TAS PowerTek TPF-56 User manual

LT Intelligent Automatic Power Factor Controller

& Data Logger

For Capacitor-Duty Thyristor Switches,

For High-Speed Power Factor Correction

TPF-56

User Manual

Version 1.1.5

Updated on: 22nd March 2016.

NOTE

These instructions do not purport to cover all details or

variations in equipment, nor to provide for every possible

contingency to be met in connection with installation,

operation or maintenance.

Should further information be desired or should particular

problems arise which are not covered sufficiently for the

purchasers purposes, the matter should be referred to our

office.

The contents of this instruction Manual shall not become

part of or modify any prior or existing agreement or

relationship. Any statements contained herein do not create

new warranties or modify the existing warranty.

The reproduction, transmission or use of this

document or its contents is not permitted

without express written authority. Offenders

will be liable for damages. All rights are

reserved.

Intelligent Power Factor Controller TPF-56

CAUTIONS:

1. There are High Voltages associated with this Unit. So, take appropriate

precautions.

2. To be installed & commissioned by a technically qualified person only.

3. Make sure that the discharge time set in the controller matches

the capacitor discharge time!

4. This Automatic Power Factor Controller (APFC), TPF-56, is to be used

indoor only.

5. Make sure that the Capacitor Bank Discharge Time set in the PF

Controller matches with the actual Capacitor Bank Discharge Time.

6. This User Manual is applicable to TPF-56 Unit with Firmware

Version 1.0.7 as on 25 JAN, 2016.

Because of continuous improvements carried out by TAS PowerTek in their

Product’s Features and Specifications, the Product as well as the Content of the User

Manual is likely to get updated without any prior notice.

Therefore, please always refer to the User Manual supplied to customer along with

the Product, at the time of product dispatch.

!

2 of 56 Version 1.1.5 22nd March, 2016

Index

Section Page No.

Index page -- 3

Ordering Information -- 4

Features -- 5

Specifications -- 8

Functional block diagram -- 15

PF correction technique -- 16

Typical wiring scheme -- 18

Front fascia -- 19

LCD display contrast & backlit -- 22

Display of various parameters -- 23

Sub menu for display of parameters -- 24

Method of Keyboard / Display usage -- 26

Keyboard / Display operations -- 29

Edit Parameters -- 30

General & I/O -- 31

System -- 31

Fault -- 32

Steps -- 35

Communication -- 36

Utilization counter -- 37

Notes On Protection

and Functionalities -- 38

Fault indications and

Fault actions -- 40

Data logging facilities -- 41

Power-fail monitoring -- 42

Commissioning Instructions -- 43

Fault finding Guidelines and

Trouble shooting procedures -- 45

Factory Default Settings -- 47

Maintenance Copy

(Blank Forms for User) -- 52

Manufacturer’s Contact Details -- 56

Intelligent Power Factor Controller TPF-56

3 of 56 Version 1.1.5 22nd March, 2016

Ordering Information

Product Specific Information Number (PSIN)

TPF-56 / nn

nn: Number of Current-sourcing, 20 milli-Amps Current-Limiting, Transistor

Output stages: 04,08, 12, or 16.

Please specify the “nn” while quoting, ordering, buying etc.

Note that the Isolated +12 V DC Supply is from User Side, and the “Return” for

all Command Outputs of TPF-56/nn are “Commoned” to 0 V of the +12 V DC

Supply, at the TAS Thyristor Switches Side.

The TPF-56 Units with TAS Capacitor-Duty Thyristor Switches make ideal

combinations for Applications in Welding Shops, Reciprocating PistonAir-

Compressors, ElectricArc Furnaces, Induction Furnaces, Rolling-Mills etc.

Intelligent Power Factor Controller TPF-56

4 of 56 Version 1.1.5 22nd March, 2016

(SimilarAPFC Unit is available with Potential-Free, Normally-Open (N. O.)

Relay Contacts, as SPF-56, for Medium-Speed, P. F. Corrections, based on Three-

Phase, Capacitor-Duty, Power Contactors & Three-Phase, Delta Connected Power

Capacitors, with Discharge Resistor and optional Current-Limiting I de-tuned

Inductive Reactors in EACH Phase to the Power Capacitor.

