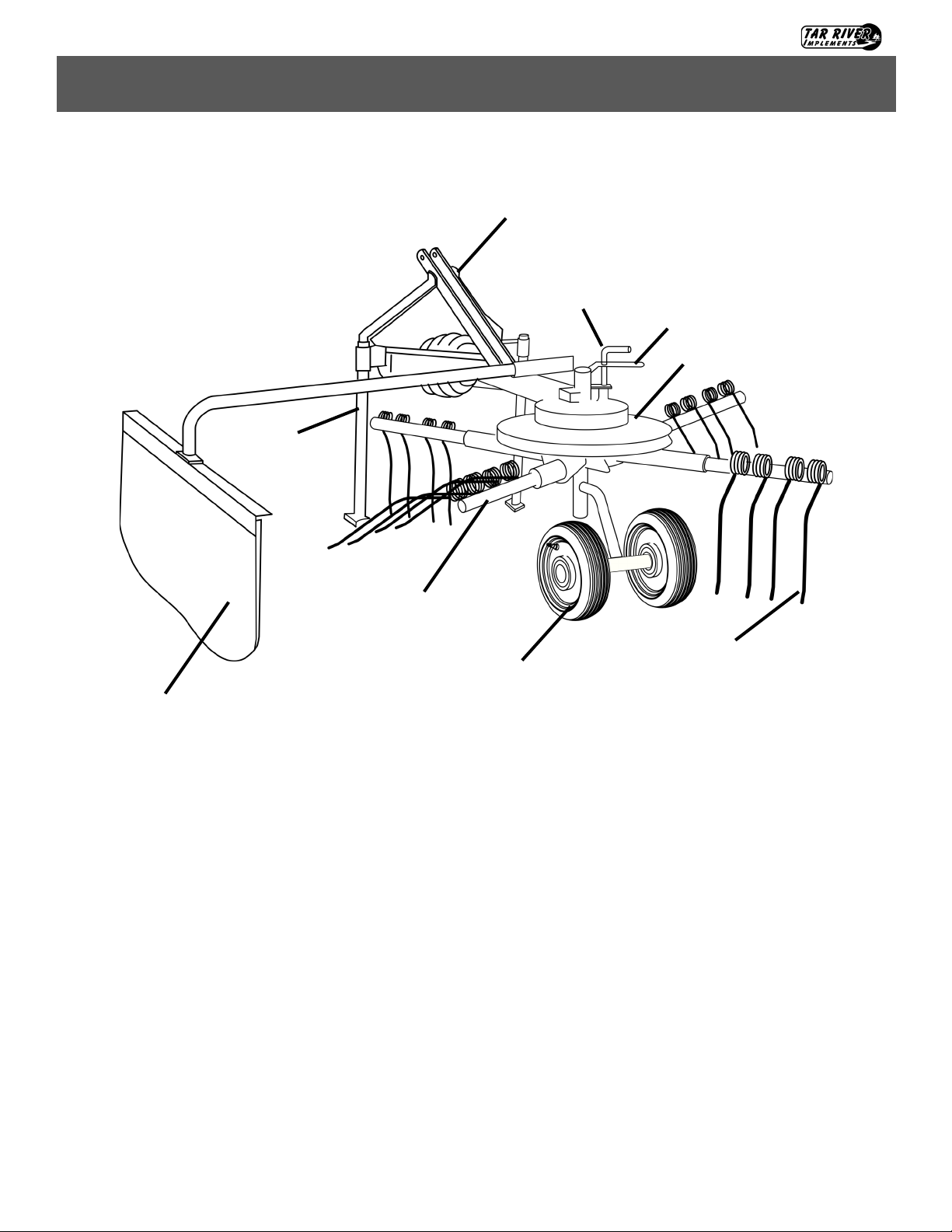

Components and their functions

• Universal joint:

Power is transmitted from tractor to Rotary Rake.

• Three point frame:

Connects Rotary Rake to a tractor.

• Windrow guard:

Working width can be adjusted by removing locking pin from frame, sliding windrow guard in or out. Re-

insert pin before beginning or continuing operation.

• Rotor:

Working position such as raking, tedding, spreading and transportation is changed by lifting locking pin

and turning change lever on rotor.

• Wheel:

Adjust ground clearance height by changing the combination of the three height adjustment collars

depending on working conditions.

