©Copyright Task Force Tips, Inc. 2008-2014 LIX-300 April 29, 2014 Rev18

2

Table Of Contents

1.0 Meaning of Safety Signal Words.............................................2

2.0 Safety ..............................................................................3

3.0 General Information...........................................................3-12

3.1 Mechanical Specifications

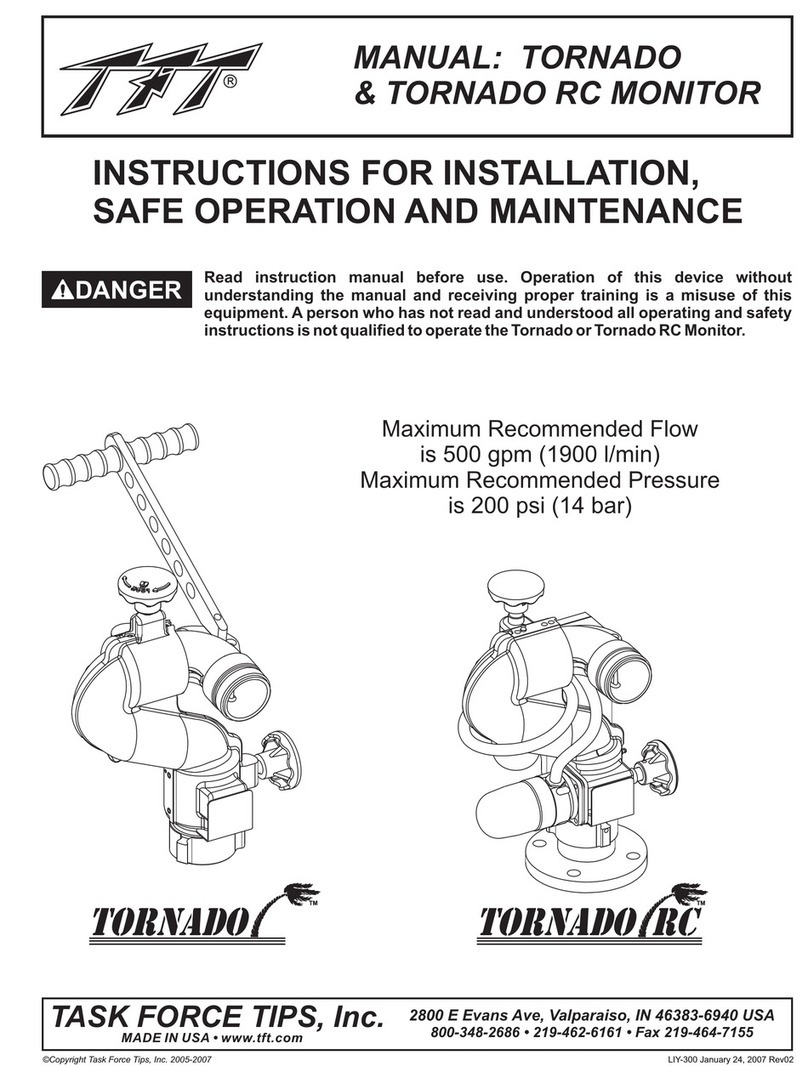

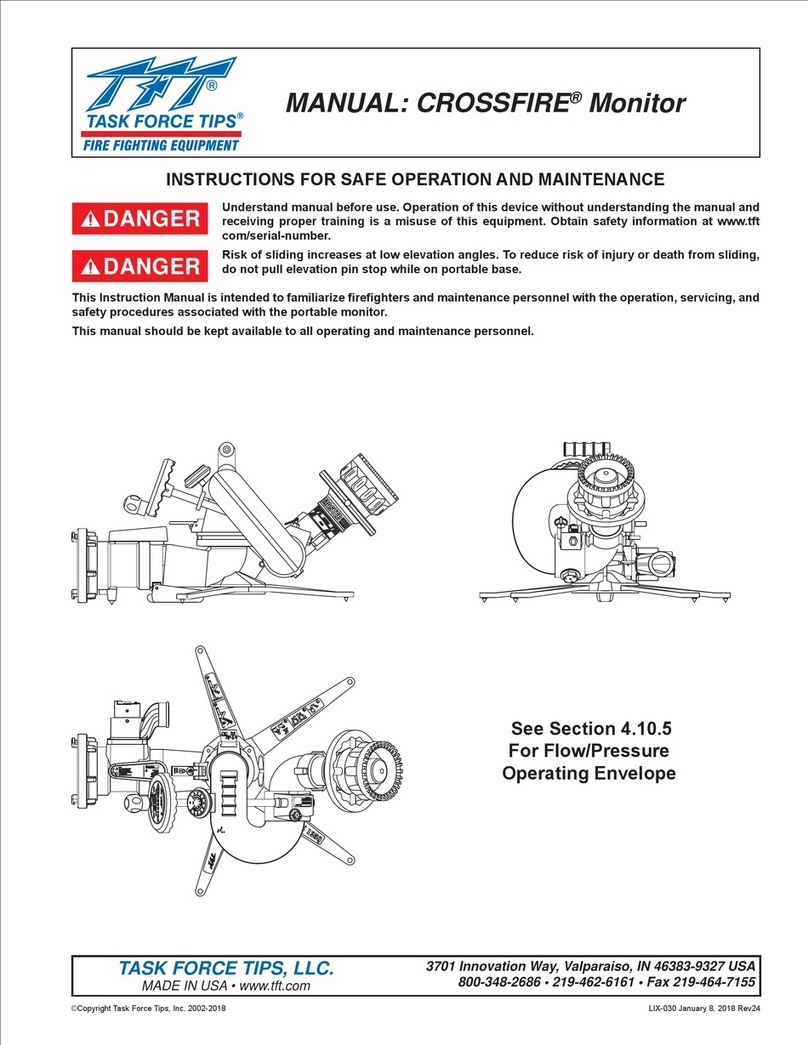

3.2 Part Identification and Models

3.3 Inlets and Outlets

3.4 Overall Dimensions

4.0 Installation .......................................................................12-17

4.1 Structural Requirements for Monitor Mounting

4.1.1 Water Supply

4.2 Inlet Mounting and Travel Ranges

4.2.1 Inlet Fitting or Extend-A-Gun RC Installation

4.2.2 Horizontal Rotation Travel Stops

4.2.3 Vertical RotationTravel Stops

4.3 Nozzle Installation

4.4 Pressure Gage Port

4.5 Automatic Drain

4.6 Handle Installation

5.0 Operation ............................................................................17

5.1 Horizontal Rotation Control

5.2 Elevation Control

5.3 Recommended Park Position

5.4 Override Knobs

6.0 Flows and Pressures........................................................18-21

6.1 Stacked Tips Flow and Reach

6.2 Automatic Masterstream Nozzles

6.3 Stream Straighteners

6.3.1 Stream Straighteners with Stacked Tips

6.3.2 Stream Straighteners with Fog Nozzles

7.0 Maintenance and Inspection.................................................22

7.1 Lubrication

7.1.1 Elevation Control Worm Gear

7.1.2 Horizontal Rotation Worm Gear

8.0 Troubleshooting ....................................................................22

9.0 Drawings and Parts List...................................................23-35

9.1 Hurricane Fixed (XFI Series)

9.2 Hurricane Fixed Extended (XFIBE Series)

9.3 Hurricane Dual Handwheel (XFIH-D Series)

9.4 Hurricane Tiller for 4.5” Quick Connect and V.U.M.

(XFIH-T Series)

9.5 Hurricane RC Monitor (XFIH-E Series)

9.6 Elevation Chain DriveAssembly

9.7 Gear MotorAssembly