The SPF-56 Firmware is compatible for the Relays and the Contactors based

Medium-Speed PF CorrectionApplications with TAS Reactors and Capacitors.

Please contact TAS PowerTek, Nasik, India, for further details.)

Features:

•Totally Micro-Controller based logic for measurements, monitoring,

analysis & control.

•Functionality Suitability: LT PF correction application for Distribution

Transformers secondary side used by Electricity Distribution

Companies, Private Industries, Offices, Establishments etc.

•Protection and Functionality to take care of Supply System

abnormalities and various faults.

•Protection against internal faults and its controlled components like

Capacitor Banks and switching thyristor.

•Communication port RS-232 for logged data downloading and for

other convenience functionalities.

•Completely Fire Retardant ABS grade plastic material body with

sufficient ventilation for cooling.

•Externally replaceable battery slot for maintenance convenience. This

battery is used primarily for RTCC –“Real Time Clock-Calendar” to

work during supply power down condition.

•LCD –16 Char. x 2 Line Yellow-green Backlight and Black Characters,

Display for Display of various parameters, symbols & functionalities

requirement.

•Keypads with soft touch 7 Nos. of keys for Scrolling between various

displays and various functionalities / settings.

•Power supply and measurement range is wide-ranging and highly

reliable operation under various supply system PQ issues like supply

voltage dips / swells, transients, cycle loss etc.

•Reliable Screw type terminals for fork/ring type lugs with externally

replaceable fuse protection for transistor outputs.

•Capacitor Banks –same value Equal Utilization logic.

Intelligent Power Factor Controller TPF-56

5 of 56 Version 1.1.5 22nd March, 2016

Features (Continued):

•Capacitor Banks actual value measurement in terms of KVAr (reactive

power) normalized values for rated supply voltage and frequency, for

monitoring it’s health. This is on-line monitoring with complex

algorithm for getting right values under variable loading conditions

authentically.

•Measurement and Display of Various Electrical values:

3-phase Voltages (Line –Neutral Values)

3-phase Currents and Neutral Current.

Individual Phase PF, Active Power, Reactive Power, Apparent

Power values.

AC Mains Supply Line frequency.

Overall Values: Average Voltage & Current, Total Active Power,

Total Reactive Power, Total Apparent Power.

Energy Values: Active Energy Consumed, Reactive Energy

Inductive (uncompensated), Reactive Energy Capacitive

(uncompensated), Apparent Energy.

Harmonics: Per Phase V-THD-F% and I-THD-F% values up to 15th

odd harmonics.

Capacitor Bank Values: Normalized for rated supply voltage and

frequency and monitored on line.

Temperature of the Unit.

Battery Voltage for RTCC / NV-RAM Battery.

•Data Logging: Unit has sufficient Non-Volatile memory to log hourly,

30min,15min,10min readings and to log last 1024 events. The

Parameters are logged for downloading on PC based program “Data

View” for viewing and report generation purpose.

The Logged values for viewing and report generation are:

Unit ID, Sr. No., Date / Time stamp.

3-phase Voltages (Line –Neutral Values)

3-phase Currents.

Supply frequency.

Overall Power Values: Total Active Power, total Reactive Power,

total Apparent Power.

Energy Values: Active Energy Consumed, Reactive Energy

Inductive (uncompensated), Reactive Energy Capacitive

(uncompensated), Apparent Energy.

Harmonics: Maximum value of Phase V-THD-F% and I-THD-F%

values.

Intelligent Power Factor Controller TPF-56

6 of 56 Version 1.1.5 22nd March, 2016

Features (Continued):

Capacitor Bank Values: Normalized for rated supply voltage and

frequency and monitored on line.

All Capacitor Bank Status.

Temperature of the TPF-56 Unit.

Battery Voltage for RTCC / NV-RAM Battery.

•Data Mobilizer –In future, we will add Hand Held Unit (HHU-01) as a separate

unit, that can be procured separately for transfer of data from remote site

located TPF-56 Unit that can be further uploaded to PC having “Data View”

software. Such Unit even have added facilities like fixed set parameter

uploading (5 pre-programmed sets of Parameters to be programmed in TPF-

56).