Assembly

Assembly Instructions

Three point frame

Lock pin

Tine arm

Tine

Tire & Wheel

Change lever

Windrow guard

Rotor

Stand

13

Rotary Rake RR-248

Applicable tractor size

This machine is designed to operate using the recommended size tractor. Attaching to an improper size tractor

could result in damage to the machine, tractor and cause serious injury or death. This will result in voiding the

Warranty.

The suitable tractor horse power for this machine is as follows:

If a tractor smaller than the applicable size is used with this machine, there may not be sufficient power to

operate the machine.

If a tractor larger than the applicable size is used, there will be too much power for the load causing damage to

the machine, tractor and possible serious injury or death.

Assembly

• Open package:

Remove the parts that are fastened to the wooden or metal crate.

• Details of packaged parts:

Make sure all of the required parts that are listed on the packing list have been included in the package.

• Assembly:

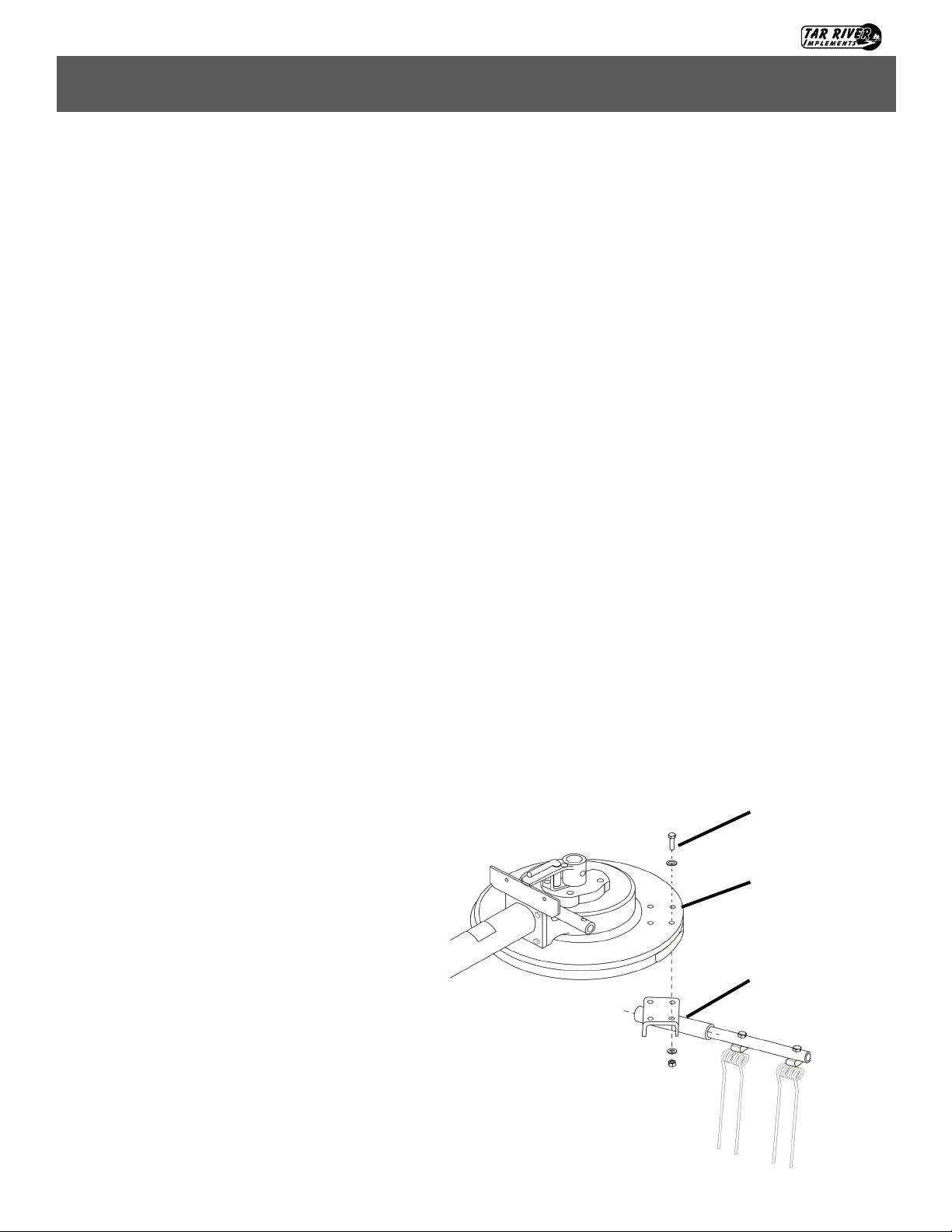

(1) Attach arm support to rotor plate using supplied hardware.

