3.1 Mechanical and Electrical Specifications

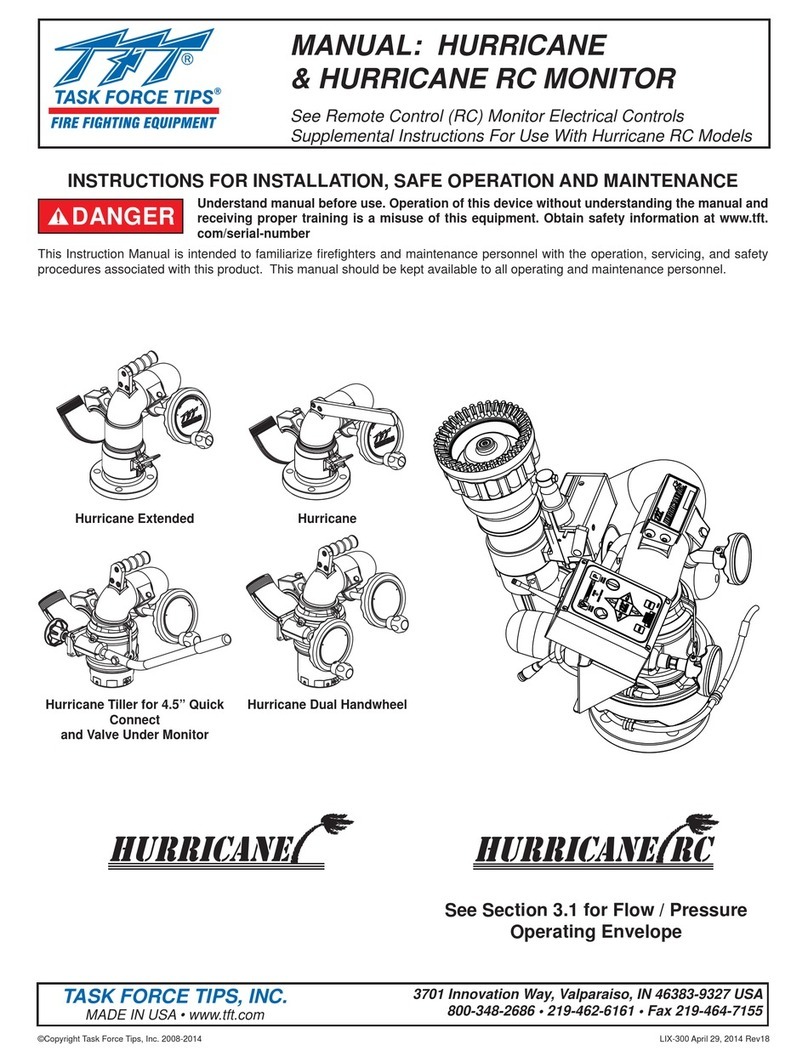

3.2 Part Identification and Models

3.3 Inlets and Outlets

3.4 Overall Dimensions

3.5 Electrical Controls

3.5.1 Motor Control Board (MCB) Auto Configure

3.5.2 Motor Current Limiting

3.5.3 Motor Soft Stops

3.5.4 Motor Slow/Fast Speed

3.5.5 Communication Protocol

3.5.6 Oscillate and Stow Features

4.1 Structural Requirements for Monitor Mounting

4.2 Quick Connect Inlet Mounting and Travel Ranges

4.3 Nozzle Installation

4.4

4.5

5.0.0 Standard Wiring Configuration

5.0.1 Alternative Wiring Configuration

5.1 Primary Monitor Operator Station

5.1.1 Mounting

5.1.2 Electrical Wiring

5.2 Optional Monitor Operator Stations

5.2.1 Mounting

5.2.2 Electrical Wiring

5.3 Tether Monitor Operator Station

5.3.1 Holster Mounting

5.3.2 Receptacle Mounting

5.3.3 Electrical Wiring

5.4 Wireless Monitor Operator Station

5.4.1 Mounting Receiver

5.4.2 Electrical Wiring Receiver

5.4.3 Mounting Charging Cradle

5.4.4 Electrical Wiring Charging Cradle

5.5 Joystick Monitor Operator Station

5.5.1 Mounting

5.5.2 Electrical Wiring

5.5.2.1 Wiring to a Communication Interface Box

5.5.2.2 Wiring to a Primary Operator Station

5.8 Monitor Position Display

5.8.1 Enclosure Mounting

5.8.2 Electrical Wiring

5.10 Electrical RC Monitor Aerial Truck Installation

5.10.1 Electronics Enclosure Mounting

5.10.2 Electrical Wiring

5.10.2.1 Ladder Installation Electrical Wiring

5.10.2.2 Platform Installation Electrical Wiring

5.11 Electric Nozzle Actuator Wiring

6.1 Manual Tiller Model

6.1.1 Horizontal Rotation and Rotation Lock

6.1.2 Elevation Control and Elevation Rotation Lock

6.1.3 Counter Balancing Nozzle, If Desired

6.2 Electrical Model

6.2.1 Operator Stations

6.2.1.1 Monitor Mounted

6.2.1.2 Primary

6.2.1.3 Optional Operator Station

6.2.1.4 Tether

6.2.1.5 Wireless

6.2.1.6 Joystick Operator Station

6.2.1.7 Toggle Switch Operator Station

6.2.2 Master Override Feature

6.2.3 Stow Feature

6.2.3.1 Programming

6.2.3.2 Stow Programming Example

6.2.4 Oscillate Feature

6.2.4.1 Programming

6.2.4.2 Oscillate Program Retain Feature

6.2.5 Operator Station Panels

6.2.6 Override Knobs

6.3 Recommended Stowing Position