•Manual Mode (Testing) facility available for convenience of checking the Turn-

On and Turn-Off of capacitor banks. This feature is additionally useful for

Manual Synchronization and for resetting the “faulty” declared capacitor banks.

•GSM (global system for mobile) :

Enabling GSM send SMS about various parameter :

3-phase Voltages (Line –Neutral Values)

3-phase Currents and Neutral Current.

Bank status .

Fault.

•RS485 communication :

There are two basic transmission modes found in serial MOD-BUS

connections, ASCII and RTU. These transmission modes determine the

way in which the MOD-BUS messages are coded.

One of the main differences between MOD-BUS/ ASCII and MOD-BUS RTU

is that ASCII allows gaps between the bytes of a message with a

maximum length of 1 second. With MOD-BUS RTU, continuous streams of

messages must be sent. Enabling Modbus ASCII or RTU gives values:

3-phase Voltages (Line –Neutral Values)

3-phase Currents and Neutral Current.

Individual Phase PF, Active Power, Reactive Power, Apparent Power values.

AC Mains Supply Line frequency.

Overall Values: Average Voltage & Current, Total Active Power, Total

Reactive Power, Total Apparent Power.

Energy Values: Active Energy Consumed, Reactive Energy Inductive

(uncompensated), Reactive Energy Capacitive (uncompensated),

Apparent Energy.

Harmonics: Per Phase V-THD-F% and I-THD-F% values.

Capacitor Bank Values: Normalized for rated supply voltage and

frequency and monitored on line.

Temperature of the Unit.

Intelligent Power Factor Controller TPF-56

7 of 56 Version 1.1.5 22nd March, 2016

Specifications of TPF-56/xx Unit:

1. Rated supply values:

3 –Phase, 4 –Wire supply system.

Line-to-Line rated voltage 440VAC sinusoidal.

Rated frequency 50Hz(+/-3Hz) Or 60Hz(+/-3Hz)

2. Auxiliary Supply:

Line to Line sinusoidal voltage range 100VAC - 500VAC.

Supply frequency range 47 Hz to 63 Hz.

Supply VA burden –8 VA maximum. (typical 6 VA)

Protected by externally replaceable 0.8 A/500VAC slow-blow

glass type standard fuse.

3. Metering (measurement) Input:

Voltage Input:

Voltage 3-Ph, 4-Wire with Ph-N values range of measurement

as 60 VAC to 300VAC.

Voltage Measurement burden < 1VA per phase.

Current Input:

Current measurement through secondary current of 3 Nos of

Current transformers with secondary rated current as either

1Amp or 5Amp AC.

Current measurement range: 1.5%INominal to 130%INominal

For 1Amp terminals: 15mA to 1.3Amp.

For 5Amp terminals: 75mA to 6.5Amp.

Maximum current withstanding capacity: 4xINominal for 1 Second.

Maximum VA burden on CT: < 1VA.

Measurement Values and Accuracy:

Per phase Voltage, Per phase & neutral Current,

Overall Power and Overall Energy values with accuracy class

1.0 as defined in IS-14697 with all Amendments till date.

This is for Active & Reactive Power / Energy.

Intelligent Power Factor Controller TPF-56

8 of 56 Version 1.1.5 22nd March, 2016

Specifications (continued):

5. Transistorized Output:

Total No. of Transistorized Output for capacitor banks

switching ON / OFF : Maximum up to 16 Numbers.

Voltage & Current Rating, Transistorized O/Ps (Short-Circuit Protected) :

+12 VDC to +24 VDC, Current-Sourcing Output, 20 mA max.

Protected by Glass cartridge fuse –200mA,+12/24V DC/fast blow.

6. Connection Terminals (rear side):

All the connectors are on rear side and suitable for connecting

fork type copper lugs with 1.5mm2or 2.5mm2wires.

Maximum applicable torque on Screws of Terminal while

tightening is 0.5 Newton-meter. Recommended torque

calibrated screw driver adjustment is 0.35 N-met.