Assembly

Assembly Instructions

Model Applicable Tractor

RR-248 11 - 22kW (15-30 HP)

Rotor plate

Bolt M10 x 30

Arm support

14

Rotary Rake RR-248

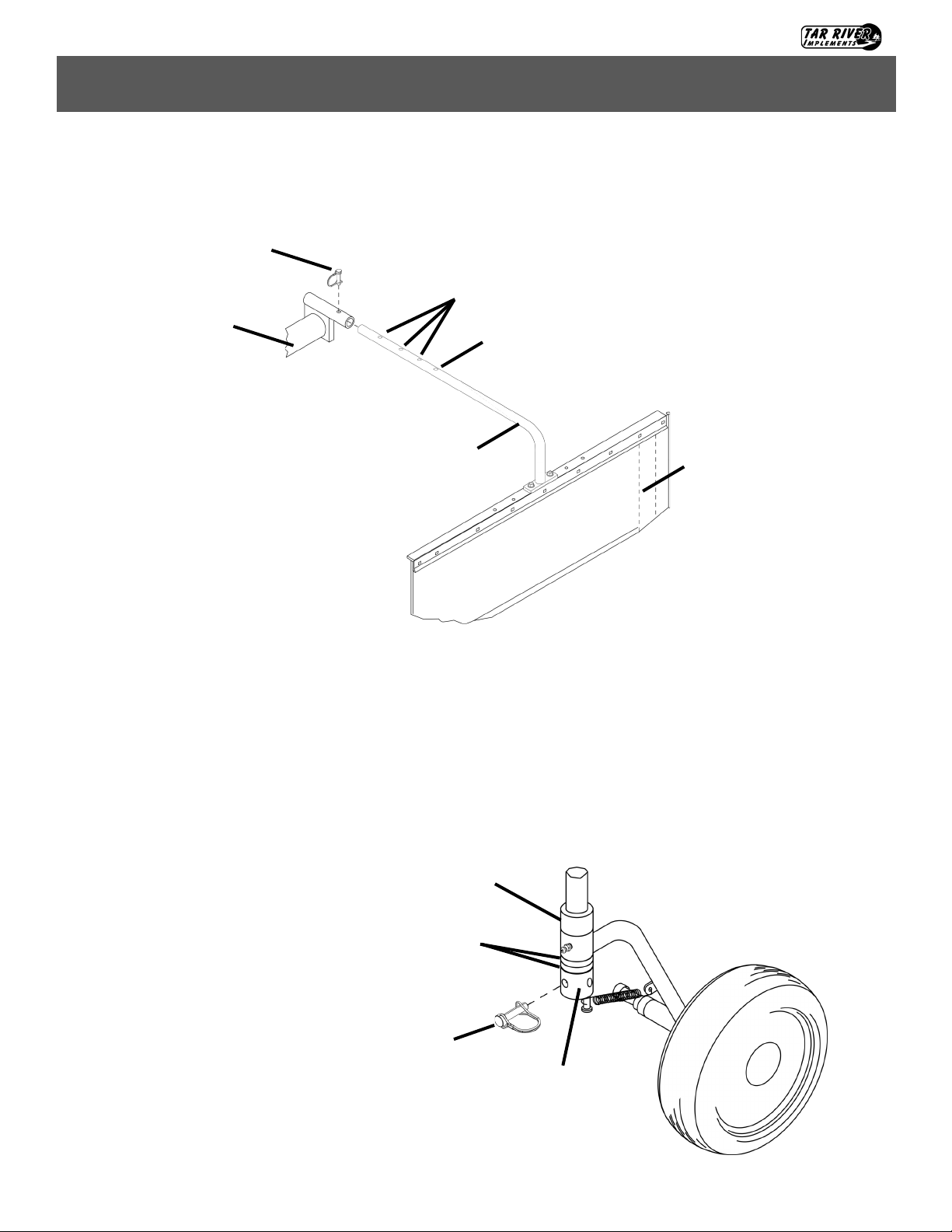

(2) Attach wheel

Standard attaching position of collar is as follows:

Attach collar with pin when Change Lever is shifted to raking position.

(3) Attach windrow guard

Slide the windrow guard arm into the frame of machine. Select hole that sets width of the windrow

desired. Do not operate the machine until the locking pin is secure.

