©Copyright Task Force Tips LLC 2010-2021 3 LIY-250 May 10, 2021 Rev03

1.0 MEANING OF SAFETY SIGNAL WORDS

A safety related message is identified by a safety alert symbol and a signal word to indicate the level of risk involved with a particular

hazard. Per ANSI Z535.6, the definitions of the four signal words are as follows:

2.0 SAFETY

3.0 GENERAL INFORMATION

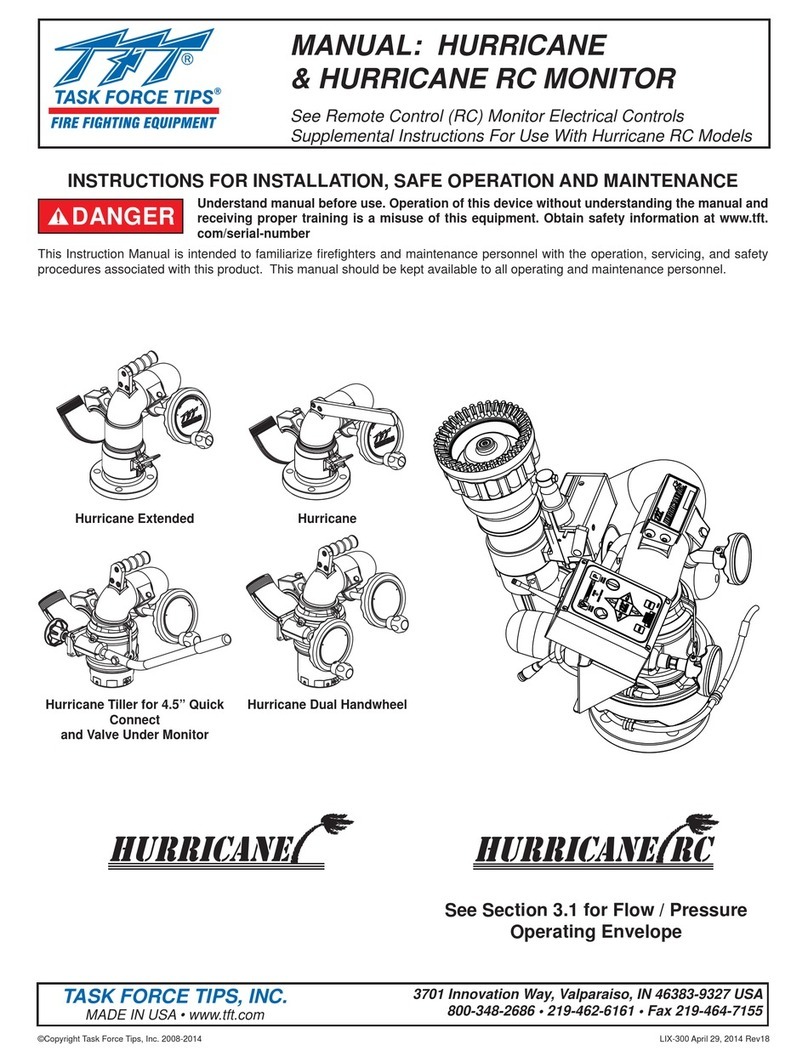

The 4.5” Quick Connect allows a monitor or elbow to be quickly and easily installed, removed and replaced. Applications include front

bumper mounts for tilt-cab chassis maintenance, and sharing monitors between multiple standpipes. A ratcheting pull pin prevents

loosening of 4.5”NH threads due to vibration. The elbow may be used to supply a fire pump in lieu of a hydrant.

Maximum operating pressure for elbow is 300 psi (20 bar), with a hydrostatic proof test pressure of 900 psi (62 bar). See monitor

instruction manuals for maximum operating pressure of Monsoon, Typhoon, and Hurricane series monitors.

3.1 SPECIFICATIONS

.0

Table 3.1

3.2 USE WITH SALT WATER

Use with salt water is permissible provided the equipment is thoroughly cleaned with fresh water after each use. The service life of the

equipment may be shortened due to the effects of corrosion, and is not covered under warranty.

DANGER indicates a hazardous situation which, if not avoided, will result in death or serious injury.

WARNING indicates a hazardous situation which, if not avoided, could result in death or serious

injury.

CAUTION CAUTION indicates a potentially hazardous situation which, if not avoided, could result in minor

or moderate injury.

NOTICE is used to address practices not related to physical injury.

An inadequate supply of pressure and/or flow will cause an ineffective stream and can result

in injury or death. Choose operating conditions to deliver adequate fire suppression. See flow

graphs.

This equipment is intended for use by trained personnel for firefighting. Use of this equipment for

other purposes may involve hazards not addressed by this manual. Seek appropriate guidance and

training to reduce risk of injury.

The stream exiting a nozzle is very powerful and capable of causing injury and property damage.

Make sure the nozzle is securely attached and pointing in a safe direction before water is turned on.

Do not direct water stream to cause injury or damage to persons or property.

Equipment may be damaged if frozen while containing significant amounts of water. Such damage

may be difficult to detect visually. Subsequent pressurization can lead to injury or death. Any time

the equipment is subject to possible damage due to freezing, it must be tested and approved for

use by qualified personnel before being considered safe for use.

US METRIC

Monitor Height Increase*

vs. model without Quick Connect

0.3 - 3.2” 0.7 - 8.1 cm

Monitor Weight Increase*

vs. model without Quick Connect

3.9 - 6.7 lb 1.8 - 3.0 kg

Elbow Dimensions**

with 5” Storz

12.3 x 8.6 x 12.3” 31 x 21 x 31 cm

Elbow Weight**

with 5” Storz

13.7 lb 6.21 kg

Operating Temperature Range of Fluid 33°F to 120°F 1°C to 50°C

Storage Temperature Range -40 to 150°F -40 to 65°C

Materials Hardcoat anodized and powder coated aluminum,

316 Stainless Steel, Nylon, Nitrile rubber

* Monitor specifications assume same inlet adapter is installed for comparison.

** Elbow specifications do not include inlet adapter and vary by outlet coupling.

See LOT-022 Price List and Product Specifications for details of each inlet adapter option.