Voltage rating across 2 adjacent terminals –380VAC.

Continuous Current rating (RMS value) –8 Amp.

7. Battery for RTCC (Real Time Clock-Calendar) & NV RAM:

Battery type to be used : CR2032. (Maxell make preferred)

Battery Voltage (New) : 3.3VDC to 3.1VDC.

Low Battery Alarm : 2.6VDC. (Range 2.65VDC to 2.55VDC)

Battery Fault Indication : < 1.8 VDC.

Expected Battery Life: @ 2½ Years to 3 Years.

Time frame for Battery replacement after Low Battery Alarm

is Maximum 6 months. Recommended period < 3months.

8. Data Log Non-Volatile Memory:

Used for TPF-56 Program Parameter storage, 1 Hour, 30min,15min,10min

interval data log, latest 1024 events data log and Power-down values

storage with “Early-Warning-Power-Failed (EWPF)” sequence.

Critical storage even with RTCC Battery Fail or Replacement for

ensuring no data loss or maintain Energy values.

Intelligent Power Factor Controller TPF-56

9 of 56 Version 1.1.5 22nd March, 2016

Specifications (continued):

9. Mechanical Dimensions:

Intelligent Power Factor Controller TPF-56

Mounting

Clamps

All 4 sides.

10 of 56 Version 1.1.5 22nd March, 2016

All Dimensions in mm.

146 mm

95 mm

•Un-packed net weight of the Unit: 880 gm.

Front fascia

LCD Display

RS-232 port with

dedicated protocol.

Key pad

I AM OK LED

(Controller

“Health”

status LED)

Intelligent Power Factor Controller TPF-56

Specifications (continued):

11 of 56 Version 1.1.5 22nd March, 2016

Leds for indication

of status of

Capacitor Banks

Back side terminals

Note:

Use appropriately rated and type, while replacing the fuse(s) in the field

Measurement voltage

(Line To Neutral 300VAC max)

Auxiliary Supply

Voltage

(100V to 500 VAC)

Load current CTs

F1: Fuse for Auxiliary

Supply ( 0.8 A/500 VAC

slow-blow glass

Cartridge.)

Intelligent Power Factor Controller TPF-56

Specifications (continued):

12 of 56 Version 1.1.5 22nd March, 2016

F2: Fuse for Capacitor

Banks 1 to 8

(200mA,+12/24 VDC

Fast- blow,

Glass Cartridge).

Output commands

to Thyristor switch

1 to 8 Outputs.

F3: Fuse for Capacitor

Banks 9 to 16

(200mA,+12/24 VDC

Fast- blow,

Glass Cartridge).

Output commands

to Thyristor switch

9 to 16 Outputs.

Other Auxiliary Arrangements:

RTCC Battery insertion slot.

Intelligent Power Factor Controller TPF-56

Battery Slot for replacement

Of CR2032, 3 Vdc Li. Battery.

(Remove black sticker over the slot

to see the battery inside)

Recommended to change the Battery

with Auxiliary Supply to Unit in ON

condition. RTCC would not be disturbed.

Ensure new battery replacement with

Correct polarity. Use tips insulated, thin

& long nose plier to remove old battery

& insert the new battery.

In case the Aux. Supply was OFF and then

this RTCC Battery is replaced, user will

have to set RTCC once again to correct

date & time.

- +

Side view of TPF-56 for seeing Battery insertion slot.

The unit after mounting in panel is compatible for

enclosure protection class as per DIN 40 050:

Front side: IP-54.

Back side: IP-10.

Specifications (continued):

10. Environmental Requirements:

Operating temperature range: 0°C to +55°C.

Storage temperature range: 0°C to +65°C.

Altitude: up to 3500 meters above sea level.

Relative Humidity range: 10% to 95% RH (Non-condensing).

11. Standards Compatibility:

Unit is designed to comply with following standards compliance.

Safety Standards: IEC61010-1:2001

EMI Standards: CISPR 11

EMC Standards: IEC61000-4-2:8kV

IEC61000-4-4:4kV

IEC61000-4-11:Class A.