Assembly

Assembly Instructions

Collar 32 x 12

Collar 32 x 23

Delta pin

Collar with pin

Spring

Wheel

Axle

Pin

Machine frame

Arm

Bolt M10 x 25

Windrow guard

15

Rotary Rake RR-248

Attachment to tractor

Before attachment:

The machine should be attached to the standard tractor three point linkages.

If the machine can not be lowered enough, lift rod of lower link are should be moved to the forward hole.

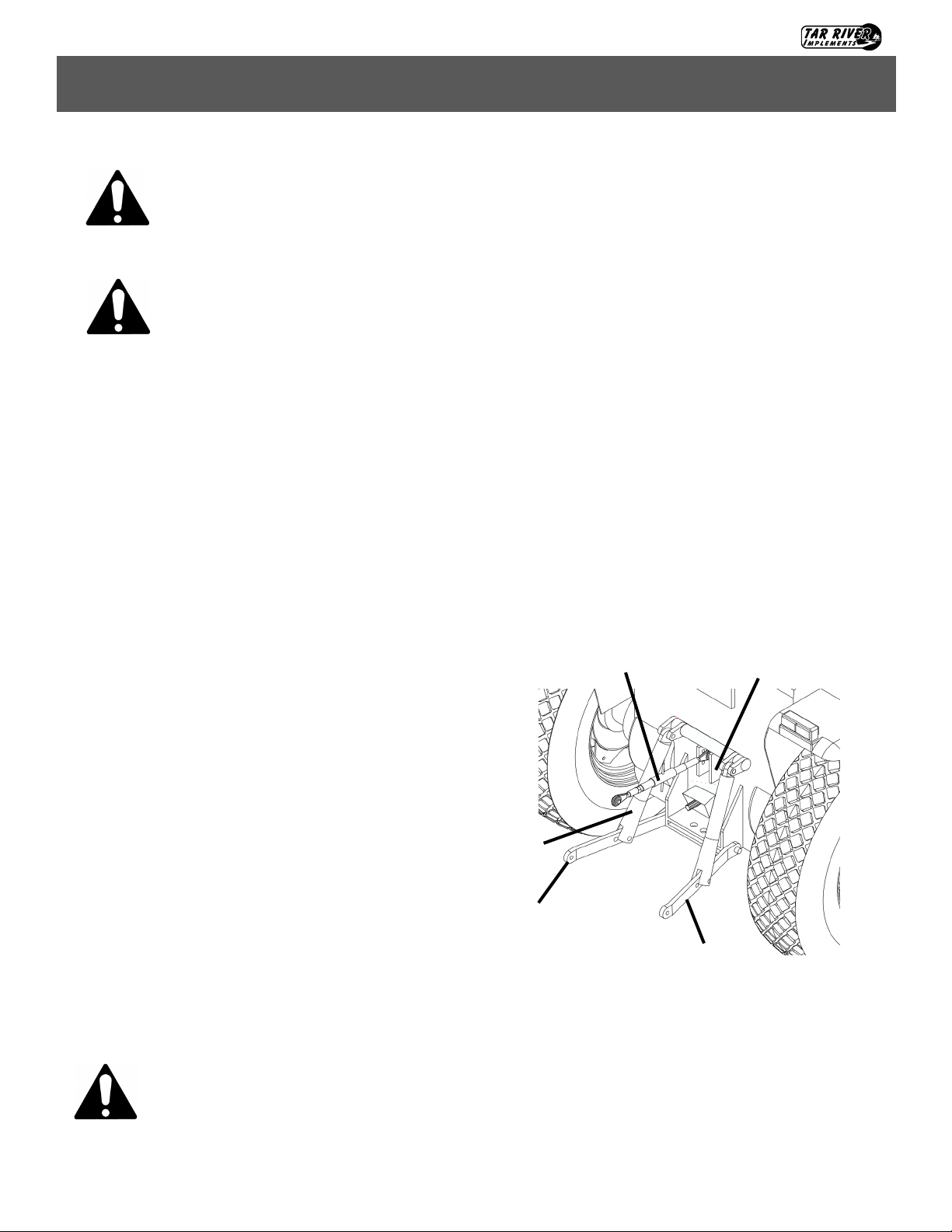

Attaching to a tractor 3 point

• Start the tractor and reverse the tractor until the end of the tractor’s lower links line up with the left and

right lower link pins of the machine. Stop the

tractor, turn off engine, remove key and apply

parking brake.