9.8 Monitor Control BoxAssembly

10.0 Warranty ............................................................. Back Cover

1.0 MEANING OF SAFETY SIGNAL WORDS

Asafety related message is identified by a safety alert symbol and a signal word to indicate the level of risk involved with a particular

hazard. Per ANSI standard Z535.6-2011, the definitions of the four signal words are as follows:

DANGER DANGER indicates a hazardous situation which, if not avoided, will result in death or serious

injury.

WARNING WARNING indicates a hazardous situation which, if not avoided, could result in death or serious

injury.

CAUTION CAUTION indicates a potentially hazardous situation which, if not avoided, could result in minor

or moderate injury.

NOTICE NOTICE is used to address practices not related to physical injury.

DANGER

PERSONAL RESPONSIBILITY CODE

The member companies of FEMSA that provide emergency response

equipment and services want responders to know and understand the

following:

1. Firefighting and Emergency Response are inherently dangerous activities

requiring proper training in their hazards and the use of extreme caution

at all times.

2. It is your responsibility to read and understand any user’s instructions,

including purpose and limitations, provided with any piece of equipment

you may be called upon to use.

3. It is your responsibility to know that you have been properly trained in

Firefighting and /or Emergency Response and in the use, precautions, and

care of any equipment you may be called upon to use.

4. It is your responsibility to be in proper physical condition and to maintain

the personal skill level required to operate any equipment you may be

called upon to use.

5. It is your responsibility to know that your equipment is in operable

condition and has been maintained in accordance with the manufacturer’s

instructions.

6. Failure to follow these guidelines may result in death, burns or other

severe injury.

FEMSA

Fire and Emergency Manufacturers and Service Association

P.O. Box 147, Lynnfield, MA 01940 • www.FEMSA.org