Accuracy Standards: IS14697: Class 1.0

13 of 56 Version 1.1.5 22nd March, 2016

Intelligent Power Factor Controller TPF-56

Specifications (continued):

9. Jumper Selection for RS485 and GSM communication

(Continued):

14 of 56 Version 1.1.5 22nd March, 2016

Fig: Berg Jumpers selection for RS232 or RS485 Interface.

Fig: Connector for RS232 and RS485

Selecting positions 1 & 2 in both JP1 and JP2

enables RS232 communication for external GSM

Modem.

Selecting positions 2 & 3 in both JP1 and JP2

enables RS485 for MOD-Bus ASCII or MOD-Bus

RTU protocol.

Contact us for RS232 to RS 485 converter

module for RS 485 communication between TPF-

56 and PC / PLC’s RS-232 Port, with Auto-Data-

Direction Control.

Figure shows connector for RS232 and RS485

Communication. RX and TX for RS 232

communication and D- and D+ for RS485

communication. Note that the Signal Ground

Terminal is common for RS-232 or RS-485.

Contact us for Separate Documents for MOD-Bus

and GSM Functionality Implementations.

Note:

Please remove the 5-way mating connector of

RS-232/RS-485 while installing the Unit in the

DIN Standard Cut-out on the Panel Door, and

replace it after the installation is done.

3

2

1

3

2

1

DI (RS485)

TX 1

TXD1 (RS232)

RO (RS485)

RX 1

RXD1 (RS232)

JP1

JP2

D+ (RS485)

D- (RS485)

GND

TXD-GSM(RS232)

RXD-GSM(RS232)

V, I, PF and Power

Measurement

Block

Three channel

Supply (load)

current feedback

Front-Panel RS-232 for

Data Downloading

Calculation

Block for

•Energy Parameters

•Harmonic analysis

•Capacitor kVAr

Power

Supply

Keyboard,

Display &

other support

function

block.

Power Factor

Correction Block

+ event monitoring.

Outputs Commands

For Capacitor

Switching.

Transistorised o/p

Capacitor

switching

commands

Serial

Communication.

Channels - 2 Ports.

Functional Description:

Functional Block Diagram

Intelligent Power Factor Controller TPF-56

RTCC & Non-

Volatile Memory

for:

•Interval Log

•Event Log

•Prog. Param

•Critical data

with EWPF

logic.

15 of 56 Version 1.1.5 22nd March, 2016

3Ph 4Wire

Voltage feedback

Rear-Panel

RS232/RS485

Functional Description (Continued):

PF correction technique

KW.

KVAR

(Ind)

KVAR

(Cap)

PFLOWER.

PFUPPER.

-KW.

PFLOWER.

PFUPPER.

Case-1: PF-UPPER & PF-LOWER both set as inductive:

smallest

Capacitor bank

kVAr x 1.5 width.

KVAR

(Ind)

KVAR

(Cap)

PFLOWER.

PFUPPER.

-KW

PFLOWER.

PFUPPER.

smallest

Capacitor bank

KVAR X 1.5 width.

Case-2: PF-UPPER as Capacitive & PF-LOWER set as Inductive:

KW

No change band.

Capacitor addition band.

Capacitor removal band.

Intelligent Power Factor Controller TPF-56

16 of 56 Version 1.1.5 22nd March, 2016

There are two PF set-points to be set in TPF-56/16. The UPPER limit and

the LOWER limit. TPF-56 ensures that PF-UPPER is never exceeded.

Additionally, “No change band” to minimum KVAR band size equal to

smallest bank KVAR x 1.5 ensures no hunting during the low KW loading.

TPF-56 is normally set for PF settings as per first two diagrams shown

where PFLOWER is inductive. This philosophy helps to optimize the

system maximum KVAR to be used as well as reduces the number of

switching operations during higher loading conditions. This ensures better

life expectancies of the switched capacitors as well as the switching

devices.

This methodology of KVAR compensation reduces the complex settings

that are used by conventional PF relays. The settings like C/K ratio and

KVAR offsets/shifts are eliminated which makes TPF-56 user friendly and

thus easy to commission.