• Connect the left lower link, then insert the

locking pin into the lower link pin to secure the

machine to the tractor. Repeat for the right side.

• Connect the top link by inserting pin, then insert

the locking pin into the top link pin to secure the

machine to the tractor.

• Adjust the left and right lower link so they are

the same height with the adjustment screw

located on the right lift rod of the tractor.

• The center of driveline should be located close

to the center of the tractor by setting the check

chain to prevent the machine from moving horizontally.

• Pull up the stand and fasten it by the delta pin.

Assembly

Attaching to tractor

Warning: Never allow bystanders between the tractor and the machine when

moving the tractor to attach or detach the machine. Serious injury of death is

possible. Never allow anyone between the tractor and the machine.

Caution: Do not attach or detach the machine to the tractor on an incline or

soft/unstable ground. This could result in an unforeseeable accident due to

unexpected movement of the tractor or the machine.

Attaching or detaching the machine should always be performed on level,

solid ground.

A counter-weight may be required for lighter tractors to prevent unstable

handling of the tractor.

Top link Top link bracket

Lower link RH

Lower link LH

Li rod

Caution: Some tractors have an automatic 3 point quick rising mechanism by

an electrical switch. Make sure the tractor and the machine do not interfere

by manual operation and limit height of lower link to have enough space be-

tween the tractor and the machine.

16

Rotary Rake RR-248

• Pull up the stand and fasten it by the locking pin.

• Lower the machine by operation of the 3 point hitch until it comes into working position.

Attachment of the universal joint

If the universal joint is used without a safety cover, there is a possibility of becoming entangled and

injured. Do not use a universal joint without a safety cover.

Assembly

Attaching to tractor

Stands

Delta Pin

Delta Pin

Danger:

• If the universal joint is used without a safety cover, there is a possibility of becoming

entangled and injured. Do not use a universal joint without a safety cover.

• If the universal joint is used with a damaged cover, there is a possibility of becoming entan-

gled and injured. If the cover becomes damaged, replace it immediately. Check for damage

before use.

• When attaching the universal joint to the machine and tractor or when detaching from tractor

and the machine, there is a possibility of injury if the universal joint is operated unknowingly

by a third person. Disengage PTO and turn off the tractor engine before performing attach-

ment.

• If the universal joint is used without installing the chains for the cover, there is a possibility

that the cover could turn and the operator could become entangled and injured.

• Connect the chains on both the tractor side and machine side so the cover does not turn.

Caution:

• If the overlap of the inner and outer pipes of the universal joint in less than 100 mm when

fully extended, there is a possibility of damage or injury.

• If the space between the inner and outer pipes of the universal joint is less than25mm when

fully retracted, then both pipes could hit each other and cause damage or injury.

• Make sure if the overlap of the pipes is proper.

17

Rotary Rake RR-248

Assembly

Maintenance Instructions

Assembly

Attaching the PTO shaft:

Before installing the PTO shaft make sure that the RPM rating and the direction of rotation match those of the

tractor. Carefully read the PTO shaft and tractor instructions. Before operation, make sure that the guards are

installed on the power take off of the tractor and PTO shaft. Make sure that they cover the PTO shaft through-

out its length. Note: The PTO shaft may be too long and require shortening. See “Shortening a PTO

driveline” below.

Press the locking pin on the PTO yoke and slide yoke on to the PTO of the tractor until the pin seats. Pull on

PTO shaft to make certain it is locked in place. Repeat the procedure for the machine end. Attach the PTO

cover’s safety chains to a stationary part of the tractor. Leave some slack in the chain to accommodate move-

ment.

Shortening a PTO driveline:

1. With the machine attached to the tractor’s

3-point hitch, and the PTO shaft not in-

stalled, separate the PTO shaft. Attach the

machine end to the machine and the other

end to the tractor PTO input shaft.

2. Raise the machine by using the tractor’s

hydraulic 3-point hitch to its maximum

lift height.

3. Hold the half shafts next to each other and

mark them so each end is approximately

1/2” from hitting the end of the telescopic

profiles.

4. Shorten the inner and outer guard tubes

equally.

5. Shorten the inner and outer profiles by the

same length as the guard tubes. Using a

rattail file, round off all sharp edges and

burrs. Grease the telescopic profile gener-

ously before reassembling.

When fully extended, the tubes must overlap by at least 1/3 of the length of the pipes

(LT). When retracted, the min. acceptable clearance is 1-2 cm (3/8”-3/4”)

Scan the QR code below for more detailed information on PTO installation.

