Tatung CM-1480 Operating and installation instructions

Other Tatung Monitor manuals

Tatung

Tatung Vibrant L2ES-TP6720 User manual

Tatung

Tatung VM-14AF User manual

Tatung

Tatung TME19A User manual

Tatung

Tatung CM-1496 Series Operating and installation instructions

Tatung

Tatung OMNISCAN SERIES User manual

Tatung

Tatung Vibrant VM78F User manual

Tatung

Tatung TME24 User manual

Tatung

Tatung VM7K9 User manual

Tatung

Tatung TCM-0902 User manual

Tatung

Tatung TME32 User manual

Tatung

Tatung C7BTR Series User manual

Tatung

Tatung Vibrant VM77S User manual

Tatung

Tatung VM9K9DA P990S User manual

Tatung

Tatung Decca CM-1380F Series User manual

Tatung

Tatung 5005L13 User manual

Tatung

Tatung TLM1905 User manual

Tatung

Tatung TME19WE User manual

Tatung

Tatung TLM-1505 User manual

Tatung

Tatung G5GS Series User manual

Tatung

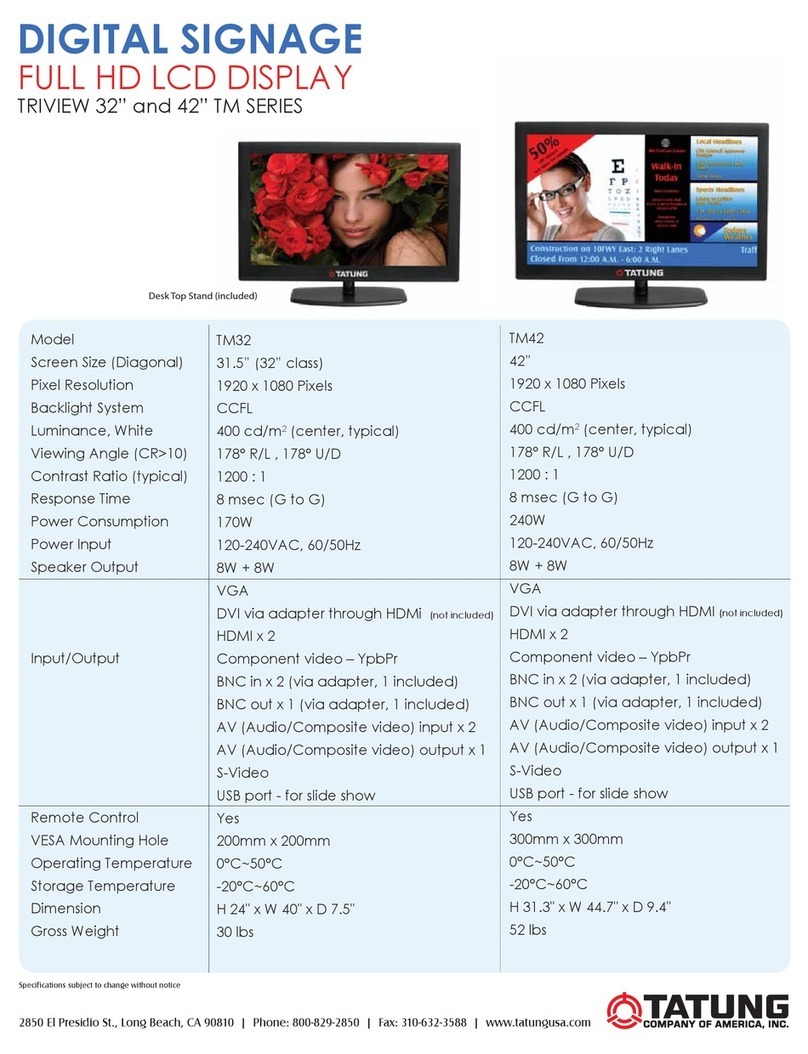

Tatung TM32 User manual