For all the three conditions shown in the above diagrams, 4-quadrant

operation is achieved. Typical example of 4-quadrant operation is “Co-

Generation Plants” and “Wind-Power Generation”. But with most

conventional consumer applications, only +Ve KW is seen, where the

Auto Synchronization feature can be used.

KVAR

(Ind)

KVAR

(Cap)

PFLOWER.

PFUPPER.

-KW

PFLOWER.

PFUPPER.

smallest

Capacitor bank

KVAR X 1.5 width.

KW.

Case-3: PF-UPPER & PF-LOWER both set as Capacitive:

No change band.

Capacitor addition band.

Capacitor removal band.

Intelligent Power Factor Controller TPF-56

17 of 56 Version 1.1.5 22nd March, 2016

Typical wiring diagram for PF correction

Intelligent Power Factor Controller TPF-56

18 of 56 Version 1.1.5 22nd March, 2016

PH1

PH2

PH3

N

L

O

A

D

TPF-56

CapacitorBank1

CapacitorBankn

S1S2

P1P2

S1S2

P1P2

S1S2

P1P2

Fuse

Fuse

Fuse

Fuse

Fuse

Fuse

External

+12/+24V

DCSupply

+0V

1Amp

EXT

Ground

CMD

+

_

CMD

+

_

ExternalDCSupply

EXTGround

ExternalDCSupply

EXTGround

ThyristorSWn

ThyristorSWn

PH1 PH2 PH3 N C 1A 1A 1AC C5A 5A 5A

PH2 PH3PH1

T1

T8

EXT

T9

T16

EXT

L1 L2

Fuse

Fuse Fuse

Front fascia –

LCD screen

First line of display indicates the PF value, inductive / capacitive PF,

mode of operation and fault /OK status:

“PF = 1.000” indicates the overall PF of the system.

“+” or “-” indicates if this PF is inductive or capacitive respectively.

“A” or “M” indicates the Auto and Manual mode of operation respectively.

“ ” or “ ” indicates the Mains and Generator mode of operation respectively.

“OK” (blinking) indicates status of the system, healthy or faulty.

Last two characters represent one of the following status:

Second line indicates the status of each capacitor bank by symbols.

‘I AM OK’ Blinking LED indicates the controller’s health status ,i.e. the

controller is working okay. If this LED stays continuously ON or

continuously OFF, then, it means the Controller is not functioning properly.

OK Controller status is OK

ZV Zero voltage

OV Over voltage

UV Under voltage

VH Voltage over-harmonics THD%

IH Current over-harmonics THD%

BF Battery Fail for Battery or RTC faulty

ZC Zero current in any one phase

Intelligent Power Factor Controller TPF-56

AS Auto-Synchronization Pending

19 of 56 Version 1.1.5 22nd March, 2016

- I am OK (Blinking Green colour LED) to indicate the

healthy state of Controller.

OB

Out of Banks (Insufficient Total

Capacitive kVAr –Warning.

OT

Over Temperature

UF

Under Frequency

OF

Over Frequency

UL

Under Load

BL

Low Battery Warning

OC

System Over Current Warning

PF=+1.000 A OK

_ _ _ _ _ _ _ _ _ _ _ _ _ _

Example of a typical LCD display screen is show below:

Meaning of this screen contents:

Total no. of banks connected is 16.

Power Factor at Load sensing CT is ‘+1.000’

‘+’ indicates Inductive.(‘-’ indicates Capacitive)

Unit is operating in ‘A’ Auto mode. (‘M’ defines Manual mode)

“ ” indicates controller is on mains.

“ ” indicates controller is on Generator.

Total number of banks that are operational are 16.

Bank no. 1 is declared as fixed and is in ON condition.

Bank no. 2 is in ON condition.

Bank no. 3 is declared as faulty.

Bank no. 4 is in discharging state.

Bank no. 5 to 16 are in OFF condition.

“I AM OK”, flashing Green LED indicates the controller health status.

This LED is located at the extreme, left-hand, bottom side of the front

panel, as viewed by the user.

This LED, if continuously ON or continuously OFF, indicates

malfunctioning of the controller.