PTO Instructions

18

Rotary Rake RR-248

Inspection before operation

Inspection should be performed before operation in order to assure long life of the machine.

Inspecting tractor

• Inspect the tractor as described in the operation manual for the tractor.

Inspecting the connection of the 3 point linkages

• Has the locking pin been inserted into the hole for the lower link?

• Has the delta pin been inserted into the hole of the top link pin?

• Are the check chains stretched properly?

• If any problems are found, handle them as described in “Connection to the 3 point linkage.”

Inspecting the universal joint

Is the clamp pin seated in the groove of the PTO shaft?

Is the stopper ring of the pin fitted in the slot of the yoke with plain hole?

Is there too much slack in the chains attached to the joint covers? Is there enough slack?

Are joint covers damaged? If there is any damage, immediately replace the cover.

If any problems are found, handle them as described in section, “Attachment of the Universal Joint.”

Inspecting the machine

Check all hardware for proper torque. See “Torque Specifications” on page 27.

Are all moving parts lubricated or greased properly? If not, lubricate them or apply grease as described in

section, “List of Places Requiring Lubrication”.

Check air pressure in tires and adjust according to the tire manufactures recommendation.

Inspecting tractor engine operation.

Caution: Never start tractor engine with PTO engaged. When the tractor engine is

running and PTO is engaged, there is a possibility for bystanders to be seriously

injured or killed. Never allow anyone near a running tractor with the PTO

engaged.

Assembly

Operating Instructions

19

Rotary Rake RR-248

Adjustment of windrow guard.

It can be adjusted in three stages, depending on type of material.

Windrow guard should be turned upward during spreading and tedding.

Adjustment of wheel height

Lift the machine using the tractor three point linkage. Remove the delta pin and adjust the height of the

wheels using the collars provided.

Standard height is as follows: Clearance between ground and tine is changed depending on the height of the

wheel. Adjust this clearance by tractor top link.

Caution: Make sure the pin on the collar is facing the rear of the machine as shown in the illustration below.

Assembly

Operating Instructions

Delta pin

Frame

Operating positions

Transport position

Arm

Windrow guard

Collar, 32x23

Collar, 32x12

Collar with pin

Delta pin

20

Rotary Rake RR-248

Tine motion adjustment

Shift the position of the lever according to the work desired. Make sure the locking pin is seated in the

proper hole. See illustration below.

Operation

Caution: During operation or while machine is rotating, coming in contact with the rotor can result in

entanglement and cause serious injury.

Warning: During operation or while machine is rotating, there is the possibility of injury due to thrown

objects such as, rocks, sticks, etc. Never allow bystanders near the machine while in operation.

There is the possibility of serious injury or death. Damage to the machine is possible if the PTO is operated

beyond the recommended rpms.

Do not exceed the recommended rpms.

Operate machine at a low speed when on an incline. Excessive speed can cause the tractor and machine to tip

over, causing damage to tractor, the machine, serious injury or death to the operator.

Before operating on an incline, shift tractor into a lower gear and slower throttle speed.

Attention: Never make adjustments to the wheels or operation change lever without first stopping the tractor

engine, setting the parking brake. Be sure all moving parts have stopped before attempting any adjustments or

repairs. Rotating parts can cause serious injury or death.

• Tedding should be done as soon as possible after cutting material, grass, hay, to accelerate drying time.

• It is better to run a tractor over the row after cutting grass, straw, or windrow after raking when tedding.

• If there is a small amount of material, gather two or three small rows into one for better productivity.

• Windrows should be uniform and small for best results.

• There is greater moisture content in the night air.

• There is a greater chance that the material will contain a higher concentration of moisture.

• To prevent excessive moisture, make windrows before stopping in the evening.

• Windrows will also aid in keeping moisture down if it rains.

Assembly

Operating Instructions

Raking

Tedding

Spread-

Transport-

Locking pin

Lever

Table of contents

Other Tar River Implements Farm Equipment manuals

Popular Farm Equipment manuals by other brands

Amazone

Amazone Cataya 3000 Super operating manual

VOSS.farming

VOSS.farming AV 1000 Pet Control Operating instruction

Montag

Montag GEN 1 Operation manual

Titan Attachments

Titan Attachments ATVLR4 owner's manual

Game Winner

Game Winner HU2220401-GW Assembly instructions

MacDon

MacDon M155 Unloading and assembly instructions