6.4 Flows and Pressures

6.4.1 Stacked Tips Flow

6.4.2 Tornado Monitor and Stream Straightener

Friction Loss

6.5 Stream Straighteners

6.5.1 Stream Straighteners with Stacked Tips

6.5.2 Stream Straighteners with Fog Nozzles

7.1 Lubrication

7.2 Performance Testing

1.0 Meaning of Safety Signal Words

2.0 Safety

3.0 General Information

4.0 Installation

5.0 Electrical Controls Installation

6.0 Operation

7.0 Maintenance and Inspection

9.0 Drawings and Parts List

10.0 Warranty

Pressure Gage Port

Drain

5.6 Toggle Switch Monitor Operator Station

5.6.1 Enclosure Mounting

5.6.2 Electrical Wiring

5.7 Communication Interface Box

5.7.1 Enclosure Mounting

5.7.2 Electrical Wiring

5.7.3 Input Signal Configuration

5.9 Connecting Monitor Cable Directly to Protected

Power Supply

5.9.1 Electrical Wiring

Operator Station

Operator Station

Operator Station

Operator Station

8.0 Troubleshooting

Table of Contents

2

The member companies of FEMSA that provide emergency response

equipment and services want responders to know and understand the

following:

1. Firefighting and Emergency Response are inherently dangerous

activities requiring proper training in their hazards and the use of extreme

caution at all times.

2. It is your responsibility to read and understand any user's instructions,

including purpose and limitations, provided with any piece of equipment

you may be called upon to use.

3. It is your responsibility to know that you have been properly trained in

Firefighting and /or Emergency Response and in the use, precautions,

and care of any equipment you may be called upon to use.

4. It is your responsibility to be in proper physical condition and to maintain

the personal skill level required to operate any equipment you may be

called upon to use.

5. It is your responsibility to know that your equipment is in operable

condition and has been maintained in accordance with the

manufacturer’s instructions.

6. Failure to follow these guidelines may result in death, burns or other

severe injury.

DANGER

PERSONAL RESPONSIBILITY CODE

Fire and Emergency Manufacturers and Services Association, Inc.

P.O. Box 147, Lynnfield, MA 01940 • www.FEMSA.org

FEMSA