On powering up the unit, there is power-on discharge time given

for the capacitors to discharge completely. However, if the user is sure

that the capacitors are discharged, then on pressing the left key would

allow the controller to come out of the discharge time and thus user

need not wait for the discharge time to get complete and thus saves

time.

Front fascia –

LCD screen

This port is used for downloading of data logged in the controller.

The interface is Standard, 3-wire, RS232. For further description about

the data logging, please refer Page No. 36 of this user manual.

Following gives the pin configuration:

Front side RS232 communication port connection

Intelligent Power Factor Controller TPF-56

20 of 56 Version 1.1.5 22nd March, 2016

Table of contents

Popular Controllers manuals by other brands

National Instruments

National Instruments Network Adapter NI PXIe-6672 installation guide

Sunlover

Sunlover SL8-RTA instructions

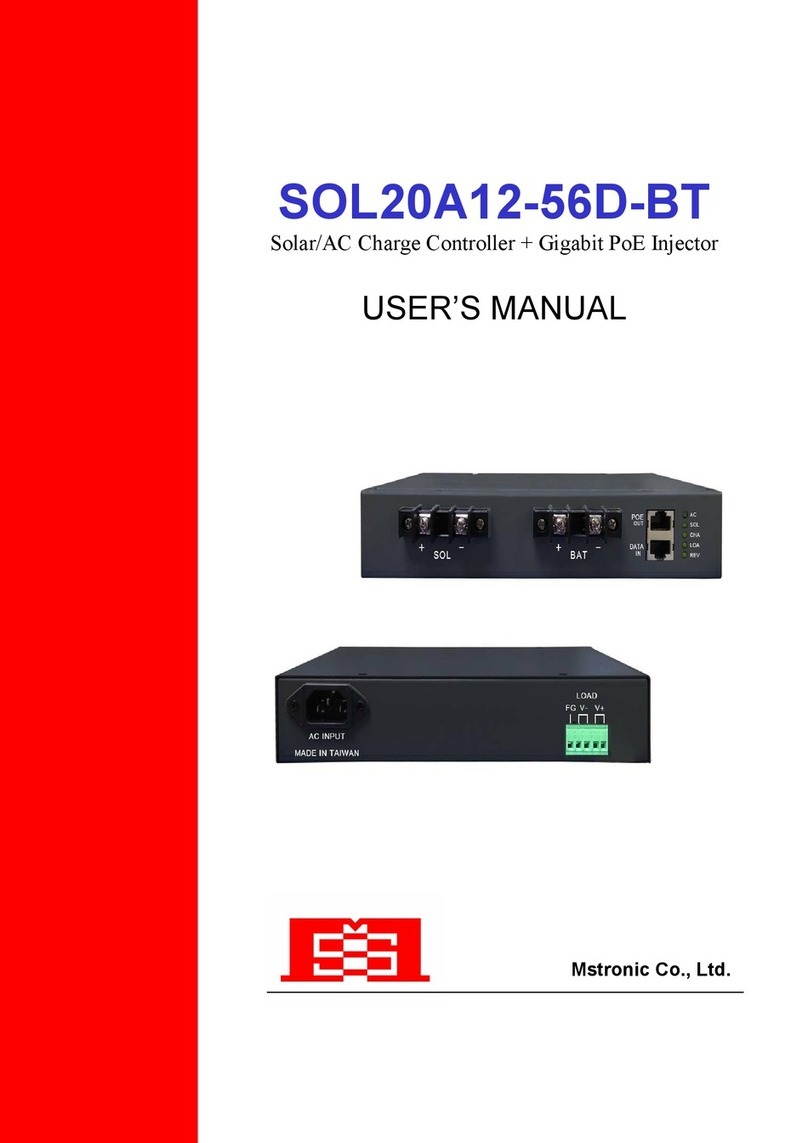

MSTRONIC

MSTRONIC SOL20A12-56D-BT user manual

GE

GE Mooney Flowgrid instruction manual

National Instruments

National Instruments cRIO-9031 user manual

Carel

Carel pCO3 series Technical leaflet